Komatsu Hydraulic Excavators PC400, PC400LC, PC400HD series Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavators PC400, PC400LC, PC400HD series, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavators PC400-1, PC400LC-1, PC400-3, PC400LC-3, PC400LC-6, PC400HD-6, PC400LC-8, PC400-7, PC400LC-7 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 5,576 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEAM4006C1 - Hydraulic Excavator PC400LC-6, PC400HD-6 Operation & Maintenance Manual.pdf

CEAM009902 - Hydraulic Excavator PC400LC-8 Operation & Maintenance Manual.pdf

CEAM208040 - Hydraulic Excavator PC400LC-5 with Cummins LTA-10C Engine Operation & Maintenance Manual.pdf

CEAM208505 - Hydraulic Excavator PC400-5 (Mighty), PC400LC-5 (Mighty), PC400HD-5 Operation & Maintenance Manual.pdf

CEBM4006C3 - Hydraulic Excavator PC400LC-6, PC400HD-6 Shop Manual.pdf

CEBM018803 - Hydraulic Excavator PC400LC-8 Shop Manual.pdf

SEAM02080305 - Hydraulic Excavator PC400-3, PC400LC-3 Operation & Maintenance Manual.pdf

SEAM02080502 - Hydraulic Excavator PC400-5, PC400LC-5 Operation & Maintenance Manual.pdf

SEBM0208A03 - Hydraulic Excavator PC400-1, PC400LC-1 Shop Manual.pdf

SEBM037602 - Hydraulic Excavator PC400-7, PC400LC-7 Shop Manual.pdf

SEBM02080307 - Hydraulic Excavator PC400-3, PC400LC-3 Shop Manual.pdf

MAIN SECTIONS

COVER...1

CONTENTS...2

01 GENERAL...29

SPECIFICATION DRAWINGS...30

SPECIFICATIONS...32

WEIGHT TABLE...34

FUEL, COOLANT AND LUBRICANTS...36

10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD...39

ENGINE RELATED PARTS...40

RADIATOR?OIL COOLER?AFTERCOOLER...41

POWER TRAIN...42

FINAL DRIVE...43

SPROCKET...45

SWING MACHINERY...47

SWING CIRCLE...49

TRACK FRAME AND RECOIL SPRING...50

IDLER...52

CARRIER ROLLER...54

TRACK ROLLER...55

TRACK SHOE...56

HYDRAULIC PIPING DRAWING...60

HYDRAULIC TANK...62

HYDRAULIC PUMP...63

LS(PC)-EPC VALVE...81

VARIABLE VOLUME VALVE...84

CONTROL VALVE...86

MAIN RELIEF VALVE...99

CLSS...100

SELF PRESSURE REDUCING VALVE...103

SWING MOTOR...106

REVERSAL PREVENTION VALVE...111

CENTER SWIVEL JOINT...113

TRAVEL MOTOR...114

TRAVEL JUNCTION VALVE...125

VALVE CONTROL...127

TRAVEL PPC SHUTTLE VALVE...128

WORK EQUIPMENT?SWING PPC VALVE...132

TRAVEL PPC VALVE...136

SERVICE PPC VALVE...143

SOLENOID VALVE...144

PPC ACCUMULATOR...146

RETURN OIL FILTER...147

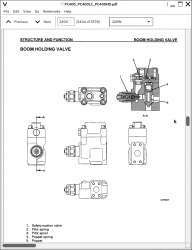

BOOM HYDRAULIC DRIFT PREVENTION VALVE...148

ARM HYDRAULIC DRIFT PREVENTION VALVE...153

QUICK RETURN VALVE...157

LIFT CHECK VALVE...159

ATTACHMENT CIRCUIT SELECTOR VALVE...160

HOLDING VALVE...162

HYDRAULIC CYLINDER...167

WORK EQUIPMENT...169

COMBUSTION HEATER AND PARTS RELATED TO HEATER...175

ENGINE CONTROL...177

ELECTRONIC CONTROL SYSTEM...182

MONITOR SYSTEM (MULTI MONITOR SPECIFICATION)...209

7-SEGMENT MONITOR SYSTEM...229

SENSOR...236

20 TESTING AND ADJUSTING...239

STANDARD VALUE TABLE FOR ENGINE...240

STANDARD VALUE TABLE FOR CHASSIS...241

TESTING AND ADJUSTING...250

TESTING, ADJUSTING, AND TROUBLESHOOTING TOOLS TABLE...251

MEASURING ENGINE SPEED...253

MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)...254

MEASURING EXHAUST TEMPERATURE...255

MEASURING EXHAUST GAS COLOR...256

ADJUSTING VALVE CLEARANCE...257

MEASURING COMPRESSION PRESSURE...259

MEASURING BLOW-BY PRESSURE...261

MEASURING ENGINE OIL PRESSURE...262

HANDLING OF FUEL SYSTEM DEVICES...263

RELEASING RESIDUAL PRESSURE FROM FUEL SYSTEM...263

MEASURING FUEL PRESSURE...264

BLEEDING AIR FROM FUEL CIRCUIT...265

INSPECTION OF FUEL CIRCUIT FOR LEAKAGE...267

ADJUSTING ENGINE SPEED SENSOR...268

TESTING AND ADJUSTING FAN BELT AND ALTERNATOR BELT TENSION...269

MEASURING CLEARANCE OF SWING CIRCLE BEARING...270

TESTING AND ADJUSTING TRACK SHOE TENSION...271

TESTING AND ADJUSTING OIL PRESSURE IN WORK EQUIPMENT, SWING, AND TRAVEL CIRCUITS...272

MEASURING BASIC PRESSURE IN CONTROL CIRCUIT...276

TESTING AND ADJUSTING OIL PRESSURE IN PUMP PC CONTROL CIRCUIT...277

TESTING AND ADJUSTING OIL PRESSURE IN PUMP LS CONTROL CIRCUIT...280

MEASURING SOLENOID VALVE OUTPUT PRESSURE...284

MEASURING PPC VALVE OUTPUT PRESSURE...287

ADJUSTING PLAY OF WORK EQUIPMENT AND SWING PPC VALVES...289

TESTING PARTS WHICH CAUSE HYDRAULIC DRIFT OF WORK EQUIPMENT...290

RELEASING RESIDUAL PRESSURE IN HYDRAULIC CIRCUIT...291

MEASURING OIL LEAKAGE...292

BLEEDING AIR FROM EACH PART...294

TESTING PROCEDURE OF DIODE...297

SPECIAL FUNCTIONS OF MONITOR PANEL (MULTI MONITOR SPECIFICATION)...298

HANDLING OF HIGH-VOLTAGE CIRCUIT OF ENGINE CONTROLLER...325

PREPARATION WORK FOR TROUBLESHOOTING FOR ELECTRICAL EQUIPMENT SYSTEM (STANDARD SPECIFICATION)...326

PM-CLINIC SERVICE...328

TROUBLESHOOTING...335

POINTS TO REMEMBER WHEN TROUBLESHOOTING...336

SEQUENCE OF EVENTS IN TROUBLESHOOTING...337

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE...338

CHECKS BEFORE TROUBLESHOOTING...346

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING...347

CONNECTOR ARRANGEMENT DRAWING AND ELECTRIC CIRCUIT DIAGRAM OF EACH SYSTEM...351

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...368

T-BRANCH BOX AND T-BRANCH TABLE...390

TROUBLESHOOTING WHEN ERROR CODE?ELECTRICAL SYSTEM?AND FAILURE CODE?MECHANICAL SYSTEM?ARE DISPLAYED...393

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE...395

ERROR CODE IN ELECTRICAL SYSTEM [E112] (SHORT-CIRCUITING IN NORMAL ROTATION SYSTEM OF WINDSHIELD WIPER MOTOR DRIVE)...397

ERROR CODE IN ELECTRICAL SYSTEM [E113] (SHORT-CIRCUITING IN REVERSE ROTATION SYSTEM OF WINDSHIELD WIPER MOTOR DRIVE)...399

ERROR CODE IN ELECTRICAL SYSTEM [E114] (SHORT-CIRCUITING IN WINDOW WASHER DRIVE SYSTEM)...401

ERROR CODE IN ELECTRICAL SYSTEM [E115] (ABNORMAL WINDSHIELD WIPER MOTION)...403

ERROR CODE IN ELECTRICAL SYSTEM [E116] (ABNORMALITY IN RETRACTING WINDSHIELD WIPER)...405

ERROR CODE IN ELECTRICAL SYSTEM [E117] (ENG. CONTROLLER S-NET COMM. ERR.)...407

ERROR CODE IN ELECTRICAL SYSTEM [E118] (PUMP CONTROLLER S-NET COMM. ERR.)...409

ERROR CODE IN ELECTRICAL SYSTEM [E128] (MONITOR COMM. ABNORMALITY)...411

ERROR CODE IN ELECTRICAL SYSTEM [E201] (SHORT-CIRCUITING IN TRAVEL INTERLOCKING SOLENOID)...413

ERROR CODE IN ELECTRICAL SYSTEM [E203] (SHORT-CIRCUITING IN SWING HOLDING BRAKE SOLENOID)...414

ERROR CODE IN ELECTRICAL SYSTEM [E204] (SHORT-CIRCUITING IN MERGE/DIVIDE SOLENOID)...416

ERROR CODE IN ELECTRICAL SYSTEM [E205] (SHORT-CIRCUITING IN 2-STAGE RELIEF SOLENOID)...417

ERROR CODE IN ELECTRICAL SYSTEM [E206] (SHORT-CIRCUITING IN TRAVEL SPEED SHIFTING SOLENOID)...418

ERROR CODE IN ELECTRICAL SYSTEM [E211] (DISCONNECTION IN TRAVEL INTERLOCKING SOLENOID)...419

ERROR CODE IN ELECTRICAL SYSTEM [E213] (DISCONNECTION IN SWING HOLDING BRAKE SOLENOID)...420

ERROR CODE IN ELECTRICAL SYSTEM [E214] (DISCONNECTION IN MERGE/DIVIDE SOLENOID)...422

ERROR CODE IN ELECTRICAL SYSTEM [E215] (DISCONNECTION IN 2-STAGE RELIEF SOLENOID)...423

ERROR CODE IN ELECTRICAL SYSTEM [E216] (DISCONNECTION IN TRAVEL SPEED SHIFTING SOLENOID)...424

ERROR CODE IN ELECTRICAL SYSTEM [E217] (ABNORMAL INPUT MODEL CODE)...425

ERROR CODE IN ELECTRICAL SYSTEM [E218] (S-NET COMM. DISC.)...427

ERROR CODE IN ELECTRICAL SYSTEM [E222] (SHORT-CIRCUITING IN LS-EPC SOLENOID)...429

ERROR CODE IN ELECTRICAL SYSTEM [E223] (DISCONNECTION IN LS-EPC SOLENOID SYSTEM)...430

ERROR CODE IN ELECTRICAL SYSTEM [E224] (F PUMP P. SENSOR ABNORMALITY)...431

ERROR CODE IN ELECTRICAL SYSTEM [E225] (R PUMP P. SENSOR ABNORMALITY)...433

ERROR CODE IN ELECTRICAL SYSTEM [E226] (PRESS. SENSOR POWER ABNORMALITY)...435

ERROR CODE IN ELECTRICAL SYSTEM [E227] (ABNORMALITY IN ENGINE ROTATION SENSOR)...437

ERROR CODE IN ELECTRICAL SYSTEM [E228] (SHORT-CIRCUITING IN ATTACHMENT RETURN SWITCHING RELAY)...438

ERROR CODE IN ELECTRICAL SYSTEM [E232] (SHORT-CIRCUITING IN PC-EPC SOLENOID)...439

ERROR CODE IN ELECTRICAL SYSTEM [E233] (DISCONNECTION IN PC-EPC SOLENOID SYSTEM)...441

ERROR CODE IN ELECTRICAL SYSTEM [E238] (DISCONNECTION IN ATTACHMENT RETURN SWITCHING RELAY)...443

ERROR CODE IN ELECTRICAL SYSTEM [E245] (SHORT-CIRCUITING IN ATTACHMENT OIL FLOW RATE ADJUSTING EPC)...445

ERROR CODE IN ELECTRICAL SYSTEM [E246] (DISCONNECTION IN ATTACHMENT OIL FLOW RATE ADJUSTING EPC)...446

ERROR CODE IN ELECTRICAL SYSTEM [E247] (ARM IN PPC PRESSURE SENSOR ABNORMALITY)...447

ERROR CODE IN ELECTRICAL SYSTEM [E248] (BUCKET CURL PPC PRESSURE SENSOR ABNORMALITY)...449

ERROR CODE IN ELECTRICAL SYSTEM [E257] (PUMP ABNORMALITY)...451

ERROR CODE IN ELECTRICAL SYSTEM [E315] (BATTERY RELAY DRIVE S/C)...453

ERROR CODE IN ELECTRICAL SYSTEM [E91B] (ENGINE NE SENSOR PROBLEM)...455

ERROR CODE IN ELECTRICAL SYSTEM [E91C] (ENGINE G SENSOR PROBLEM)...456

ERROR CODE IN ELECTRICAL SYSTEM [E920] (ENGINE TYPE SELECTION ERROR)...457

ERROR CODE IN ELECTRICAL SYSTEM [E921] (ENGINE TYPE MISMATCH)...459

ERROR CODE IN ELECTRICAL SYSTEM [E931] (FUEL DIAL SYS. ERROR)...460

ERROR CODE IN ELECTRICAL SYSTEM [E934] (ENGINE COOLANT SENSOR HI ERROR)...462

ERROR CODE IN ELECTRICAL SYSTEM [E936] (ENGINE OIL PRESS. SW. ERROR)...464

ERROR CODE IN ELECTRICAL SYSTEM [E93C] (ENGINE BOOST SENSOR ERROR)...466

ERROR CODE IN ELECTRICAL SYSTEM [E93D] (ENGINE FUEL TEMP. SENSOR ERROR)...468

ERROR CODE IN ELECTRICAL SYSTEM [E953] (ENGINE COMM. ABNORMALITY)...470

ERROR CODE IN ELECTRICAL SYSTEM [E954] (SHORT ENGINE STARTER SW.)...472

ERROR CODE IN ELECTRICAL SYSTEM [E955] (ENGINE S-NET ERROR)...474

ERROR CODE IN ELECTRICAL SYSTEM [E956] (ENGINE POWER FAILURE (1))...476

ERROR CODE IN ELECTRICAL SYSTEM [E957] (ENGINE POWER FAILURE (2))...478

ERROR CODE IN ELECTRICAL SYSTEM [E95A] (ENGINE Q-ADJ. SW. SIGNAL ERROR)...480

ERROR CODE IN ELECTRICAL SYSTEM [E96A] (ENGINE COOLANT SENSOR LO ERROR)...481

ERROR CODE IN ELECTRICAL SYSTEM [E970] (PCV1 OVER CURRENT)...483

ERROR CODE IN ELECTRICAL SYSTEM [E971] (PCV2 OVER CURRENT)...484

ERROR CODE IN ELECTRICAL SYSTEM [E974] (PCV1 LINE CUT)...485

ERROR CODE IN ELECTRICAL SYSTEM [E975] (PCV2 LINE CUT)...486

ERROR CODE IN ELECTRICAL SYSTEM [E977] (RAIL PRESS. SENSOR ERROR)...487

ERROR CODE IN ELECTRICAL SYSTEM [E979] (RAIL PRESS. HIGH)...489

ERROR CODE IN ELECTRICAL SYSTEM [E97A] (RAIL PRESS. ABNORMAL)...489

ERROR CODE IN ELECTRICAL SYSTEM [E97B] (RAIL PRESS. LOW)...490

ERROR CODE IN ELECTRICAL SYSTEM [E97C] (RAIL PRESS. TOO LOW)...492

ERROR CODE IN ELECTRICAL SYSTEM [E97D] (RAIL PRESS. OUT OF CONTROL)...492

ERROR CODE IN ELECTRICAL SYSTEM [E980] (ENG. CONTROLLER ABNORMALITY)...493

ERROR CODE IN ELECTRICAL SYSTEM [E981] (FUEL INJECTOR 1 DISC.)...495

ERROR CODE IN ELECTRICAL SYSTEM [E982] (FUEL INJECTOR 2 DISC.)...496

ERROR CODE IN ELECTRICAL SYSTEM [E983] (FUEL INJECTOR 3 DISC.)...497

ERROR CODE IN ELECTRICAL SYSTEM [E984] (FUEL INJECTOR 4 DISC.)...498

ERROR CODE IN ELECTRICAL SYSTEM [E985] (FUEL INJECTOR 5 DISC.)...499

ERROR CODE IN ELECTRICAL SYSTEM [E986] (FUEL INJECTOR 6 DISC.)...500

ERROR CODE IN ELECTRICAL SYSTEM [E98A] (FUEL INJECTOR 1-3 S/C)...501

ERROR CODE IN ELECTRICAL SYSTEM [E98B] (FUEL INJECTOR 4-6 S/C)...503

ERROR CODE IN MECHANICAL SYSTEM [A000N1] (ENGINE HIGH-IDLING SPEED OUT OF STANDARD)...505

ERROR CODE IN MECHANICAL SYSTEM [A000N2] (ENGINE LOW-IDLING SPEED OUT OF STANDARD)...505

FAILURE CODE IN MECHANICAL SYSTEM [AA10NX] (AIRCLEANER CLOGGING)...506

FAILURE CODE IN MECHANICAL SYSTEM [AB00KE] (CHARGE VOLTAGE LOW)...508

FAILURE CODE IN MECHANICAL SYSTEM [B@BAZG] (ENG. OIL PRESS. LOW)...510

FAILURE CODE IN MECHANICAL SYSTEM [B@BAZK] (ENG. OIL LEVEL LOW)...512

FAILURE CODE IN MECHANICAL SYSTEM [B@BCNS] (ENG. WATER OVERHEAT)...513

FAILURE CODE IN MECHANICAL SYSTEM [B@BCZK] (ENG. WATER LVL LOW)...514

FAILURE CODE IN MECHANICAL SYSTEM [B@HANS] (HYDR. OIL OVERHEAT)...515

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)...516

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE...518

E-1 ENGINE DOES NOT START (THE ENGINE DOES NOT ROTATE)...519

E-2 PREHEATER DOES NOT OPERATE...522

E-3 AUTO ENGINE WARM-UP DEVICE DOES NOT WORK...524

E-4 AUTO-DECELERATOR DOES NOT OPERATE...525

E-5 ALL WORK EQUIPMENT, SWING AND TRAVEL DO NOT MOVE...526

E-6 ONE-TOUCH POWER MAX, FUNCTION DOES NOT OPERATE...528

E-7 MACHINE PUSH-UP FUNCTION DOES NOT OPERATE NORMALLY...529

E-8 ATTACHMENT CIRCUIT DOES NOT CHANGE...531

E-9 NO DISPLAY IN MONITOR PANEL AT ALL...533

E-10 PART OF DISPLAY ON MONITOR PANEL IS MISSING...534

E-11 MONITOR PANEL DISPLAYS CONTENTS IRRELEVANT TO THE MODEL...534

E-12 FUEL LEVEL MONITOR RED LAMP LIGHTS UP WHILE ENGINE IS RUNNING...535

E-13 ENGINE WATER TEMPERATURE GAUGE DOES NOT DISPLAY CORRECTLY...536

E-14 HYDRAULIC OIL TEMPERATURE GAUGE DOES NOT DISPLAY CORRECTLY...538

E-15 FUEL GAUGE DOES NOT DISPLAY CORRECTLY...539

E-16 SWING LOCK MONITOR DOES NOT DISPLAY CORRECTLY...540

E-17 WHEN MONITOR SWITCH IS OPERATED, NOTHING IS DISPLAYED...542

E-18 WINDSHIELD WIPER AND WINDOW WASHER DO NOT WORK...544

E-19 ALARM BUZZER CANNOT BE CANCELLED...548

E-20 "BOOM RAISE" IS NOT CORRECTLY DISPLAYED IN MONITOR FUNCTION...549

E-21 "BOOM LOWER" IS NOT CORRECTLY DISPLAYED IN MONITOR FUNCTION...550

E-22 "ARM IN" IS NOT DISPLAYED NORMALLY IN MONITORING FUNCTION...551

E-23 "ARM DUMPING" IS NOT CORRECTLY DISPLAYED IN MONITORING FUNCTION...552

E-24 "BUCKET CURL" IS NOT DISPLAYED NORMALLY IN MONITORING FUNCTION...553

E-25 "BUCKET DUMPING" IS NOT CORRECTLY DISPLAYED IN MONITORING FUNCTION...554

E-26 "SWING" IS NOT DISPLAYED NORMALLY IN MONITORING FUNCTION...555

E-27 "TRAVEL" IS NOT CORRECTLY DISPLAYED IN MONITORING FUNCTION...557

E-28 "TRAVEL DIFFERENTIAL PRESSURE" IS NOT CORRECTLY DISPLAYED IN MONITORING FUNCTION...559

E-29 "SERVICE" IS NOT CORRECTLY DISPLAYED IN MONITORING FUNCTION...561

E-30 TRAVEL ALARM DOES NOT SOUND OR DOES NOT STOP SOUNDING...563

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)...565

SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEM...566

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE...568

H-1 ALL WORK EQUIPMENT LACK POWER, OR TRAVEL AND SWING SPEEDS ARE LOW...569

H-2 ENGINE SPEED SHARPLY DROPS OR ENGINE STALLS...570

H-3 NO WORK EQUIPMENT, TRAVEL OR SWING MOVE...571

H-4 ABNORMAL NOISE IS HEARD FROM AROUND HYDRAULIC PUMP...571

H-5 AUTO-DECELERATOR DOES NOT WORK...572

H-6 FINE CONTROL MODE DOES NOT FUNCTION...572

H-7 BOOM MOVES SLOWLY OR LACKS POWER...573

H-8 ARM MOVES SLOWLY OR LACKS POWER...574

H-9 BUCKET MOVES SLOWLY OR LACKS POWER...575

H-10 WORK EQUIPMENT DOES NOT MOVE IN ITS SINGLE OPERATION...575

H-11 WORK EQUIPMENT HAS A BIT TOO FAST HYDRAULIC DRIFT...576

H-12 WORK EQUIPMENT HAS BIG TIME LAG...577

H-13 OTHER WORK EQUIPMENT MOVES WHEN RELIEVING SINGLE CIRCUIT...577

H-14 ONE-TOUCH POWER MAX. FUNCTION DOES NOT WORK...577

H-15 MACHINE PUSH-UP FUNCTION DOES NOT WORK...578

H-16 IN COMPOUND OPERATION, WORK EQUIPMENT WITH LARGER LOAD MOVES SLOWLY...579

H-17 IN SWING + BOOM RAISE OPERATION, BOOM MOVES SLOWLY...579

H-18 IN SWING + TRAVEL, TRAVEL SPEED DROPS SHARPLY...579

H-19 MACHINE SWERVES IN TRAVEL...580

H-20 MACHINE TRAVELS SLOWLY...581

H-21 MACHINE CANNOT BE EASILY STEERED OR LACKS POWER...582

H-22 TRAVEL SPEED DOES NOT SHIFT, OR IT IS SLOWER OR FASTER THAN PRESET SPEED...583

H-23 TRACK SHOE DOES NOT TURN (ON ONE SIDE ONLY)...584

H-24 MACHINE DOES NOT SWING...585

H-25 SWING ACCELERATION IS POOR, OR SWING SPEED IS SLOW...586

H-26 EXCESSIVE OVERRUN WHEN STOPPING SWING...587

H-27 THERE IS BIG SHOCK WHEN STOPPING SWING...588

H-28 THERE IS BIG ABNORMAL NOISE CAUSED WHEN STOPPING SWING...588

H-29 SWING NATURAL DRIFT IS TOO BIG...589

H-30 ATTACHMENT CIRCUIT DOES NOT CHANGE...590

H-31 FLOW RATE IN ATTACHMENT CIRCUIT CANNOT BE ADJUSTED...590

TROUBLESHOOTING OF ENGINE (S MODE)...591

POINTS TO REMEMBER WHEN TROUBLESHOOTING...592

METHOD OF USING TROUBLESHOOTING CHARTS...593

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)...596

S-2 ENGINE DOES NOT START...597

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)...600

S-4 ENGINE STOPS DURING OPERATIONS...601

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)...602

S-6 ENGINE LACKS OUTPUT (OR LACKS POWER)...603

S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION)...604

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)...605

S-9 OIL BECOMES CONTAMINATED QUICKLY...606

S-10 FUEL CONSUMPTION IS EXCESSIVE...607

S-11 OIL IS IN COOLING WATER (OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN)...608

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)...609

S-13 OIL LEVEL RISES (WATER, FUEL IN OIL)...610

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)...611

S-15 ABNORMAL NOISE IS MADE...612

S-16 VIBRATION IS EXCESSIVE...613

30 DISASSEMBLY AND ASSEMBLY...614

HOW TO READ THIS MANUAL...615

PRECAUTIONS WHEN PERFORMING OPERATION...617

SPECIAL TOOL LIST...619

REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY...626

REMOVAL AND INSTALLATION OF ENGINE REAR SEAL...633

REMOVAL AND INSTALLATION OF ENGINE FRONT SEAL...637

REMOVAL AND INSTALLATION OF FUEL SUPPLY PUMP ASSEMBLY...640

REMOVAL AND INSTALLATION OF FUEL INJECTOR ASSEMBLY...643

REMOVAL AND INSTALLATION OF NOZZLE TIP...646

REMOVAL AND INSTALLATION OF STARTING MOTOR ASSEMBLY...648

REMOVAL AND INSTALLATION OF RADIATOR ASSEMBLY...649

REMOVAL AND INSTALLATION OF HYDRAULIC OIL COOLER ASSEMBLY...651

REMOVAL AND INSTALLATION OF ENGINE AND HYDRAULIC PUMP ASSEMBLY...653

REMOVAL AND INSTALLATION OF SWING CIRCLE ASSEMBLY...658

REMOVAL AND INSTALLATION OF SWING MOTOR AND SWING MACHINERY ASSEMBLY...659

DISASSEMBLY AND ASSEMBLY OF SWING MOTOR AND SWING MACHINERY ASSEMBLY...660

REMOVAL AND INSTALLATION OF SPROCKET...667

REMOVAL AND INSTALLATION OF TRAVEL MOTOR AND FINAL DRIVE ASSEMBLY...668

DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY...669

DISASSEMBLY AND ASSEMBLY OF CARRIER ROLLER ASSEMBLY...676

DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY...678

DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY...679

DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING ASSEMBLY...682

EXPANSION AND INSTALLATION OF TRACK SHOE ASSEMBLY...684

REMOVAL AND INSTALLATION OF OPERATOR?S CAB (STANDARD SPECIFICATION)...686

REMOVAL AND INSTALLATION OF PUMP CONTROLLER (STANDARD SPECIFICATION)...689

REMOVAL AND INSTALLATION OF REVOLVING FRAME ASSEMBLY...690

REMOVAL AND INSTALLATION OF COUNTERWEIGHT ASSEMBLY...693

REMOVAL AND INSTALLATION OF HYDRAULIC TANK ASSEMBLY...694

REMOVAL AND INSTALLATION OF HYDRAULIC PUMP ASSEMBLY...696

REMOVAL AND INSTALLATION OF OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT...699

REMOVAL AND INSTALLATION OF CONTROL VALVE ASSEMBLY...700

DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE ASSEMBLY...703

REMOVAL AND INSTALLATION OF CENTER SWIVEL JOINT ASSEMBLY...707

DISASSEMBLY AND ASSEMBLY OF OF CENTER SWIVEL JOINT ASSEMBLY...709

DISASSEMBLY AND ASSEMBLY OF WORK EQUIPMENT PPC VELVE ASSEMBLY...710

DISASSEMBLY AND ASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY...711

DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY...712

REMOVAL AND INSTALLATION OF WORK EQUIPMENT ASSEMBLY...717

REMOVAL AND INSTALLATION OF OPERATOR?S CAB GLASS (STUCK GLASS)...720

REMOVAL AND INSTALLATION OF FRONT WINDOW ASSEMBLY...730

70 SUPPLEMENT FOR OFF-SET BOOM EXCAVATOR...736

SPECIFICATION DRAWINGS...737

SPECIFICATIONS...738

WEIGHT TABLE...739

TESTING AND ADJUSTING...741

TROUBLESHOOTING...742

MAINTENANCE STANDARD...744

90 OTHERS...754

HYDRAULIC CIRCUIT DIAGRAM (1/2)...755

HYDRAULIC CIRCUIT DIAGRAM (2/2)...756

ELECTRICAL CIRCUIT DIAGRAM (1/5) (EXTREME COLD SPEC.)...757

ELECTRICAL CIRCUIT DIAGRAM (2/5) (EXTREME COLD SPEC.)...758

ELECTRICAL CIRCUIT DIAGRAM (3/5) (EXTREME COLD SPEC.)...759

ELECTRICAL CIRCUIT DIAGRAM (4/5) (EXTREME COLD SPEC.)...760

ELECTRICAL CIRCUIT DIAGRAM (5/5) (EXTREME COLD SPEC.)...761