Komatsu 170 Series Engine Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu 170-3, 170E-5, 8V170-1, 12V170-1, 12V170-2, 6D170-1, 6D170-2 Series Engines, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu 170-3, 170E-5, 8V170-1, 12V170-1, 12V170-2, 6D170-1, 6D170-2 Series Engines workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 3,907 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SEBD6161A16 - 6D170-1 Series Diesel Engine Shop Manual.pdf

SEBD61700104 - 8V170-1 Series Diesel Engine Shop Manual.pdf

SEBD61800104 - 12V170-1 Series Diesel Engine Shop Manual.pdf

SEBE61800105 - 12V170-1 Series Engine Shop Manual.pdf

SEBES6161000 - 6D170-1 Series Diesel Engine Shop Manual.pdf

SEBM008107 - 6D170-2 Series Diesel Engine Shop Manual.pdf

SEBM023407 - 170-3 Series Diesel Engine Shop Manual.pdf

SEBM023412 - 170-3 Series (QSK23) Diesel Engine Shop Manual.pdf

SEBM036601 - 12V170-2 Series Engine Shop Manual.pdf

SEN00190-13 - 170E-5 Series Engine Shop Manual.pdf

MAIN SECTIONS

COVER...1

CONTENTS...2

01 GENERAL...25

APPLICABLE MACHINE...26

SPECIFICATIONS...28

OVERALL DRAWING...32

WEIGHT TABLE...52

ENGINE PERFORMANCE CURVE...53

11 STRUCTURE AND FUNCTION...61

INTAKE AND EXHAUST SYSTEM...62

AIR CLEANER...62

TURBOCHARGER...65

AFTER COOLER...70

ENGINE BODY...72

CYLINDER HEAD...72

CYLINDER BLOCK...74

MAIN CIRCULATION SYSTEM...76

FLYWHEEL AND FLYWHEEL HOUSING...78

VIBRATION DAMPER...79

GEAR TRAIN...80

TIMING GEAR...81

VALVE SYSTEM...82

LUBRICATION SYSTEM...84

LUBRICATION SYSTEM DIAGRAM...84

OIL PUMP...85

OIL FILTER, SAFETY VALVE...87

OIL COOLER...88

FUEL SYSTEM ...89

FUEL SYSTEM DIAGRAM...89

ENGINE CONTROLLER CONTROL SYSTEM...91

FUEL PUMP PRESSURE CONTROL CIRCUIT...94

FUEL PUMP...95

INJECTOR...99

HPI FUEL INJECTION SYSTEM...100

FUEL COOLER...101

FUEL FILTER...102

COOLING SYSTEM...103

COLING SYSTEM DIAGRAM...103

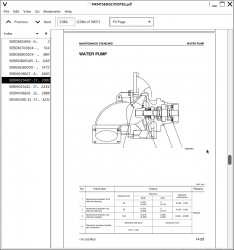

WATER PUMP...104

THERMOSTAT...105

FAN, TENSION PULLEY...106

ELECTRICAL EQUIPMENT...110

ALTERNATOR...110

STARTING MOTOR...116

STARTING AID...118

12 TESTING AND ADJUSTING...122

STANDARD VALUE TABLE FOR TROULESHOOTING...123

STANDARD VALUE TABLE FOR ELECTRICAL PARTS...128

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING...131

MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)...133

MEASURING EXHAUSTTEMPERATURE (OVERALL ENGINE)...133

TROUBLESHOOTING FOR INJECTOR...134

ADJUSTING VALVE CLEARANCE...135

ADJUSTING INJECTOR SET LOAD...136

MEASURING COMPRESSION PRESSURE...137

MEASURING BLOW-BY PRESSURE...138

MEASURING OIL PRESSURE...139

HANDLING EQUIPMENT IN FUEL CIRCUIT...139

MEASRING FUEL CICUIT PRESSURE...140

VIDUAL INSPECTION OF RETURN FUEL...141

BLEEDING AIR FROM FUEL CIRCUIT...142

ADJUSTING SPEED SENSOR...143

REPLACING AND ADJUSTING FAN BELT...144

TESTING AND ADJUSTING ALTERNATOR BELT TENSION...146

PRECAUTIONS WHEN OPERATION ENGINE AS AN INDVIDUAL PART...147

ARRANGEMENT OF CONTROL DEVICES AND ELECTRIC CIRCUIT FOR HPI...148

RUN-IN STANDARD...151

PERFORMANCE TEST STANDARDS...152

TROUBLESHOOTING OF MECHANICAL SYSTEM (S MODE)...157

POINTS TO REMEMBER WHEN TROUBLESHOOTING...158

METHOD OF USING TROUBLESHOOTING CHARTS...159

S-1 STARTING PERFORMANCE IS POOR (STARING ALWAYS TAKES TIME)...162

S-2 ENGINE DOES NOT START...164

a) ENGINE DOES NOT TURN...164

b) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)...165

c) EXHAUST SMOKE COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)...167

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)...169

S-4 ENGINE STOPS DURING OPERATIONS...171

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)...173

S-6 ENGINE LACKS OUTPUT (NO LACKS POWER)...175

S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION)...177

S-8 OIL COMSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)...179

S-9 OIL BECOMES CONTAMINATED QUICKLY...180

S-10 FUEL CONSUMPTION IS EXCESSIVE...181

S-11 OIL IS COOLING WATER,OR WATER SPURTS BACK,OR WATER LEVEL GOES DOWN...182

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)...183

S-13 OIL LEVEL RISES...184

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)...185

S-15 ABNORMAL NOISE IS MADE...186

S-16 VIBRATION IS EXCESSIVE...187

TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM OF ENGINE FOR CONSTRUCTION EQUIPMENT (EA MODE)...188

POINTS TO REMEMBER WHEN TROUBLESHOOTING...190

METHOD OF USING TROUBLESHOOTING CHARTS...192

ERROR CODE DISPLAY AND POINTS TO REMEMBER WHEN TROUBLESHOOTING...193

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED...197

EA-1 ERROR CODE [111] (ABNORMALITY IN CONTROLLER MEMORY)...207

EA-2 ERROR CODE [112] (ABNORMALITY IN TIMING RAIL ACTUATOR)...207

EA-3 ERROR CODE [113] (ABNORMALITY WITH ELECTRIC CURRENT IN TIMING RAIL ACTUATOR SYSTEM)...208

EA-4 ERROR CODE [115] (ABNORMALITY IN ENGINE SPEED SENSOR 2 SYSTEM)...209

EA-5 ERROR CODE [116] (ABNORMALITY IN TIMING RAIL PRESSURE SENSOR SYSTEM HIGH LEVEL)...211

EA-6 ERROR CODE [117] (ABNORMALITY IN TIMING RAIL PRESSURE SENSOR SYSTEM LOW LEVEL)...212

EA-7 ERROR CODE [118] (ABNORMALITY IN FUEL PUMP PRESSURE SENSOR SYSTEM HIGH LEVEL)...213

EA-8 ERROR CODE [119] (ABNORMALITY IN FUEL PUMP PRESSURE SENSOR SYSTEM LOW LEVEL)...214

EA-9 ERROR CODE [121] (ABNORMALITY IN ENGINE SPEED SENSOR 1 SYSTEM)...215

EA-10 ERROR CODE [122] (ABNORMALITY IN BOOST PRESSURE SENSOR SYSTEM HIGH LEVEL)...216

EA-11 ERROR CODE [123] (ABNORMALITY IN BOOST PRESSURE SENSOR SYSTEM LOW LEVEL)...217

EA-12 ERROR CODE [131] (ABNORMALITY IN THROTTLE SENSOR SYSTEM HIGH LEVEL)...218

EA-13 ERROR CODE [132] (ABNORMALITY IN THROTTLE SENSOR SYSTEM LOW LEVEL)...219

EA-14 ERROR CODE [133] (ABNORMALITY IN REMOTE THROTTLE SENSOR SYSTEM HIHG LEVEL)...219

EA-15 ERROR CODE [134] (ABNORMALITY IN REMOTE THROTTLE SENSOR SYSTEM LOW LEVEL)...220

EA-16 ERROR CODE [135] (ABNORMALITY IN OIL PRESSURE SENSOR SYSTEM HIGH LEVEL)...221

EA-17 ERROR CODE [141] (ABNORMALITY IN OIL PRESSURE SENSOR SYSTEM LOW LEVEL)...222

EA-18 ERROR CODE [143] (ABNORMAL DROP IN OIL PRESSURE (LEVEL 1))...223

EA-19 ERROR CODE [144] (ABNORMALITY IN WATER TEMPERATURE SENSOR SYSTEM HIGH LEVEL)...224

EA-20 ERROR CODE [145] (ABNORMALITY IN WATER TEMPERATURE SENSOR SYSTEM LOW LEVEL)...225

EA-21 ERROR CODE [151] (ABNORMALITY RISE IN WATER TEMPERATURE)...225

EA-22 ERROR CODE [153] (ABNORMALITY IN INTAKE AIR TEMPERATURE SENSOR SYSTEM HIGH LEVEL)...226

EA-23 ERROR CODE [154] (ABNORMALITY IN INTAKE AIR TEMERATURE SENSOR SYSTEM LOW LEVEL)...226

EA-24 ERROR CODE [221] (ABNORMALITY IN ATMOSPHERIC PRESSURE SENSOR SYSTEM HIGH LEVEL)...227

EA-25 ERROR CODE [222] (ABNORMALITY IN ATMOSPHERIC PRESSURE SENSOR SYSTEM LOW)...228

EA-26 ERROR CODE [234] (OVERSPEED)...229

EA-27 ERROR CODE [254] (ABNORMALITY IN FUEL SHUT-OFF VALVE SYSTEM VOLTAGE)...230

EA-28 ERROR CODE [259] (ABNORMALITY IN FUEL SHUT-OFF VALVE)...231

EA-29 ERROR CODE [261] (ABNORMAL RISE IN FUEL TEMPERATURE)...231

EA-30 ERROR CODE [263] (ABNORMALITY IN FUEL TEMPERATURE SENSOR SYSTEM HIGH LEVEL)...232

EA-31 ERROR CODE [265] (ABNORMALITY IN FUEL TEMPERATURE SENSOR SYSTEM LOW LEVEL)...232

EA-32 ERROR CODE [316] (ABNORMALITY IN FUEL PUMP ACTUATOR SYSTEM CURRENT)...233

EA-33 ERROR CODE [318] (ABNORMALITY IN FUEL PUMP ACTUATOR)...234

EA-34 ERROR CODE [343] (ABNORMALITY IN CONTROLLER INTERNAL COMMUNICATION)...235

EA-35 ERROR CODE [346] (ABNORMALITY IN CONTROLLER POWER DOWN)...235

EA-36 ERROR CODE [384] (ABNORMALITY IN PREHEATING HEATER CONTROL SYSTEM)...237

EA-37 ERROR CODE [415] (ABNORMAL DROP IN OIL PRESSURE (LEVEL 2))...237

EA-38 ERROR CODE [423] (ABNORMALITY IN TIMING RAIL PRESSURE SENSOR SYSTEM IN RANGE)...238

EA-39 ERROR CODE [431] (ABNORMALITY 1 IN IDLING VALIDATION SWITCH SYSTEM)...240

EA-40 ERROR CODE [432] (IDLING VALIDATION PROCESS ERROR)...241

EA-41 ERROR CODE [441] (ABNORMALITY IN BATTERY VOLTAGE LOW LEVEL)...242

EA-42 ERROR CODE [442] (ABNORMALITY IN BATTERY VOLTAGE HIGH LEVEL)...242

EA-43 ERROR CODE [451] (ABNORMALITY IN FUEL RAIL PRESSURE SENSOR SYSTEM HIGH LEVEL)...243

EA-44 ERROR CODE [452] (ABNORMALITY IN FUEL RAIL PRESSURE SENSOR SYSTEM LOW LEVEL)...244

EA-45 ERROR CODE [455] (ABNORMALITY IN FUEL RAIL ACTUATOR SYSTEM CURRENT)...245

EA-46 ERROR CODE [467] (ABNORMALITY IN TIMING RAIL ACTUATOR CONTROL)...246

EA-47 ERROR CODE [468] (ABNORMALITY IN FUEL RAIL ACTUATOR CONTROL)...246

EA-48 ERROR CODE [514] (ABNORMALITY IN FUEL RAIL ACTUATOR)...246

EA-49 ERROR CODE [527] (ABNORMALITY IN DUAL OUTPUT SOLENOID A SYSTEM)...247

EA-50 ERROR CODE [529] (ABNORMALITY IN DUAL OUTPUT SOLENOID B SYSTEM)...248

EA-51 ERROR CODE [551] (ABNORMALITY 2 IN IDLING VALIDATION SWITCH SYSTEM)...248

EA-52 ERROR CODE [554] (ABNORMALITY IN FUEL RAIL PRESSURE SENSOR IN RANGE)...249

TROUBLESHOOTING OF CONTROLLER SYSTEM OF ENGING FOR GENERATOR EQUIPMENT...251

POINTS TO REMEMBER WHEN TROUBLESHOOTING...252

METHOD OF USING TROUBLESHOOTING CHARTS...254

ERROR CODE DISPLAY AND POINTS TO REMEMBER WHEN TROUBLESHOOTING...255

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED...258

EB-1 ERROR CODE [E-10] (ABNORMALITY IN POWER SOURCE VOLTAGE SYSTEM)...266

EB-2 ERROR CODE [E-16] (ABNORMALITY IN FUEL SHUT-OFF VALVE SYSTEM VOLTAGE)...267

EB-3 ERROR CODE [E-1b] (ABNORMALITY IN ENGING SPEED SENSOR A SYSTEM)...268

EB-4 ERROR CODE [E-1C] (ABNORMALITY IN ENGINE SPEED SENSOR B SYSTEM)...269

EB-5 ERROR CODE [E-21] (MISTAKEN OF CONNECTION OF WIRING HARNESS CONNECTOR)...270

EB-6 ERROR CODE [E-22] (OVERRUN)...271

EB-7 ERROR CODE [E-23] (OVERHEAT)...271

EB-9 ERROR CODE [E-34] (ABNORMALITY IN COOLANT TEMPERATURE SENSOR SYSTEM)...273

EB-10 ERROR CODE [E-56] (ABNORMALITY IN SOLENOID POWER SOURCE 1 SYSTEM)...274

EB-11 ERROR CODE [E-57] (ABNORMALITY IN SOLENOID POWER SOURCE 2 SYSTEM)...275

EB-12 ERROR CODE [E-58] (ABNORMALITY IN BACKUP POWER SOURCE SYSTEM)...276

EB-13 ERROR CODE [E-59] (ABNORMALITY IN SWITCH POWER SOURCE SYSTEM)...277

EB-14 ERROR CODE [E-70] (ABNORMALITY IN FUEL RAIL PRESSURE SENSOR SYSTEM HIGH LEVEL)...278

EB-15 ERROR CODE [E-71] (ABNORMALITY IN FUEL RAIL PRESSURE SENSOR SYSTEM LOE LEVEL)...279

EB-16 ERROR CODE [E-72] (ABNORMALITY IN FUEL RAIL PRESSURE SENSOR SYSTEM IN RANGE)...280

EB-17 ERROR CODE [E-73] (ABNORMALITY IN FUEL RAIL ACTUATOR)...281

EB-18 ERROR CODE [E-75] (ABNORMALITY WITH ELECTRIC CURRENT IN FUEL RAIL ACTUATOR SYSTEM)...282

EB-19 ERROR CODE [E-80] (ABNORMALITY IN TIMING RAIL PRESSURE SENSOR SYSTEM HIGH LEVEL)...284

EB-20 ERROR CODE [E-81] (ABNORMALITY IN TMING RAIL PRESSURE SENSOR SYSTEM LOW LEVEL)...285

EB-21 ERROR CODE [E-82] (ABNORMALITY IN TIMING RAIL PRESSURE SRNSOR SYSTEM IN RANGE)...286

EB-22 ERROR CODE [E-83] (ABNORMALITY IN TIMING RAIL ACTUATOR)...288

EB-23 ERROR CODE [E-85] (ABNORMALITY WITH ELECTRIC CURRENT IN TIMING RAIL ACTUATOR SYATEM)...289

EB-24 ERROR CODE [E-90] (ABNORMALITY IN FUEL PUMP PRESSURE SENSOR SYSTEM HIGH LEVEL)...290

EB-25 ERROR CODE [E-91] (ABNORMALITY IN FUEL PUMP PRESSURE SENSOR SYSTEM LOW LEVEL)...291

EB-26 ERROR CODE [E-93] (ABNORMALITY IN FUEL PUMP ACTUATOR)...292

EB-27 ERROR CODE [E-95] (ABNORMALITY WITH ELECTRIC CURRENT IN FUEL PUMP ACTUATOR SYSTEM)...293

EB-28 ERROR CODE [E-A0] (ABNORMALITY IN FUEL SHUT-OFF VALVE)...294

EB-29 ERROR CODE [E-A1] (ABNORMALITY IN STARTING SWITCH ON SIGNAL SYSTEM)...295

EB-30 ERROR CODE [E-A2] (ABNORMALITY IN POWER SOURCE RETENTION RELAY SYSTEM)...296

EB-31 ERROR CODE [E-A3] (ABNORMALITY IN EMERGENCY STOP SIGNAL INPUT)...297

EB-32 ERROR CODE [E-b0] (ABNORMALITY IN ATMOSPHERIC PRESSURE SENSOR SYSTEM HIGH LEVEL)...298

EB-33 ERROR CODE [E-b1] (ABNORMALITY IN ATMOSPHERIC PRESSUER SENSOR SYSTEM LOW LEVEL)...299

EB-34 ERROR CODE [E-b2] (ABNORMALITY IN BOOST AIR PRESSURE SENSOR SYSTEM HIGH LEVEL)...300

EB-35 ERROR CODE [E-b3] (ABNORMALITY IN BOOST AIR PRESSURE SENSOR SYSTEM LOW LEVEL)...301

EB-36 ERROR CODE [E-b4] (ABNORMALITY IN BOOST AIR PRESSURE SENSOR SYSTEM IN RANGE)...302

EB-37 ERROR CODE [E-b6] (ABNORMALITY IN DROOP ADJUSTMENT VOLUME SYSTEM)...302

EB-38 ERROR CODE [E-b7] (ABNORMALITY IN RATED SPEED ADJUSTMENT VOLUME SYSTEM)...304

EB-39 ERROR CODE [E-b8] (ABNORMALITY IN LI SPEED ADJUSTMENT VOLUME SYSTEM)...306

EB-40 ERROR CODE [E-b9] (ABNORMALITY IN LAMP IME ADJUSTMENT VOLUME SYSTEM)...308

EB-41 ERROR CODE [E-bA] (ABNORMALITY IN P CONSTANT ADJUSTMENT VOLUME SYSTEM)...310

EB-42 ERROR CODE [E-bb] (ABNORMALITY I CONSTANT ADJUSTMENT VOLUME SYSTEM)...312

EB-43 ERROR CODE [E-bC] (ABNORMALITY IN D CONSTANT ADJUSTMENT VOLUME SYSTEM)...314

EB-44 ERROR CODE [E-bd] (ABNORMALITY IN FUEL TEMPERATURE SENSOR SYSTEM)...316

EB-45 ERROR CODE [E-bE] (ABNORMALITY RISE IN FUEL TEMPERATURE)...317

13 DISASSEMBLY AND ASSEMBLY...318

METHOD OF USING MANUAL...319

PRECAUTIONS WHEN CARRYING OUT OPERATION...320

SPECIAL TOOL LIST...322

DISASSEMBLY OF ENGINE...324

WASHING PARTS...370

MEASURING PARTS...371

14 MAINTENANCE STANDARD...376

NTAKE AND EXHAUST SYSTEM...377

TURBOCHARGER...377

ENGINE BODY...383

CYLINDER HEAD...383

VALVE, VALVE GUIDE...384

CROSSHAD AND CROSSHEAD GUIDE...385

TAPPET AND PUSH ROD...386

ROCKERR ARM...388

CYLINDER BLOCK...390

CYLINDRE LINER...392

CRANKSHAFT...393

CAMSHAFT...395

GEAR TRAIN...396

TIMING GEAR...398

PISTON, PISTON RING, PISTON PIN...400

CONNECTING ROD...401

LUBRICATION SYSTEM...402

OIL PUMP...402

OIL COOLER...404

COOLING SYSTEM...405

WATER PUMP...405

THERMOSTAT...406

15 REPAIR AND REPLACEMENT OF PARTS...407

TABLE OF SPECIAL TOOLS...408

TESTING AND INSPECTING CYINDER HEAD...409

REPAIRING MOUNTING FACE OF CYLINDER HEAD BY GRINDING...412

REPLACING VALVE SEAT INSERTS...413

PRESSURE TEST METHOD...418

REPLACING VALVE GUIDE...419

REPLACING CROSS HEAD GUIDE...420

GRINDING VALVE...421

TESTING AND INSPECTING CYLINDER BLOCK...422

GRINDING THE TOP SURFACE OF CYLINDER BLOCK...425

REPLACING MAIN BEARING CAP...431

REPLACING CAM BUSHING...433

TESTING AND INSPECTING CRANKSHAFT...435

CORRECTING SURFACE ROUGHNESS OF CRANKSHAFT JOURNAL PORTION...437

REPAIRING CRANKSHAFT...442

TESTING AND INSPECTING OF CONNECTING ROD...450

REPLACING CRANKSHAFT GEAR...452

REPLACING CAMSHAFT GEAR...453

REPLACING FLYWHEEL RING GEAR...454