Hitachi Zaxis 160LC-5G Excavator Repair Service Manual (TM12648)

Complete Repair Service Technical Manual for Hitachi Zaxis 160LC-5G Excavator, with all the shop information to maintain, repair, and rebuild like professional mechanics.

Hitachi Zaxis 160LC-5G (ZX160LC-5G) workshop technical manual (repair) includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM12648 - Hitachi Zaxis 160LC-5G Excavator Technical Manual - Repair.pdf

TM12650 - Hitachi Excavadora Zaxis160LC-5G.pdf

TM12649 - Hitachi Excavatrice Zaxis160LC-5G.pdf

TM12651 - Hitachi Escavadeira Zaxis160LC-5G.pdf

PRODUCT DETAILS:

Total Pages: 724 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English Spanish French Portuguese

Models: John Deere / HITACHI - Excavator - 1FFDBGH0__C230001

TABLE OF CONTENTS...1

Section 00: General Information...10

Group 01: Safety...10

Recognize Safety Information...14

Understand Signal Words...15

Follow Safety Instructions...16

Prepare for Emergencies...17

Wear Protective Clothing...18

Protect Against Noise...19

Inspect Machine...20

General Precautions for Cab...21

Use Handholds and Steps...22

Adjust the Operator's Seat...23

Ensure Safety Before Rising From or Leaving Operator’s Seat...24

Fasten Your Seat Belt...25

Move and Operate Machine Safely...26

Operate Only From Operator's Seat...27

Jump Starting...28

Keep Riders Off Machine...29

Precautions for Operations...30

Investigate Job Site Beforehand...31

Install OPG Guard...33

Restriction of Attachment Installation...34

Provide Signals for Jobs Involving Multiple Machines...35

Confirm Direction of Machine to be Driven...36

Drive Machine Safely...37

Avoid Injury From Rollaway Accidents...41

Avoid Injury From Back-Over and Swing Accidents...42

Keep Person Clear From Working Area...44

Never Position Bucket Over Anyone...45

Avoid Undercutting...46

Avoid Tipping...47

Never Undercut a High Bank...49

Dig With Caution...50

Operate With Caution...51

Avoid Power Lines...52

Precautions for Lightning...53

Object Handling...54

Protect Against Flying Debris...55

Park Machine Safely...56

Handle Fluids Safely−Avoid Fires...57

Transport Safely...58

Practice Safe Maintenance...59

Warn Others of Service Work...61

Support Machine Properly...62

Stay Clear of Moving Parts...63

Prevent Parts From Flying...64

Avoid Injury from Attachment Falling Accident...65

Prevent Burns...66

Replace Rubber Hoses Periodically...67

Avoid High-Pressure Fluids...68

Prevent Fires...70

Evacuating in Case of Fire...72

Beware of Exhaust Fumes...73

Precautions for Welding and Grinding...74

Avoid Heating Near Pressurized Fluid Lines...75

Remove Paint Before Welding or Heating...76

Beware of Asbestos and Silicon Dust and Other Contamination...77

Prevent Battery Explosions...78

Service Air Conditioning System Safely...79

Handle Chemical Products Safely...80

Dispose of Waste Properly...81

Never Ride Attachment...82

Precautions for Communication Terminal...83

FCC Notifications to User...84

Before Returning the Machine to the Customer...85

Notes on Protection of Operator’s Station When the Machine Rolls Over...86

Group 3: Torque Values...12

Metric Bolt and Cap Screw Torque Values...90

Additional Metric Cap Screw Torque Values...92

Unified Inch Bolt and Cap Screw Torque Values...94

Service Recommendations for 37° Flare and 30° Cone Seat Connectors...96

Service Recommendations for O-Ring Boss Fittings...98

Service Recommendations for Flared Connections—Straight or Tapered Threads...100

Service Recommendations for Flat Face O-Ring Seal Fittings...102

O-Ring Boss Fittings in Aluminum Housing Service Recommendations—Excavators...104

O-Ring Face Seal Fittings With SAE Inch Hex Nut and Stud End for High-Pressure Service Recommendations...107

O-Ring Face Seal Fittings With Metric Hex Nut and Stud End for Standard Pressure Service Recommendations...109

O-Ring Face Seal Fittings With Metric Hex Nut and Stud End for High-Pressure Service Recommendations...112

Service Recommendations for Metric Series Four Bolt Flange Fitting...115

Service Recommendations For Inch Series Four Bolt Flange Fittings...117

Inch Series Four Bolt Flange Fitting for High-Pressure Service Recommendations...119

Service Recommendations For Non-Restricted Banjo (Adjustable) Fittings...121

Service Recommendations For O-Ring Boss Fittings With Shoulder...124

Metric 24° O-Ring Seal DIN 20078 Service Recommendations...127

Section 01: Tracks...131

Group 0130: Track System...131

Track Roller Remove and Install...136

Track Roller Disassemble and Assemble...140

Track Roller Pressure Test...143

Track Carrier Roller Remove and Install...146

Metal Face Seals Repair...149

Track Shoe Remove and Install...152

Track Chain Remove and Install...155

Track Chain Disassemble and Assemble...162

Track Chain Repair to Replace Broken Part...165

Sprocket Remove and Install...171

Front Idler Remove and Install...174

Front Idler Disassemble and Assemble...176

Track Adjuster and Recoil Spring Remove and Install...180

Track Adjuster and Recoil Spring Disassemble and Assemble...182

Track Adjuster Cylinder Disassemble and Assemble...189

Section 02: Axles, Differentials, and Suspension Systems...191

Group 0250: Axle Shaft, Bearings, and Reduction Gears...191

Travel Gear Case Remove and Install...196

Travel Gear Case Disassemble and Assemble...200

Group 0260: Hydraulic System...191

Travel Motor and Park Brake Remove and Install...215

Travel Motor and Park Brake Disassemble and Assemble...219

Park Brake Valve Disassemble and Assemble...230

Travel Motor and Park Brake Start-Up Procedure...233

Metal Face Seal Install...234

Section 04: Engine...240

Group 0400: Removal and Installation...240

Engine Remove and Install...251

Section 05: Engine Auxiliary System...261

Group 0510: Cooling Systems...261

Radiator Remove and Install...266

Hydraulic Oil Cooler Remove and Install...270

Charge Air Cooler Remove and Install...274

Fan, Fan Guard, and Fan Shroud Remove and Install...276

Coolant Recovery Tank Remove and Install...279

Group 0560: External Fuel Supply Systems...261

Fuel Tank Remove and Install...286

Section 07: Damper Drive (Flex Coupling)...291

Group 0752: Elements...291

Damper Drive (Flex Coupling) Remove and Install...296

Section 17: Frame or Supporting Structure...300

Group 1740: Frame Installation...300

Welding on Machine...303

Group 1749: Chassis Weights...300

Counterweight Remove and Install...309

Section 18: Operator's Station...313

Group 1800: Removal and Installation...313

Cab Remove and Install...325

Group 1810: Operator Enclosure...313

Windshield Remove and Install...338

Windshield Disassemble and Assemble...340

Sliding Windows Remove and Install...350

Windowpanes Remove and Install...352

Windowpanes Dimensions...353

Group 1821: Seat and Seat Belt...313

Seat Remove and Install...363

Seat Belt Remove and Install...365

Mechanical Suspension Seat Disassemble and Assemble...370

Air Suspension Seat Disassemble and Assemble...376

Group 1830: Heating and Air Conditioning...313

R134a Refrigerant Cautions and Proper Handling...382

R134a Refrigerant Oil Information...383

R134a Refrigerant Recovery, Recycling, and Charging Station Installation Procedure...385

Recover R134a Refrigerant...387

Flush and Purge Air Conditioning System...388

Evacuate R134a System...391

Charge R134a System...393

Air Conditioner Compressor Remove and Install...395

Condenser Remove and Install...397

Heater and Air Conditioner Remove and Install...398

Heater and Air Conditioner Blower Motor Remove and Install...403

Receiver-Dryer Remove and Install...409

Section 19: Sheet Metal and Styling...411

Group 1910: Hood or Engine Enclosure...411

Hood Remove and Install...414

Section 33: Excavator...416

Group 3302: Buckets...416

Bucket Remove and Install...419

Adjust Bucket Pivot End Play...420

Bucket Pin-Up Data...422

Group 3340: Frames...416

Bucket Links Remove and Install...427

Arm Remove and Install...430

Boom Remove and Install...434

Inspect Pins, Bushings, and Bosses—Front Attachment...442

Cylinder Specifications...445

Bushings and Seal Remove and Install...446

Group 3360: Hydraulic System...416

Apply Vacuum to Hydraulic Oil Tank...450

Hydraulic Oil Cleanup Procedure Using Portable Filter Caddy...452

Pump 1 and 2 Remove and Install...453

Pump 1 and 2 Disassemble and Assemble...458

Pump 1 and 2 Inspection...476

Pump 1 and 2 Start-Up Procedure...481

Pump 1 and 2 Regulator Remove and Install...483

Pump 1 and 2 Regulator Disassemble and Assemble...485

Pilot Pump Remove and Install...488

Pilot Pump Disassemble and Assemble...491

Pilot Pressure Regulating Valve and Filter Remove and Install...493

Pilot Pressure Regulating Valve and Filter Disassemble and Assemble...495

Pilot Shutoff Solenoid Valve Remove and Install...497

Pilot Shutoff Solenoid Valve Disassemble and Assemble...500

Solenoid Valve Manifold Remove and Install...502

Solenoid Valve Remove and Install—Power Dig/Travel Speed (SG), Arm Regenerative (SC), and Dig Regenerative (SF) Valves...504

Solenoid Valve Disassemble and Assemble—Power Dig/Travel Speed (SG), Arm Regenerative (SC), and Dig Regenerative (SF) Valves...507

Pilot Valve (Left and Right) Remove and Install...509

Pilot Valve (Left and Right) Disassemble and Assemble...512

Travel Pilot Valve Remove and Install...521

Travel Pilot Valve Disassemble and Assemble...524

Pilot Signal Manifold Remove and Install...528

Pilot Signal Manifold Disassemble and Assemble...530

Control Valve Remove and Install...533

Control Valve Halves Disassemble and Assemble...538

Control Valve (5-Spool) Disassemble and Assemble...540

Control Valve (4-Spool) Disassemble and Assemble...566

Hydraulic Oil Tank Remove and Install...589

Hydraulic Oil Tank Disassemble and Assemble...595

Restriction Valve Remove and Install...599

Hydraulic Oil Cooler Bypass Valve Remove and Install...601

Boom Cylinder Remove and Install...603

Boom Cylinder Disassemble and Assemble...608

Arm Cylinder Remove and Install...614

Arm Cylinder Disassemble and Assemble...618

Bucket Cylinder Remove and Install...624

Bucket Cylinder Disassemble and Assemble...628

Hydraulic Cylinder Bleed Procedure...634

Section 43: Swing or Pivoting System...635

Group 4350: Mechanical Drive Elements...635

Swing Gear Case Remove and Install...639

Swing Gear Case Disassemble and Assemble...642

Swing Gear Case Start-Up Procedure...652

Upperstructure Remove and Install...654

Swing Bearing Remove and Install...659

Swing Bearing Disassemble and Assemble...662

Swing Bearing Upper Seal Install...665

Swing Bearing Lower Seal Install...666

Group 4360: Hydraulic System...635

Center Joint Remove and Install...672

Center Joint Disassemble and Assemble...676

Center Joint Air Test...680

Swing Motor and Park Brake Remove and Install...681

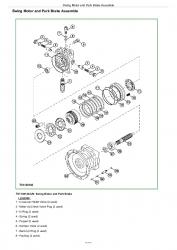

Swing Motor and Park Brake Disassemble...684

Swing Motor and Park Brake Inspection...688

Swing Motor and Park Brake Assemble...693

Swing Motor and Park Brake Start-Up Procedure...697

Crossover Relief Valve and Make-Up Check Valve Remove and Install...698

Make-Up Check Valve Disassemble and Assemble...702

Swing Park Brake Check Valve and Orifice Remove and Install...704

Section 99: Dealer Fabricated Tools...707

Group 9900: Dealer Fabricated Tools...707

DF1063 Lift Bracket...710

ST4920 Track Recoil Spring Disassembly and Assembly Tool...712

DFT1087 Track Recoil Spring Disassembly and Assembly Guard Tool...717

DFT1110 Spacer...718

DFT1130 Adapter...719

DFT1036A Travel Gear Case Nut Wrench...720

DFT1109 Holding Bar...721

Center Joint (Rotary Manifold) Lifting Tool...722

DFT1220 Swing Gear Case Nut Spanner Wrench...724

Hitachi Zaxis 160LC-5G Excavator Repair Service Manual (TM12648)