Komatsu Hydraulic Excavator PC200LL, PC220LL Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC200LL-8, PC220LL-8, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC200LL-8, PC220LL-8 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEBM001505 - Hydraulic Excavator PC200LL-8, PC220LL-8 Shop Manual.pdf

SERIAL NUMBERS PC200LL-8 A87001 and up; PC220LL-8 A87001 and up

ENGINE 6D107E-1

MAIN SECTIONS

COVER PC200LL/220LL-8...0

CONTENTS...2

00 FOREWORD...15

SAFETY...15

Safety Notice...15

Important Safety Notice...15

General Precautions...15

Preparations For Work...15

Precautions During Work...15

GENERAL...18

HOW TO READ THE SHOP MANUAL...19

Volumes...19

Distribution And Updating...19

Filing Method...19

Revised Edition Mark...19

Revisions...19

Symbols...19

HOISTING INSTRUCTIONS...20

Hoisting...20

Wire Ropes...20

HANDLING ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENTS...21

Points To Remember When Handling Electric Equipment...21

Points To Remember When Handling Hydraulic Equipment...27

PUSH PULL COUPLER...29

Type 1...29

Disconnection...29

Connection...29

Type 2...30

Disconnection...30

Connection...30

Type 3...31

Disconnection...31

Connection...31

EXPLANATION OF MAINTENANCE STANDARD TERMS...32

STANDARD TIGHTENING TORQUE...34

Bolts And Nuts...34

Tightening Torque Of Hose Nuts...35

Tightening Torque Of Split Flange Bolts...35

Tightening Torque For Flared Nuts...35

Tightening Torques For O-ring Boss Piping Joints...36

Table Of Tightening Torques For O-ring Boss Plugs...36

Torque Table For Hoses (Taper Seal Type And Face Seal Type)...36

ELECTRIC WIRE CODE...37

Classification By Thickness...37

Classification By Color And Code...37

How To Read Electric Wire Code...38

CONVERSION TABLES...41

Method Of Using The Conversion Table...41

COATING MATERIALS...47

01 GENERAL...49

SPECIFICATIONS...50

Dimensions PC200LL-8...50

Road Builder...50

Log Loader - 36 Ft Komatsu Forest Front...50

Dimensions PC220LL-8...52

Road Builder...52

Log Loader - 38 Ft Komatsu Forest Front...52

Working Ranges...54

Road Builder...54

PC200LL-8 Log Loader - 36 Ft Komatsu Forest Front...55

PC220LL-8 Log Loader - 38 Ft Komatsu Forest Front...55

Specifications PC200LL-8...56

Specifications PC220LL-8...58

WEIGHT TABLE...61

PC200LL-8...61

PC220LL-8...63

FUEL, COOLANT, AND LUBRICANTS...65

Recommended Brands, Recommended Quality for Products Other Than Komatsu Genuine Oil...67

10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD...69

ENGINE AND COOLING SYSTEM...74

Engine Related Parts...74

Radiator, Oil Cooler, Aftercooler, and Fuel Cooler...75

Specifications...75

POWER TRAIN...76

Power Train...76

FINAL DRIVE...78

PC200LL-8...78

Specifications...79

PC220LL-8...80

Specification...81

SWING MACHINERY...82

PC200LL-8...82

Specifications...83

PC220LL-8...84

Specifications...85

SWING CIRCLE...86

PC200LL-8...86

Specifications...86

PC220LL-8...88

Specifications...88

UNDERCARRIAGE AND FRAME...90

Track Frame and Recoil Spring...90

Standard Shoe...91

PC200LL-8...91

PC220LL-8...91

Idler...92

PC200LL-8...92

PC220LL-8...94

TRACK AND CARRIER ROLLER...96

PC200LL-8...96

PC220LL-8...97

TRACK SHOES...98

PC200LL-8...98

PC220LL-8...102

Double Grouser Shoe...104

PC200LL-8...104

PC220LL-8...104

Triple Grouser Shoe...105

PC200LL-8...105

PC220LL-8...105

HYDRAULIC SYSTEM...106

Hydraulic Equipment Layout...106

Hydraulic Tank and Filter...108

Specifications...108

Hydraulic Pump...110

Type: HPV95+95...110

LS valve...116

PC valve...121

LS (PC)-EPC valve...129

Pilot Oil Filter...132

Control Valve...134

General View...135

Sectional View (1/5)...138

Sectional View (2/5)...140

Sectional View (3/5)...142

Sectional View (4/5)...144

Sectional View (5/5)...146

CLSS...148

Outline Of CLSS...148

Functions and Operation by Valve...152

Hydraulic Circuit Diagram and the Name of Valves...152

Unload Valve...154

Introduction of LS Pressure...156

LS By-pass Plug...157

Pressure Compensation Valve...158

Pressure Compensation Valve Inner Shuttle Valve...161

Boom Regeneration Circuit...163

Arm Regeneration Circuit...165

Merge-Divider Valve...167

LS Select Valve...169

Self Pressure Reducing Valve...170

Travel Junction Valve...174

Travel PPC Shuttle Valve...177

Boom Drift Prevention Valve...179

Arm Drift Prevention Valve...182

Quick Return Valve...186

Lift Check Valve...188

Main Relief Valve...189

Swing Motor...191

PC200LL-8 Type: KMF125ABE-6...191

PC220LL-8 Type: KMF230ABE-5...195

Swing Holding Brake...198

Relief Valve Portion...199

Reverse Prevention Valve...200

Center Swivel Joint...204

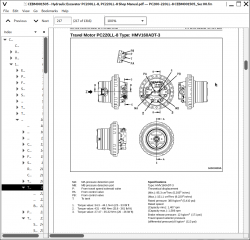

Travel Motor PC200LL-8 Type: HMV110ADT-3...206

Operation of motor...210

Operation of Parking Brake...212

Brake Valve...214

Travel Motor PC220LL-8 Type: HMV160ADT-3...217

Operation of Motor...220

Operation of Parking Brake...222

Brake Valve...224

PPC Valve...229

Work Equipment and Swing PPC Valve...229

Travel PPC Valve...235

Service PPC Valve (with EPC Valve)...244

Service Valve (Straight Travel Option)...250

Valve Control...252

Solenoid Valve...254

Attachment Solenoid Valve...256

PPC Accumulator...258

CRN (Canadian certified) PPC Accumulator...258

Return Oil Filter...259

Hydraulic Cylinder - Road Builder PC200LL-8...260

Boom Cylinder...260

Arm Cylinder...260

Bucket Cylinder...260

Hydraulic Cylinders - Log Loader PC200LL-8...262

Boom Cylinder...262

Arm Cylinder...262

Heel Cylinder...262

Hydraulic Cylinder - Road Builder PC220LL-8...264

Boom Cylinder...264

Arm Cylinder...264

Bucket Cylinder...264

Hydraulic Cylinders - Log Loader PC220LL-8...266

Boom Cylinder...266

Arm Cylinder...266

Heel Cylinder...266

WORK EQUIPMENT...268

Dimensions of Components...268

PC200LL-8...269

PC220LL-8...270

Arm...272

Bucket...274

CAB AND ITS ATTACHMENTS...276

Air Conditioner Piping...276

ELECTRICAL SYSTEM...277

Engine Control...277

Fuel Control Dial...278

Engine Controller...279

CN-CE01...280

CN-CE02...281

CN-CE03...282

Coolant Temperature Sensor...283

Oil Pressure Switch...283

Rotation Sensor...284

Boost Pressure and Temperature Sensor...284

WIF (Water-In-Fuel Detection) Sensor...285

Engine Oil Level Sensor...285

ELECTRICAL CONTROL SYSTEM...286

Machine Control System Diagram...286

Engine and Pump Composite Control Function...288

Pump and Valve Control Function...292

Power Maximizing Function...294

Auto-deceleration Function...295

Auto-warm-up and Overheat Prevention Function...296

Swing Control Function...299

Swing Control Function with Soft Swing (Option)...301

Travel Control Function...303

System Component Parts...305

MONITOR SYSTEM...311

Machine Monitor...312

Input And Output Signals...313

Monitor Control, Display Portion...317

Monitor Items and Display...319

Switches...323

Buzzer Cancel Switch...323

Auto-deceleration Switch...323

Guidance Icon and Function Switch...324

Working Mode Selector Switch...325

Travel Speed Selector Switch...326

Window Washer Switch...326

Wiper Switch...326

Air Conditioner Control Switch...327

Camera Screen Display Function...328

Service Meter/Time Selector Function...329

Maintenance Function...330

User Mode...332

Breaker/Attachment Setting...332

Changing Breaker Mode Setting...333

Changing Attachment Mode Setting...335

Message Display...337

Screen Adjustment...337

Clock Adjustment...338

Language Setting...339

Economy Mode Adjustment...339

Idle Stop Guidance Function...340

Service Meter Check Function...340

Display LCD Check Function...341

User Code/Failure Code Display Function...342

SENSORS...343

Fuel Level Sensor...343

Air Cleaner Clogging Sensor...344

Coolant Level Sensor...344

KOMTRAX TERMINAL SYSTEM...345

Komtrax Communication Orbcomm...346

20 STANDARD VALUE TABLES...349

STANDARD SERVICE VALUE TABLE...350

Engine Related Parts...350

PC200LL-8...350

PC220LL-8...351

Chassis Related Parts...352

PC200LL-8...352

PC220LL-8...359

MACHINE POSTURE...367

Measuring Performance And Measurement Procedure...367

Control Valve: Spool Stroke...367

Swing 1: Swing Brake Angle, Time Taken To Start Swing, Time Taken To Swing...367

Swing 2: Hydraulic Drift Of Swing...367

Travel 1: Travel Speed (Without Load)...367

Travel 2: Travel Speed (Actual Run), Travel Deviation...368

Travel 3: Travel Deviation...368

Travel 4: Hydraulic Drift Of Travel...368

Work Equipment 1: Hydraulic Drift Of Work Equipment...368

Work Equipment 2: Boom Speed...369

Work Equipment 3: Arm Speed...369

Work Equipment 4: Bucket Speed...369

Work Equipment 5: Boom Time Lag...369

Work Equipment 6: Arm Time Lag...370

Work Equipment 7: Bucket Time Lag...370

30 TESTING AND ADJUSTING...371