Case Skid Steer 410, 420 Repair & Service Manual

Complete repair service manual for Case Skid Steer 410, 420, with all the technical information to maintain, diagnose, and repair like professional mechanics.

Case Skid Steer 410, 420 workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

...

6-78950 - Case 410, 420 SKID STEER Service Manual.pdf

PRODUCT DETAILS:

Total Pages: 468 pages

File Format: PDF (Windows & Mac & Linux)

Language: English

FLUIDS AND LUBRICANTS...5

CAPACITIES AND LUBRICANTS 3...6

ENVIRONMENT 3...6

CAPACITIES AND LUBRICANTS...7

ENVIRONMENT...7

Before you service this machine and dispose of oil, fluids and lubricants, always remember the environment. Do not put oil or fl...7

Engine Oil Selection...8

BS00H001...0

Oil Viscosity/Temperature Ranges...8

BS99N019...8

Fuel Storage...9

Specifications for Acceptable No. 2 Diesel Fuel...9

NOTES...10

7_52931.pdf...0

STANDARD TORQUE SPECIFICATIONS...11

TABLE OF CONTENTS...12

TORQUE SPECIFICATIONS - DECIMAL HARDWARE...13

Grade 5 Bolts, Nuts, and Studs...13

Grade 8 Bolts, Nuts, and Studs...13

TORQUE SPECIFICATIONS - METRIC HARDWARE...14

Grade 8.8 Bolts, Nuts, and Studs...14

Grade 10.9 Bolts, Nuts, and Studs...14

Grade 12.9 Bolts, Nuts, and Studs...14

TORQUE SPECIFICATIONS - STEEL HYDRAULIC FITTINGS...15

37 Degree Flare Fitting...15

Straight Threads with O-ring...15

Split Flange Mounting Bolts...16

O-Ring Face Seal End...16

O-Ring Boss End Fitting or Lock Nut...16

Pipe fittings...17

7_52950.pdf...0

METRIC CONVERSION CHART...19

TABLE OF CONTENTS...20

CONVERSION FACTORS...21

Metric to U.S...21

U.S. to Metric...22

6_79130.pdf...0

ENGINE AND RADIATOR REMOVAL AND INSTALLATION...25

6_79540.pdf...0

ELECTRICAL SYSTEM SPECIFICATIONS, TROUBLESHOOTING, AND SCHEMATICS...47

TABLE OF CONTENTS...48

GENERAL INFORMATION 7...48

SWITCH PANEL 98...51

GENERAL INFORMATION...0

Circuit Diagram Legends...0

Wire Identification...0

WIRE SIZE IN MM...0

0.8 MM 2.0 MM...0

1.0 MM 5.0 MM...0

WIRE SIZE IN STANDARD...0

18 - gauge 14 - gauge...0

16 - gauge 10 - gauge...0

Fuses...0

4...0

373247A2...0

1. LIGHTS...0

2. WIPER (IF EQUIPPED)...0

3. INTERLOCK/INSTRUMENT CLUSTER...0

4. HORN/BACKUP ALARM...0

5. FRONT ELECTRIC/ACCESSORY...0

6. HEATER/AIR CONDITIONING (IF EQUIPPED)...0

7. HAZARD/HIGH FLOW (IF EQUIPPED)...0

8. HYDRAULIC COUPLER/BEACON (IF EQUIPPED)...0

1 Battery...0

NOTE: The battery must be at full charge and all connections clean and tight before doing any testing of the electrical system. Use a multimeter for the following tests...0

2 Alternator...0

3 Starter Motor and Solenoid...0

5 Starting Relay...0

7 Ignition Switch...55

1. BATTERY...56

2. ALTERNATOR...56

3. STARTER AND SOLENOID...56

4. CIRCUIT BREAKERS...56

5. STARTER RELAY...56

6. RESISTOR (50 OHM)...56

7. IGNITION SWITCH...56

ELECTRICAL SCHEMATIC FRAME 1...56

8 Main Power Relay...57

11 Primary Fuse Block...57

12 Options Fuse Block...58

8. MAIN POWER RELAY...59

9. OPTIONS POWER RELAY...59

10. DIODE (REVERSE POLARITY)...59

11. PRIMARY FUSE BLOCK...59

12. OPTIONS FUSE BLOCK...59

ELECTRICAL SCHEMATIC FRAME 2...59

15 Fuel Hold In Solenoid...60

13. NOT USED...61

14. FUEL PUMP...61

15. FUEL HOLD-IN SOLENOID...61

ELECTRICAL SCHEMATIC FRAME 3...61

16. COIL...62

17. GLOW PLUGS...62

ELECTRICAL SCHEMATIC FRAME 4...62

18 Interlock Relay...63

19 Seat Switch...63

20 Seat Bar Switch...63

22 and 23 Loader Valve Solenoids...64

24 Brake Release Solenoid...64

18. INTERLOCK RELAY...65

19. SEAT SWITCH...65

20. SEAT BAR SWITCH...65

21. NOT USED...65

22. LOADER VALVE SOLENOID...65

23. LOADER VALVE SOLENOID...65

24. BRAKE RELEASE/TANDEM PUMP NEUTRAL OVERRRIDE SOLENOID...65

25. OPTION NOT AVAILABLE 410 AND 420...65

ELECTRICAL SCHEMATIC FRAME 5...65

Instrument Cluster...66

27 Hydraulic Filter Pressure Switch...66

28 Hydraulic Oil Temperature Sender...66

29 Engine Coolant Temperature Sender...67

30 Air Filter Restriction Switch...67

32 Engine Oil Pressure Switch...68

26. NOT USED...69

27. HYDRAULIC FILTER PRESSURE SWITCH...69

28. HYDRAULIC OIL TEMPERATURE SENDER...69

29. ENGINE COOLANT TEMPERATURE SENDER...69

30. AIR FILTER RESTRICTION SWITCH...69

31. FUEL SENDER...69

32. ENGINE OIL PRESSURE SWITCH...69

33. CHARGE PRESSURE SWITCH...69

ELECTRICAL SCHEMATIC FRAME 6...69

Work/Road Light Switch...70

37 Left Front Work Lamp...70

38 Right Front Work Lamp...70

39 Rear Work Lamp...70

40 Left Rear Indicator Lamp...70

41 Right Rear Indicator Lamp...71

34. DIODE...72

35. LIGHT RELAY NO. 1...72

36. LIGHT RELAY NO.2...72

37. LEFT FRONT WORKLIGHT...72

38. RIGHT FRONT WORKLIGHT...72

39. REAR WORKLIGHT...72

40. LEFT REAR INDICATOR LAMP...72

41. RIGHT REAR INDICATOR LAMP...72

ELECTRICAL SCHEMATIC FRAME 7...72

44 Horn...73

44. HORN...74

ELECTRICAL SCHEMATIC FRAME 8...74

45 Backup Alarm Switch (Left)...75

46 Backup Alarm Switch (Right)...75

47 Backup Alarm...76

45. BACKUP ALARM SWITCH (LEFT)...77

46. BACKUP ALARM SWITCH (RIGHT)...77

47. BACKUP ALARM...77

ELECTRICAL SCHEMATIC FRAME 9...77

48 Cab Door Switch...78

48. CAB DOOR SWITCH...79

48a. WIPER/WASHER SWITCH...79

ELECTRICAL SCHEMATIC FRAME 10...79

49 High Flow Switch...80

52 Forward High Flow Solenoid...80

53 Reverse High Flow Solenoid...80

49. ELECTRO-HYDRAULIC HIGH FLOW SWITCH...81

50. DIODE...81

51. COMBINATION SOLENOID...81

52. FORWARD SOLENOID...81

53. REVERSE SOLENOID...81

ELECTRICAL SCHEMATIC FRAME 11...81

54 Ride Control Solenoid...82

54. RIDE CONTROL SOLENOID...83

ELECTRICAL SCHEMATIC FRAME 12...83

55 Rotating Beacon Switch...84

56 Rotating Beacon...84

55. ROTATING BEACON SWITCH...85

56. ROTATING BEACON...85

ELECTRICAL SCHEMATIC FRAME 13...85

Electrical Accessory Outlet (Optional)...86

ELECTRICAL SCHEMATIC FRAME 14...87

57 Hydraulic Coupler Switch...88

59 Hydraulic Coupler Release Solenoid...88

57. HYDRAULIC COUPLER SWITCH...89

58. DIODE...89

59. HYDRAULIC COUPLER RELEASE SOLENOID...89

ELECTRICAL SCHEMATIC FRAME 15...89

Dome Lamp with Switch...90

62 Fan Speed Switch...90

61. HEAT CONTROL SWITCH...91

62. FAN SPEED SWITCH...91

63. BLOWER MOTOR...91

64. OPTION NOT AVAILABLE 410 AND 420...91

65. OPTION NOT AVAILABLE 410 AND 420...91

66. OPTION NOT AVAILABLE 410 AND 420...91

67. OPTION NOT AVAILABLE 410 AND 420...91

ELECTRICAL SCHEMATIC FRAME 16...91

ELECTRICAL SCHEMATIC FRAME 17...92

ELECTRICAL SCHEMATIC FRAME 18...93

70 Starting Interlock Relay...94

69. AUXILIARY HYDRAULIC NEUTRAL SWITCH...95

70. STARTING INTERLOCK RELAY...95

71. FUEL SOLENOID RELAY...95

72. DIODE...95

ELECTRICAL SCHEMATIC FRAME 19...95

73. HAZARD SWITCH...96

74. FLASHER MODULE...96

75. DIODE PACK...96

ELECTRICAL SCHEMATIC FRAME 20...96

60. LEFT FRONT HEADLAMP...97

68. RIGHT FRONT HEADLIGHT...97

76. LEFT REAR TURNLIGHT...97

77. RIGHT REAR TURNLIGHT...97

78. LEFT FRONT TURNLIGHT...97

78. RIGHT FRONT TURNLIGHT...97

80. LEFT FRONT POSITION LIGHT...97

81. RIGHT FRONT POSITION LIGHT...97

82. LICENSE PLATE LIGHT...97

83. RESISTOR...97

ELECTRICAL SCHEMATIC FRAME 21...97

bc04m092-22...98

84. LOADER LOCKOUT SWITCH (OPTIONAL)...98

ELECTRICAL SCHEMATIC FRAME 22...98

bc04m092-23...99

85. NOT USED...99

86. LEFT BRAKE LIGHT SWITCH (EURO)...99

87. RIGHT BRAKE LIGHT SWITCH (EURO)...99

88. BRAKE LIGHT SWITCH TIMER RELAY (EURO)...99

ELECTRICAL SCHEMATIC FRAME 23...99

90 Turn Signal Switch...100

91 Attachment Hydraulic Switch...100

98 Attachment Hydraulic Forward Flow “ON” Switch...100

89. TWO (2) SPEED SWITCH...101

90. TURN SIGNAL SWITCH...101

91. ATTACHMENT HYDRAULIC SWITCH...101

98. ATTACHMENT HYDRAULIC FORWARD FLOW “ON” SWITCH...101

ELECTRICAL SCHEMATIC FRAME 24...101

92 Horn Switch...102

94 Front Electric Control Switch No. 1...102

95 Front Electric Control Switch No. 2...103

96 Front Electric Control Switch No. 3...103

97 Front Electric Control Switch No. 4...103

92. HORN SWITCH...104

93. RIDE CONTROL SWITCH...104

94. FRONT ELECTRIC CONTROL SWITCH nO. 1...104

95. FRONT ELECTRIC CONTROL SWITCH nO. 2...104

96. FRONT ELECTRIC CONTROL SWITCH nO. 3...104

97. FRONT ELECTRIC CONTROL SWITCH nO. 4...104

ELECTRICAL SCHEMATIC FRAME 25...104

ELECTRICAL SCHEMATIC FRAME 26...105

CONNECTORS SCHEMATIC FRAME 1...106

Connector 4 Alternator...106

PAC_12186568...106

Connector 7 Starter Relay...106

245731C1...106

Connector 8...106

256357A1...106

Connector 8A...107

256356A1...107

Connector 9 Ignition Switch...107

pac_12052856...107

Connector 52...107

FRA54201016...107

Connector 52A...108

FRA54201009...108

CONNECTORS SCHEMATIC FRAME 2...108

Connector 14 Main Power Relay...108

245731C1...108

Connector 25...108

CNH_style_24...108

Connector 64 Options Power Relay...108

245731C1...108

CONNECTORS SCHEMATIC FRAME 3...109

Connector 60...109

CONNECTORS SCHEMATIC FRAME 5...109

Connector 8A...109

256356A1...109

Connector 8...109

256357A1...109

Connector 18 Interlock Relay...110

245731C1...110

Connector 23 Instrument Cluster...110

AMP_3_1437290_8...110

Connector 50...110

CNH_STYLE_24...110

Connector 57...111

256340A1...111

Connector 58...111

253294A1‘...111

Connector 59...111

253294A1...111

Connector 79...111

256340A1...111

Connector 80...112

225316C1...112

Connector 103...112

256340A1...112

Connector 127...112

256346A1...112

Connector 127A...112

256346A1...112

CONNECTORS SCHEMATIC FRAME 6...113

Connector 8...113

256357A1...113

Connector 8A...113

256356A1...113

Connector 23 Instrument Cluster...114

AMP_3-1437290-8...114

Connector 29...114

291718A1...114

Connector 30...114

245482C1...114

Connector 52...115

FRA_54201009...115

Connector 52A...115

FRA_54201016...115

CONNECTORS SCHEMATIC FRAME 7...116

Connector 8...116

256357A1...116

Connector 8A...116

256356A1...116

Connector 32...116

256340A1...116

Connector 33...116

256340A1...116

Connector 34...117

256340A1...117

Connector 93...117

245731C1...117

Connector 96...117

245731C1...117

Connector 99...118

CNH_style_24...118

CONNECTORS SCHEMATIC FRAME 8...118

Connector 39 (Grey)...118

256340A1...118

CONNECTORS SCHEMATIC FRAME 10...118

Connector 50A...118

CNH_style_24...118

Connector 51...118

225295C1...118

Connector 51A...119

225295C1...119

Connector 65...119

182069A1...119

Connector 65A...119

182069A1...119

Connector 112...119

239451a1...119

Connector 113...120

AMP_480115_1...120

Connector 140...120

225351C1...120

Connector 140A...120

225350C1...120

Connector 141 Wiper/Washer Switch...120

CONNECTORS SCHEMATIC FRAME 11...121

Connector 70...121

DE_HDP26-24-21S...121

Connector 70A...121

DE_HDP24-24-21P...121

Connector 72...121

245432C1...121

Connector 81...121

225316A1...121

Connector 81B...122

225315C1...122

Connector 120...122

245482C1...122

Connector 121...122

291718A1...122

Connector 122...122

291718A1...122

Connector 123...123

253294A1...123

Connector 124...123

CNH_STYLE-24...123

CONNECTORS SCHEMATIC FRAME 12...123

Connector 77...123

256340A1...123

CONNECTORS SCHEMATIC FRAME 13...123

Connector 67...123

245781C1...123

Connector 68...124

CNH_STYLE-24...124

CONNECTORS SCHEMATIC FRAME 14...124

Connector 71...124

877291R1...124

Connector 71A (Euro)...124

877290R1...124

CONNECTORS SCHEMATIC FRAME 15...124

Connector 70...124

DE_HDP26-24-21S...124

Connector 70A...125

DE_HDP24-24-21P...125

Connector 73...125

CNH_STYLE-24...125

Connector 75...125

245432C1...125

Connector 76...125

225316C1...125

Connector 115...126

256340A1...126

Connector 115A...126

256341A1...126

CONNECTORS SCHEMATIC FRAME 16...126

Connector 69...126

CNH_STYLE-24...126

Connector 117...126

877291R1...126

Connector 117A...127

Connector 170...127

Connector 171...127

Connector 174...128

Connector 175...128

Connector 176...128

CONNECTORS SCHEMATIC FRAME 17...128

Connector 66...128

256351A1...128

Connector 66A...129

256350A1...129

Connector 85...129

256345A1...129

Connector 86...129

256345A1...129

CONNECTORS SCHEMATIC FRAME 18...130

Connector 49...130

225320C1...130

Connector 107...130

225233C1...130

Connector 138...131

225389C1...131

Connector 138A...131

225388C1...131

Connector 150...132

182069A1...132

Connector 150A...132

182069A1...132

CONNECTORS SCHEMATIC FRAME 19...132

Connector 125...132

245731C1...132

Connector 127B...133

256347A1...133

Connector 127C...133

256346A1...133

Connector 128...133

245731C1...133

Connector 129...133

CNH_STYLE_30...133

Connector 130...134

256341A1...134

CONNECTORS SCHEMATIC FRAME 20...134

Connector 66B...134

256350A1...134

Connector 66C...134

256351A1...134

Connector 92...135

245781C1...135

Connector 275...135

245731C1...135

Connector 276...135

245488C1...135

CONNECTORS SCHEMATIC FRAME 21...136

Connector 86B...136

256344A1...136

Connector 226...136

225326C1...136

Connector 227...137

225326C1...137

Connector 228...137

277905A1...137

Connector 229...138

277905A1...138

Connector 230...138

245482C1...138

CONNECTORS SCHEMATIC FRAME 22...138

Connector 50C...138

CNH_STYLE_24...138

Connector 50D...138

CNH_STYLE_24...138

Connector 119...139

245781C1...139

CONNECTORS SCHEMATIC FRAME 23...139

Connector 71B (Euro)...139

872291R1...139

Connector 71C...139

877290R1...139

Connector 190 (Euro)...139

245731C1...139

CONNECTORS SCHEMATIC FRAME 24...140

Connector 79B...140

256341A1...140

Connector 79C...140

256341A1...140

Connector 79D...140

256341A1...140

Connector 85A...140

256344A1...140

Connector 85D...141

256344A1...141

Connector 123B...141

256294A1...141

Connector 123C...141

256294A1...141

Connector 123D...141

256294A1...141

CONNECTORS SCHEMATIC FRAME 25...142

Connector 39F...142

253294A1...142

Connector 39G...142

253294A1...142

Connector 39H...142

253294A1...142

Connector 49H...143

DEU_DT06-8S...143

Connector 77H...143

256341A1-...143

1...144

BD05A089...144

1. KEY SWITCH...144

2. INSTRUMENT (EIC) PANEL...144

SWITCH PANEL...144

1...144

BD04N043...144

1. TEMPERATURE CONTROL...144

2. BLOWER FAN SWITCH...144

3. AIR CONDITIONING SWITCH (IF EQUIPPED)...144

4. BLANK FOR SWITCH...144

5. HYDRAULIC COUPLER SWITCH (IF EQUIPPED)...144

6. ROTATING BEACON SWITCH LOCATION (IF EQUIPPED)...144

7. HAZARD FLASHER SWITCH LOCATION (IF EQUIPPED)...144

8. HIGH/LOW HYDRAULIC CONTROL SWITCH (IF EQUIPPED)...144

1...145

bd05a089...145

1. SEAT BELT INDICATOR LAMP...145

2. ENGINE OIL PRESSURE INDICATOR LAMP AND ALARM...145

3. PARK BRAKE INDICATOR LAMP...145

4. FUEL GUAGE...145

5. HOURMETER...145

6. ROAD LAMP SWITCH...145

7. AUXILIARY HYDRAULIC INTERLOCK OVERRIDE SWITCH...145

8. WORK LAMP SWITCH...145

9. PARK BRAKE “ON/OFF” SWITCH...145

10. HYDRAULIC OIL FILTER WARNING LAMP...145

11. COOLANT TEMPERATURE WARNING LAMP AND ALARM...145

12. ENGINE AIR FILTER WARNING LAMP...145

13. ENGINE PREHEATER LAMP (IF EQUIPPED)...145

14. CHARGE PRESSURE WARNING LAMP...145

15. HYDRAULIC FLUID TEMPERATURE WARNING LAMP...145

Monitored functions and parameters:...146

1. Operator (in/out seat) - lighted indicator...146

2. Operator seat restraint bar (up/down), - lighted indicator (same as lighted indicator in (1)...146

3. Engine oil pressure (high/low) - lighted indicator...146

4. Hydraulic charge pressure (high/low) - lighted indicator...146

5. Hydraulic oil temperature (high/low) - lighted indicator...146

6. Engine coolant temperature (high/low) - lighted indicator...146

7. Hydraulic oil filter condition (free/restricted) - lighted indicator...146

8. Engine air filter condition (free/restricted) - lighted indicator...146

9. Parking brake state (ON/OFF) - lighted indicator...146

10. Engine preheat state (ON/OFF) - lighted indicator...146

11. Battery voltage (over/under) - displayed in place of engine hours when out of limits high/low...146

12. Engine hours (accumulated to tenth hour) - character display...146

13. Fuel level - eight element vertical bar graph...146

Controlled Functions:...146

1. Hydraulic interlock solenoid output - inhibits boom/bucket movement when operator out of seat or the seat restraint bar is in the raised position...146

2. Hydraulic brake output - prevents loader motion when the operator is out of the seat, or the seat restraint bar is in the raised position...146

3. Grid heat output (if equipped) - applies power to the grid heater relay for an interval of time determined by the temperature of the engine coolant each time the ignition key is turned from off to on...146

4. Hydraulic auxiliary override - enables a continuous hydraulic flow to attachments when an operator leaves the seat to operate...146

A. (6) Work lights (ON/OFF)...146

B. (8) Road lights (ON/OFF)...146

C. (9) Parking brake (SET/RELEASE)...146

D. (7) Auxiliary hydraulic interlock override...146

Push Button Functional Description:...146

Restraint System: The EIC contains logic to ensure operator safety. The EIC continually monitors the seat switch and the seat re...147

EIC Special Functions (Setup Menu):...147

A. (1) Select engine type: (for correct cold engine preheat profile)...147

B. (2) Select brake type: hydraulic or no brake...147

C. (3) Display EIC software revision level...147

D. (5) Modify engine hours: (coded entry required)...147

Push Button Definitions:...147

1. Any button: Any button may be depressed and held for six seconds to enter the setup mode. The seat must be unoccupied and the ignition key off during this time, but the operator may sit in the seat after the setup mode is entered...147

2. Parking brake: Provides for editing the values that a setup menu item (engine type, brake type, engine hours) can have. When ...147

3. Road light: Used to view in succession all of the values that an item can have. When changing engine hours, this button increments a flashing digit value in a circular manner from 0 - 9...147

4. Work light: Used to navigate to the next menu item. When changing engine hours, this button causes the flashing emphasis to move to the next digit to the right...147

5. Auxiliary override: This button functions as an unconditional setup exit without save from any location in the menu. When thi...147

6. To Exit the Setup Menu: (1) Leave the loader. After three seconds the EIC will automatically power down, (2) place the ignition key in either the ACC or the ON position or (3) push and release the auxiliary override button...147

Special Feature Choices:...148

1. Display/select engine type...148

2. Display/change brake type...148

3. Display/change engine hours are the only values that may be modified...148

Detailed Description of Setup Items:...148

Selecting an Engine Preheat Profile:...148

Changing Brake Type:...148

Changing Engine Hours:...148

TROUBLESHOOTING ELECTRONIC INSTRUMENT CLUSTER (EIC)...149

NOTES...152

p003_usl.pdf...0

GENERAL INFORMATION...53

Circuit Diagram Legends...53

Wire Identification...53

WIRE SIZE IN MM...53

0.8 MM 2.0 MM...53

1.0 MM 5.0 MM...53

WIRE SIZE IN STANDARD...53

18 - gauge 14 - gauge...53

16 - gauge 10 - gauge...53

Fuses...53

4...53

87457332...53

1. LIGHTS...53

2. WIPER (IF EQUIPPED)...53

3. INTERLOCK/INSTRUMENT CLUSTER...53

4. HORN/BACKUP ALARM...53

5. FRONT ELECTRIC/ACCESSORY...53

6. HEATER/AIR CONDITIONING (IF EQUIPPED)...53

7. HAZARD/HIGH FLOW (IF EQUIPPED)...53

8. HYDRAULIC COUPLER/BEACON (IF EQUIPPED)...53

9. INTERLOCK RELAY...53

10. MAIN POWER RELAY...53

11. STARTER RELAY...53

12. n/a...53

13. ACCESSORY POWER RELAY...53

14. AUXILIARY INTERLOCK / FUEL SHUTOFF RELAY...53

15. AUXILIARY INTERLOCK / STARTER RELAY...53

16. WORK LIGHT / ROAD LIGHT RELAY...53

17. HAZARD FLASHER...53

1 Battery...54

NOTE: The battery must be at full charge and all connections clean and tight before doing any testing of the electrical system. Use a multimeter for the following tests...54

2 Alternator...54

3 Starter Motor and Solenoid...54

5 Starting Relay...54

7 Ignition Switch...0

1. BATTERY...0

2. ALTERNATOR...0

3. STARTER AND SOLENOID...0

4. CIRCUIT BREAKERS...0

5. STARTER RELAY...0

6. RESISTOR (50 OHM)...0

7. IGNITION SWITCH...0

ELECTRICAL SCHEMATIC FRAME 1...0

8 Main Power Relay...0

11 Primary Fuse Block...0

12 Options Fuse Block...0

8. MAIN POWER RELAY...0

9. OPTIONS POWER RELAY...0

10. DIODE (REVERSE POLARITY)...0

11. PRIMARY FUSE BLOCK...0

12. OPTIONS FUSE BLOCK...0

ELECTRICAL SCHEMATIC FRAME 2...0

15 Fuel Hold In Solenoid...0

13. NOT USED...0

14. FUEL PUMP...0

15. FUEL HOLD-IN SOLENOID...0

ELECTRICAL SCHEMATIC FRAME 3...0

16. COIL...0

17. GLOW PLUGS...0

ELECTRICAL SCHEMATIC FRAME 4...0

18 Interlock Relay...0

19 Seat Switch...0

20 Seat Bar Switch...0

22 and 23 Loader Valve Solenoids...0

24 Brake Release Solenoid...0

18. INTERLOCK RELAY...0

19. SEAT SWITCH...0

20. SEAT BAR SWITCH...0

21. NOT USED...0

22. LOADER VALVE SOLENOID...0

23. LOADER VALVE SOLENOID...0

24. BRAKE RELEASE/TANDEM PUMP NEUTRAL OVERRRIDE SOLENOID...0

25. OPTION NOT AVAILABLE 410 AND 420...0

ELECTRICAL SCHEMATIC FRAME 5...0

Instrument Cluster...0

27 Hydraulic Filter Pressure Switch...0

28 Hydraulic Oil Temperature Sender...0

29 Engine Coolant Temperature Sender...0

30 Air Filter Restriction Switch...0

32 Engine Oil Pressure Switch...0

26. NOT USED...0

27. HYDRAULIC FILTER PRESSURE SWITCH...0

28. HYDRAULIC OIL TEMPERATURE SENDER...0

29. ENGINE COOLANT TEMPERATURE SENDER...0

30. AIR FILTER RESTRICTION SWITCH...0

31. FUEL SENDER...0

32. ENGINE OIL PRESSURE SWITCH...0

33. CHARGE PRESSURE SWITCH...0

ELECTRICAL SCHEMATIC FRAME 6...0

Work/Road Light Switch...0

37 Left Front Work Lamp...0

38 Right Front Work Lamp...0

39 Rear Work Lamp...0

40 Left Rear Indicator Lamp...0

41 Right Rear Indicator Lamp...0

34. DIODE...0

35. LIGHT RELAY NO. 1...0

36. LIGHT RELAY NO.2...0

37. LEFT FRONT WORKLIGHT...0

38. RIGHT FRONT WORKLIGHT...0

39. REAR WORKLIGHT...0

40. LEFT REAR INDICATOR LAMP...0

41. RIGHT REAR INDICATOR LAMP...0

ELECTRICAL SCHEMATIC FRAME 7...0

44 Horn...0

44. HORN...0

ELECTRICAL SCHEMATIC FRAME 8...0

45 Backup Alarm Switch (Left)...0

46 Backup Alarm Switch (Right)...0

47 Backup Alarm...0

45. BACKUP ALARM SWITCH (LEFT)...0

46. BACKUP ALARM SWITCH (RIGHT)...0

47. BACKUP ALARM...0

ELECTRICAL SCHEMATIC FRAME 9...0

48 Cab Door Switch...0

48. CAB DOOR SWITCH...0

48a. WIPER/WASHER SWITCH...0

ELECTRICAL SCHEMATIC FRAME 10...0

49 High Flow Switch...0

52 Forward High Flow Solenoid...0

53 Reverse High Flow Solenoid...0

49. ELECTRO-HYDRAULIC HIGH FLOW SWITCH...0

50. DIODE...0

51. COMBINATION SOLENOID...0

52. FORWARD SOLENOID...0

53. REVERSE SOLENOID...0

ELECTRICAL SCHEMATIC FRAME 11...0

54 Ride Control Solenoid...0

54. RIDE CONTROL SOLENOID...0

ELECTRICAL SCHEMATIC FRAME 12...0

55 Rotating Beacon Switch...0

56 Rotating Beacon...0

55. ROTATING BEACON SWITCH...0

56. ROTATING BEACON...0

ELECTRICAL SCHEMATIC FRAME 13...0

Electrical Accessory Outlet (Optional)...0

ELECTRICAL SCHEMATIC FRAME 14...0

57 Hydraulic Coupler Switch...0

59 Hydraulic Coupler Release Solenoid...0

57. HYDRAULIC COUPLER SWITCH...0

58. DIODE...0

59. HYDRAULIC COUPLER RELEASE SOLENOID...0

ELECTRICAL SCHEMATIC FRAME 15...0

Dome Lamp with Switch...0

62 Fan Speed Switch...0

61. HEAT CONTROL SWITCH...0

62. FAN SPEED SWITCH...0

63. BLOWER MOTOR...0

64. OPTION NOT AVAILABLE 410 AND 420...0

65. OPTION NOT AVAILABLE 410 AND 420...0

66. OPTION NOT AVAILABLE 410 AND 420...0

67. OPTION NOT AVAILABLE 410 AND 420...0

ELECTRICAL SCHEMATIC FRAME 16...0

ELECTRICAL SCHEMATIC FRAME 17...0

ELECTRICAL SCHEMATIC FRAME 18...0

70 Starting Interlock Relay...0

69. AUXILIARY HYDRAULIC NEUTRAL SWITCH...0

70. STARTING INTERLOCK RELAY...0

71. FUEL SOLENOID RELAY...0

72. DIODE...0

ELECTRICAL SCHEMATIC FRAME 19...0

73. HAZARD SWITCH...0

74. FLASHER MODULE...0

75. DIODE PACK...0

ELECTRICAL SCHEMATIC FRAME 20...0

60. LEFT FRONT HEADLAMP...0

68. RIGHT FRONT HEADLIGHT...0

76. LEFT REAR TURNLIGHT...0

77. RIGHT REAR TURNLIGHT...0

78. LEFT FRONT TURNLIGHT...0

78. RIGHT FRONT TURNLIGHT...0

80. LEFT FRONT POSITION LIGHT...0

81. RIGHT FRONT POSITION LIGHT...0

82. LICENSE PLATE LIGHT...0

83. RESISTOR...0

ELECTRICAL SCHEMATIC FRAME 21...0

bc04m092-22...0

84. LOADER LOCKOUT SWITCH (OPTIONAL)...0

ELECTRICAL SCHEMATIC FRAME 22...0

bc04m092-23...0

85. NOT USED...0

86. LEFT BRAKE LIGHT SWITCH (EURO)...0

87. RIGHT BRAKE LIGHT SWITCH (EURO)...0

88. BRAKE LIGHT SWITCH TIMER RELAY (EURO)...0

ELECTRICAL SCHEMATIC FRAME 23...0

90 Turn Signal Switch...0

91 Attachment Hydraulic Switch...0

98 Attachment Hydraulic Forward Flow “ON” Switch...0

89. TWO (2) SPEED SWITCH...0

90. TURN SIGNAL SWITCH...0

91. ATTACHMENT HYDRAULIC SWITCH...0

98. ATTACHMENT HYDRAULIC FORWARD FLOW “ON” SWITCH...0

ELECTRICAL SCHEMATIC FRAME 24...0

92 Horn Switch...0

94 Front Electric Control Switch No. 1...0

95 Front Electric Control Switch No. 2...0

96 Front Electric Control Switch No. 3...0

97 Front Electric Control Switch No. 4...0

92. HORN SWITCH...0

93. RIDE CONTROL SWITCH...0

94. FRONT ELECTRIC CONTROL SWITCH nO. 1...0

95. FRONT ELECTRIC CONTROL SWITCH nO. 2...0

96. FRONT ELECTRIC CONTROL SWITCH nO. 3...0

97. FRONT ELECTRIC CONTROL SWITCH nO. 4...0

ELECTRICAL SCHEMATIC FRAME 25...0

ELECTRICAL SCHEMATIC FRAME 26...0

CONNECTORS SCHEMATIC FRAME 1...0

Connector 4 Alternator...0

PAC_12186568...0

Connector 7 Starter Relay...0

245731C1...0

Connector 8...0

256357A1...0

Connector 8A...0

256356A1...0

Connector 9 Ignition Switch...0

pac_12052856...0

Connector 52...0

FRA54201016...0

Connector 52A...0

FRA54201009...0

CONNECTORS SCHEMATIC FRAME 2...0

Connector 14 Main Power Relay...0

245731C1...0

Connector 25...0

CNH_style_24...0

Connector 64 Options Power Relay...0

245731C1...0

CONNECTORS SCHEMATIC FRAME 3...0

Connector 60...0

CONNECTORS SCHEMATIC FRAME 5...0

Connector 8A...0

256356A1...0

Connector 8...0

256357A1...0

Connector 18 Interlock Relay...0

245731C1...0

Connector 23 Instrument Cluster...0

AMP_3_1437290_8...0

Connector 50...0

CNH_STYLE_24...0

Connector 57...0

256340A1...0

Connector 58...0

253294A1‘...0

Connector 59...0

253294A1...0

Connector 79...0

256340A1...0

Connector 80...0

225316C1...0

Connector 103...0

256340A1...0

Connector 127...0

256346A1...0

Connector 127A...0

256346A1...0

CONNECTORS SCHEMATIC FRAME 6...0

Connector 8...0

256357A1...0

Connector 8A...0

256356A1...0

Connector 23 Instrument Cluster...0

AMP_3-1437290-8...0

Connector 29...0

291718A1...0

Connector 30...0

245482C1...0

Connector 52...0

FRA_54201009...0

Connector 52A...0

FRA_54201016...0

CONNECTORS SCHEMATIC FRAME 7...0

Connector 8...0

256357A1...0

Connector 8A...0

256356A1...0

Connector 32...0

256340A1...0

Connector 33...0

256340A1...0

Connector 34...0

256340A1...0

Connector 93...0

245731C1...0

Connector 96...0

245731C1...0

Connector 99...0

CNH_style_24...0

CONNECTORS SCHEMATIC FRAME 8...0

Connector 39 (Grey)...0

256340A1...0

CONNECTORS SCHEMATIC FRAME 10...0

Connector 50A...0

CNH_style_24...0

Connector 51...0

225295C1...0

Connector 51A...0

225295C1...0

Connector 65...0

182069A1...0

Connector 65A...0

182069A1...0

Connector 112...0

239451a1...0

Connector 113...0

AMP_480115_1...0

Connector 140...0

225351C1...0

Connector 140A...0

225350C1...0

Connector 141 Wiper/Washer Switch...0

CONNECTORS SCHEMATIC FRAME 11...0

Connector 70...0

DE_HDP26-24-21S...0

Connector 70A...0

DE_HDP24-24-21P...0

Connector 72...0

245432C1...0

Connector 81...0

225316A1...0

Connector 81B...0

225315C1...0

Connector 120...0

245482C1...0

Connector 121...0

291718A1...0

Connector 122...0

291718A1...0

Connector 123...0

253294A1...0

Connector 124...0

CNH_STYLE-24...0

CONNECTORS SCHEMATIC FRAME 12...0

Connector 77...0

256340A1...0

CONNECTORS SCHEMATIC FRAME 13...0

Connector 67...0

245781C1...0

Connector 68...0

CNH_STYLE-24...0

CONNECTORS SCHEMATIC FRAME 14...0

Connector 71...0

877291R1...0

Connector 71A (Euro)...0

877290R1...0

CONNECTORS SCHEMATIC FRAME 15...0

Connector 70...0

DE_HDP26-24-21S...0

Connector 70A...0

DE_HDP24-24-21P...0

Connector 73...0

CNH_STYLE-24...0

Connector 75...0

245432C1...0

Connector 76...0

225316C1...0

Connector 115...0

256340A1...0

Connector 115A...0

256341A1...0

CONNECTORS SCHEMATIC FRAME 16...0

Connector 69...0

CNH_STYLE-24...0

Connector 117...0

877291R1...0

Connector 117A...0

Connector 170...0

Connector 171...0

Connector 174...0

Connector 175...0

Connector 176...0

CONNECTORS SCHEMATIC FRAME 17...0

Connector 66...0

256351A1...0

Connector 66A...0

256350A1...0

Connector 85...0

256345A1...0

Connector 86...0

256345A1...0

CONNECTORS SCHEMATIC FRAME 18...0

Connector 49...0

225320C1...0

Connector 107...0

225233C1...0

Connector 138...0

225389C1...0

Connector 138A...0

225388C1...0

Connector 150...0

182069A1...0

Connector 150A...0

182069A1...0

CONNECTORS SCHEMATIC FRAME 19...0

Connector 125...0

245731C1...0

Connector 127B...0

256347A1...0

Connector 127C...0

256346A1...0

Connector 128...0

245731C1...0

Connector 129...0

CNH_STYLE_30...0

Connector 130...0

256341A1...0

CONNECTORS SCHEMATIC FRAME 20...0

Connector 66B...0

256350A1...0

Connector 66C...0

256351A1...0

Connector 92...0

245781C1...0

Connector 275...0

245731C1...0

Connector 276...0

245488C1...0

CONNECTORS SCHEMATIC FRAME 21...0

Connector 86B...0

256344A1...0

Connector 226...0

225326C1...0

Connector 227...0

225326C1...0

Connector 228...0

277905A1...0

Connector 229...0

277905A1...0

Connector 230...0

245482C1...0

CONNECTORS SCHEMATIC FRAME 22...0

Connector 50C...0

CNH_STYLE_24...0

Connector 50D...0

CNH_STYLE_24...0

Connector 119...0

245781C1...0

CONNECTORS SCHEMATIC FRAME 23...0

Connector 71B (Euro)...0

872291R1...0

Connector 71C...0

877290R1...0

Connector 190 (Euro)...0

245731C1...0

CONNECTORS SCHEMATIC FRAME 24...0

Connector 79B...0

256341A1...0

Connector 79C...0

256341A1...0

Connector 79D...0

256341A1...0

Connector 85A...0

256344A1...0

Connector 85D...0

256344A1...0

Connector 123B...0

256294A1...0

Connector 123C...0

256294A1...0

Connector 123D...0

256294A1...0

CONNECTORS SCHEMATIC FRAME 25...0

Connector 39F...0

253294A1...0

Connector 39G...0

253294A1...0

Connector 39H...0

253294A1...0

Connector 49H...0

DEU_DT06-8S...0

Connector 77H...0

256341A1-...0

1...0

BD05A089...0

1. KEY SWITCH...0

2. INSTRUMENT (EIC) PANEL...0

SWITCH PANEL...0

1...0

BD04N043...0

1. TEMPERATURE CONTROL...0

2. BLOWER FAN SWITCH...0

3. AIR CONDITIONING SWITCH (IF EQUIPPED)...0

4. BLANK FOR SWITCH...0

5. HYDRAULIC COUPLER SWITCH (IF EQUIPPED)...0

6. ROTATING BEACON SWITCH LOCATION (IF EQUIPPED)...0

7. HAZARD FLASHER SWITCH LOCATION (IF EQUIPPED)...0

8. HIGH/LOW HYDRAULIC CONTROL SWITCH (IF EQUIPPED)...0

1...0

bd05a089...0

1. SEAT BELT INDICATOR LAMP...0

2. ENGINE OIL PRESSURE INDICATOR LAMP AND ALARM...0

3. PARK BRAKE INDICATOR LAMP...0

4. FUEL GUAGE...0

5. HOURMETER...0

6. ROAD LAMP SWITCH...0

7. AUXILIARY HYDRAULIC INTERLOCK OVERRIDE SWITCH...0

8. WORK LAMP SWITCH...0

9. PARK BRAKE “ON/OFF” SWITCH...0

10. HYDRAULIC OIL FILTER WARNING LAMP...0

11. COOLANT TEMPERATURE WARNING LAMP AND ALARM...0

12. ENGINE AIR FILTER WARNING LAMP...0

13. ENGINE PREHEATER LAMP (IF EQUIPPED)...0

14. CHARGE PRESSURE WARNING LAMP...0

15. HYDRAULIC FLUID TEMPERATURE WARNING LAMP...0

Monitored functions and parameters:...0

1. Operator (in/out seat) - lighted indicator...0

2. Operator seat restraint bar (up/down), - lighted indicator (same as lighted indicator in (1)...0

3. Engine oil pressure (high/low) - lighted indicator...0

4. Hydraulic charge pressure (high/low) - lighted indicator...0

5. Hydraulic oil temperature (high/low) - lighted indicator...0

6. Engine coolant temperature (high/low) - lighted indicator...0

7. Hydraulic oil filter condition (free/restricted) - lighted indicator...0

8. Engine air filter condition (free/restricted) - lighted indicator...0

9. Parking brake state (ON/OFF) - lighted indicator...0

10. Engine preheat state (ON/OFF) - lighted indicator...0

11. Battery voltage (over/under) - displayed in place of engine hours when out of limits high/low...0

12. Engine hours (accumulated to tenth hour) - character display...0

13. Fuel level - eight element vertical bar graph...0

Controlled Functions:...0

1. Hydraulic interlock solenoid output - inhibits boom/bucket movement when operator out of seat or the seat restraint bar is in the raised position...0

2. Hydraulic brake output - prevents loader motion when the operator is out of the seat, or the seat restraint bar is in the raised position...0

3. Grid heat output (if equipped) - applies power to the grid heater relay for an interval of time determined by the temperature of the engine coolant each time the ignition key is turned from off to on...0

4. Hydraulic auxiliary override - enables a continuous hydraulic flow to attachments when an operator leaves the seat to operate...0

A. (6) Work lights (ON/OFF)...0

B. (8) Road lights (ON/OFF)...0

C. (9) Parking brake (SET/RELEASE)...0

D. (7) Auxiliary hydraulic interlock override...0

Push Button Functional Description:...0

Restraint System: The EIC contains logic to ensure operator safety. The EIC continually monitors the seat switch and the seat re...0

EIC Special Functions (Setup Menu):...0

A. (1) Select engine type: (for correct cold engine preheat profile)...0

B. (2) Select brake type: hydraulic or no brake...0

C. (3) Display EIC software revision level...0

D. (5) Modify engine hours: (coded entry required)...0

Push Button Definitions:...0

1. Any button: Any button may be depressed and held for six seconds to enter the setup mode. The seat must be unoccupied and the ignition key off during this time, but the operator may sit in the seat after the setup mode is entered...0

2. Parking brake: Provides for editing the values that a setup menu item (engine type, brake type, engine hours) can have. When ...0

3. Road light: Used to view in succession all of the values that an item can have. When changing engine hours, this button increments a flashing digit value in a circular manner from 0 - 9...0

4. Work light: Used to navigate to the next menu item. When changing engine hours, this button causes the flashing emphasis to move to the next digit to the right...0

5. Auxiliary override: This button functions as an unconditional setup exit without save from any location in the menu. When thi...0

6. To Exit the Setup Menu: (1) Leave the loader. After three seconds the EIC will automatically power down, (2) place the ignition key in either the ACC or the ON position or (3) push and release the auxiliary override button...0

Special Feature Choices:...0

1. Display/select engine type...0

2. Display/change brake type...0

3. Display/change engine hours are the only values that may be modified...0

Detailed Description of Setup Items:...0

Selecting an Engine Preheat Profile:...0

Changing Brake Type:...0

Changing Engine Hours:...0

TROUBLESHOOTING ELECTRONIC INSTRUMENT CLUSTER (EIC)...0

NOTES...0

7_53091.pdf...0

STARTER AND STARTER SOLENOID...161

SPECIFICATIONS 3...162

LUBRICATION 3...162

NO-LOAD TEST 3...162

DISASSEMBLY 6...162

INSPECTION 9...162

ASSEMBLY 13...162

STARTER SOLENOID TEST 18...162

SPECIFICATIONS...163

LUBRICATION...163

NO-LOAD TEST...163

General Information...163

Test Equipment...163

Test Procedure...163

B795328M...163

B831430J...164

2. 2. BATTERY TERMINAL...164

3. 3. NEGATIVE BATTERY CABLE...164

B831431J...164

2. 2. NEGATIVE LOAD CABLE...164

B831432J...164

2. 2. MOTOR TERMINAL...164

B831433J...164

B831434J...165

B831435J...165

2. 2. BATTERY TERMINAL...165

3. 3. SWITCH TERMINAL...165

B831436J...165

2. 2. LOAD CONTROL...165

3. 3. VOLTMETER...165

4. 4. AMMETER...165

5. 5. HAND HELD TACHOMETER...165

DISASSEMBLY...166

B330732M...166

B330733M...166

B330735M...167

B330736M...167

B330737M...167

B330739M...167

B330740M...167

B330741M...167

B330743M...168

B330744M...168

B330702M...168

B330703M...168

B330704M...168

B330705M...168

B330706M...169

B330708M...169

B330709M...169

B330710M...169

INSPECTION...169

Brushes and Brush Springs...169

Brush Holder...169

B313142M...170

Armature...170

B313141M...170

b313141m...170

Field Coil Test...170

B610614M...170

B610616M...171

11...172

BS05B254...172

2. SPRING STARTER...172

3. CAP SCREW...172

4. STARTER DRIVE HOUSING...172

5. O-RING...172

6. STARTER DRIVE...172

7. STEEL BALL...172

8. SPRING...172

9. BEARING CAGE...172

10. PINION...172

11. STARTER SOLENOID ASSEMBLY...172

12. ROLLER...172

13. DRAIN BUSHING...172

14. NUT...172

15. PLUNGER...172

16. GASKET...172

17. COVER...172

18. SCREW...172

19. FIELD FRAME...172

20. CAP SCREW...172

21. BRUSH HOLDER...172

22. BEARING...172

23. ARMATURE...172

24. CLAMP...172

ASSEMBLY...173

B330711M...173

B330708M...173

B330712M...173

B330714M...173

B330715M...173

B330834M...173

B330704M...174

B330703‘M...174

B330837M...174

B330838M...174

B330841M...174

B330802M...174

B330803M...175

B330804M...175

B330741M...175

B330805M...175

B330807M...175

B330740M...175

B330739M...176

B330738M...176

B330808M...176

B330809M...176

B330810M...176

B330811M...176

B330812M...177

B330813M...177

B330814M...177

B330815M...177

B330816M...177

B330818M...177

B330731M...178

STARTER SOLENOID TEST...178

Starter Solenoid Test Procedure...178

B831438R...178

2. STARTER...178

3. BATTERY TERMINAL...178

4. SWITCH TERMINAL...178

5. MOTOR TERMINAL...178

6_79330.pdf...0

HYDROSTATIC SYSTEM TROUBLESHOOTING...181

SPECIAL TOOLS 4...182

CHECKS TO DO BEFORE TROUBLESHOOTING. 5...182

SPECIAL TOOLS...184

b009638M...184

CHECKS TO DO BEFORE TROUBLESHOOTING...185

One Transmission (Right or Left) Works Correctly and the Other Does Not...186

Machine Does Not Have Enough Power...186

Check 1- Checking Charge Pressure/Flow...187

hi01e019...187

GM98H002...187

Check 2 - Checking Circuit Relief Valve Pressure...188

hi01e019...188

hi01e019...188

hi01e018...189

2. CHARGE PUMP INLET...189

NOTES...190

6_79530.pdf...0

REMOVAL AND INSTALLATION OF HYDROSTATIC COMPONENTS...191

TORQUE SPECIFICATIONS 3...192

TORQUE SPECIFICATIONS...193

Tandem Pump to Bracket Mounting Bolts (Apply Locktite 243 to the Threads) 110 to 122 Nm (80 to 90 pound-feet)...193

Tandem Pump Mounting Bracket to Chassis Mounting Bolts (Apply Locktite 243 to the Threads) 54 to 60 Nm (40 to 44 pound-feet)...193

410 Hydraulic Drive Motor Mounting Bolts 56 Nm (40 pound-feet) plus Turn Additional 65°...193

420 Hydraulic Drive Motor Mounting Bolts (Apply Locktite 243 to the Threads) 122 Nm (90 pound-feet) plus Turn Additional 60°...193

Removal...194

STEP 1...194

STEP 2...194

STEP 3...194

STEP 4...194

BD05C001...194

STEP 5...194

BD05A085...194

STEP 6...194

STEP 7...194

STEP 8...194

STEP 9...194

STEP 10...194

BD05C001...194

STEP 11...194

BD05C001...194

STEP 12...195

BD05C001...195

STEP 13...195

STEP 14...195

Installation...195

STEP 1...195

STEP 2...195

BD05C001...195

STEP 3...195

BD05C001...195

STEP 4...196

BD05C001...196

STEP 5...196

STEP 6...196

STEP 7...196

STEP 8...196

STEP 9...196

BD05C001...196

STEP 10...196

BD05A085...196

STEP 11...196

STEP 12...196

STEP 13...196

STEP 14...196

STEP 15...196

STEP 16...196

1...197

BS04N063...197

1. BOLTS...197

2. PUMP DRIVE JOINT...197

3. BELL HOUSING...197

4. FLYWHEEL...197

DRIVE COUPLING INSTALLATION...197

Removal...198

STEP 1...198

1...198

Bd01C103...198

STEP 2...198

1...198

BD01F305...198

STEP 3...198

STEP 4...198

STEP 5...198

STEP 6...198

STEP 7...198

BD05A087...198

STEP 8...198

STEP 9...198

STEP 10...198

BD05A086...198

Installation...199

STEP 11...199

STEP 12...199

BD05A086...199

STEP 13...199

STEP 14...199

Bdo5A087...199

STEP 15...199

STEP 16...199

STEP 17...199

1...199

BD01F305...199

STEP 18...199

STEP 19...199

STEP 20...199

Bd01C258...199

STEP 21...200

Bd01C268...200

STEP 22...200

STEP 23...200

STEP 24...200

STEP 25...200

STEP 26...200

STEP 27...200

1...201

BS05C069...201

1. HYDROSTATIC PUMP...201

2. DRIVE MOTOR...201

3. BRAKE VALVE...201

4. GEAR PUMP...201

5. FILTER ASSEMBLY...201

410 HYDROSTATIC DRIVE SYSTEM...201

Removal...202

STEP 1...202

1...202

Bd01C103...202

STEP 2...202

1...202

BD01F305...202

STEP 3...202

STEP 4...202

STEP 5...202

STEP 6...202

STEP 7...202

BS05C072...202

STEP 8...202

STEP 9...202

STEP 10...202

BS05C072...202

Installation...203

STEP 11...203

STEP 12...203

BS05C072...203

STEP 13...203

STEP 14...203

BS05C072...203

STEP 15...203

STEP 16...203

STEP 17...203

1...203

BD01F305...203

STEP 18...203

STEP 19...203

STEP 20...203

Bd01C258...203

STEP 21...204

Bd01C268...204

STEP 22...204

STEP 23...204

STEP 24...204

STEP 25...204

STEP 26...204

STEP 27...204

1...205

BS05C071...205

1. HYDROSTATIC PUMP...205

2. DRIVE MOTOR...205

3. BRAKE VALVE...205

4. GEAR PUMP...205

5. FILTER ASSEMBLY...205

420 HYDROSTATIC DRIVE SYSTEM...205

NOTES...206

6_79120.pdf...0

DRIVE COUPLER...207

TORQUE SPECIFICATIONS 3...208

TORQUE SPECIFICATIONS...209

Disassembly...210

Inspection...210

1...211

BS04N063...211

2. PUMP DRIVE JOINT...211

3. BELL HOUSING...211

4. FLYWHEEL...211

Assembly...212

6_49580.pdf...0

PISTON PUMP...213

SPECIFICATIONS 3...214

SPECIAL TORQUES 3...214

GENERAL INFORMATION 3...214

SEPARATING THE PUMPS 3...214

ASSEMBLING THE PUMPS 4...214

REAR PUMP 4...214

FRONT PUMP 30...214

6_79000.pdf...0

SINGLE SPEED DRIVE MOTOR...253

TABLE OF CONTENTS...254

SINGLE SPEED DRIVE MOTOR 3...254

SINGLE SPEED DRIVE MOTOR...255

Disassembly...255

STEP 1...255

BD04E002...255

STEP 2...255

BD04E002...255

STEP 3...255

BD04E004...255

STEP 4...255

BD04E005...255

STEP 5...255

BD04E006...255

STEP 6...255

BD04E008...255

STEP 7...256

BD04E009...256

STEP 8...256

BD04E010...256

STEP 9...256

BD04E011...256

STEP 10...256

BD04E014...256

STEP 11...256

BD04E015...256

STEP 12...256

BD04E016...256

STEP 13...257

BD04E017...257

STEP 14...257

BD04E020...257

STEP 15...257

BD04E021...257

STEP 16...257

BD04E022...257

STEP 17...257

BD04E023...257

STEP 18...257

BD04E024...257

STEP 19...258

BD04E025...258

STEP 20...258

BD04E026...258

STEP 21...258

BD04E028...258

STEP 22...258

BD04E029...258

STEP 23...258

BD04E030...258

STEP 24...258

BD04E042...258

STEP 25...259

BD04E031...259

STEP 26...259

BD04E032...259

STEP 27...259

BD04E033...259

STEP 28...259

BD04E034...259

STEP 29...259

BD04E035...259

STEP 30...259

BD04E041...259

STEP 31...260

BD04E063...260

STEP 32...260

BD04E065...260

STEP 33...260

BD04E066...260

STEP 34...260

BD04E068...260

Inspection...260

1. Clean all parts in cleaning solvent. Use a lint free cloth or air dry all of the parts...260

2. Inspect the bearings and cups for any damage. Use new parts as required. Bearings and cups must be installed as a set...260

3. Inspect the shaft for any wear or damage. Use new parts as required...260

4. Inspect the cam, rollers and pistons for any wear or damage. Use new parts as required...260

5. Inspect the distributor for any wear or damage. Use new parts as required...260

6. Inspect the spool, springs, and poppet of the flushing valve for any wear or damage. Use new parts as required...260

7. Inspect the brake discs and shims for any wear or damage. Use new parts as required...260

8. Replace all seals and O-rings as required. Use clean hydraulic oil to lubricate all seals and O-rings before installation...260

Assembly...261

STEP 35...261

BD04E061...261

STEP 36...261

BD04E067...261

STEP 37...261

STEP 38...261

STEP 39...261

STEP 40...261

STEP 41...261

STEP 42...261

BD04E059...261

STEP 43...261

BD04E039...261

STEP 44...262

BD04E038...262

STEP 45...262

BD04E040...262

STEP 46...262

BD04E039...262

STEP 47...262

STEP 48...262

STEP 49...262

BD04E035...262

STEP 50...262

BD04E034...262

STEP 51...263

BD04E033...263

STEP 52...263

BD04E032...263

STEP 53...263

BD04E031...263

STEP 54...263

BD04E030...263

STEP 55...263

BD04E029...263

STEP 56...263

BD04E028...263

STEP 57...264

BD04E027...264

STEP 58...264

BD04E025...264

STEP 59...264

BD04E023...264

STEP 60...264

BD04E022...264

STEP 61...264

BD04E020...264

STEP 62...264

BD04E017...264

STEP 63...265

BD04E016...265

STEP 64...265

BD04E015...265

STEP 65...265

BD04E013...265

STEP 66...265

BD04E012...265

STEP 67...265

BD04E010...265

STEP 68...265

BD04E009...265

STEP 69...266

BD04E006...266

STEP 70...266

BD04E005...266

STEP 71...266

BD04E004...266

STEP 72...266

BD04E003...266

6_79300.pdf...0

SPROCKETS, CHAINS, AND AXLE ASSEMBLIES...267

TORQUE SPECIFICATIONS 3...268

TORQUE SPECIFICATIONS...269

Nuts for Axle Housings 223 to 265 Nm (165 to 195 pound-feet)...269

Wheel Nuts (Stamped Center Wheels with Tapered Type Lug Nuts) 135 to 163 Nm (100 to 120 pound-feet)...269

Wheel Nuts (Solid Center Wheels with Flange Type Lug Nuts) 224 to 265 Nm (165 to 195 pound-feet)...269

Bolts for Chain Tank 101 to 113 Nm (93 to 112 pound-feet)...269

Bolts for Drive Sprockets 247 to 320 Nm (185 to 235 pound-feet)...269

(All threads are to be clean and free of rust, dirt and oil. Apply Loctite 243 to the first 10 to 15 threads of the cap screw)...269

NOTE: Be sure to recheck the wheel nuts every two hours until the wheel nuts remain tight. See Operations Manual...269

1. Lower the loader bucket or attachment to the ground...270

2. Use a jack or hoist to lift the machine off of the ground. Place approved jack strands under the machine. Loosen and remove the wheel nuts (1) and wheels. See illustration on page 5...270

3. Clean the area around both chain tank inspection covers. Loosen and remove the (6) inspection cover retaining bolts and special flat washers...270

4. Remove the inspection cover and gasket. Check the gasket for damage and replace if necessary...270

5. Start the machine...270

6. Push both steering control levers all the way forward for 5 seconds...270

7. Stop the engine...270

8. Check the deflection of the chains (3) on the slack side (8). The slack side is on top of the front chain and on the bottom o...270

9. Loosen the axle housing (9) and mounting nuts (2), so the axle is free to move...270

10. Insert a pry bar against the adjusting spud and axle housing (9)...270

11. Pry against the axle housing (9) until it stops moving. Tighten one or two axle mounting nuts (2) to hold the axle housing (9) in place and check the chain deflection (8)...270

12. When the chain deflection (8) is correct, 3.0 to 12.0 mm (0.12 to 0.50 inch, tighten the axle mounting nuts (2) to a torque of 7 Nm (5 pound-feet)...270

13. Repeat the previous steps for the remaining drive chains (3)...270

14. Following adjustment of all drive chains (3), start the engine and run at low idle...270

15. Move the drive control levers all of the way forward for 5 seconds and stop the engine...270

16. Check the deflection of all four drive chains. The drive chains (3) are correctly adjusted if the deflection is 3.0 to 12.0 mm (0.12 to 0.50 inch)...270

17. If necessary, tighten or loosen the drive chains to get the correct deflection...270

18. Tighten the axle housing mounting nuts (2) to a torque of 223 to 2654 Nm (165 to 190 pound-feet)...270

19. Apply RTV sealant between the gasket cover and chassis and install the inspection cover...270

20. Tighten the inspection cover retaining bolts to a torque of 101 to 113 Nm (75 to 83 pound-feet)...270

21. Install the four wheels and tighten the wheel nuts. For machines equipped with Stamped Center Wheels with tapered type lug n...270

22. Remove the approved jack stands and lower the machine to the ground...270

9...271

BT96M075...271

1. WHEEL NUTS...271

2. AXLE HOUSING NUTS...271

3. ROLLER CHAIN...271

4. DRIVE SPROCKET...271

5. DRIVEN SPROCKET...271

6. CAP SCREW (DRIVEN SPROCKET)...271

7. WASHER...271

8. CENTER OF SLACK SIDE OF CHAIN...271

9. AXLE HOUSING...271

10. O-RING...271

ILLUSTRATION OF SPROCKETS, CHAINS, AND AXLE ASSEMBLIES...271

Removal...272

1. Raise the machine off the floor and place approved jack stands under the machine...272

2. Loosen and remove the wheel nuts (1) and wheels. See illustration on page 7...272

3. Loosen and remove the chain tank inspection cover retaining bolts and washers...272

4. Remove the cover and the gasket. Check the gasket for damage and replace if necessary...272

5. Loosen the flange nuts (2) that hold the axle housings (9) enough to allow the axle housings (9) to move, refer to the illustration on page 7...272

6. Insert a pry bar against the adjusting spud and the axle housing (9)...272

7. Pry against the axle housing (9) until the chain (3) is loose enough to remove from the drive sprocket (4)...272

8. Remove the 4 rubber plugs inside the chassis to gain access to the bolt (6). Remove bolt (4) and washers (7)...272

9. Remove the flange nuts (2) and axle assembly (9) from the chassis...272

10. Remove the O-ring (10) and discard...272

11. Remove the chain (8) from the sprocket (5)...272

Installation...272

1. Install the sprocket (5) on the axle assembly (9)...272

2. Install the chain (3) on the sprocket (5) and align sprocket (5) with the axle opening in the chassis...272

3. Install a new O-ring (10) on axle assembly (9)...272

4. Align the splines on the axle assembly (9) with the splines in sprocket (5) and install axle assemblies (9) and flange nuts (2) on the chassis...272

5. Install bolt (5) and washer (7) in the axle assembly (9) through the opening on the inside of the chassis. Be sure to install washer (7) with the recess area on the washer towards the axle...272

6. Tighten bolt (4) to a torque of 247 to 320 Nm (185 to 235 pound-feet). Install the rubber plugs in the chassis...272

7. Adjust the deflection of the chains, refer to ADJUSTING DEFLECTION OF THE CHAINS in this section...272

8. Install inspection cover and gasket. Tighten inspection cover retaining bolts to a torque of 101 to 113 Nm (75 to 83 pound-feet)...272

9. Install wheels and wheel nuts (1)...272

10. For machines equipped with Stamped Center Wheels with tapered type lug nuts, tighten wheel nuts (1) to a torque of 135 to 16...272

11. Remove supports and lower machine to the ground...272

9...273

BT96M075...273

1. WHEEL NUTS...273

2. AXLE HOUSING NUTS...273

3. ROLLER CHAIN...273

4. DRIVE SPROCKET...273

5. DRIVEN SPROCKET...273

6. CAP SCREW (DRIVEN SPROCKET)...273

7. WASHER...273

8. CENTER OF SLACK SIDE OF CHAIN...273

9. AXLE HOUSING...273

10. O-RING...273

EXPLODED VIEW OF DRIVELINE...273

Axle Disassembly...274

STEP 1...274

BP96K019...274

STEP 2...274

BP96K020...274

STEP 3...274

BK96ZK022...274

STEP 4...274

BP96K023...274

STEP 5...275

BP96K024...275

STEP 6...275

BP96K027...275

STEP 7...275

BP96K028...275

STEP 8...275

BP96K030...275

STEP 9...276

BP96K031...276

STEP 10...276

BP96K032...276

Inspection...276

1. Use cleaning solvent to clean the bearings. Make sure all grease is removed from the bearings...276

2. Remove the grease from the bore of the axle housing...276

3. Inspect the rollers of each bearing for flat areas, pitting, scoring, or other damage. If you find any damage, install a new bearing and cup...276

4. Inspect each bearing cup for flat areas, pitting, scoring, or other damage. If you find any damage, install a new bearing and cup...276

5. Check for wear, cracks or damage to the splines on the axle. If any damage is found, replace the axle shaft...276

5...277

BC00H048...277

1. AXLE SHAFT...277

2. AXLE HOUSING...277

3. BEARING...277

4. BEARING CUP...277

5. AXLE SEAL...277

6. PLASTIC GREASE DISC...277

7. AXLE SEAL DETAIL...277

CROSS SECTION OF AXLE ASSEMBLY...277

6...278

BT00G044...278

1. AXLE HOUSING...278

2. AXLE SHAFT...278

3. SEAL GUARD...278

4. ’STUD...278

5. SEAL...278

6. BEARING...278

7. BEARING CUP...278

8. PLASTIC GREASE DISC...278

EXPLODED VIEW OF AXLE ASSEMBLY...278

Axle Assembly...279

STEP 11...279

BP96K033...279

STEP 12...279

BP96K034...279

STEP 13...279

BP96K024...279

STEP 14...279

BP96K035...279

STEP 15...279

BP96K036...279

STEP 16...279

BP96K037...279

STEP 17...280

BP96K038...280

STEP 18...280

BP96K039...280

STEP 19...280

BP96K040...280

STEP 20...280

BP96K041...280

STEP 21...280

BP96K042...280

STEP 22...281

BP96K043...281

STEP 23...281

BP96K045...281

STEP 24...281

BP96K046...281

NOTES...282

6_79310.pdf...0

WHEELS AND TIRES...283

TABLE OF CONTENTS...284

WHEELS AND TIRES 3...284

WHEELS AND TIRES...285

Tire Pressure...285

Check the air pressure and the condition of the tires every 50 hours of operation...285

10 x 16.5 275 to 265 kPa (40 to 50 psi)...285

12 x 16.5 241 to 310 kPa (35 to 45 psi))...285

13 X 16.5 206 to 275 kPa (30 to 40 psi)...285

15.50 X 16.5 172 to 341 kPa (25 to 35 psi)...285

Inflating the Tire...285

2. Use an air hose with remote shut-off valve and a self-locking air chuck...285

3. Stand behind the tread of the tire and make sure all persons are away from the side of the tire before you start to add air...285

4. Inflate the tire to the recommended air pressure. DO NOT inflate the tire more than the recommended pressure...285

Wheel Nut Torque...285

BP96N057...285

NOTES...286

6_79570.pdf...0

REMOVAL AND INSTALLATION OF PARK BRAKE COMPONENTS...289

SPECIFICATIONS 3...290

SPECIFICATIONS...291

410 Brake System...291

420 Brake System...291

Safety Rules...291

84-108...291

Removal...292

Installation...292

Removal...293

Installation...293

Removal...294

Installation...294

1...295

bs05c070...295

2. WIRING HARNESS...295

3. HYDRAULIC HOSE...295

4. MOUNTING BOLTS...295

5. TO MANIFOLD VALVE...295

6. RIGHT HAND BRAKE LINE...295

7. LEFT HAND BRAKE LINE...295

1...296

BS05B102...296

2. WIRING HARNESS...296

3. HYDRAULIC HOSE...296

4. MOUNTING BOLTS...296

5. MANIFOLD VALVE...296

6. RIGHT HAND BRAKE LINE...296

7. LEFT HAND BRAKE LINE...296

6_79580.pdf...0

420 BRAKES SPRING APPLIED - HYDRAULIC RELEASE...297

DISASSEMBLY 3...298

DISASSEMBLY...299

bdoom166...299

bd00m165...299

bd00m167...299

bd00m169...299

bd00m170...299

bd00m177...300

bd00m178...300

bd00m171...300

bd00m172...300

bd00m173...300

bd00m187...300

bd00m188...301

1...301

bd00m176...301

bd00m179...301

bd00m180...301

bd00m185...301

bd00m186...301

bd00m181...302

bd00m182...302

1...302

bd00m183...302

1...302

bd00m184...302

4...303

bs00j128...303

2. sprocket housing...303

3. friction housing...303

4. motor flange...303

5. piston...303

6. friction shim...303

7. stator plate...303

8. lining assembly...303

9. disc spring...303

10. quad seal...303

11. o-ring...303

12. o-ring...303

13. o-ring...303

14. o-ring...303

15. o-ring...303

16. bearing cup...303

17. bearing cone...303

18. bearing cup...303

19. bearing cone...303

20. bolt...303

21. snap ring...303

22. port plug...303

23. shaft plug...303

24. shaft end seal...303

1...304

bd00m184...304

1...304

bd00m183...304

1...304

bd00m176...304

1...304

bd00m189...304

1...305

bd00m182...305

2...305

bd00m188...305

2. sprocket housing...305

3. piston...305

bd00m197...305

1...305

bd00m198...305

2. bearing cone...305

bd00m174...306

bd00m186...306

bd00m185...306

bd00m199...306

bd00m200...307

bd00m201...307

bd00m178...307

bd00m177...307

bdoom170...307

bd00m204...307

bd00m206...308

bd00m205...308

bd00m204...308

1...308

bd00m207...308

2. stator plate...308

1...309

bdoom208...309

bd00m169...309

bdoom168...309

NOTES...310

6_79510.pdf...0

SPECIFICATIONS 3...314

TESTING CIRCUIT RELIEF VALVES WITH A HAND PUMP 5...314

U.S. MEASURE CHECK SHEET 11...314

6_79520.pdf...0

REMOVAL AND INSTALLATION OF HYDRAULIC COMPONENTS...345

Removal...347

Installation...347

3...347

BD05A085...347

Removal...348

1...348

BD05B009...348

Installation...348

11. Clean up any hydraulic fluid from equipment or floor...348

12. Start and run the engine at low idle...348

13. Operate the loader controls to completely extend and retract the lift and tilt cylinders in order to remove any air from the hydraulic system...348

14. Lower the loader arm to the floor...348

15. Stop the engine...348

16. Check for oil leakage...348

17. Check the level of the oil in the hydraulic reservoir. Add oil as required...348

1...349

Bs05B066...349

2. LIFT CYLINDER...349

3. TILT CYLINDER...349

4. LIFT SPOOL...349

5. TILT SPOOL...349

6. AUXILIARY SPOOL...349

Removal...350

Inspection...350

Installation...350

bS04M122...351

2. BOLT...351

3. LOCK NUT...351

4. BOLT...351

5. WASHER...351

6. FILTER HEAD...351

7. WASHER...351

8. NUT...351

9. LOCK WASHER...351

10. O-RING...351

11. O-RING...351

12. INDICATOR...351

13. FILTER ELEMENT...351

Removal...352

Installation...352

3...352

BD05A085...352

Removal...353

1...353

BD05B009...353

Installation...353

Removal...354

1...354

BD05B010...354

Installation...354

1...355

BS05C073...355

2. HIGH FLOW VALVE...355

3. HIGH FLOW ACCUMULATOR...355

4. RETURN OIL MANIFOLD...355

Removal...356

2. Place a shop towel under the control valve (1)...356

1...356

BS05C081...356

Installation...356

1...357

Bs05C082...357

2. PEDAL...357

3. COUPLERS...357

Removal...358

1...358

BD05B012...358

2...358

BD05B012...358

Installation...358

2...358

BD05B012...358

1...358

BD05B012...358

Removal...359

1...359

BD05B011...359

BD05B011...359

BD05B011...359

Installation...360

1...360

BD05B011...360

BD05B011...360

1...360

BD05B011...360

1...361

BS05B088...361

2. SOLENOID VALVE...361

3. LOADER CONTROL VALVE...361

4. MANIFOLD VALVE...361

Removal...362

1...362

BD05B013...362

1...362

BD05B013...362

2...362

BD05B013...362

Installation...363

2...363

BD05B013...363

BD05B013...363

1...363

BD05B013...363

Removal...364

1...364

bd05b014...364

1...364

Installation...364

1...364

1...364

Removal...365

1...365

Bd04C007...365

1...365

Bd05A024...365

1...365

BD05A026...365

BD04C026...366

1...366

BD04C007...366

1...366

BD05A025...366

BD04K036...366

1...366

BD04K036...366

2...367

Installation...367

Removal...368

1...368

bd05a025...368

1...368

bd05a026...368

Installation...368

Removal...369

Installation...369

1...370

BS05B101...370

2. RELIEF VALVE...370

3. LOADER CONTROL VALVE...370

6_79350.pdf...0

GEAR PUMP (EQUIPMENT) AND (HIGH FLOW)...371

GEAR (EQUIPMENT) PUMP 3...372

GEAR (EQUIPMENT) PUMP...373

Disassembly...373

STEP 1...373

GD98J801...373

STEP 2...373

GD98J802...373

STEP 3...373

GD98J803...373

STEP 4...373

GD98J804...373

STEP 5...373

1...373

GD98J805...373

1. DOWEL PINS...373

STEP 6...373

GD98J806...373

STEP 7...374

GD98J807...374

STEP 8...374

GD98J808...374

STEP 9...374

GD98J809...374

STEP 10...374

GD98J810...374

STEP 11...374

GD98J811...374

STEP 12...374

GD98J812...374

STEP 13...375

GD98J813...375

STEP 14...375

GD98J814...375

Inspection...375

STEP 15...375

GD98J815...375

STEP 16...375

GD98J816...375

STEP 17...375

GD98J817...375

STEP 18...375

GD98J818...375

Assembly...376

STEP 19...376

GD98J814...376

STEP 20...376

GD98J813...376

STEP 21...376

GD98J812...376

STEP 22...376

GD98J811...376

STEP 23...376

GD98J810...376

STEP 24...376

GD98J809...376

STEP 25...377

GD98J808...377

STEP 26...377

STEP 27...377

GD98J806...377

STEP 28...377

1...377

GD98J805...377

1. GUIDE DOWELS...377

STEP 29...377

STEP 30...377

GD98J803...377

STEP 31...378

GD98J802...378

5...379

Bs05A088...379

1. SHAFT SEAL...379

2. COVER...379

3. GEAR PLATE...379

4. DOWEL PIN...379

5. DRIVE SHAFT...379

6. IDLER SHAFT...379

7. SEAL...379

8. SEAL RING...379

9. WEAR PLATE...379

10. COVER...379

11. SOCKET HEAD BOLT...379

GEAR PUMP (EQUIPMENT)...379

5...380

BS05A089...380

1. SHAFT SEAL...380

2. COVER...380

3. GEAR PLATE...380

4. DOWEL PIN...380

5. DRIVE SHAFT...380

6. IDLER SHAFT...380

7. SEAL...380

8. SEAL RING...380

9. WEAR PLATE...380

10. COVER...380

1. SOCKET HEAD BOLT...380

2...380

GEAR PUMP (HIGH FLOW)...380

6_79360.pdf...0

CYLINDERS...381

SPECIFICATIONS 3...382

SPECIAL TOOLS 3...382

GENERAL 3...382

6_79500.pdf...0

PEDALS AND LEVERS...409

TABLE OF CONTENTS...410

SPECIFICATIONS 3...410

AUXILIARY HYDRAULIC PEDAL 13...410

SPECIFICATIONS...411

16...412

BS05B255...412

2. nut...412

3. WASHER...412

4. SPECIAL WASHER...412

5. THROTTLE ROD...412

6. INJECTOR PUMP LEVER...412

7. BALL JOINT...412

8. JAM NUT...412

9. FRICTION DISC...412

10. RUBBER WASHER...412

11. THROTTLE PIVOT...412

12. THROTTLE PIVOT BOLT...412

13. CAP SCREW...412

14. CRANK...412

15. CLAMP...412

16. FLYWHEEL COVER...412

17. SPRING...412

Hand Throttle Lever Tension Adjustment...413

2. The tension adjusting nut (2) is not to be so tight the throttle lever is difficult to move...413

3. Remove any attachments from the loader lift arms...413

4. Refer to the operators manual for the correct procedure and tilt the ROPS for service...413

5. The throttle control lever (1) may be in any working position during the adjustment procedure...413

6. Measure the resistance that is required to move the throttle control lever (1) from the low idle to high idle position.The effort required to move the throttle control lever (1) should be measured at the top of the throttle control lever (1)...413

7. Loosen the jam nut (8)...413

8. Tighten or loosen the nut (2) until the force required to move the throttle control lever (1) is 50 ± 10 N...413

9. When the effort required to move the throttle control lever (1) is correct tighten the jam nut (8) against the nut (2)...413

10. Lower the ROPS to the operating position...413

Hand Throttle Adjustment (With Foot Throttle Option)...413

2. The tension adjusting nut (2) is not to be so tight the throttle lever is difficult to move...413

3. Remove any attachments from the loader lift arms...413

4. Refer to the operators manual for the correct procedure and tilt the ROPS for service...413

5. Disconnect the foot throttle linkage from the linkage controller so that the only input to the controller is from the hand throttle...413

6. The throttle control lever (1) may be in any working position during the adjustment procedure...413

7. Measure the resistance that is required to move the throttle control lever (1) from the low idle to high idle position.The effort required to move the throttle control lever (1) should be measured at the top of the throttle control lever (1)...413

8. Loosen the jam nut (8)...413

9. Tighten or loosen the nut (2) until the force required to move the throttle control lever (1) is 50 ± 10 N...413

10. When the effort required to move the throttle control lever (1) is correct tighten the jam nut (8) against the nut (2)...413

11. Lower the ROPS to the operating position...413

8...414

BD05B256...414

2. THROTTLE ROD EXTENSION...414

3. WASHER...414

4. WASHER...414

5. SELF TAPPING SCREW...414

6. SLEEVE...414

7. FOOT THROTTLE PEDAL...414

8. ROD...414

9. SPRING...414

10. ROCKER ARM...414

11. BEARING...414

12. PIVOT SLEEVE...414

13. BUSHING...414

14. SQUARE NUT...414

1...415

BD05B005...415

1...415

BD01J006...415

2. DIMENSION FOR DELUXE CONTROL HANDLE (LARGE HEAD) (15 TO 30 MM)...415

1...416

BD05B007...416

Control Handle Fore and Aft Adjustment...416

BD05B003...416

1...416

BD05B004...416

2. DELUXE HANDLE DIMENSION 5 TO 25 MM...416

1...416

BD05B006...416

Controls - Pump Shim Dimensions...417

Controls Adjustment - Dynamic Straight Tracking...417

1...417

BD05B007...417

2. STRAIGHT TRACKING SET SCREW...417

1...418

BS05B040...418

2. LOADER LIFT LINKAGE...418

3. LOADER TILT LINKAGE...418

4. GROUND DRIVE LINKAGE...418

5. BRAKE CONTACT ROD...418

6. PIVOT...418

7. BRAKE CAM...418

8. CRANK...418

9. LEFT LEVER ASSEMBLY...418

10. RIGHT LEVER ASSEMBLY...418

11. HYDRAULIC BYPASS CABLE...418

12. TRACKING SET SCREW...418

3...419

BS05B041...419

2. LOADER LIFT LINKAGE...419

3. LOADER TILT LINKAGE...419

4. GROUND DRIVE LINKAGE...419

5. BRAKE CONTACT ROD...419

6. PIVOT...419

7. BRAKE CAM...419

8. CRANK...419

9. LEFT LEVER ASSEMBLY...419

10. RIGHT LEVER ASSEMBLY...419

11. HYDRAULIC BYPASS CABLE...419

12. SPRING...419

13. PIN...419

14. SEAT BAR CONTROL ROD...419

2...420

Hs01E003...420

2. ADJusting Screw...420

3. Lap bar...420

4. CROSSMEMBER...420

AUXILIARY HYDRAULIC PEDAL...421

1...421

BS05B060...421

2. auxiliary hydraulic pedal lock lever...421

3. loader control valve...421

4. control cable...421

5. clevis...421

6. bracket...421

7. electrical harness...421

8. relay...421

NOTE: Make sure the auxiliary spool in the control valve is in the neutral position. Adjust the cable until the auxiliary hydraulic pedal is in the horizontal position...421

NOTES...422

6_79390.pdf...0

LOADER...423

REMOVAL OF THE LOADER FRAME 4...424

INSTALLATION OF THE LOADER FRAME 8...424

6_79400.pdf...0

ATTACHMENT COUPLER...431

6_79410.pdf...0

ROPS CANOPY, SEAT, SEAT BELTS AND OPERATORS COMPARTMENT...441

POSSIBLE DAMAGE TO THE ROPS CANOPY 3...442

MAINTENANCE AND INSPECTION OF THE ROPS CANOPY 3...442

INSTALLATION OF THE ROPS CANOPY 4...442

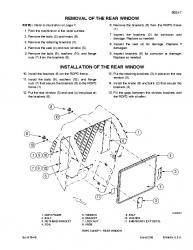

INSTALLATION OF THE REAR WINDOW 7...442

REMOVAL OF THE SIDE WINDOWS 8...442

INSTALLATION OF THE SIDE WINDOWS 8...442

INSTALLATION OF TOP WINDOW 10...442

INSTALLATION OF THE DOOR FRAME WINDOW 12...442

REMOVAL OF THE FRONT DOOR 12...442

INSTALLATION OF THE FRONT DOOR 12...442

INSTALLATION OF THE SEAT BELTS 16...442

INSTALLATION OF THE NON-SUSPENSION SEAT 16...442

INSTALLATION OF THE SEAT BELTS 18...442

INSTALLATION OF THE SUSPENSION SEAT 18...442

6_79450.pdf...0

HEATER...461

Removal...463

1...463

BD05B015...463

Inspection...463

Installation...463

5...464

BS05B104...464

2. shut-off valve...464

3. supply hose...464

4. return hose...464

5. COVER...464

6. CONTROL VALVE...464

7. UPPER MOUNTING BOLTS...464

8. REAR MOUNTING BOLTS...464

9. HEADLINER...464

10. TEMPERATURE CONTROL...464

11. blower switch...464

2...465

BS05B105...465

2. BLOWER MOTOR ASSEMBLY...465

3. FILTER ELEMENT...465

4. FILTER ELEMENT COVER...465

5. COVER...465

6. BLOWER MOTOR ASSEMBLY COVER...465

7. SUPPLY TUBE...465

8. RETURN TUBE...465

00...0

bs05b106...466

2. HEADLINER...466

3. VENT...466