John Deere Wheeled Excavator 190GW Repair Technical Service Manual (TM13248X19)

Complete Technical repair manual in English / French / Spanish for John Deere 190GW (PIN: 1FF190GW__E051001-), with all the workshop information to maintain, repair, and rebuild like professional mechanics.

John Deere 190GW workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM13248X19 - John Deere 190GW Wheeled Excavator Technical Manual - Repair.pdf

TM13248X63 - John Deere 190GW Excavadora sobre ruedas 190GW.pdf

TM14308X28 - John Deere Excavatrice à roues 190GW.pdf

PRODUCT DETAILS:

Total Pages: 1,022 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English / French / Spanish

MAIN SECTIONS

Foreword

Manual Identification-READ THIS FIRST!

Technical Information Feedback Form

General Information

Safety

Torque Values

Wheels

Wheels and Fasteners

Axles and Suspension Systems

Drive Axle Housing and Support

Differential or Bevel Drive

Axle Shaft, Bearings, and Reduction Gears

Axles, Differentials, and Suspension Systems Hydraulics

Transmission

Removal and Installation

Gear, Shafts, and Power Shift Clutches

Hydraulic System

Engine

Removal and Installation

Engine Auxiliary System

Cooling System

External Exhaust System

External Fuel Supply System

Damper Drive (Flex Coupling)

Elements

Steering System

Removal and Installation

Steering Hydraulic System

Service Brakes

Service Brake Active Elements

Service Brakes Hydraulic System

Frame or Supporting Structure

Frame Installation

Chassis Weights

Operator`s Station

Removal and Install

Operator Enclosure

Seat and Seat Belt

Heating and Air Conditioning

Excavator

Buckets

Frames

Hydraulic System

Swing or Pivoting System

Mechanical Drive Elements

Hydraulic System

Dealer Fabricated Tools

!!! # Generated bmk file

TABLE OF CONTENTS....1

Section 00: General Information....16

Group 0001: Safety....16

Recognize Safety Information....19

Follow Safety Instructions....20

Operate Only If Qualified....21

Wear Protective Equipment....22

Avoid Unauthorized Machine Modifications....23

Control Pattern Selector—If Equipped....24

Add Cab Guarding for Special Uses....25

Inspect Machine....26

Stay Clear of Moving Parts....27

Avoid High-Pressure Fluids....28

Avoid High-Pressure Oils....29

Work In Ventilated Area....30

Avoid Static Electricity Risk When Refueling....31

Prevent Fires....33

Prevent Battery Explosions....34

Handle Chemical Products Safely....35

Decommissioning — Proper Recycling and Disposal of Fluids and Components....36

Exhaust Filter Ash Handling and Disposal....37

Prepare for Emergencies....38

Clean Debris from Machine....39

Use Steps and Handholds Correctly....40

Start Only From Operator's Seat....41

Use and Maintain Seat Belt....42

Prevent Unintended Machine Movement....43

Avoid Work Site Hazards....44

Keep Riders Off Machine....46

Avoid Backover Accidents....47

Inspect and Maintain ROPS....48

Avoid Machine Tip Over....49

Operating or Traveling On Public Roads....50

Use Special Care When Lifting Objects....51

Travel Safely....52

Prevent Acid Burns....53

Add and Operate Attachments Safely....55

Park and Prepare for Service Safely....56

Service Cooling System Safely....57

Remove Paint Before Welding or Heating....58

Service Tires Safely....59

Follow Tire Recommendations....60

Make Welding Repairs Safely....61

Drive Metal Pins Safely....62

Clean Exhaust Filter Safely....63

Group 0003: Torque Values....17

Metric Bolt and Cap Screw Torque Values....68

Additional Metric Cap Screw Torque Values....70

Unified Inch Bolt and Cap Screw Torque Values....72

Service Recommendations for 37° Flare and 30° Cone Seat Connectors....74

Service Recommendations for O-Ring Boss Fittings....76

Service Recommendations for Flared Connections—Straight or Tapered Threads....78

Service Recommendations for Flat Face O-Ring Seal Fittings....80

O-Ring Boss Fittings In Aluminum Housing Service Recommendations—Excavators....82

O-Ring Face Seal Fittings With SAE Inch Hex Nut and Stud End for High-Pressure Service Recommendations....85

O-Ring Face Seal Fittings With Metric Hex Nut and Stud End for Standard Pressure Service Recommendations....87

O-Ring Face Seal Fittings With Metric Hex Nut and Stud End for High-Pressure Service Recommendations....90

Service Recommendations for Metric Series Four Bolt Flange Fitting....93

Service Recommendations For Inch Series Four Bolt Flange Fittings....95

Inch Series Four Bolt Flange Fitting for High-Pressure Service Recommendations....97

Service Recommendations For Non-Restricted Banjo (Adjustable) Fittings....99

Service Recommendations For O-Ring Boss Fittings With Shoulder....102

Metric 24° O-Ring Seal DIN 20078 Service Recommendations....105

Section 01: Wheels....109

Group 0110: Wheels and Fasteners....109

Wheel Remove and Install....114

Tire Remove and Install....118

Section 02: Axles and Suspension Systems....121

Group 0201: Drive Axle Housing and Support....121

Front Axle Remove and Install....127

Front Axle Disassemble and Assemble....132

Front Axle Adjustment....149

Rear Axle Remove and Install....150

Rear Axle Disassemble and Assemble....154

Group 0210: Differential or Bevel Drive....121

Differential Disassemble and Assemble....172

Check Gear Tooth Contact Pattern....178

Group 0250: Axle Shaft, Bearings, and Reduction Gears....121

Front Axle Planetary Drive Remove and Install....191

Front Axle Planetary Drive Disassemble and Assemble....200

Rear Axle Planetary Drive Remove and Install....208

Rear Axle Planetary Drive Disassemble and Assemble....213

Group 0260: Axles, Differentials, and Suspension Systems Hydraulics....121

Axle Lock Cylinder Remove and Install....950

Axle Lock Cylinder Disassemble and Assemble....954

Axle Lock Cylinder Check Valve Remove and Install....956

Axle Lock Cylinder Check Valve Disassemble and Assemble....958

Section 03: Transmission....226

Group 0300: Removal and Installation....226

Drive Shaft Remove and Install....231

Transmission Remove and Install....235

Group 0350: Gear, Shafts, and Power Shift Clutches....226

Drive Shaft Disassemble and Assemble....242

Transmission Disassemble....245

Transmission Assemble....266

Group 0360: Hydraulic System....226

Travel Motor Remove and Install....317

Travel Motor Disassemble and Assemble....320

Travel Motor Start-Up Procedure....339

Travel Motor Counterbalance Valve Remove and Install....341

Travel Motor Counterbalance Valve Disassemble and Assemble....343

Travel Pilot Valve Remove and Install....349

Travel Pilot Valve Disassemble and Assemble....350

Transmission Control Valve Remove and Install....800

Travel Shockless Valve Remove and Install....353

Travel Shockless Valve Disassemble and Assemble....355

Transmission Shift Interlock Remove and Install....357

Transmission Shift Interlock Disassemble and Assemble....359

Section 04: Engine....372

Group 0400: Removal and Installation....372

Engine Remove and Install....385

Section 05: Engine Auxiliary System....397

Group 0510: Cooling System....397

Radiator Remove and Install....402

Hydraulic Oil Cooler Remove and Install....406

Charge Air Cooler Remove and Install....410

Fuel Cooler Remove and Install....414

Fan, Fan Guard, and Fan Shroud Remove and Install....415

Coolant Recovery Tank Remove and Install....418

Group 0530: External Exhaust System....397

Exhaust Tube Remove and Install....422

Diesel Particulate Filter (DPF) Remove and Install....424

Aftertreatment Remove and Install....425

Aftertreatment Disassemble and Assemble....429

Group 0560: External Fuel Supply System....397

Fuel Tank Remove and Install....442

Section 07: Damper Drive (Flex Coupling)....448

Group 0752: Elements....448

Damper Drive (Flex Coupling) Remove and Install....453

Section 09: Steering System....457

Group 0900: Removal and Installation....457

Steering Wheel Remove and Install....460

Steering Column Remove and Install....462

Steering Valve Remove and Install....467

Group 0960: Steering Hydraulic System....457

Steering Cylinder Disassemble and Assemble....482

Section 10: Service Brakes....493

Group 1011: Service Brake Active Elements....493

Brake Wear Measurement Procedure....497

Front Axle Brake Disassemble and Assemble....500

Rear Axle Brake Disassemble and Assemble....511

Group 1060: Service Brakes Hydraulic System....493

Brake Valve Remove and Install....526

Brake Valve Disassemble and Assemble....529

Brake Accumulator Manifold Remove and Install....534

Accumulator Charging Valve Remove and Install....536

Accumulator Charging Valve Disassemble and Assemble....538

Section 17: Frame or Supporting Structure....540

Group 1740: Frame Installation....540

Welding on Machine....543

Group 1749: Chassis Weights....540

Counterweight Remove and Install....551

Section 18: Operator's Station....557

Group 1800: Removal and Install....557

Cab Remove and Install....568

Group 1810: Operator Enclosure....557

Windshield Remove and Install....580

Windshield Disassemble and Assemble....582

Sliding Windows Remove and Install....592

Windowpanes Remove and Install....594

Windowpanes Dimensions....595

Group 1821: Seat and Seat Belt....557

Seat Remove and Install....605

Seat Belt Remove and Install....607

Mechanical Suspension Seat Disassemble and Assemble....612

Group 1830: Heating and Air Conditioning....557

R134a Refrigerant Cautions and Proper Handling....619

R134a Refrigerant Oil Information....620

R134a Refrigerant Recovery, Recycling, and Charging Station Installation Procedure....622

Recover R134a Refrigerant....624

Flush and Purge Air Conditioning System....625

Evacuate R134a System....628

Charge R134a System....630

Air Conditioner Compressor Remove and Install....632

Condenser Remove and Install....634

Heater and Air Conditioner Remove and Install....636

Receiver-Dryer Remove and Install....644

Section 33: Excavator....646

Group 3302: Buckets....646

Bucket Remove and Install....650

Adjust Bucket Pivot End Play....651

Bucket Pin-Up Data....653

Group 3340: Frames....646

Bucket Links Remove and Install....658

Arm Remove and Install....661

Monoblock Boom Remove and Install....664

Two-Piece Boom Upper Section Remove and Install....671

Two-Piece Boom Lower Section Remove and Install....676

Inspect Pins, Bushings, and Bosses—Front Attachment....682

Cylinder Specifications....688

Bushings and Seal Remove and Install....689

Outrigger Remove and Install....691

Blade Assembly Remove and Install....694

Blade Assembly Disassemble and Assemble....699

Group 3360: Hydraulic System....646

Apply Vacuum to Hydraulic Oil Tank....704

Pump 1 and 2 Remove and Install....706

Pump 1 and 2 Disassemble and Assemble....712

Pump 1 and 2 Inspection....730

Pump 1 and 2 Start-Up Procedure....735

Pump 1 and 2 Regulator Remove and Install....737

Pump 1 and 2 Regulator Disassemble and Assemble....739

Flow Rate Control Solenoid Valve Remove and Install....742

Pilot Pump Remove and Install....744

Pilot Pump Disassemble and Assemble....747

Steering Pump Remove and Install....749

Steering Pump Disassemble and Assemble....751

Steering Pump Drive Shaft Remove and Install....753

Pilot Filter and Bypass Valve Remove and Install....754

Pilot Pressure Regulating Valve Remove and Install....756

Pilot Pressure Regulating Valve Disassemble and Assemble....758

Pilot Shutoff Solenoid Valve Remove and Install....760

Pilot Shutoff Solenoid Valve Disassemble and Assemble....763

Solenoid Valve Manifold Remove and Install....766

Solenoid Valve Manifold Disassemble and Assemble....768

Torque Control and Pump Flow Rate Limit Solenoid Valve Remove and Install....770

Solenoid Valve Block Remove and Install....771

Solenoid Valve Block Disassemble and Assemble....774

Pilot Valve (Left and Right) Remove and Install....780

Pilot Valve (Left and Right) Disassemble and Assemble....784

Travel Pilot Control Valve Remove and Install....800

Travel Pilot Control Valve Disassemble and Assemble....790

Pilot Signal Manifold Remove and Install....793

Pilot Signal Manifold Disassemble and Assemble....796

Control Valve Remove and Install....800

Control Valve Halves Disassemble and Assemble....810

Two-Piece Boom Positioning Control Valve Remove and Install....812

Control Valve (5-Spool) Disassemble and Assemble....814

Control Valve (4-Spool) Disassemble and Assemble....843

Two-Piece Boom Positioning Control Valve Disassemble and Assemble....872

Hydraulic Assist Control Valve Disassemble and Assemble....874

Hydraulic Oil Tank Remove and Install....876

Hydraulic Oil Tank Disassemble and Assemble....882

Restriction Valve Remove and Install....884

Hydraulic Oil Cooler Bypass Valve Remove and Install....886

Boom Cylinder Remove and Install....888

Boom Cylinder Disassemble and Assemble....894

Positioning Cylinder Remove and Install—If Equipped....900

Positioning Cylinder Disassemble and Assemble—If Equipped....905

Arm Cylinder Remove and Install....911

Arm Cylinder Disassemble and Assemble....915

Bucket Cylinder Remove and Install....921

Bucket Cylinder Disassemble and Assemble....926

Outrigger Cylinder Remove and Install....932

Outrigger Cylinder Disassemble and Assemble....936

Blade Cylinder Remove and Install....941

Blade Cylinder Disassemble and Assemble....945

Axle Lock Cylinder Remove and Install....950

Axle Lock Cylinder Disassemble and Assemble....954

Axle Lock Cylinder Check Valve Remove and Install....956

Axle Lock Cylinder Check Valve Disassemble and Assemble....958

Hydraulic Cylinder Bleed Procedure....960

Section 43: Swing or Pivoting System....961

Group 4350: Mechanical Drive Elements....961

Swing Gear Case Remove and Install....965

Swing Gear Case Disassemble and Assemble....968

Swing Gear Case Start-Up Procedure....982

Upperstructure Remove and Install....983

Swing Bearing Remove and Install....989

Swing Bearing Disassemble and Assemble....994

Swing Bearing Upper Seal Install....999

Swing Bearing Lower Seal Install....1000

Group 4360: Hydraulic System....961

Center Joint Remove and Install....1006

Center Joint Disassemble and Assemble....1010

Center Joint Air Test....1013

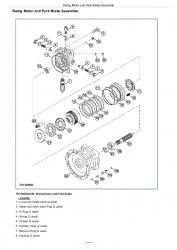

Swing Motor and Park Brake Remove and Install....1014

Swing Motor and Park Brake Disassemble....1017

Swing Motor and Park Brake Inspection....1020

Swing Motor and Park Brake Assemble....1025

Swing Motor and Park Brake Start-Up Procedure....1029

Crossover Relief Valve and Make-Up Check Valve Remove and Install....1031

Make-Up Check Valve Disassemble and Assemble....1035

Section 99: Dealer Fabricated Tools....1037

Group 9900: Dealer Fabricated Tools....1037

DFT1144 Guide Pin....1039

DFT1119 Pump Support....1040

DFT1264 Locator Screw....1041

DFT1351 Swing Gear Case Nut Spanner Wrench....1042

Center Joint (Rotary Manifold) Lifting Tool....1044

DFT1265 Axle Support....1045

John Deere Wheeled Excavator 190GW Repair Technical Service Manual (TM13248X19)