Komatsu Hydraulic Excavator PC200Z-6LE Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC200Z-6LE, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC200Z-6LE workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 948 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEBM001700 - Hydraulic Excavator PC200Z-6LE Shop Manual.pdf

CEAM001800 - Hydraulic Excavator PC200Z-6LE Operation & Maintenance Manual.pdf

SEAM021700 - Hydraulic Excavator PC200Z-6 Operation & Maintenance Manual.pdf

MAIN SECTIONS

CONTENTS

01 GENERAL. . .. . .. . .. . .. . .. . .. . ... . . . 01-1

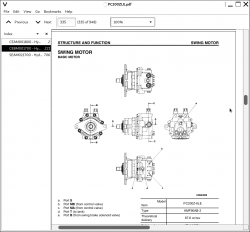

10 STRUCTURE AND FUNCTION. . .. . .. . .. . .. . . . . 10-1

20 TESTING, ADJUSTING AND TROUBLESHOOTING. . .. . . 20-1

30 DISASSEMBLY AND ASSEMBLY. . .. . .. . .. . .. . . 30-1

40 MAINTENANCE STANDARD. . .. . .. . .. . ... . . . 40-1

1. FOREWORD...2

2. SAFETY INFORMATION...3

3. INTRODUCTION...4

4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR...5

5. CONTENTS...6

SAFETY...10

6. GENERAL PRECAUTIONS ...11

7. PRECAUTIONS DURING OPERATION ...19

7.1 BEFORE STARTING ENGINE ...19

7.2 AFTER STARTING ENGINE ...21

7.3 TRANSPORTATION ...28

7.4 BATTERY ...29

7.5 TOWING ...31

7.6 LIFTING OPERATIONS ...31

7.7 BUCKET WITH HOOK...32

8. PRECAUTIONS FOR MAINTENANCE ...34

8.1 BEFORE CARRYING OUT MAINTENANCE ...34

8.2 DURING MAINTENANCE ...38

9. POSITION FOR ATTACHING SAFETY LABELS ...44

OPERATION...48

10. GENERAL VIEW ...49

10.1 GENERAL VIEW OF MACHINE ...49

10.2 GENERAL VIEW OF CONTROLS AND GAUGES ...50

11. EXPLANATION OF COMPONENTS ...51

11.1 MACHINE MONITOR ...51

11.2 SWITCHES ...56

11.3 CONTROL LEVERS AND PEDALS ...60

11.4 CEILING WINDOW ...65

11.5 FRONT WINDOW ...66

11.6 DOOR LOCK ...68

11.7 ASHTRAY ...68

11.8 CAP, COVER WITH LOCK ...69

11.9 HANDLING CAR HEATER ...70

11.10 FUSE ...71

11.11 FUSIBLE LINK ...72

11.12 TOOL BOX ...72

11.13 GREASE PUMP HOLDER ...72

11.14 HANDLING ACCUMULATOR ...73

12. OPERATION ...74

12.1 CHECK BEFORE STARTING ENGINE ...74

12.2 STARTING ENGINE ...84

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE ...86

12.4 MOVING MACHINE OFF ...88

12.5 STEERING MACHINE ...91

12.6 STOPPING MACHINE ...93

12.7 SWINGING...94

12.8 OPERATION OF WORK EQUIPMENT ...95

12.9 PROHIBITIONS FOR OPERATION ...96

12.10 PRECAUTIONS FOR OPERATION ...98

12.11 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS ...99

12.12 HOW TO ESCAPE FROM MUD ...101

12.13 WORK POSSIBLE USING HYDRAULIC EXCAVATOR ...102

12.14 REPLACEMENT AND INVERSION OF BUCKET ...103

12.15 PARKING MACHINE ...105

12.16 CHECK AFTER FINISHING WORK...106

12.17 STOPPING ENGINE ...107

12.18 CHECK AFTER STOPPING ENGINE ...108

12.19 LOCKING ...108

13. TRANSPORTATION ...109

13.1 LOADING, UNLOADING WORK ...109

13.2 PRECAUTIONS FOR LOADING ...111

13.3 PRECAUTIONS FOR TRANSPORTATION ...112

14. COLD WEATHER OPERATION ...113

14.1 PRECAUTIONS FOR LOW TEMPERATURE ...113

14.2 PRECAUTIONS AFTER COMPLETION OF WORK...115

14.3 AFTER COLD WEATHER ...115

15. LONG-TERM STORAGE ...116

15.1 BEFORE STORAGE ...116

15.2 DURING STORAGE ...117

15.3 AFTER STORAGE ...117

15.4 STARTING MACHINE AFTER LONG-TERM STORAGE ...117

16. TROUBLESHOOTING ...118

16.1 PHENOMENA THAT ARE NOT FAILURES ...118

16.2 METHOD OF TOWING MACHINE...118

16.3 USING METHOD FOR LIGHT-WEIGHT TOWING HOLE ...118

16.4 PRECAUTIONS ON PARTICULAR JOBSITES ...119

16.5 IF BATTERY IS DISCHARGED ...119

16.6 OTHER TROUBLE ...123

MAINTENANCE...127

17. GUIDES TO MAINTENANCE ...128

18. OUTLINES OF SERVICE ...131

18.1 OUTLINE OF OIL, FUEL, COOLANT ...131

18.2 OUTLINE OF ELECTRIC SYSTEM ...134

18.3 OUTLINE OF HYDRAULIC SYSTEM ...135

19. WEAR PARTS LIST ...136

20. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE ...137

21. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS...142

21.1 INTRODUCTION OF NECESSARY TOOLS ...142

21.2 TORQUE LIST...143

22. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS ...144

23. MAINTENANCE SCHEDULE CHART ...148

23.1 MAINTENANCE SCHEDULE CHART ...148

23.2 MAINTENANCE INTERVAL WHEN USING HYDRAULIC BREAKER ...150

24. SERVICE PROCEDURE ...151

24.1 INITIAL 250 HOURS SERVICE ...151

24.2 WHEN REQUIRED ...152

24.3 CHECK BEFORE STARTING ...171

24.4 EVERY 100 HOURS SERVICE ...176

24.5 EVERY 250 HOURS SERVICE ...179

24.6 EVERY 500 HOURS SERVICE ...185

24.7 EVERY 1000 HOURS SERVICE ...190

24.8 EVERY 2000 HOURS SERVICE ...193

24.9 EVERY 4000 HOURS SERVICE ...196

24.10 EVERY 5000 HOURS SERVICE ...197

SPECIFICATIONS...202

25. SPECIFICATIONS ...203

OPTIONS, ATTACHMENTS...208

26. GENERAL PRECAUTIONS ...209

26.1 PRECAUTIONS RELATED TO SAFETY ...209

26.2 PRECAUTIONS WHEN INSTALLING ATTACHMENTS ...210

27. HANDLING BUCKET WITH HOOK ...211

27.1 CHECKING FOR DAMAGE TO BUCKET WITH HOOK...211

27.2 PROHIBITED OPERATIONS ...211

27.3 PRECAUTIONS DURING OPERATIONS ...211

28. AIR CONDITIONER (MACHINES EQUIPPED WITH AIR CONDITIONER) ...212

28.1 AIR CONDITIONER ...212

29. MACHINES READY FOR ATTACHMENTS ...215

29.1 EXPLANATION OF COMPONENTS ...215

29.2 HYDRAULIC CIRCUIT ...217

29.3 ATTACHMENT MOUNTING/DISMOUNTING PROCEDURE ...219

29.4 OPERATION ...221

29.5 LONG-TERM STORAGE ...222

29.6 SPECIFICATIONS ...222

30. INTRODUCTION OF ATTACHMENTS ...223

30.1 BUCKET SELECTION ...223

30.2 BUCKET INSTALLATION COMBINATIONS ...223

30.3 BACKHOE CONTROL PATTERN CONVERSION ...225

30.4 SELECTION OF TRACK SHOES ...226

30.5 HANDLING RUBBER PAD SHOE ...227

30.6 HANDLING TRAPEZOIDAL BUCKET ...229

30.7 HANDLING EXTENSION ARM ...230

30.8 HANDLING CLAMSHELL BUCKET ...231

31. EXTENDING MACHINE SERVICE LIFE ...232

31.1 HYDRAULIC BREAKER ...232

31.2 POWER RIPPER ...235

31.3 FORK GRAB ...236

31.4 GRAPPLE BUCKET ...237

31.5 SCRAP GRAPPLE ...238

31.6 CRUSHER & CUTTER ...239

31.7 HYDRAULIC PILE DRIVER ...240

31.8 HYDRAULIC EXCAVATOR WITH MULTI-PURPOSE CRANE ...241