John Deere 1070D Harvester Operator's Manual (OMF070957 TM2122 TM2155)

Complete service Operator's Manual for John Deere 1070D Harvester.

OMF070957 - John Deere 1070D Harvester serial number wj1070d001301- Operator's Manual.pdf

TM2122 - John Deere Harvesters Technical Manual - Repair.pdf

TM2155 - John Deere TMC Technical Manual.pdf

PRODUCT DETAILS:

Total Pages: 633 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

OMF070957 - John Deere 1070d harvester serial number wj1070d001301- Operator's Manual...2

TABLE OF CONTENTS...2

Section 0-1: Warranty...15

Standard warranty clauses...16

Standard Warranty...17

Machines with Extended Coverage(For specified machines only!)...15

Periodic Maintenance...434

Section 1-1: Safety - Safety Features...20

John Deere 1070D Harvester Safety Features...21

Section 1-2: Safety - General Precautions...22

General...325

Recognize Safety Information...24

Understand Signal Words...25

Prepare for Emergencies...26

Wear Protective Clothing...27

Handle Fluids Safely - Avoid Fires...28

Handle Chemical Products Safely...29

Replace Safety Signs...30

Maintain Safety Cabin...471

Install Radio Transmitters Properly...32

Section 1-3: Safety - Operating Precautions...33

Inspect Machine...34

Attach Do not Operate Tag...35

Prevent Machine Runaway...36

Use Handholds and Steps...37

Handle Starting Fluids Safely...38

Pay Attention to Bystanders...39

Keep Riders of the Machine...40

Use Seat Belt...41

Avoid Risks under Difficult Conditions...42

Stop Working if Machine Gives an Alarm...43

Keep Danger Zone Clear...44

Avoid Crush Points...45

Avoid Power Cables...46

Driving/Transporting on Public Roads...48

Ensure Safety before Driving on Frozen Waters...49

Prevent Fires...50

What to Do if the Machine Fires?...33

Section 1-4: Safety - Maintenance Precautions...52

General...325

Before Servicing...54

Use Proper Clothing...56

Use Proper Tools...57

Support Machine Properly...58

Shut Down Engine, Disconnect Battery Cable...59

Service Cooling System Safely...60

Prevent Battery Explosions...61

Prevent Acid Burns...62

Start Only from Operator's Seat...64

Beware of Exhaust Fumes...65

Avoid High Pressure Fluids...66

Avoid Heating near Pressurized Fluid Lines...67

Make Welding Repairs Safely...68

Service Tires Safely...69

Refueling and Servicing Fuel System...347

Dispose of Waste Properly...71

Section 2-1: Cabin and Controls...72

Cab Component Locator...73

Main Switch...75

Control Lights...76

Dashboard...78

Boom Controls...84

Control Keypads...85

Air Conditioner, Operation Instructions...87

Pedals...89

Adjusting the Operator's Seat...90

Section 3-1: Operating Instructions...92

General...325

Safety Switches and Emergency Stop...94

Boom...95

Brakes...466

Steering...467

High/Low Gear and Front Wheel Drive...99

Differential Locks...101

Frame Brake...102

Before Starting the Engine for the First Time in a Working Day...103

Starting the Engine...463

Cold Weather Starting...106

After Starting...107

Turning off the Engine...463

Off-Road Driving...110

On-Road Driving...111

Section 3-2: Transporting and Towing...113

Transporting the Machine...114

Towing the Machine...115

Releasing the Parking Brake...117

Disengaging the Power Transmission System...118

Releasing the Work Brake...119

Releasing the Steering...467

Stowing a Disabled Boom...121

Section 4-1: Maintenance - General...325

Maintenance...434

Servicing Safety Precautions...126

Assembly Instructions...128

Lifting the Front Hood...129

Tightening Torque for Bolted Joints...131

Welding Instructions...133

Instructions for Cleaning of Lexan/Marguard Windows...136

Wheels...137

Changing Wheels...138

Anti-Slip Fitting...141

Bogie Tracks, Fitting...142

Section 4-2: Maintenance - Lubricants and Fluids...145

Recommended Lubricants and Fluids...146

Capacities...147

Diesel Fuel...148

Engine Oil...149

Coolant...151

Grease...152

Hydraulic Oil...153

Brake Fluid...154

Gear Oil...155

Section 4-3: Maintenance Intervals...241

Checklist - Base Machine...157

Reguired Parts...158

Section 4-4: Maintenance - Every 10 Hours or Daily...242

Check the Hydraulic Oil Level...161

Check the Engine Oil Level...162

Drain Water and Sediment from Fuel Filters...163

Check the Radiator Grille Cleanness...165

Check the Tires Visually for Air Pressure and Overall Shape...167

Other Procedures...224

At the End of the Day Make the Following Maintenance and Check-Ups...169

Fill Up the Fuel Tank...170

Section 4-5: Maintenance - Every 50 Hours or Weekly...243

Check the Driving Brake Oil Level and Window Washer Fluid Level...172

Grease the Center Hinge Bearings and Steering Cylinder Bearings...173

Other Procedures...224

Section 4-6: Maintenance - Every 250 Hours...246

Clean the Machine...176

Check Oil Levels in the High/Low Gear, Differentials, Bogie Casings and Hub Gears...177

Grease Bogie Bearings...179

Check the Proper Function of the Door Safety Switch...180

Other Procedures...224

Section 4-7: Maintenance - Every 500 Hours...182

Change Engine Oil and Oil Filter...183

Clean Crank Case Vent Tube...186

Check Air Intake System...187

Replace Fuel Filters...189

Check Belt Wear...192

Check Belt Tensioner...193

Check Cooling System...195

Remove Sediment and Water from the Fuel Tank...196

Check the Batteries for Charge and Electrolyte Level...197

Check Wear on Frame Brake Linings...199

Grease the Driveshafts...200

Other Procedures...224

Section 4-8: Maintenance - Every 1000 Hours...248

Change Hydraulic Oil and Return Filters (2 pcs)...203

Change the Off-line Filter *) Element...202

Change the Hydraulic Tank Breather...207

Change the Filter of the Driving Pump...208

Change the Brake Pedal Circuit Oil...209

Other Procedures...224

Section 4-9: Maintenance - Every 2000 Hours...249

Check Valve Clearance...213

Change the Coolant...215

Check Crankshaft Vibration Damper...219

Change Oil in the High/Low Gear, Differentials, Bogie Casings and Hub Gears...220

Other Procedures...224

Section 4-10: Maintenance - As Required...225

When Necessary, Service and Adjust the Following...226

Adding the Coolant...227

Checking Air Filter Elements...228

Replacing Drive Belt...230

Cleaning the Fuel Tank Filler Filter...231

Adjusting the Rotator Link Brakes...466

Adjusting the Seat Turntable Brake...234

Bleeding the Fuel System...347

Section 4-11: Maintenance - Periodic Maintenance...434

Maintenance after every Six Months...238

Annual Maintenance...434

Section 4-12: Maintenance - Boom...240

Maintenance Intervals...241

Every 10 Hours or Daily...242

Every 50 Hours or Weekly...243

Every 250 Hours...246

Every 1000 Hours...248

Every 2000 Hours...249

Section 4-13: Maintenance - Machine Storage...250

Preparing Machine for Storage...251

After Storage...253

Section 5-1: Hydraulic System - General...325

Working Hydraulic System...469

Hydrostatic System...389

Hydraulic Tank...344

Vacuum Pump...262

Taking an Oil Sample from Hydraulic System...469

Section 5-2: Hydraulic System - Bleeding...265

Bleeding Air from the Hydraulic Tank...344

Bleeding Air from the Hydrostatic System...389

Bleeding Air From the Working Hydraulic System...469

Bleeding the Brakes...466

Section 5-3: Hydrostatic System - Checking and Adjusting...275

Supply Pressure on the Drive Pump...276

Drive Pressure...278

Drive motor, checking flushing pressure...281

Drive motor, pressure cut-off...283

Drive motor, adjustment in TMC™...288

Section 5-4: Working Hydraulics - Checking and Adjusting...289

General...325

Pressure Difference Dp...291

Main Pressure Relief Valve...293

Maximum Pressure Settings of the Working Hydraulic Pump...296

Pilot Pressure, Working Hydraulics...300

Boom Valve, LS Pressure Limits...301

The Back-Pressure Valve of the Boom Tank Line...303

Section 5-5: Brake System - Checking and Adjusting...304

Checking the Brakes...466

Mechanical Adjustment of Brakes...466

Checking the Service Brake...308

Checking the Work Brake...309

Checking the Load and Release Range...310

Checking the Relief Valve of the Brake Charging Pressure...311

Section 5-6: Hydraulic System - Hydraulic Scheme...314

Hydraulic Scheme...314

Section 6-1: Electrical System...468

General...325

Using Booster Batteries...326

Main Switch and Switch Panel...329

Main Fuses...328

Switch Panel...329

Instrument Compartment...331

Relays, Instrument Compartment...332

Fuse box, Instrument Compartment...333

PC board, Instrument Compartment...334

Section 6-2: Electrical System - Sensors...338

Engine Sensors and Connectors...339

Air Cleaner Sensors...342

Coolant Level Sensor...343

Hydraulic Tank...344

Transmission...464

Brake System...346

Fuel System...347

Position Sensors...348

Section 6-3: Electrical System - Electrical Scheme...350

Electrical Scheme...350

Section 7-1: Transmission...464

Transmission Operation...418

Hydrostatic System...389

Control of Transmission...464

Brakes...466

Section 8-1: Boom...393

General Description of the Boom...394

Operating Safety Precautions...395

General Operating Instructions...396

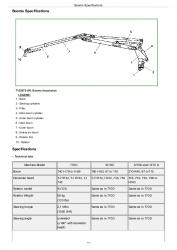

Tj 180 H Technical Data...398

Tj 180 S Technical Data...399

Tj 180 H 83 and S 83...400

Tj 180 H 97 and S 97...401

Tj 180 H 110 and S 110...402

Rotator AV12S...403

Rotator H122...404

Rotator BBR15HD...405

Section 9-1: Equipment - Air Conditioner...407

Air Conditioner...407

Danger and Precautions...408

Configuration and Location of the Air Conditioner...409

Maintenance of the Air Conditioner...411

Troubleshooting the Air Conditioner...415

Section 9-2: Equipment - Engine and Cabin Preheater...416

Configuration...417

Operation...418

Maintenance of the Engine Preheater...420

Timer for Engine and Cabin Preheater...421

Engine and Cabin Preheater Remote Control *)...416

Service Codes of the Engine Preheater...426

Section 9-3: Equipment - Fire Extinguisher System...429

Configuration and Use of the System...430

Control Unit...433

Maintenance...434

Hand-Held Fire Extinguishers...436

Section 9-4: Equipment - Stump Treatment System...438

Configuration and Function...439

Operation of Stump Treatment...440

Section 9-5: Equipment - Cabin Sideways Levelling...441

Cabin Sideways Levelling Modes...442

Cabin Sideways Levelling Controls...443

Control System of Cabin Sideways Levelling...445

Maintenance of Cabin Sideways Levelling...446

Section 9-6: Equipment - Seat Levelling...448

Operation of Seat Levelling...449

Control Unit and Functions...450

Programming...451

Section 9-7: Equipment - Boom Levelling...453

Operation of Boom Levelling...454

Boom Levelling Controls...455

Section 9-8: Equipment - Approach Lights...457

Approach Lights *)...457

Section 10-1: Specifications...460

Dimensions and Weights...461

Alternative Wheel Equipment...462

Engine...463

Transmission...464

Axles...465

Brakes...466

Steering...467

Electrical System...468

Hydraulic System...469

Boom and Harvester Head...470

Cabin...471

tm2122 - John Deere Harvesters Technical Manual - Repair...484

TABLE OF CONTENTS...484

Section 00: General Information...495

Group 0010: Safety features...495

General...499

Recognize Safety Information...500

Understand Signal Words...501

Prepare for Emergencies...502

Wear Protective Clothing...518

Handle Fluids Safely - Avoid Fires...504

Handle Chemical Products Safely...505

Replace Safety Signs...506

Maintain Safety Cabin...507

Park Machine Safely...508

Use Proper Lifting Equipment...509

Remove Paint Before Welding or Heating...510

Welding Cautions...511

Attach Do not Operate Tag...512

Illuminate Work Area Safely...513

Driving and Service...514

Use of Radio-transmitters...515

Dispose of waste properly...516

Avoid High-Pressure Fluids...517

Wear Protective Clothing...518

Group 0020: General Specifications...495

About this goup...566

Timberjack Tools For Harvesters...521

General Component Locator...522

Machine Dimensions...523

Power Unit Specifications...526

Power Train Specifications...527

Hydraulic System Specifications...529

Tire Specifications...535

Booms Specifications...536

Conversion Table for Pressures...540

Group 0030: Torque Values...496

About this goup...566

Tightening Torque For Bolted Joints...543

Unified Inch Bolt and Cap Screw Torque Values...548

Metric Bolt and Cap Screw Torque Values...550

Service Recommendations For O-Ring Boss Fittings...552

Service Recommendations For Flat Face O-Ring Seal Fittings...554

Service Recommendations For Inch Series Four Bolt Flange Fittings...556

Service Recommendations for Metric Series Four Bolt Flange Fitting...558

Metric Flanged Head...560

O-ring Fittings...561

SAE Code 61 and 62 Flanges...562

Tapered Pipe Treads (NPTF and NPT)...563

Flare Fittings...564

Group 0040: Fluids And Lubricants...496

About this goup...566

Recommended Lubricants and Fluids...567

Fluid Capacities...568

Diesel Fuel...569

Engine Oil...570

Coolant...572

Grease...573

Hydraulic Oil...574

Brake Fluid...575

Gear Oil...576

Lubricant Storage...577

Group 0050: Transporting and Towing...496

Transporting the Machine...579

Towing the Machine...580

Releasing the Parking Brake...582

Disengaging the 770D and 1070D Transmission System...583

Disengaging the 1270D and 1470D Transmission System...584

Releasing the Work Brake...585

Releasing the 770D and 1070D Steering...1203

Releasing the 1270D and 1470D Steering...1203

Stowing a Disabled Boom in 770D and 1070D...588

Group 0060: Welding instructions...497

Welding...596

Section 01: Wheels...600

Group 0110: Wheels Service...600

Service Equipment and Tools...862

Wheel Removal...603

Wheel Installation...1197

Wheel Inspection...607

Tire Removal and Installation...1197

Tire Pressure...610

Anti-Slip Fitting...611

Bogie Tracks, Fitting...613

Section 02: Power Train...620

Group 0210: Theory of Operation...1325

About this group...861

Power Train...620

Drive Coupling...623

Transmission...1180

Transfer Case...625

Group 0220: Transfer case...616

About this group...861

Transfer Case Removal...629

Transfer Case Installation...1197

Checking The Transfer Case Oil...642

Changing The Transfer Case Oil...645

Group 0230: Drive shaft...616

Essential Tools...1283

Other Material...1282

Drive Shafts Overall View...651

Bearing Drive Shafts...654

Diagnose Drive Lines...655

Universals...656

Center Hinge Drive Shaft Removal and Installation...1197

Center Hinge Bearing Drive Shaft Removal...660

Center Hinge Bearing Drive Shaft Installation...1197

Group 0240: Axles / Bogies...616

Essential Tools...1283

Other Material...1282

770D Front Axle...667

1070D, 1270D and 1470D Front Bogie...668

Front Bogie / Axle Removal...670

Front Bogie / Axle Installation...1197

Rear axle...682

Rear Axle Removal...683

Rear Axle Installation...1197

Bleeding The Differential Lock...689

General Instructions For Checking Oil Level And Fill Ups...690

Checking The Differentials Oil Level (2pcs)...691

Changing The Differentials Oil (2pcs)...692

Checking Bogie Housings Oil Level...694

Changing Bogie Housings Oil...696

Check Single Axle Wheel Ends ( Hub gear) Oil...699

Change Single Axle Wheel Ends ( Hub gear) Oil...701

Bogie Bearing Grease Points...703

Group 0250: Brakes...617

Overall Description of Brakes...710

Emergency Manual Release of The Parking Brake...715

Bleeding the Brakes...718

Checking the Brakes...720

Mechanical Adjustment of Brakes...721

Checking the Service Brake...723

Checking the Work Brake...725

Checking the Load and Release Range...726

Diagnose Brake Hydraulics...727

Group 0250: Appendix...617

NAF LOK Axle Service Manuals...729

NAF LOK Transfer Case Service Manuals...730

Section 03: Hydraulics System...731

Group 0310: General...499

Essential Tools...1283

Other Material...1282

Hydrostatic System...737

Hydraulic System...738

Bleeding the Air from the System...740

Bleeding Air from the Hydrostatic System...741

Bleeding Air From the Working Hydraulic System in 770D...744

Bleeding Air From the Working Hydraulic System in 1070D, 1270D and 1470D...747

Taking an Oil Sample from Hydraulic System...751

Hydraulic Tank...1179

Vacuum Pump...757

Group 0320: Drive hydraulics...731

Hydrostatic Pump and Motor Start-up Procedure...764

Motor Start of Control Point Adjustment...770

Diagnostic Information...773

Group 0330: Driving hydraulics service...731

Drive Motor Removal and installation...782

Drive Motor Servicing...785

Drive Pump Removal and Installation...1197

Drive Pump Servicing...793

Hydrostatic System Troubleshooting...837

Group 0340: Working hydraulics...731

Work Pump Theory of Operation...1325

Work Pump Start-up Procedure...846

Valves General...848

Group 0350: Working Hydraulics-service...731

About this group...861

Service Equipment and Tools...862

Work Pump Removal and Installation...1197

Drive Shaft Seal Replacement...864

Work Pump Disassembly and Assembly...866

Hydraulic Pressure Filter Replacement...887

Return Filter Replacement...888

Hydraulic Tank Removal...891

Extension Cylinder Service...893

Main Boom Cylinder Service...898

Outer Cylinder Servicing...901

Cylinder seal replacement...904

Auxiliary Valve Removal and Installation...1197

Boom Control Valve Removal and installation...912

Boom Control Valve Disassembly and Assembly...916

Thermostat Valve Removal and Installation...1197

Group 0360: Working Hydraulics - Checking and adjusting...732

Pressure Tests and Adjustments...928

Hydraulic Function Cycle Times...932

Boom / Steer Functions Pressures...933

Hose Inspection and Replacement...936

Cylinder Internal Seal Leak Test...937

Group 0370: Hydraulic Schematics...732

About This Group...1050

Hydraulic Scheme Symbols...944

770D Hydraulic Scheme...957

1070D Hydraulic Scheme...967

1270D Hydraulic Scheme...977

1470D Hydraulic Scheme...989

Group 0380: Appendix...732

Rexroth Drive Motors...1002

Rexroth Drive Pumps...1003

Rexroth Hydraulic Work Pumps...1004

VOAC / Parker Boom Control Valves...1005

Section 04: Engine...1006

Group 0410: Engine mounting and dismounting...1006

Engine Removal...1009

Engine Installation...1197

Group 0420: Engine...1006

Deere 6081 HTJ03...1013

Deere Engine 6068 HTJ 76 in 1070D model...1019

Deere Engine Deere 4045HTJ77 in 770D model...1020

Section 05: Engine Auxiliary system...1016

Group 0510: Auxiliary Systems...1016

Deere Engine 6081 HTJ 03 in 1270D and 1470D models...1018

Deere Engine 6068 HTJ 76 in 1070D model...1019

Deere Engine Deere 4045HTJ77 in 770D model...1020

Section 16: Electrical-System...1021

Group 1610: Main Electrical System...1021

System Description...1024

Battery...1025

770D and 1070 Main Switch And Fuses...1029

1270D And 1470D Main Switch and Fuses...1031

Using a Digital Multimeter...1037

Electrical Circuit Malfunction...1038

Troubleshooting Circuit Malfunctions...1040

Inspect Visually Electrical System...1044

Seven Step Electrical Test Procedure...1045

Group 1620: Electrical Scheme...1021

About This Group...1050

Electrical Schematic Symbols...1053

770D Electrical Scheme...1056

1070D Electrical Scheme...1093

1270D/1470D Electrical Scheme...1128

Group 1630: 770D and 1070D Electrical Sensors...1021

Engine Sensors...1178

Hydraulic Tank...1179

Transmission...1180

Brake System...1181

Fuel System...1182

Group 1630: 1270D and 1470D Electrical Sensors...1021

Engine Sensors...1178

Hydraulic Tank...1179

Transmission...1180

Brake System...1181

Fuel System...1182

Position Sensors...1183

Group 1640: Measuring System Timbermatic™ 300...1022

See Operator`s Manual For Detailed Information...1186

Group 1650: Total Machine Control System TMC™...1022

See TMC Workshop Manuals For Detailed Information...1188

Section 17: Frames...1189

Group 1710: General...499

Overall Structure Description...1191

Group 1720: Frames...1189

Rear Frame...1193

Front Frame...1194

Group 1730: Center hinge...1189

Installation...1197

Center Hinge and Steering Cylinder Greasing Points...1199

Frame Brake Theory Of Operation...1325

Friction Pad Changing...1202

Steering...1203

Section 18: Cabin...1204

Group 1810: Cabin Environment...1204

Dashboard...1207

Control Keypads...1209

Control Lights...1211

Warning lamps and beeper on the roof...1212

Boom Controls...1213

Operator's Seat...1215

Cabin Service...1220

Group 1830: Removal and Installation...1197

Other Material...1282

Cabin Removal...1225

Cabin Mount Replacement...1230

Cabin Installation...1233

Cabin Sideways Levelling...1236

Section 19: Air Conditioning and Heating System...1237

Group 1910: General...499

Theory of operation...1239

Configuration and Location of the AC...1240

AC Operation Instructions...1242

AC Component Operation...1325

AC Safety Precautions...1246

Group 1920: Air coditioning / Heater Components...1237

AC Compressor...1249

AC Condenser...1250

AC Receiver Dryer...1251

AC Expansion Valve...1253

AC Evaporator...1255

AC Refrigerant...1256

Group 1930: Diagnosing Air Coditioning / Heater System...1237

AC Operational Checks...1265

Heater/ AC System Operational Checkout Record Sheet...1273

Troubleshooting the Air Conditioner...1274

Diagnose Heater/Air Conditioner...1237

Section 80: Optional Equipments...1320

Group 8010: Engine and Cabin Preheater...1320

Configuration...1323

Operation...1325

Maintenance of The Engine Preheater...1327

Timer for Engine And Cabin Preheater...1328

Service Codes of The Engine Preheater...1332

Group 8020: Boom Levelling...1320

Operation of Boom Levelling...1336

Group 8040: Stump Treatment System...1320

Configuration and Operation...1338

Group 8040: Appendix...1320

Ebensprächer...1340

Section 99: Tool Drawings...1341

Group 9900: Dealer Fabricated Tools...1341

TA0898 Frame Support...1343

TA0899 Axle Support...1344

TA0902 Frame Support...1345

tm2155 - John Deere TMC Technical Manual...1349

TABLE OF CONTENTS...1349

Section : Operation...1352

Group 1: Overview...1352

General...1453

Service mode basic window...1356

Display's symbols...1359

Group 2: Service mode settings...1352

General...1453

Auxiliary adjustment...1364

AUX1...1365

AUX2...1366

AUX3...1367

Adjustable ALS Load Space Functions...1368

Cabin levelling adjustment...1369

Cabin side levelling adjustment...1372

F and S operator parameter settings...1374

System history data...1375

Alarm log...1378

Engine Alarm Logs Printouts *)...1352

D-models' engine alarm list...1383

Service window...1389

Adjustment of engine idling speed and maximum speed...1390

Engine operating minimum and maximum values...1391

Automatic adjustment of power transmission...1395

Automatic adjustment of a diesel engine (770, 1070)...1399

Adjustment of servo motor (770, 1070)...1403

Module program versions...1404

Alarm settings window...1406

Control of the system...1409

General machine settings...1411

Machine profiling...1416

Machine service code...1419

Automatic program update...1420

Machine immobilizer...1422

Use the lock parameters...1425

Test window...1427

Adjusting electrically controlled workpump...1429

Engine Control Unit (ECU) Info...1432

Error diagnostic...1434

Group 3: Functional requirements for outputs...1353

General...1453

Function of driving power transmission...1438

Engine speed control (not in D-model machines)...1439

High/low gear...1440

Service brake...1441

Release of rear-wheel drive (forwarders) or front-wheel drive (harvesters)...1442

Differential lock; front-wheel drive...1443

Differential lock; rear-wheel drive...1444

Release of frame brake...1445

Excitation valve of working pump...1446

Unloading of working pump...1447

Crane module...1448

Chair module...1450

Hub module...1451

Group 4: System maintenance...1353

General...1453

Loading programs...1454

Working with parameters...1455

Transmitting parameters to the system...1456

John Deere 1070D Harvester Operator's Manual (OMF070957 TM2122 TM2155)