John Deere 470GLC Excavator Troubleshooting (PIN 1FF470GX_ _C047001— ) Technical Manual (TM13180X19)

Complete Troubleshooting service manual for John Deere 470GLC Excavator, with all the technical information to maintain, diagnose, repair, and rebuild your JD excavators like professional mechanics.

TM13180X19 - John Deere 470GLC Excavator Troubleshooting (PIN 1FF470GX_ _C047001— ) Technical Manual.pdf

tm13180x54 - Resolução de problemas Escavadeira 470GLC (PIN: 1FF470GX_ _C047001— ).pdf

tm13180x63 - Excavadora 470GLC Localización de averías (PIN: 1FF470GX_ _C047001— ).pdf

PRODUCT DETAILS:

Total Pages: 553 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: Portuguese Spanish English

Models: John Deere - 470GLC Excavator - 1FF470GX__C047001

Category: Operation and Test

TABLE OF CONTENTS

Section Safety: Safety...16

Group : Safety...16

Recognize Safety Information...19

Follow Safety Instructions...20

Operate Only If Qualified...21

Wear Protective Equipment...22

Avoid Unauthorized Machine Modifications...23

Add Cab Guarding for Special Uses...24

Inspect Machine...25

Stay Clear of Moving Parts...26

Avoid High-Pressure Fluids...27

Avoid High-Pressure Oils...28

Work In Ventilated Area...29

Prevent Fires...30

Prevent Battery Explosions...31

Handle Chemical Products Safely...32

Dispose of Waste Properly...33

Prepare for Emergencies...34

Clean Debris from Machine...35

Use Steps and Handholds Correctly...36

Start Only From Operator's Seat...37

Use and Maintain Seat Belt...38

Prevent Unintended Machine Movement...39

Avoid Work Site Hazards...40

Keep Riders Off Machine...42

Avoid Backover Accidents...43

Inspect and Maintain ROPS...44

Avoid Machine Tip Over...45

Use Special Care When Lifting Objects...47

Add and Operate Attachments Safely...48

Park and Prepare for Service Safely...49

Service Cooling System Safely...50

Remove Paint Before Welding or Heating...51

Make Welding Repairs Safely...52

Drive Metal Pins Safely...53

MEMO...553

Section T4: Operational Performance Test...56

Group 1: Introduction...199

Operational Performance Tests...59

Preparation for Performance Tests...60

Group 2: Standard...56

Operational Performance Standard Table...66

Main Pump P-Q Diagram...70

MPDR. Monitor Indicating Values (MC)...71

MPDr. Monitor Indicating Values (ECF)...75

Sensor Activating Range...76

Group 3: Engine Test...56

Engine Speed...81

Engine Compression Pressure...85

Valve Clearance...87

Nozzle...90

Injection Timing...93

Lubricant Consumption...95

Group 4: Machine Performance Test...56

Travel Speed...99

Mistrack Check...102

Travel Motor Leakage...104

Swing Speed...106

Swing Function Drift Check...108

Swing Motor Leakage...111

Maximum Swingable Slant Angle...113

Swing Bearing Play...115

Hydraulic Cylinder Cycle Time...118

Dig Function Drift Check...121

Control Lever Operating Force...124

Control Lever Stroke...126

Boom Raise/Swing Combined Operation Check...127

Group 5: Component Test...56

Primary Pilot Pressure...132

Secondary Pilot Pressure...135

4-Spool Solenoid Valve Set Pressure...137

2-Spool Solenoid Valve Set Pressure...139

Main Pump Delivery Pressure...143

Main Relief Valve Set Pressure...145

Overload Relief Valve Set Pressure...154

Main Pump Flow Rate Measurement...158

Swing Motor Drainage...165

Travel Motor Drainage...169

Group 6: Adjustment...57

Installation and Adjustment of Pump Displacement Angle Sensor...178

Engine Speed Adjustment and Engine Learning...183

Positions of Governor Lever and Fuel Cut Lever...186

MEMO...553

MEMO...553

Section T5: Troubleshooting...513

Group 1: Diagnosing Procedure...193

Introduction...199

Diagnosis Procedure...201

Electric System Inspection...205

Precautions for Inspection and Maintenance...206

Instructions for Disconnecting Connectors...209

Fuse Inspection...211

Fusible Link Inspection...214

Battery Voltage Check...216

Alternator Check...217

Continuity Check...219

Voltage and Current Measurement...222

Check by False Signal...229

Test Harness...231

Group 2: Monitor...193

Outline...503

Operating Procedures of Service Menu (Built-In Diagnosing System)...237

Setting Menu...281

Inspection of Hour Meter and Fuel Gauge...284

Fuel Gauge and Coolant Temperature Gauge...285

Group 3: e-Service...193

Outline...503

List of Operation Data...288

Snapshot Data...291

Communication System...292

Group 4: Component Layout...193

Main Component...296

Electrical System (Overview)...299

Electrical System (Rear Tray)...300

Electrical System (Switch Panel)...302

Electrical System (Cab Behind Side)...304

Isolation Switch (Optional)...306

Engine...307

Pump Device...309

Control Valve...310

Check Valve / Accumulator...311

Signal Control Valve...312

Swing Device...314

Travel Device...315

4-Spool Solenoid Valve Unit...316

2-Spool Solenoid Valve Unit...317

Layout of Attachment Spec. Parts (Hydraulic System)...318

Layout of Control Valve...321

Pilot Port (Signal Control Valve)...332

Group 5: Troubleshooting A...194

Troubleshooting A (Base Machine Diagnosis by Using Fault Codes) Procedure...337

MC Fault Code List...339

ECF Fault Code List...347

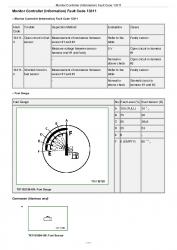

Monitor Controller (Monitor) Fault Code List...348

Monitor Controller (Information) Fault Code List...349

Air Conditioner Controller Fault Code List...514

Communication Terminal Fault Code List...354

MC Fault Codes 11000 to 11002...355

MC Fault Code 11003ECF Fault Code 16603...194

MC Fault Codes 11006, 11007,11009ECF Fault Code 16604Monitor Controller (Monitor) Fault Codes 13002, 13003, 13005...194

CAN0 Harness Check...361

MC Fault Codes 11008, 11010Monitor Controller (Monitor) Fault Codes 13004, 13006, 13007...194

CAN1 Harness Check...366

MC Fault Code 11101...371

MC Fault Codes 11200, 11202...372

MC Fault Codes 11301, 11302...374

MC Fault Code 11303...376

MC Fault Codes 11304, 11325...377

MC Fault Code 11405...379

MC Fault Code 11408...380

MC Fault Code 11428...381

MC Fault Code 11901...382

MC Fault Code 11940...384

MC Fault Code 11941...385

MC Fault Codes 11942, 11944...386

MC Fault Code 11945...388

MC Fault Code 11948...389

MC Fault Code 11950...390

MC Fault Code 11951...391

MC Fault Code 11953...392

MC Fault Codes 11955, 11956...393

MC Fault Codes 11978, 11979...395

MC Fault Code 11980...397

MC Fault Code 11989...398

MC Fault Codes 11995, 11997...399

MC Fault Code 11998...401

MC Fault Codes 20062...402

ECF Fault Codes 16600 to 16602...403

ECF Fault Code 16605...404

ECF Fault Code 16606...405

Air Conditioner Controller Fault Codes 11 to 22...516

Air Conditioner Controller Fault Codes 43 to 92...518

Monitor Controller (Information) Fault Codes 13304, 13310...409

Monitor Controller (Information) Fault Code 13311...411

Monitor Controller (Information) Fault Codes 20100 to 20114...413

Group 6: Troubleshooting B...195

Troubleshooting B (Machine Diagnosis by Using Troubleshooting Symptom) Procedure...416

Relationship Between Machine Trouble Symptoms and Related Parts...418

Correlation Between Trouble Symptoms and Part Failures...438

Engine System Troubleshooting...513

All Actuator System Troubleshooting...513

Front Attachment System Troubleshooting...513

Swing System Troubleshooting...513

Travel System Troubleshooting...513

Other System Troubleshooting...513

Exchange Inspection...496

How to Lowering Boom in Case of Emergency and When Engine Stops...499

Group 7: Air Conditioner...196

Refrigerant Cautions and Proper Handling...502

Outline...503

Functions of Main Parts...507

Troubleshooting...513

Air Conditioner Controller Fault Code List...514

Air Conditioner Controller Fault Codes 11 to 22...516

Air Conditioner Controller Fault Codes 43 to 92...518

Work after Replacing Components...537

Refill Compressor Oil...538

Charge Air Conditioner with Refrigerant...540

Hose and Pipe Tightening Torque...551

MEMO...553

Technical Information Feedback Form...555

The Attached Diagram List...556

John Deere 470GLC Excavator Troubleshooting (PIN 1FF470GX_ _C047001— ) Technical Manual (TM13180X19)