John Deere Crawler Dozers 750C, 850C, 750C Series II, 850C Series II Repair Service Manual (TM1589)

Complete service repair manual for John Deere Crawler Dozers 750C, 850C, 750C Series II, 850C Series II, with workshop information to maintain, repair, and service like professional mechanics.

John Deere Crawler Dozers 750C, 850C, 750C Series II, 850C Series II workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

for complete service information also see:

750C, 850C, Crawler Dozer Operation and Test - TM1588

6068 Engine - CTM8

6068 POWERTECH Engine - CTM104

6076 Engine - CTM42

6081 POWERTECH Engine Repair - CTM86

Undercarriage Appraisal Manual - SP326

TM1589 - 750C, 850C, 750C Series II, 850C Series II Crawler Dozers Technical Manual (Repair).pdf

TM9010 - Reparación Bulldozer sobre orugas 750C, 750C Serie II,850C, 850C Serie II.pdf

Total Pages: 997 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable)

Category: Repair

Language: English Spanish

Published on 2018/03/01

Main Sections

Foreword

Technical Information Feedback Form

General Information

Safety

General Specifications

Torque Values

Fuels and Lubricants

Tracks

Track System

Dealer Fabricated Tools

Axles and Suspension Systems

Drive Axle Housing and Support

Axle Shaft, Bearings and Reduction Gears

Dealer Fabricated Tools

Transmission

Remove and Install

Control Linkage

Hydrostatic System

Dealer Fabricated Tools

Engine

Removal and Installation

Engine Auxiliary Systems

Cold Weather Starting Aid

Cooling System

Speed Controls

Intake System

External Exhaust Systems

External Fuel Supply Systems

Dealer Fabricated Tools

Dampener Drive

Elements

Park Brake

Park Brake

Control Linkage

Hydraulic System

Equipment Attaching

Drawbar

Electrical System

Batteries, Support, and Cables

Alternator, Regulator and Charging System Wiring

Lighting System

Wiring Harness and Switches

System Controls

Motors and Actuators

Frames, Chassis, or Supporting Structure

Frame Installation

Frame Bottom Guards

Chassis Weights

Operator’s Station

Removal and Installation

Operator Enclosure

Seat and Seat Belt

Heating and Air Conditioning

Sheet Metal

Hood and Engine Enclosures

Grille and Grille Housing

Safety, Convenience and Miscellaneous

Horn and Warning Devices

Bulldozer

Removal and Installation

Blade

Controls Linkage

Frames

Hydraulic System

Dealer Fabricated Tools

tm1589 - 750C, 750C Series II, 850C, 850C Series II Crawler Dozer

Table of Contents

Foreword

Technical Information Feedback Form

Section 00: General Information

Group 01: Safety

Handle Fluids Safely—Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Handle Chemical Products Safely

Avoid High-Pressure Fluids

Park Machine Safely

Support Machine Properly

Wear Protective Clothing

Work in Clean Area

Service Machines Safely

Work In Ventilated Area

Illuminate Work Area Safely

Replace Safety Signs

Use Proper Lifting Equipment

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Keep ROPS Installed Properly

Practice Safe Maintenance

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Live With Safety

Group 02: General Specifications

750C Series II Specifications

750C Series II Capacity Specifications

750C Series II General Specifications

750C LT Series II Dimensions

750C WT Series II Dimensions

750C LGP Series II Dimensions

850C Series II Specifications

850C Series II Capacity Specifications

850C Series II General Specifications

850C LT Series II Dimensions

850C WT Series II Dimensions

850C LGP Series II Dimensions

Group 03: Torque Values

Hardware Torque Specifications

Keeping ROPS Installed Properly

Checking Track Shoe Cap Screw Torque

Checking Track Shoe Cap Screw Torque—Master Link

Metric Bolt and Screw Torque Values

Additional Metric Cap Screw Torque Values

Service Recommendations for Metric Series Four Bolt Flange Fitting

Unified Inch Bolt and Screw Torque Values

Check Oil Lines And Fittings

Service Recommendations for O-Ring Boss Fittings

Service Recommendations For Flat Face O-Ring Seal Fittings

Service Recommendations For Inch Series Four Bolt Flange Fittings

Group 04: Fuels and Lubricants

Diesel Fuel

Handling and Storing Diesel Fuel

Fuel Tank

Low Sulfur Diesel Fuel Conditioner

Diesel Fuel Storage

Diesel Engine Oil — Non-Emissions Certified and Certified Tier 1 and Stage I

Transmission, Hydraulic, and Hand Pump Reservoir Oil

Inner and Outer Final Drive Oil

Track Rollers, Front Idler, Carrier Roller and Track Frame Outer Pivot Oil

Grease

Lubricant Storage

Alternative and Synthetic Lubricants

Mixing of Lubricants

Diesel Engine Coolant (engine with wet sleeve cylinder liners)

Section 01: Tracks

Group 0130: Track System

Essential Tools

Service Equipment and Tools

Other Material

Specifications

Remove and Install Rock Guards and Track Guides

Measure Carrier Roller Wear

Remove and Install Carrier Roller

Disassemble and Assemble Carrier Roller

Inspect Metal Face Seals

Test Carrier Roller for Oil Leakage

Measure Track Roller Wear

Remove and Install Track Roller

Disassemble Track Roller

Assemble Track Roller

Test Track Roller for Leakage

Measure Track Shoe Grouser Wear

Remove and Install Track Shoe

Exploded View of Front Crossbar and Support—750C

Remove and Install Front Crossbar and Support—750C

Remove and Install Front Crossbar and Support—850C (S.N. —833331)

Check and Adjust Front Crossbar-to-Crossbar Support and Main Frame Clearances (S.N. —833331)

Remove and Install Support Wear Plates (S.N. —833331)

Remove and Install Pinned Crossbar and Support—850C (S.N. 833332—907600)

Remove and Install Crossbar and Lube Lines—850C (S.N. 907601— )

Disassemble and Assemble Crossbar—850C (907601— )

Measure Link Height

Measure Bushing Outside Diameter for Lubricated Track Chain

Measure Track Pitch for Lubricated Track Chain

Remove and Install Lubricated Track Chain

Disassemble Lubricated Track Chain to Turn Bushings and Lubricate Chain

Assemble Lubricated Track Chain to Turn Bushings and Lubricate Chain

Disassemble and Assemble Lubricated Track Chain to Turn Pins and Bushings and Not Lubricate

Adjust Track Sag

Track Adjuster Exploded View

Remove Track Adjuster and Recoil Spring

Install Track Adjuster and Recoil Spring

Disassemble and Assemble Recoil Spring

Disassemble and Assemble Track Adjuster Cylinder

Remove Track Frame

Welding Procedure

Remove and Install A-Frame Bearing and A-Frame Bushings

Install Track Frame

Remove and Install Wear Strip on Inner Guide

Remove and Install Track Frame Upper Wear Strips

Remove and Install Track Frame Lower Wear Strips

Remove and Install Track Frame Wear Strip Bar

Measure Front Idler Wear

Remove Front Idler

Disassemble Front Idler

Inspect Metal Face Seals

Exploded View of Front Idler

Assemble Front Idler

Install Front Idler

Adjust Front Idler Vertical Movement

Adjust Front Idler Horizontal Movement

Test Front Idler for Oil Leakage

Remove and Install Sprocket Segment

Group 0199: Dealer Fabricated Tools

DFT1087 Track Recoil Spring Compression Tool Guard

DF1041 Track Nut Removal Tool

ST4920 Track Recoil Spring Compression Tool

Section 02: Axles and Suspension Systems

Group 0201: Drive Axle Housing and Support

Service Equipment and Tools

Other Material

Specifications

Remove and Install Final Drive Axle Housing And Support

Group 0250: Axle Shaft, Bearings and Reduction Gears

Service Equipment and Tools

Other Material

Specifications

Planet Carrier Housing Assembly Cross Section

Remove and Install Planet Housing

Disassemble and Assemble Planet Carrier Housing

Remove Ring Gear, Hub and Sprocket Frame

Disassemble and Assemble Ring Gear Hub and Sprocket Frame

Inspect Metal Face Seals

Install Gear, Hub and Sprocket Frame

Remove and Install Final Drive Housing Assembly

Disassemble and Assemble Final Drive Housing Cover Assembly

Group 0299: Dealer Fabricated Tools

Dealer Fabricated Tools

DFT1079 Final Drive Lifting Fixture Adapter

DFT1260 Final Drive Lifting Fixture

Section 03: Transmission

Group 0300: Remove and Install

Essential Tools

Service Equipment and Tools

Other Material

Specifications

Remove and Install Hydrostatic Pumps

Remove and Install Hydrostatic Motors

Hydrostatic Motor Speed Sensor Adjustment

Hydrostatic Pump and Motor Initial Start-Up Procedure

Group 0315: Control Linkage

Essential Tools

Service Equipment and Tools

Other Material

Specifications

Remove and Install Steering Pedal

Disassemble and Assemble FNR Control Assembly—Pedal Steer (S.N. —883331)

FNR Control Assembly Component Location—Pedal Steer (S.N. —883331)

FNR and Neutral Start Switch Adjustment—Pedal Steer (S.N. —883331)

Disassemble and Assemble FNR Control Assembly—Single Lever Steer (S.N. —883331)

FNR Control Assembly Component Location—Single Lever Steer (S.N. —883331)

FNR and Neutral Start Switch Adjustment—Single Lever Steer (S.N. —883331)

Single Lever Control (SLC) Exploded View With Speed In Grip (S.N. 883332— )

Remove and Install Single Lever Control (SLC) With Speed In Grip (S.N. 883332— )

Disassemble and Assemble Single Lever Control Linkage (SLC) With Speed In Grip (S.N. 883332— )

Rotary Sensor Component Location With (SIG) Speed In Grip (S.N. 883332— )

Park Lock Linkage Adjustment

Group 0360: Hydrostatic System

Essential Tools

Service Equipment and Tools

Other Material

Specifications

Disassemble Hydrostatic Pump

Disassemble and Assemble Charge Pump

Disassemble and Assemble Pump Displacement Control Valve (PDCV)

Remove and Install Multi-Function Valve

Remove and Install Charge Pressure Manifold

Disassemble and Assemble Multi-Function Valve

Assemble Hydrostatic Pump

Disassemble and Assemble Oil Cooler Bypass Valve

Disassemble Hydrostatic Motor

Assemble Hydrostatic Motor

Remove and Install Hydrostatic Oil Filter

Group 0399: Dealer Fabricated Tools

DFT1063 Pump Lifting Bracket

DFT1130 Adapter

DFT1132 Hydrostatic Motor Removal and Installation Tool

DFT1137 Hydrostatic Motor Removal and Installation Tool

DFT1164 Speed Sensor Adjusting Tool

Section 04: Engine

Group 0400: Removal and Installation

6068 John Deere Engine—Use CTM8

6068 John Deere POWERTECH POWERTECH is a trademark of Deere & Company Engine—Use CTM104

6076 John Deere Engine—Use CTM42

6081 John Deere POWERTECH POWERTECH is a trademark of Deere & Company Engine Repair—Use CTM86

Essential Tools

Other Material

Specifications

Remove and Install Engine

Remove and Install Oil Pan

Remove and Install Fuel Filter Check Valve—850C

Remove DB4 Fuel Injection Pump—750C

Installing DB4 Fuel Injection Pump—750C

Remove In-Line Fuel Injection Pump—850C

Install In-Line Fuel Injection Pump—850C

JT07158 TIME TRAC TIME TRAC is a registered trademark of Stanadyne Automotive Corp, Installation

Injection Pump Dynamic Timing—750C

Fuel Shut-Off Solenoid Adjustment—850C (S.N. —822867)

Disassemble and Assemble Final Fuel Filter—750C

Disassemble and Assemble Primary Fuel Filter (Water Separator)

Bleed the Fuel System—750C

Bleed the Fuel System—850C

Primary Fuel Filter, Drain Valve—750C

Primary Fuel Filter, Drain Valve—850C

Remove and Install Engine Mounts

Section 05: Engine Auxiliary Systems

Group 0505: Cold Weather Starting Aid

Specifications

Remove and Install Engine Coolant Heater

Group 0510: Cooling System

6068 John Deere Engine—Use CTM8

6068 John Deere POWERTECH POWERTECH is a trademark of Deere & Company Engine—Use CTM104

6076 John Deere Engine—Use CTM42

6081 John Deere POWERTECH POWERTECH is a trademark of Deere & Company Engine Repair—Use CTM86

Essential Tools

Service Equipment and Tools

Specifications

Remove and Install Guards, Shroud and Fan

Remove and Install Fan Belt and Adjuster—750C (S.N.—831315)

Remove, Install, Inspect Serpentine Belt

Remove and Install Radiator and Oil Cooler

Remove and Install Hydraulic Oil Cooler

Group 0515: Speed Controls

Essential Tools

Service Equipment and Tools

Other Material

Specifications

JT05801 Clamp-On Digital Tachometer Installation

Remove and Install Engine Speed Control

Remove and Install Engine Speed Control Linkage and Shaft 750C and 850C (S.N. —822867)

Remove and Install Engine Speed Control Linkage and Shaft 850C (S.N. 822868—)

Engine Speed Control Linkage Rod—850C (S.N. —822867)

Engine Speed Control Linkage Rod—750C

Remove and Install Decelerator

Engine Speed Adjustment—750C

Engine Speed Adjustment—850C

Engine Speed Control Cable Adjustment

Engine Speed Control Sensor Adjustment (750C, 850C S.N.—875378)

Decelerator Sensor Adjustment—Single Lever Steer

Throttle Sensor Adjustment—850C (S.N. 822868— )

Group 0520: Intake System

Remove and Install Air Cleaner

Test Air Intake System for Leaks

Group 0530: External Exhaust Systems

Remove and Install Muffler

Group 0560: External Fuel Supply Systems

Other Material

Specifications

Remove and Install Fuel Tank

Remove and Install Fuel Lines—750C

Remove and Install Fuel Lines—850C

Group 0599: Dealer Fabricated Tools

DFT1140 Serpentine Belt Removal and Installation Tool (850C)

Section 07: Dampener Drive

Group 0752: Elements

Other Material

Specifications

Remove and Install Dampener Drive

Replace Dampener Drive—750C

Section 11: Park Brake

Group 1100: Park Brake

Specifications

Park Brake Cross Section

Remove and Install Park Brakes

Group 1115: Control Linkage

Service Equipment and Tools

Specifications

Remove and Install Park Brake Pedal

Remove and Install Park Brake Valve Linkage

Remove and Install Park Lock Lever and Brake Cable and Linkage

Park Lock Linkage Adjustment

Group 1160: Hydraulic System

Remove and Install Park Brake Valve

Disassemble and Assemble Park Brake Valve

Section 15: Equipment Attaching

Group 1511: Drawbar

Specifications

Remove and Install Extended Rigid Drawbar

Remove and Install Rigid Drawbar

Section 16: Electrical System

Group 1671: Batteries, Support, and Cables

Service Equipment and Tools

Specifications

Service Batteries Carefully

Procedure for Testing Batteries

Checking Electrolyte Specific Gravity

Check Battery Electrolyte Level and Terminals

Using Booster Batteries—24 Volt System

Charge Battery

Remove and Install Batteries

Group 1672: Alternator, Regulator and Charging System Wiring

Alternators and Starting Motors—Use CTM77

Essential Tools

Specifications

Remove and Install Alternator

Group 1673: Lighting System

Remove and Install Light Switch

Remove and Install Halogen Bulb

Remove and Install Dome Light and Swivel Light

Group 1674: Wiring Harness and Switches

Essential Tools

Cab/ROPS Harness Component Identification—(750C S.N. —883331) and (850C S.N. —822867)

Cab/ROPS Harness Component Identification—850C (S.N. 822868—883331)

Cab/ROPS Harness Component Identification—750C, 850C (S.N. 883332— )

Chassis Harness Component Identification

Engine/Pump Harness Component Identification—750C (S.N. —831315)

Engine/Pump Harness Component Identification—750C (S.N. 831316— )

Engine/Pump Harness Component Identification—850C (S.N. —822867)

Engine/Pump Harness Component Identification—850C (S.N. 822868—)

Grille Housing Harness Component Identification—750C (S.N. —831315) and 850C (S.N. —822867)

Grille Housing Harness Component Identification—750C (S.N. 831316— ) and 850C (S.N. 822868— )

Motor Harness Electrical Component Identification

Wiper Harness Electrical Component Identification

A/C Compressor Harness Component Identification—750C (S.N. —831315) and 850C (S.N. —822867)

A/C Condenser Harness Electrical Component Identification

Replace DEUTSCH DEUTSCH is a trademark of Deutsch Co. Connectors

Install DEUTSCH DEUTSCH is a trademark of Deutsch Co. Contact

Replace WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Connectors

Install WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Contact

Replace METRI-PACK METRI-PACK is a trademark of Packard Electric Connector

Remove Connector Body from Blade Terminals

Group 1675: System Controls

Welding Procedure

Remove and Install Transmission Controller

Remove and Install Display Monitor

Remove and Install Engine Controller—850C (S.N. 822868— )

Group 1677: Motors and Actuators

John Deere Starting Motor—Use CTM77

Remove and Install Starting Motor

Section 17: Frames, Chassis, or Supporting Structure

Group 1740: Frame Installation

Specifications

Welding Repair of Major Structures

Remove and Install Sub-Frame Fasteners

Group 1746: Frame Bottom Guards

Other Material

Remove and Install Bottom Guards—750C

Remove and Install Bottom Guards—850C

Group 1749: Chassis Weights

Specifications

Remove and Install Counterweight—850C

Section 18: Operator’s Station

Group 1800: Removal and Installation

Service Equipment and Tools

Specifications

Remove and Install Cab/ROPS

Group 1810: Operator Enclosure

Other Material

Specifications

Disassemble and Assemble Cab/ROPS Tilt Cylinder

Remove and Install Cab/ROPS Tilt Cylinder

Remove and Install Hand Pump Assembly

Disassemble and Assemble Hand Pump

Remove and Install Cab/ROPS Mounts and Isolators

Remove and Install Window

Remove and Install Windowpanes

Remove and Install Cab Covers

Remove and Install Wiper Motor Assemblies

Remove and Install Cab Doors and Hinges

Remove and Install Door Hold Open Latch

Remove and Install Windshield Washer

Group 1821: Seat and Seat Belt

Disassemble and Assemble Seat

Group 1830: Heating and Air Conditioning

Essential Tools

Service Equipment and Tools

Other Material

Specifications

R134a Refrigerant Theory of Operation

R134a Refrigerant Cautions

R134a Compressor Oil Charge Check

R134a Compressor Oil Removal

R134a Component Oil Charge

R134a Refrigerant Recovery, Recycling and Charging Station Installation Procedure

Recover R134a System

Evacuate R134a System

Charge R134a System

Check and Adjust Compressor Belt Tension—750C (S.N. —831315)

Remove and Install Air Conditioning Compressor—750C (S.N. —831315)

Remove and Install Air Conditioning Compressor—750C (S.N. 831316— )

Remove and Install Air Conditioning Compressor—850C

Disassemble and Inspect Compressor

Assemble Compressor

Inspect Compressor Manifolds

Remove and Install Receiver/Dryer

Remove and Install Evaporator

Remove and Install Condenser

Remove and Install Heater Pressurizer

Section 19: Sheet Metal

Group 1910: Hood and Engine Enclosures

Specifications

Remove and Install Hood

Remove and Install Hood Support and Engine Side Shields

Group 1921: Grille and Grille Housing

Specifications

Remove and Install Grille Housing

Section 20: Safety, Convenience and Miscellaneous

Group 2004: Horn and Warning Devices

Remove and Install Reverse Alarm

Adjust Reverse Warning Alarm Volume

Section 32: Bulldozer

Group 3200: Removal and Installation

Specifications

Remove and Install Angledozer or Bulldozer Blade and Frame (Outside Dozer)

Remove and Install Trunnion (Outside Dozer)

Trunnion Shim Adjustment and 850C Pat Trunnion (S.N. —898365)

Trunnion Shim Adjustment 850C (PAT) (S.N. 898366— )

Remove and Install (PAT) All Hydraulic Blade with C—Frame 850C

Group 3201: Blade

Specifications

Remove and Install Bulldozer (Outside Dozer)

Remove and Install Cutting Edges and End Bits

Remove and Install (PAT) Six Way Blade 850C

Group 3215: Controls Linkage

Other Material

Specifications

Remove and Install T-Bar Linkage

Remove and Install Two Function Hydraulic Linkage

Remove and Install Third Function Hydraulic Linkage

Group 3240: Frames

Specifications

Remove and Install Bulldozer Pushbeam

Remove and Install Pitch Jack

Remove and Install Struts

Disassemble and Assemble Pushbeams, Struts and Pitch Jack

Blade Pitch Adjustment

Disassemble and Assemble Lift Cylinder Pivot Sub-frame

Group 3260: Hydraulic System

Special or Essential Tools

Service Equipment and Tools

Other Material

Specifications

Remove and Install Hydraulic Pump

Disassemble and Assemble Hydraulic Pump

Remove and Install Plug Or Winch PTO Shaft From Hydraulic Pump

Remove and Install Hydrostatic and Hydraulic Reservoir

Hydraulic and Hydrostatic Reservoir Cleanout Cover Remove and Install (S.N. 925753— )

Disassemble and Assemble Reservoir

Remove and Install Hydraulic Filter

Disassemble and Assemble Hydraulic Filter

Remove and Install Dozer Control Valve

Component Location—All Hydraulic Dozer

Component Location—Bulldozer Hydraulics

Component Location—Angle Dozer Hydraulics

Component Location—850C (PAT) Blade (S.N. 883332— )

Disassemble and Assemble Dozer Control Valve

Installing Valve Seal Kit in Cap End

Installing Valve Seal Kit in Tang End

Disassemble and Assemble System Relief Valve

Disassemble and Assemble Circuit Relief Valve with Anti-Cavitation

Remove and Install Quick Drop Valve

Disassemble and Assemble Quick Drop Valve

Remove and Install Tilt Cylinder—Outside Dozer

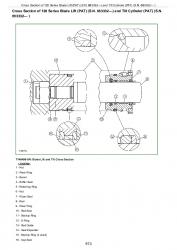

Cross Section of a 180 Series (Tilt) Cylinder—Outside Dozer

Disassemble Tilt Cylinder—Outside Dozer

Assemble Tilt Cylinder—Outside Dozer

Remove and Install Blade Lift Cylinder—Outside Dozer

Disassemble and Assemble Blade Lift Cylinder (S.N.—831315 )

Disassemble and Assemble Blade Lift Cylinder—Outside Dozer (S.N. 831316— )

Remove and Install Tilt Cylinder For (PAT) Six-Way Blade 850C (S.N. —883331)

Remove and Install Angle Cylinder For (PAT) Six-Way Blade 850C (S.N. —883331)

Disassemble 120 Series Blade Tilt (PAT) (S.N. 883332— ) and Lift Cylinder (PAT) (S.N. 883332— )

Cross Section of 120 Series Blade Lift (PAT) (S.N. 883332—) and Tilt Cylinder (PAT) (S.N. 883332— )

Assemble 120 Series Blade Tilt (PAT) (S.N. 883332—) and Lift Cylinder (PAT) (S.N. 883332— )

Disassemble 125 Series Blade Angle Cylinder (PAT) (S.N. 883332— )

Cross Section of 125 Series Blade Angle Cylinder (PAT) (S.N. 883332— )

Assemble 125 Series Blade Angle Cylinder (PAT) (S.N. 883332— )

Group 3299: Dealer Fabricated Tools

DFT1180 Cylinder Nut Torque Tool

Section 9900: Dealer Fabricated Tools

Group 0999: Dealer Fabricated Tools

DF1065 Final Drive and Pump Adapter Bracket

DFT1041 Track Nut Removal Tool

DFT1063 Final Drive Lift Bracket

DFT1132 Hydrostatic Motor Removal and Installation Tool

DFT1137 Hydrostatic Motor Removal and Installation Tool

DFT1167 Final Drive Lifting Bracket Adapter Spacer

DFT1243 Lifting Bracket Extension

DFT1250 Lifting Bracket

DFT1260 Final Drive Lifting Fixture

DFT1261 Rolling Torque Measurement Tool

John Deere Crawler Dozers 750C, 850C, 750C Series II, 850C Series II Repair Service Manual (TM1589)