Komatsu Wheel Loader WA30 Repair Service Manual

Komatsu Wheel Loader WA30 Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Wheel Loader WA30-5, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Wheel Loader WA30-5 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,052 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SEBM016503 - Wheel Loader WA30-5 avance Shop Manual.pdf

SEAM010700 - Wheel Loader WA20-2, WA30-5, WA40-3, WA50-3 Operation & Maintenance Manual.pdf

SEAM034300 - Wheel Loader WA30-5, WA50-3 Operation & Maintenance Manual.pdf

SEAM03610102 - Wheel Loader WA20-1 Operation & Maintenance Manual.pdf

TEN00071-00 - Wheel Loader WA30-5, WA50-3 Operation & Maintenance Manual.pdf

MAIN SECTIONS

SEAM010700 - Wheel Loader WA20-2, WA30-5, WA40-3, WA50-3 Operation & Maintenance Manual.....2

COVER.....2

1. FOREWORD.....3

2. SAFETY INFORMATION.....4

3. INTRODUCTION.....5

4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR.....6

5. CONTENTS.....8

SAFETY.....11

6. GENERAL PRECAUTIONS.....12

7. PRECAUTIONS DURING OPERATION.....17

7.1 BEFORE STARTING ENGINE.....17

7.2 OPERATING MACHINE.....19

7.3 TRANSPORTATION.....24

7.4 BATTERY.....25

7.5 TOWING.....26

8. PRECAUTIONS FOR MAINTENACE.....27

8.1 BEFORE CARRYING OUT MAINTENANCE.....27

8.2 DURING MAINTENANCE.....31

8.3 TIRES.....35

9. POSITION FOR ATTACHING SAFETY LABELS.....37

OPERATION.....41

10. GENERAL VIEW.....42

10.1 GENERAL VIEW OF MACHINE.....42

10.2 GENERAL VIEW OF CONTROLS AND GAUGES.....43

11. EXPLANATION OF COMPONENTS.....44

11.1 METER, LAMPS.....44

11.2 SWITCHES.....48

11.3 CONTROL LEVERS, PEDALS.....50

11.4 CAP WITH LOCK.....54

11.5 SAFETY BAR.....54

11.6 TILT HOOD.....55

11.7 TOWING PIN.....55

11.8 FUSE.....55

11.9 FUSIBLE LINK.....56

11.10 MANUAL POCKET.....57

11.11 CONNECTORS.....57

12. OPERATION.....58

12.1 CHECK BEFORE STARTING ENGINE.....58

12.2 STARTING ENGINE.....69

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE.....72

12.4 MOVING MACHINE OFF.....74

12.5 CHANGING DIRECTION.....76

12.6 TURNING.....76

12.7 STOPPING MACHINE.....77

12.8 OPERATION OF WORK EQUIPMENT.....78

12.9 WORK POSSIBLE USING WHEEL LOADER.....79

12.10 PRECAUTIONS FOR OPERATION.....83

12.11 ADJUSTING WORK EQUIPMENT POSTURE.....85

12.12 PARKING MACHINE.....86

12.13 CHECKS AFTER COMPLETIONOF OPERATION.....87

12.14 STOPPING ENGINE.....88

12.15 CHECK AFTER STOPPING ENGINE.....88

12.16 LOCKING.....88

12.17 HANDLING THE TIRES.....89

13. TRANSPORTATION.....92

13.1 LOADING, UNLOADING WORK.....92

13.2 PRECAUTIONS FOR LOADING.....93

13.3 LIFTING MACHINE.....93

13.4 PRECAUTIONS FOR TRANSPORTATION.....96

13.5 REMOVING AND INSTALLATION OF CANOPY.....96

14. COLD WEATHER OPERATION.....98

14.1 PRECAUTIONS FOR LOW TEMPERATURE.....98

14.2 PRECAUTIONS AFTER COMPLETION OF WORK.....100

14.3 AFTER COLD WEATHER.....100

15. LONG-TERM STORAGE.....101

15.1 BEFORE STORAGE.....101

15.2 DURING STORAGE.....101

15.3 AFTER STORAGE.....101

16. TROUBLESHOOTING.....102

16.1 WHEN MACHINE RUNS OUT OF FUEL.....102

16.2 TOWING THE MACHINE.....103

16.3 IF BATTERY IS DISCHARGED.....106

16.4 OTHER TROUBLE.....110

MAINTENANCE.....115

17. GUIDES TO MAINTENANCE.....116

18. OUTLINES OF SERVICE.....119

18.1 OUTLINE OF OIL, FUEL, COOLANT.....119

18.2 OUTLINE OF ELECTRIC SYSTEM.....122

19. WEAR PARTS LIST.....123

20. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE.....124

21. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS.....128

21.1 INTRODUCTION OF NECESSARY TOOLS.....128

21.2 TORQUE LIST.....130

22. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS.....131

23. MAINTENANCE SCHEDULE CHART.....138

23.1 MAINTENANCE SCHEDULE CHART.....138

24. SERVICE PROCEDURE.....141

24.1 INITIAL 250 HOURS SERVICE.....141

24.2 WHEN REQUIRED.....142

24.3 CHECK BEFORE STARTING.....156

24.4 EVERY 50 HOURS SERVICE.....162

24.5 EVERY 250 HOURS SERVICE.....163

24.6 EVERY 500 HOURS SERVICE.....168

24.7 EVERY 1000 HOURS SERVICE.....171

24.8 EVERY 2000 HOURS SERVICE.....174

SPECIFICATIONS.....177

25. SPECIFICATIONS.....178

OPTIONS, ATTACHMENTS.....179

26. OPTIONAL PARTS AND ATTACHMENTS.....180

27. SEAT BELT.....181

27.1 FASTENING AND REMOVING BELT.....181

27.2 ADJUST BELT LENGTH.....182

27.3 CHECK SEAT BELT AND MOUNTS.....182

28. EQUIPMENT WITH CAB.....183

28.1 SWITCHES.....183

28.2 REAR WINDOW.....187

28.3 CHECK AND MAINTENANCE.....188

SEAM034300 - Wheel Loader WA30-5, WA50-3 Operation & Maintenance Manual.....197

COVER PAGE.....197

1. FOREWORD.....198

2. SAFETY INFORMATION.....199

3. INTRODUCTION.....200

4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR.....201

5. CONTENTS.....202

SAFETY.....205

6. GENERAL PRECAUTIONS.....206

7. PRECAUTIONS DURING OPERATION.....211

7.1 BEFORE STARTING ENGINE.....211

7.2 OPERATING MACHINE.....213

7.3 TRANSPORTATION.....218

7.4 BATTERY.....219

7.5 TOWING.....220

8. PRECAUTIONS FOR MAINTENANCE.....221

8.1 BEFORE CARRYING OUT MAINTENANCE.....221

8.2 DURING MAINTENANCE.....225

8.3 PRECAUTIONS WITH TIRES.....229

9. POSITION FOR ATTACHING SAFETY LABELS.....230

OPERATION.....235

10. GENERAL VIEW.....236

10.1 GENERAL VIEW OF MACHINE.....236

10.2 GENERAL VIEW OF CONTROLS AND GAUGES.....237

11. EXPLANATION OF COMPONENTS.....239

11.1 METER, LAMPS.....239

11.2 SWITCHES.....242

11.3 CONTROL LEVERS, PEDALS.....244

11.4 CAP WITH LOCK.....248

11.5 SAFETY BAR.....248

11.6 TILT HOOD.....249

11.7 TOWING PIN.....249

11.8 FUSE.....249

11.9 FUSIBLE LINK.....250

11.10 MANUAL POCKET.....251

11.11 CONNECTORS.....251

12. OPERATION.....252

12.1 CHECK BEFORE STARTING ENGINE.....252

12.2 STARTING ENGINE.....265

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE.....268

12.4 MOVING MACHINE OFF.....270

12.5 CHANGING DIRECTION.....272

12.6 TURNING.....272

12.7 STOPPING MACHINE.....273

12.8 OPERATION OF WORK EQUIPMENT.....274

12.9 OPERATING FRONT ATTACHMENT SERVICE HYDRAULIC CIRCUIT.....275

12.10 WORK POSSIBLE USING WHEEL LOADER.....277

12.11 PRECAUTIONS FOR OPERATION.....281

12.12 ADJUSTING WORK EQUIPMENT POSTURE.....283

12.13 PARKING MACHINE.....284

12.14 CHECKS AFTER COMPLETION OF OPERATION.....285

12.15 STOPPING ENGINE.....286

12.16 CHECK AFTER STOPPING ENGINE.....286

12.17 LOCKING.....286

12.18 HANDLING THE TIRES.....287

13. TRANSPORTATION.....290

13.1 LOADING, UNLOADING WORK.....290

13.2 PRECAUTIONS FOR LOADING.....291

13.3 LIFTING MACHINE.....291

13.4 PRECAUTIONS FOR TRANSPORTATION.....294

14. COLD WEATHER OPERATION.....295

14.1 PRECAUTIONS FOR LOW TEMPERATURE.....295

14.2 PRECAUTIONS AFTER COMPLETION OF WORK.....297

14.3 AFTER COLD WEATHER.....297

15. LONG-TERM STORAGE.....298

15.1 BEFORE STORAGE.....298

15.2 DURING STORAGE.....298

15.3 AFTER STORAGE.....298

16. TROUBLESHOOTING.....299

16.1 WHEN MACHINE RUNS OUT OF FUEL.....299

16.2 TOWING THE MACHINE.....300

16.3 IF BATTERY IS DISCHARGED.....303

16.4 OTHER TROUBLE.....307

MAINTENANCE.....312

17. GUIDES TO MAINTENANCE.....313

18. OUTLINES OF SERVICE.....316

18.1 OUTLINE OF OIL, FUEL, COOLANT.....316

18.2 OUTLINE OF ELECTRIC SYSTEM.....318

19. WEAR PARTS LIST.....319

20. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE.....320

21. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS.....324

21.1 INTRODUCTION OF NECESSARY TOOLS.....324

21.2 TORQUE LIST.....326

22. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS.....327

23. MAINTENANCE SCHEDULE CHART.....328

23.1 MAINTENANCE SCHEDULE CHART.....328

24. SERVICE PROCEDURE.....331

24.1 INITIAL 250 HOURS SERVICE.....331

24.2 WHEN REQUIRED.....332

24.3 CHECK BEFORE STARTING.....345

24.4 EVERY 50 HOURS SERVICE.....351

24.5 EVERY 250 HOURS SERVICE.....352

24.6 EVERY 500 HOURS SERVICE.....357

24.7 EVERY 1000 HOURS SERVICE.....361

24.8 EVERY 2000 HOURS SERVICE.....364

SPECIFICATIONS.....366

25. SPECIFICATIONS.....367

SEAM03610102 - Wheel Loader WA20-1 Operation & Maintenance Manual.....370

COVER.....370

FOREWORD.....371

BREAKING IN YOUR NEW MACHINE.....372

CONTENTS.....373

SAFETY HINTS.....374

GENERAL LOCATIONS AND SPECIFICATIONS.....379

INSTRUMENTS AND CONTROLS.....380

CHECK BEFORE STARTING.....390

OPERATING YOUR MACHINE.....394

BUCKET OPERATION.....401

HOW TO USE INCHING PEDAL.....405

TIRE REPLACEMENT.....407

HANDLING THE TIRES.....408

HANDLING OF BATTERY.....409

MACHINE MOVEMENT.....411

COLD WEATHER OPERATION.....412

TRANSPORTATION.....415

PERIODIC MAINTENANCE.....416

PRECAUTIONS FOR MAINTENANCE.....417

PERIODIC REPLACEMENT OF PARTS FOR SAFETY.....421

MAINTENANCE TABLE.....422

OIL FILLER AND LEVEL GAUGE POSITIONS.....425

EVERY 50 HOURS SERVICE.....426

EVERY 250 HOURS SERVICE.....426

EVERY 500 HOURS SERVICE.....433

EVERY 1000 HOURS SERVICE.....437

EVERY 2000 HOURS SERVICE.....440

WHEN REQUIRED.....441

ADJUSTMENT.....446

STORAGE.....448

SERVICE METER.....450

MACHINE AND ENGINE SERIAL NUMBERS.....451

FUEL,COOLANT AND LUBRICANTS.....452

SEBM016503 - Wheel Loader WA30-5 avance Shop Manual.....456

COVER.....456

CONTENTS.....457

01 GENERAL.....480

GENERAL ASSEMBLY DRAWING.....481

SPECIFICATIONS.....483

WEIGHT TABLE.....486

LIST OF LUBRICANT AND WATER.....487

10 STRUCTURE AND FUNCTION.....489

POWER TRAIN.....490

POWER TRAIN SYSTEM.....491

RADIATOROIL COOLER.....493

DAMPER COUPLING.....494

HST PIPING.....495

HST HYDRAULIC SYSTEM DIAGRAM.....496

HST HYDRAULIC CIRCUIT DIAGRAM.....497

MAIN PISTON PUMP.....498

HIGH-PRESSURE RELIEF VALVE.....500

LOW-PRESSURE RELIEF VALVE.....502

WORK EQUIPMENTSTEERING PUMP, HST CHARGE PUMP.....503

CHARGE PUMP OIL FILTER.....504

SPEED RELATED VALVE (DA VALVE).....505

PISTON MOTOR.....506

DIRECTIONAL SHUTTLE VALVE.....508

SERVO VALVE.....509

INCHING VALVE.....510

TRANSFER.....511

HST CONTROL.....512

DRIVE SHAFT.....513

AXLE.....514

DIFFERENTIAL.....516

FINAL DRIVE.....519

AXLE MOUNT.....521

TIREWHEEL.....522

CENTER HINGE PIN.....523

STEERING PIPING.....524

STEERING COLUMN.....525

PRIORITY VALVE.....526

STEERING VALVE (ORBIT-ROLL).....530

BRAKE, PARKING BRAKE CONTROL.....538

BRAKE (ALSO USED AS PARKING BRAKE).....539

WORK EQUIPMENT PIPING.....540

WORK EQUIPMENT HYDRAULIC SYSTEM DIAGRAM.....541

WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM.....542

WORK EQUIPMENT LEVER LINKAGE.....543

HYDRAULIC TANK.....544

HYDRAULIC FILTER.....545

MAIN CONTROL VALVE.....546

WORK EQUIPMENT LINKAGE.....553

BUCKET.....554

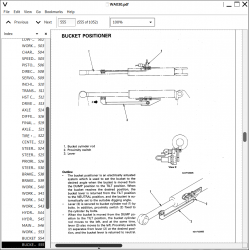

BUCKET POSITIONER.....555

PROXIMITY SWITCH.....556

ROPS CANOPY.....557

CENTRAL PANEL (CLUSTER GAUGE).....558

ENGINE START CIRCUIT.....559

ENGINE STOP CIRUIT.....559

PREHEATING CIRCUIT.....560

PARKING BRAKE CIRCUIT.....561

20 TESTING AND ADJUSTING.....562

STANDARD VALUE TABLE FOR ENGINE.....563

STANDARD VALUE TABLE FOR CHASSIS.....565

TABLE OF TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING.....570

ADJUSTING VALVE CLEARANCE.....571

MEASURING COMPRESSION PRESSURE.....574

TESTING AND ADJUSTING FUEL INJECTION TIMING.....575

BLEEDING AIR FROM FUEL CIRCUIT.....581

TESTING AND ADJUSTING FAN BELT TENSION.....582

TESTING FOR ABNORMALITY IN FUEL LEVEL SENSOR.....584

MEASURING ACCELERATOR PEDAL.....585

MEASURING OPERATING EFFORT, TRAVEL OF DIRECTIONAL LEVER.....587

MEASURING STALL SPEED.....588

MEASURING HST OIL PRESSURE.....589

TESTING AND ADJUSTING STEERING WHEEL.....590

MEASURING OPERATING TIME FOR STEERING WHEEL.....591

MEASURING STEERING PRESSURE.....592

TESTING AND ADJUSTING BRAKE PEDAL.....593

MEASURING OPERATING EFFORT, TRAVEL OF BRAKE PEDAL.....595

MEASURING BRAKE PERFORMANCE.....596

MEASURING PARKING BRAKE PERFORMANCE.....597

MEASURING BRAKE DISC WEAR.....598

TESTING AND ADJUSTING INCHING VALVE LINKAGE.....599

MEASURING AND ADJUSTING WORK EQUIPMENT CONTROL LEVER.....600

MEASURING TRAVEL OF MAIN CONTROL VALVE SPOOL.....602

MEASURING WORK EQUIPMENT PRESSURE.....603

TESTING AND ADJUSTING BUCKET POSITIONER.....605

TROUBLESHOOTING.....607

POINTS TO REMEMBER WHEN TROUBLESHOOTING.....608

SEQUENCE OF EVENTS IN TROUBLESHOOTING.....609

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE.....610

CHECKS BEFORE TROUBLESHOOTING.....618

TROUBLESHOOTING OF ELECTRICAL SYSTEM.....619

E-1 ENGINE DOES NOT START.....620

TROUBLESHOOTING OF HYDRAULIC SYSTEM (H MODE).....625

TROUBLESHOOTING.....626

CHECKING MACHINE BEFORE TROUBLESHOOTING.....626

CHECKING HST BEFORE TROUBLESHOOTING.....627

H-1 IMPOSSIBLE TO TRAVEL IN EITHER DIRECTION (FORWARD OR REVERSE).....629

H-2 IMPOSSIBLE TO TRAVEL IN ONE DIRECTION ONLY (EITHER FORWARD OR REVERSE).....630

H-3 LACKS SPEED IN BOTH DIRECTIONS (FORWARD AND REVERSE).....631

H-4 LACKS SPEED IN ONE DIRECTION ONLY (FORWARD OR REVERSE).....632

H-5 LACKS DRAWBAR PULL IN BOTH DIRECTIONS (FORWARD AND REVERSE).....632

H-6 LACKS DRAWBAR PULL IN ONE DIRECTION ONLY (FORWARD OR REVERSE).....633

H-7 ENGINE SPEED IS HIGH WHEN STARTING IN BOTH DIRECTIONS (FORWARD AND REVERSE).....633

H-8 ENGINE SPEED IS HIGH WHEN STARTING IN ONE DIRECTION ONLY (FORWARD OR REVERSE).....633

30 DISASSEMBLY AND ASSEMBLY.....634

HOW TO READ THIS MANUAL.....635

PRECAUTIONS WHEN CARRYING OUT OPERATION.....637

SPECIAL TOOLS LIST.....639

FUEL INJECTION PUMP.....640

REMOVAL.....640

INSTALLATION.....641

ENGINE.....642

REMOVAL AND INSTALLATION.....642

RADIATOR.....672

REMOVAL AND INSTALLATION.....672

FUEL TANK.....681

REMOVAL AND INSTALLATION.....681

MAIN PISTON PUMP.....682

REMOVAL.....682

INSTALLATION.....687

DISASSEMBLY AND ASSEMBLY.....691

PISTON MOTOR.....697

REMOVAL.....697

INSTALLATION.....699

DISASSEMBLY.....701

ASSEMBLY.....702

ENGINE AND TRANSFER.....703

REMOVAL AND INSTALLATION.....703

TRANSFER.....731

DISASSEMBLY.....731

ASSEMBLY.....734

DRIVE SHAFT.....738

DISASSEMBLY.....738

ASSEMBLY.....739

FRONT AXLE.....740

REMOVAL.....740

INSTALLATION.....741

REAR AXLE.....742

REMOVAL.....742

INSTALLATION.....745

DIFFERENTIALS.....748

DISASSEMBLY.....748

ASSEMBLY.....751

AXLE HOUSINGS.....762

DISASSEMBLY.....762

ASSEMBLY.....767

CENTER HINGE PIN.....773

REMOVAL.....773

INSTALLATION.....780

STEERING VALVE.....790

REMOVAL AND INSTALLATION.....790

DISASSEMBLY.....791

ASSEMBLY.....794

RELIEF VALVE HOUSING SIDE OF STEERING VALVE.....799

DISASSEMBLY.....799

ASSEMBLY.....800

STEERING CYLINDER.....801

REMOVAL AND INSTALLATION.....801

PARKING BRAKE.....802

REMOVAL.....802

INSTALLATION.....804

HYDRAULIC TANK.....807

REMOVAL AND INSTALLATION.....807

WORK EQUIPMENT VALVE.....808

REMOVAL AND INSTALLATION.....808

DUMP CYLINDER.....809

REMOVAL AND INSTALLATION.....809

LIFT CYLINDER.....810

REMOVAL AND INSTALLATION.....810

HYDRAULIC CYLINDER.....811

DISASSEMBLY.....811

ASSEMBLY.....813

WORK EQUIPMENT.....815

REMOVAL.....815

INSTALLATION.....818

COUNTERWEIGHT.....821

REMOVAL AND INSTALLATION.....821

INSTRUMENTS PANEL.....822

REMOVAL AND INSTALLATION.....822

40 MAINTENANCE STANDARD.....823

TRANSMISSIONENGINE MOUNT.....824

WORK EQUIPMENTSTEERING PUMP, HST CHARGE PUMP.....825

TRANSFER.....826

HST INCHING VALVE.....828

DRIVE SHAFT.....829

DIFFERENTIAL (1/2).....830

DIFFERENTIAL (2/2).....831

FINAL DRIVE.....833

AXLE MOUNT.....834

STEERING COLUMN.....835

PRIORITY VALVE.....836

STEERING CYLINDER MOUNT.....837

BRAKE.....838

HYDRAULIC CYLINDER.....839

CENTER HINGE PIN.....841

WORK EQUIPMENT LINKAGE.....842

BUCKET POSITIONER.....844

BUCKET.....845

90 OTHERS.....846

ELECTRICAL CIRCUIT DIAGRAMSERIAL NO. 22005-26000.....847

ELECTRICAL CIRCUIT DIAGRAM (1/2)SERIAL NO. 26001 AND UP.....848

ELECTRICAL CIRCUIT DIAGRAM (2/2)SERIAL NO. 26001 AND UP.....849

BACKHOE.....850

CONTENTS.....851

GENERAL.....852

GENERAL ASSEMBLY DRAWING.....852

SPECIFICATIONS.....853

WEIGHT TABLE.....855

STRUCTURE AND FUNCTION.....856

VALVE CONTROL.....856

HYDRAULIC CIRCUIT DIAGRAM.....857

BACKHOE CONTROL VALVE.....858

CHECK VALVE.....860

WORK EQUIPMENT.....862

ACTUAL ELECTRICAL WIRING DIAGRAM.....863

ELECTRICAL CIRCUIT DIAGRAM.....864

TESTING AND ADJUSTING.....865

ADJUSTING BACKHOE SWING.....865

TEN00071-00 - Wheel Loader WA30-5, WA50-3 Operation & Maintenance Manual.....866

COVER.....866

FOREWORD.....867

FOREWORD.....868

SAFETY INFORMATION.....871

INTRODUCTION.....873

FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE.....873

NECESSARY INFORMATION.....874

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE.....874

ENGINE SERIAL NO. PLATE AND POSITION.....874

POSITION OF SERVICE METER.....874

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR.....875

CONTENTS.....876

SAFETY.....879

SAFETY.....880

SAFETY LABELS.....882

LOCATION OF SAFETY LABELS.....883

SAFETY LABELS.....884

GENERAL PRECAUTIONS.....888

SAFETY RULES.....888

IF ABNORMALITIES ARE FOUND.....888

CLOTHING AND PERSONAL PROTECTIVE ITEMS.....888

FIRE EXTINGUISHER AND FIRST AID KIT.....888

SAFETY FEATURES.....888

KEEP MACHINE CLEAN.....889

INSIDE OPERATOR'S COMPARTMENT.....889

ALWAYS APPLY LOCK WHEN LEAVING OPERATOR'S SEAT.....889

HANDRAILS AND STEPS.....890

MOUNTING AND DISMOUNTING.....890

NO PEOPLE ON ATTACHMENTS.....890

DO NOT GET CAUGHT IN ARTICULATED PORTION.....891

PREVENTION OF BURNS.....891

FIRE PREVENTION.....892

ACTION IF FIRE OCCURS.....893

WINDOW WASHER LIQUID.....893

PRECAUTIONS WHEN USING ROPS (ROLL OVER PROTECTIVE STRUCTURE).....893

PRECAUTIONS FOR ATTACHMENTS, OPTIONS.....893

UNAUTHORIZED MODIFICATION.....893

SAFETY AT WORKSITE.....894

WORKING ON LOOSE GROUND.....894

DO NOT GO CLOSE TO HIGH-VOLTAGE CABLES.....894

ENSURE GOOD VISIBILITY.....895

VENTILATION FOR ENCLOSED AREAS.....895

CHECKING SIGNALMAN'S SIGNALS AND SIGNS.....895

EMERGENCY EXIT FROM OPERATOR'S CAB.....895

BE CAREFUL ABOUT ASBESTOS DUST.....896

PRECAUTIONS FOR OPERATION.....897

STARTING ENGINE.....897

CHECKS BEFORE STARTING ENGINE.....897

PRECAUTIONS WHEN STARTING.....897

PRECAUTIONS IN COLD AREAS.....898

OPERATION.....899

CHECKS BEFORE OPERATION.....899

PRECAUTIONS WHEN TRAVELING IN FORWARD OR REVERSE.....899

PRECAUTIONS WHEN TRAVELING.....900

PRECAUTIONS WHEN USING A SMOKE POT.....900

TRAVELING ON SLOPES.....901

PROHIBITED OPERATIONS.....902

PRECAUTIONS WHEN OPERATING.....902

METHODS OF USING BRAKE.....903

OPERATE CAREFULLY ON SNOW.....903

PARKING MACHINE.....904

TRANSPORTATION.....905

LOADING AND UNLOADING.....905

SHIPPING.....905

BATTERY.....906

BATTERY HAZARD PREVENTION.....906

STARTING WITH BOOSTER CABLES.....907

TOWING.....908

WHEN TOWING.....908

PRECAUTIONS FOR MAINTENANCE.....909

WARNING TAG.....909

KEEP WORK PLACE CLEAN AND TIDY.....909

APPOINT LEADER WHEN WORKING WITH OTHERS.....909

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE.....910

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING.....911

PROPER TOOLS.....911

PERSONNEL.....912

ATTACHMENTS.....912

WORK UNDER THE MACHINE.....912

NOISE.....912

PRECAUTIONS WHEN USING HAMMER.....913

REPAIR WELDING.....913

REMOVING BATTERY TERMINAL.....913

PRECAUTIONS WITH HIGH-PRESSURE OIL.....913

HANDLING HIGH-PRESSURE HOSES.....914

WASTE MATERIALS.....914

COMPRESSED AIR.....914

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS.....914

PRECAUTIONS WITH TIRES.....915

HANDLING TIRES.....915

PRECAUTIONS WHEN STORING TIRES.....915

OPERATION.....916

GENERAL VIEW.....917

GENERAL VIEW OF MACHINE.....917

GENERAL VIEW OF CONTROLS AND GAUGES.....918

EXPLANATION OF COMPONENTS.....920

MACHINE MONITOR.....920

SWITCHES.....929

CONTROL LEVERS, PEDALS.....931

CAP WITH LOCK.....935

FRAME LOCK BAR.....936

TILT HOOD.....936

TOWING PIN.....936

FUSE.....937

FUSIBLE LINK.....938

MANUAL POCKET.....938

POWER OUTLET.....938

OPERATION.....939

CHECK BEFORE STARTING ENGINE, ADJUST.....939

STARTING ENGINE.....950

OPERATIONS AND CHECKS AFTER STARTING ENGINE.....953

STOPPING ENGINE.....954

MOVING THE MACHINE (DIRECTIONAL, SPEED), STOPPING THE MACHINE.....955

TURNING.....959

OPERATION OF WORK EQUIPMENT.....960

HANDLING FRONT ATTACHMENT SERVICE HYDRAULIC CIRCUIT (IF EQUIPPED).....961

WORK POSSIBLE USING WHEEL LOADER.....962

PRECAUTIONS FOR OPERATION.....966

ADJUSTING WORK EQUIPMENT POSTURE.....968

PARKING MACHINE.....970

CHECKS AFTER COMPLETION OF OPERATION.....972

LOCKING.....972

HANDLING THE TIRES.....973

TRANSPORTATION.....976

TRANSPORTATION PROCEDURE.....976

LOADING, UNLOADING WORK WITH TRAILERS.....976

LIFTING MACHINE.....979

REMOVAL, INSTALLATION OF CANOPY.....983

COLD WEATHER OPERATION.....985

PRECAUTIONS FOR LOW TEMPERATURE.....985

PRECAUTIONS AFTER COMPLETION OF WORK.....986

AFTER COLD WEATHER.....987

LONG-TERM STORAGE.....988

BEFORE STORAGE.....988

DURING STORAGE.....988

AFTER STORAGE.....988

TROUBLESHOOTING.....989

WHEN MACHINE RUNS OUT OF FUEL.....989

TOWING THE MACHINE.....989

IF BATTERY IS DISCHARGED.....991

OTHER TROUBLE.....994

MAINTENANCE.....999

GUIDES TO MAINTENANCE.....1000

OUTLINES OF SERVICE.....1002

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC.....1002

OUTLINE OF ELECTRIC SYSTEM.....1004

WEAR PARTS.....1005

WEAR PARTS LIST.....1005

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO .....1006

PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS.....1006

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS.....1010

TORQUE LIST.....1010

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS.....1011

MAINTENANCE SCHEDULE CHART.....1012

MAINTENANCE SCHEDULE CHART.....1012

SERVICE PROCEDURE.....1014

INITIAL 250 HOURS SERVICE OR INITIAL 3 MONTHS (ONLY AFTER THE FIRST 250.....1014

WHEN REQUIRED.....1015

REPLACE AIR CLEANER ELEMENT.....1015

CLEAN INSIDE OF COOLING SYSTEM.....1016

DRAIN WATER AND SEDIMENT FROM FUEL TANK.....1018

CLEAN WATER SEPARATOR ELEMENT.....1019

CHECK OIL LEVEL IN TRANSFER CASE, ADD OIL.....1020

CHECK AXLE OIL LEVEL, ADD OIL.....1021

CLEAN TRANSFER CASE BREATHER.....1022

CLEAN AXLE CASE BREATHER.....1022

CLEAN AND CHECK RADIATOR FINS.....1023

TURN, REPLACE BOLT-ON CUTTING EDGE.....1023

CHECK PARKING BRAKE.....1024

ADJUST PARKING BRAKE RELEASE LEVER.....1024

CHECK BRAKE PEDAL.....1024

SELECTION AND INSPECTION OF TIRES.....1025

CHECK BEFORE STARTING.....1027

EVERY 50 HOURS SERVICE OR EVERY 1 MONTH.....1028

CLEAN AIR CLEANER DUST CUP.....1028

EVERY 250 HOURS SERVICE OR EVERY 3 MONTHS.....1029

LUBRICATING.....1029

CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL.....1030

CLEAN AIR CLEANER ELEMENT.....1031

CHECK FAN BELT TENSION, ADJUST.....1032

CHECK BATTERY ELECTROLYTE LEVEL.....1033

CHECK FOR LOOSE WHEEL HUB BOLTS, TIGHTEN.....1035

EVERY 500 HOURS SERVICE OR EVERY 6 MONTHS.....1036

LUBRICATE REAR AXLE PIVOT PIN (2 PLACES).....1036

REPLACE FUEL FILTER CARTRIDGE.....1036

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE.....1038

EVERY 1000 HOURS SERVICE OR EVERY 1 YEAR.....1039

CHANGE OIL IN HYDRAULIC TANK, REPLACE HYDRAULIC OIL FILTER CARTRIDGE AND HST.....1039

LUBRICATING.....1040

EVERY 2000 HOURS SERVICE OR EVERY 2 YEARS.....1041

CHANGE OIL IN TRANSFER CASE.....1041

CHANGE AXLE OIL.....1042

CHECK ALTERNATOR, STARTING MOTOR.....1042

CHECK ENGINE VALVE CLEARANCE, ADJUST.....1042

SPECIFICATIONS.....1043

SPECIFICATIONS.....1044

ATTACHMENTS, OPTIONS.....1045

HANDLING SEAT BELT.....1046

FASTENING AND REMOVING BELT.....1046

ADJUST BELT LENGTH.....1046

CHECK SEAT BELT AND MOUNTS.....1047

HANDLING SERVICE HYDRAULIC CIRCUIT.....1048

CONNECTING HYDRAULIC CIRCUIT.....1048

ROUTE OF HYDRAULIC CIRCUIT.....1049

INDEX.....1050