Komatsu Hydraulic Excavator PC228US-3E0, PC228USLC-3E0 Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC228US-3E0, PC228USLC-3E0, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC228US-3E0, PC228USLC-3E0 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

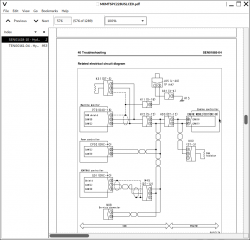

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,289 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SEN01418-10 - Hydraulic Excavator PC228US-3E0, PC228USLC-3E0 Shop Manual.pdf

TEN00161-04 - Hydraulic Excavator GALEO PC228US-3E0, PC228USLC-3E0 Operation & Maintenance Manual.pdf

MAIN SECTIONS

COVER...1

00 Index and foreword...0

Index...2

Composition of shop manual...3

Table of contents...5

Foreword and general information...14

Safety notice...15

How to read the shop manual...20

Explanation of terms for maintenance standard...22

Handling of electric equipment and hydraulic component...24

Handling of connectors newly used for engines...33

How to read electric wire code...36

Precautions when carrying out operation...39

Method of disassembling and connecting push-pull type coupler...42

Standard tightening torque table...45

Conversion table...49

01 Specification...0

Specification and technical data...56

Specification dimension drawings...57

Working range diagram...58

Specifications...59

Weight table...61

Table of fuel, coolant and lubricants...63

10 Structure, function and maintenance standard...0

Engine and cooling system...67

Engine related parts...67

Radiator, oil cooler, aftercooler and fuel cooler...68

Power train...70

Power train...71

Final drive...72

Swing machinery...74

Swing circle...76

Undercarriage and frame...78

Track frame...79

Idler...81

Carrier roller...83

Track roller...84

Track shoe...85

Hydraulic system, Part 1...91

Hydraulic equipment layout drawing...92

Hydraulic tank...94

Hydraulic pump...95

Hydraulic system, Part 2...118

Control valve...119

CLSS...131

Functions and operation by valve...135

Merge-divider valve...150

Attachment circuit selector valve...173

Hydraulic drift prevention valve...175

Hydraulic system, Part 3...182

Valve control...183

PPC valve...185

PPC Accumulator...203

Return oil filter...204

Center swivel joint...205

Travel motor...206

Swing motor...216

Hydraulic cylinder...225

Work equipment...228

Dimensions of components...231

Cab and its attachments...236

Air conditioner piping...237

Electrical system...239

Engine control...240

Electrical control system...250

Monitor system...276

Sensor...294

KOMTRAX system...297

20 Standard value table...0

Standard service value table...301

Standard value table for engine related parts...302

Standard value table for chassis...303

30 Testing and adjusting...0

Testing and adjusting, Part 1...315

Tools for testing, adjusting, and troubleshooting...317

Sketches of special tools...322

Testing engine speed...323

Testing intake air pressure (boost pressure)...324

Checking exhaust gas color...325

Adjusting valve clearance...326

Testing compression pressure...328

Testing blow-by pressure...331

Testing engine oil pressure...332

Handling fuel system parts...333

Releasing residual pressure from fuel system...333

Testing fuel pressure...334

Reduced cylinder mode operation...337

No-injection cranking...337

Testing fuel delivery, return rate and leakage...338

Bleeding air from fuel circuit...341

Checking fuel circuit for leakage...342

Checking and adjusting air conditioner compressor belt tension...343

Replacement of fan belt...344

Testing and adjusting, Part 2...347

Testing clearance in swing circle bearings...348

Checking and adjusting track shoe tension...349

Testing and adjusting hydraulic oil pressure in hydraulic circuit for work equipment, swing and travel...350

Testing control circuit oil pressure...354

Testing and adjusting pump PC control circuit oil pressure...355

Testing and adjusting pump LS control circuit oil pressure...358

Testing solenoid valve output pressure...363

Testing PPC valve output pressure...366

Adjusting play of work equipment and swing PPC valves...367

Inspection of locations of hydraulic drift of work equipment...368

Release of residual pressure from hydraulic circuit...370

Testing oil leakage...371

Bleeding air from each part...374

Procedure for replacing boom angle potentiometer...376

Inspection procedures for diode...377

Adjusting mirrors...378

Testing and adjusting, Part 3...381

Special functions of machine monitor...382

Handling voltage circuit of engine controller...410

Starting KOMTRAX terminal operations...411

Indicator lamps of KOMTRAX terminal...415

Preparation work for troubleshooting of electrical system...418

Pm-clinic service...420

40 Troubleshooting...0

Failure code table and fuse locations...427

Failure code table...428

Fuse locations...431

General information on troubleshooting...435

Points to remember when troubleshooting...436

Sequence of events in troubleshooting...437

Checks before troubleshooting...438

Classification and troubleshooting steps...439

Information in troubleshooting table...440

Possible problems and troubleshooting No...442

Connection table for connector pin numbers...445

T- branch box and T- branch adapter table...481

Troubleshooting by failure code (Display of code), Part 1...485

Failure code [AA10NX] Air cleaner Clogging...487

Failure code [AB00KE] Charge Voltage Low...488

Failure code [B@BAZG] Eng Oil Press Low...490

Failure code [B@BAZK] Eng Oil Level Low...491

Failure code [B@BCNS] Eng Water Overheat...492

Failure code [B@BCZK] Eng Water Level Low...493

Failure code [B@HANS] Hyd Oil Overheat...494

Failure code [CA111] EMC Critical Internal Failure...494

Failure code [CA115] Eng Ne and Bkup Speed Sens Error...495

Failure code [CA122] Chg Air Press Sensor High Error...496

Failure code [CA123] Chg Air Press Sensor Low Error...498

Failure code [CA131] Throttle Sensor High Error...500

Failure code [CA132] Throttle Sensor Low Error...502

Failure code [CA144] Coolant Temp Sens High Error...504

Failure code [CA145] Coolant Temp Sens Low Error...506

Failure code [CA153] Chg Air Temp Sensor High Error...508

Failure code [CA154] Chg Air Temp Sensor Low Error...510

Failure code [CA155] Chg Air Temp High Speed Derate...512

Failure code [CA187] Sens Supply 2 Volt Low Error...514

Failure code [CA221] Ambient Press Sens High Error...516

Failure code [CA222] Ambient Press Sens Low Error...518

Failure code [CA227] Sens Supply 2 Volt High Error...520

Failure code [CA234] Eng. Overspeed...521

Failure code [CA238] Ne Speed Sens Supply Volt Error...522

Failure code [CA271] IMV/PCV1 Short Error...523

Failure code [CA272] IMV/PCV1 Open Error...524

Failure code [CA322] Inj #1 (L#1) Open/Short Error...526

Failure code [CA323] Inj #5 (L#5) Open/Short Error...528

Failure code [CA324] Inj #3 (L#3) Open/Short Error...530

Failure code [CA325] Inj #6 (L#6) Open/Short Error...532

Failure code [CA331] Inj #2 (L#2) Open/Short Error...534

Failure code [CA332] Inj #4 (L#4) Open/Short Error...536

Troubleshooting by failure code (Display of code), Part 2...539

Failure code [CA342] Calibration Code Incompatibility...541

Failure code [CA351] Injectors Drive Circuit Error...542

Failure code [CA352] Sens Supply 1 Volt Low Error...544

Failure code [CA386] Sens Supply 1 Volt High Error...546

Failure code [CA428] Water in Fuel Sensor High Error...548

Failure code [CA429] Water in Fuel Sensor Low Error...550

Failure code [CA435] Eng Oil Press Sw Error...552

Failure code [CA441] Battery Voltage Low Error...553

Failure code [CA442] Battery Voltage High Error...556

Failure code [CA449] Rail Press Very High Error...558

Failure code [CA451] Rail Press Sensor High Error...560

Failure code [CA452] Rail Press Sensor Low Error...562

Failure code [CA488] Chg Air Temp High Torque Derate...564

Failure code [CA553] Rail Press High Error...564

Failure code [CA559] Rail Press Low Error...565

Failure code [CA689] Eng Ne Speed Sensor Error...567

Failure code [CA731] Eng Bkup Speed Sens Phase Error...569

Failure code [CA757] All Continuous Data Lost Error...570

Failure code [CA778] Eng Bkup Speed Sensor Error...572

Failure code [CA1633] KOMNET Datalink Timeout Error...574

Failure code [CA2185] Throt Sens Sup Volt High Error...576

Failure code [CA2186] Throt Sens Sup Volt Low Error...577

Failure code [CA2249] Rail Press Very Low Error...578

Failure code [CA2311] IMV Solenoid Error...580

Failure code [CA2555] Grid Htr Relay Volt High Error...582

Failure code [CA2556] Grid Htr Relay Volt Low Error...584

Troubleshooting by failure code (Display of code), Part 3...587

Failure code [D110KB] Battery Relay Drive Short Circuit...588

Failure code [D196KA] Service Return Relay Disc...590

Failure code [D196KB] Service Return Relay S/C...592

Failure code [DA22KK] Pump Solenoid Power Low Error...594

Failure code [DA25KP] 5V Sensor 1 Power Abnormality...596

Failure code [DA2RMC] CAN Discon (Pump Con Detected)...598

Failure code [DA2SKQ] Model Selection Abnormality...600

Failure code [DAFRMC] CAN Discon (Monitor Detected)...602

Failure code [DGH2KB] Hyd Oil Sensor Short...604

Failure code [DHPAMA] F Pump Press Sensor Abnormality...606

Failure code [DHPBMA] R Pump Press Sensor Abnormality...608

Failure code [DHSAMA] Sw RH PPC Press Sen. Abnormality...610

Failure code [DHSBMA] Sw LH PPC Press Sen. Abnormality...612

Troubleshooting by failure code (Display of code), Part 4...615

Failure code [DW43KA] Travel Speed Sol Open Circuit...618

Failure code [DW43KB] Travel Speed Sol Short Circuit...620

Failure code [DW45KA] Swing Brake Sol Open Circuit...622

Failure code [DW45KB] Swing Brake Sol Short Circuit...626

Failure code [DW91KA] Travel Junction Sol Open Circuit...628

Failure code [DW91KB] Travel Junction Sol Short Circuit...630

Failure code [DW4GKA] Boom Slow Down Sol. Disc...632

Failure code [DW4GKB] Boom Slow Down Sol. S/C...634

Failure code [DWJ0KA] Merge-divider Sol Open Circuit...636

Failure code [DWJ0KB] Merge-divider Sol Short Circuit...638

Failure code [DWK0KA] 2-stage Relief Sol Open Circuit...640

Failure code [DWK0KB] 2-stage Relief Sol Short Circuit...642

Failure code [DXA0KA] PC-EPC Sol Open Circuit...644

Failure code [DXA0KB] PC-EPC Sol Short Circuit...646

Failure code [DXE0KA] LS-EPC Sol Open Circuit...648

Failure code [DXE0KB] LS-EPC Sol Short Circuit...650