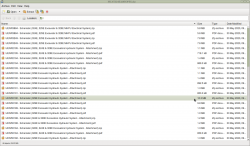

Caterpillar 324E & 329E Hydraulic Excavators Repair Service Manuals

Caterpillar 324E & 329E Hydraulic Excavators Repair Service Manuals

Complete service repair manual with Electrical Wiring Diagrams for Caterpillar 324E & 329E Hydraulic Excavators, with all the shop information to maintain, diagnostic, repair, service like professional mechanics.

Caterpillar 324E & 329E Hydraulic Excavators workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 3,221 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

324E & 329E Hydraulic Excavator Instructor Technical Training Documents

KENR7970 - Testing & Adjusting (312E,F, 313F, 316E,F, 318E,F, 320E,F, 323E,F, 324E, 325F, 326F, 329E,F, 330F, 335F, 336E,F, 340F, 349E,F, 352F, 374F, 390F AC & Heating)

Air Conditioning and Heating System Troubleshooting

Air Conditioning E11 - Intake Air Temperature Sensor (Open Circuit)

Air Conditioning E12 - Intake Air Temperature Sensor (Short Circuit)

Air Conditioning E13 - Ambient Air Temperature Sensor (Open Circuit)

Air Conditioning E14 - Ambient Air Temperature Sensor (Short Circuit)

Air Conditioning E15 - Water Temperature Sensor (Short Circuit)

Air Conditioning E16 - Water Temperature Sensor (Short Circuit)

Air Conditioning E21 - Evaporator Sensor (Open Circuit)

Air Conditioning E22 - Evaporator Sensor (Short Circuit)

Air Conditioning E43 - Air Outlet Damper Error

Air Conditioning E44 - Air Blend Damper Error

Air Conditioning E45 - Air Inlet Damper Error

Air Conditioning Performance - Test

General Troubleshooting Information

Machine Preparation for Troubleshooting

Manifold Gauge Set (Refrigerant) - Install

Manifold Gauge Set (Refrigerant) - Remove

Refrigerant Compressor Oil - Check

Refrigerant Leakage - Test

Refrigerant Recovery

Refrigerant System - Charge

Refrigerant System - Evacuate

Refrigerant System - Flush

Required Tools

Troubleshooting Faults With Service Codes

Visual Inspection

KENR9509 - Systems Operation (E Series Monitor Monitoring System)

Calibration Menu

Configuration Menu

Current Totals Menu

Data Link

Device Test Menu

Diagnostic Menu

Display Setting Menu

ECM Summary Menu

Engine Shutdown Setting Menu

General Information

Input Components

Language Select Menu

Maintenance Intervals Menu

Menu Outline

Override Parameters Menu

Password Change Menu

Password Entry

Performance Menu

Power Mode Setting Menu

Prestart Monitoring Function - If Equipped

Service Menu

Status Menu

System Schematic

Tool Programming Menu

Warning Operation

WinFlash Menu

Work Tool Select Menu

KENR9698 - Systems Operation (320E, 320F, 323E, 323F, 324E, 326F, 329E, 329F & 330F Excavators Tool Control System)

Combined Function - Electric Control

Combined Function - Hydraulic Control

General Information

Medium Pressure Hydraulic System

One-WayOne or Two Pump - Electric Control

One-WayOne or Two Pump - Hydraulic Control

Sensors

Solenoid Valves

Switches

Two-WayOne Pump - Electric Control

Work Tool Parameters - Control Functions

KENR9698 - Testing & Adjusting (320E, 320F, 323E, 323F, 324E, 326F, 329E, 329F & 330F Excavators Tool Control System)

Combined Function - Electric Control Default Value of Work Tool Parameters (1)

Combined Function - Electric Control Default Value of Work Tool Parameters (2)

Combined Function - Electric Control Parameter Adjustment

Combined Function - Electric Control Parameter Setting

Combined Function - Electric Control Relief Valve (Line) - Test and Adjust

Combined Function - Hydraulic Control Default Value of Work Tool Parameters

Combined Function - Hydraulic Control Parameter Adjustment

Combined Function - Hydraulic Control Parameter Setting

Combined Function - Hydraulic Control Relief Valve (Line) - Test and Adjust

Control (Pedal) - Calibrate

Control (Thumb Wheel) - Calibrate

Medium Pressure Default Value of Work Tool Parameters

Medium Pressure Relief Valve (Line) - Test and Adjust

Medium Pressure Relief Valve (Main) - Test and Adjust

One-WayOne or Two Pump - Electric Control Default Value of Work Tool Parameters (1)

One-WayOne or Two Pump - Electric Control Default Value of Work Tool Parameters (2)

One-WayOne or Two Pump - Electric Control Parameter Adjustment

One-WayOne or Two Pump - Electric Control Parameter Setting

One-WayOne or Two Pump - Electric Control Relief Valve (Line) - Test and Adjust

One-WayOne or Two Pump - Electric Control Relief Valve (Line) - Test and Adjust - Tool Relief Valve

One-WayOne or Two Pump - Hydraulic Control Default Value of Work Tool Parameters

One-WayOne or Two Pump - Hydraulic Control Parameter Adjustment

One-WayOne or Two Pump - Hydraulic Control Parameter Setting

One-WayOne or Two Pump - Hydraulic Control Relief Valve (Line) - Test and Adjust

One-WayOne or Two Pump - Hydraulic Control Relief Valve (Line) - Test and Adjust - Tool Relief Valve

Process for Setting Up the Work Tool

Solenoid Valve (Proportional Reducing) - Calibrate - Attachment Valves

Solenoid Valve (Proportional Reducing) - Calibrate - Flow Limit Valves (1)

Solenoid Valve (Proportional Reducing) - Calibrate - Flow Limit Valves (2)

Solenoid Valve (Proportional Reducing) - Calibrate - Pilot Pressure Limit

Solenoid Valve (Proportional Reducing) - Calibrate - Variable Relief Valves

System Identification

Two-WayOne Pump - Electric Control Default Value of Work Tool Parameters

Two-WayOne Pump - Electric Control Parameter Adjustment

Two-WayOne Pump - Electric Control Parameter Setting

Two-WayOne Pump - Electric Control Relief Valve (Line) - Test and Adjust

Work Tool Parameter - Program

Work Tool - Select

KENR9843 - Disassembly & Assembly (324E & 329E Excavators & 329E MHPU Mobile Hydraulic Power Unit C7.1 Engine Supplement)

Aftercooler - Remove and Install

Air Cleaner - Remove and Install

Alternator - Remove and Install

Battery - Remove and Install

Belt Tightener - Remove and Install

Clean Emissions Module - Remove and Install

Combustion Head - Remove and Install - Clean Emissions Module

Cooling System Package (Radiator, Hydraulic Oil Cooler, and Aftercooler) - Remove and Install

Crankshaft Vibration Damper and Pulley - Remove and Install

Diesel Particulate Filter - Install

Diesel Particulate Filter - Remove

Electric Starting Motor - Remove and Install

Electronic Control (ARD Combustion Air) - Remove and Install - Clean Emissions Module

Engine Electronic Control - Remove and Install (1)

Engine Electronic Control - Remove and Install (2)

Engine Front Mount - Remove and Install

Engine Oil Cooler - Remove and Install

Engine Oil Filter and Oil Filter Base - Remove and Install

Engine Oil Pump - Remove and Install

Engine Rear Mount - Remove and Install

Engine - Remove and Install

Exhaust Elbow - Remove and Install

Fan Drive - Remove and Install

Fan - Remove and Install

Fuel Cooler - Remove and Install

Fuel Filter and Base - Remove and Install

Fuel Injection Pump - Install

Fuel Injection Pump - Remove

Fuel Manifold - Remove and Install

Hood - Remove and Install

Hydraulic Oil Cooler - Remove and Install

Ignition Coil - Remove and Install - Clean Emissions Module

Nozzle Heater Harness - Remove and Install - Harness Assembly

Oil Pan - Remove and Install

Pressure Sensor (ARD Combustion Air) - Remove and Install

Pressure Sensor (DPF) - Remove and Install

Radiator - Remove and Install

Refrigerant Compressor - Remove and Install

Refrigerant Condenser - Remove and Install

Relay (ARD Nozzle Heater) - Remove and Install

Soot Antenna - Remove and Install

Soot Sensor - Remove and Install

System Pressure - Release

Temperature Sensor (DPF) - Remove and Install

Turbocharger - Remove and Install - First Stage Turbocharger

Turbocharger - Remove and Install - Second Stage Turbocharger

Water Pump - Remove and Install

Water Separator and Fuel Priming Pump - Remove and Install

Water Temperature Regulator - Remove and Install

KENR9844 - Disassembly & Assembly (324E & 329E Excavators & 329E MHPU Mobile Hydraulic Power Unit Machine Systems)

Accumulator - Remove and Install

Actuator Motor (Air Distributor) - Remove and Install

Auxiliary Pilot Valve (Straight Travel) - Remove and Install

Boom Bearings and Seals - Remove and Install

Boom Cylinder - Remove and Install

Boom - Remove and Install

Bucket Cylinder - Remove and Install

Bucket Linkage Bearings and Seals - Remove and Install

Bucket Linkage - Remove and Install

Bucket - Remove and Install

Cab - Remove and Install

Check Valve (Cooler Bypass) - Remove and Install

Control Manifold (Pilot Oil) - Assemble - Hydraulic Lockout, Swing Brake, Travel with Aluminium Valve Body

Control Manifold (Pilot Oil) - Disassemble - Hydraulic Lockout, Swing Brake, Travel with Aluminium Valve Body

Control Manifold (Pilot Oil) - Remove and Install - Hydraulic Lockout, Swing Brake, Travel

Control Module (Automatic Temperature Control Unit) - Remove and Install

Control Valve (Medium Pressure) - Remove and Install

Counterbalance Valve (Travel) - Assemble

Counterbalance Valve (Travel) - Disassemble

Counterbalance Valve (Travel) - Remove and Install

Counterweight - Remove and Install

Duo-Cone Conventional Seals - Install

Final Drive - Assemble

Final Drive - Disassemble

Final Drive - Install

Final Drive - Remove

Front Idler and Recoil Spring - Install

Front Idler and Recoil Spring - Remove

Fuel Tank - Remove and Install

Gear Pump (Auxiliary) - Remove and Install

Gear Pump (Pilot) - Remove and Install

Heating and Air Conditioning Unit - Remove and Install

Hydraulic Lockout Control - Remove and Install

Hydraulic Tank - Remove and Install

Hydraulic Track Adjusters - Assemble

Hydraulic Track Adjusters - Disassemble

Hydraulic Track Adjusters - Remove and Install

Load Control Valve (Boom Cylinder) - Assemble

Load Control Valve (Boom Cylinder) - Disassemble

Load Control Valve (Boom Cylinder) - Remove and Install

Load Control Valve (Stick Cylinder) - Assemble

Load Control Valve (Stick Cylinder) - Disassemble

Load Control Valve (Stick Cylinder) - Remove and Install

Main Control Valve - Assemble

Main Control Valve - Disassemble

Main Control Valve - Remove and Install

Main Hydraulic Pump - Assemble

Main Hydraulic Pump - Disassemble

Main Hydraulic Pump - Remove and Install

Manual Valve (Auxiliary Shutoff) - Install

Manual Valve (Auxiliary Shutoff) - Remove

Pilot Valve (Joystick) - Assemble

Pilot Valve (Joystick) - Disassemble

Pilot Valve (Joystick) - Remove and Install

Pilot Valve (Travel) - Assemble

Pilot Valve (Travel) - Disassemble

Pilot Valve (Travel) - Remove and Install

Pressure Reducing Valve (Boom Priority) - Remove and Install

Pressure Reducing Valve (Medium Pressure) - Remove and Install

Pressure Switch (Refrigerant Pressure Cutoff) - Remove and Install

Pump Drive Coupling - Remove and Install

Quick Coupler - Remove and Install

Recoil Spring - Assemble

Recoil Spring - Disassemble

Refrigerant Receiver-Dryer - Remove and Install

Relief Valve (Pilot) - Remove and Install

Seat - Remove and Install

Seat Support - Remove and Install

Seat Suspension - Remove and Install

Selector Valve (Alternate Pattern Control) - Remove and Install

Shuttle Valve - Remove and Install - Pilot Oil

Shuttle Valve - Remove and Install - Straight Travel

Solenoid Valve (Auxiliary Circuit) - Remove and Install - Tool Relief

Solenoid Valve (Heavy Lift) - Remove and Install

Solenoid Valve (Negative Flow Control, Proportional Reducing Valve) - Assemble

Solenoid Valve (Negative Flow Control, Proportional Reducing Valve) - Disassemble

Solenoid Valve (Negative Flow Control, Proportional Reducing Valve) - Remove and Install

Solenoid Valve (Two-Way Flow and One PumpTwo Pump) - Remove and Install

Sprocket - Remove and Install

Stick Bearings and Seals - Install

Stick Bearings and Seals - Remove

Stick Cylinder - Remove and Install

Stick - Remove and Install

Storage Box and Covers (Cab) - Remove and Install

Swing Cushion Valve - Assemble - Fine Swing Solenoid

Swing Cushion Valve - Disassemble - Fine Swing Solenoid

Swing Cushion Valve - Remove and Install

Swing Drive - Assemble

Swing Drive - Disassemble

Swing Drive - Install

Swing Drive - Remove

Swing Gear and Bearing - Install

Swing Gear and Bearing - Remove

Swing Motor - Assemble

Swing Motor - Disassemble

Swing Motor - Install

Swing Motor - Remove

Swivel - Assemble

Swivel - Disassemble

Swivel - Install

Swivel - Remove

System Pressure - Release

Track Carrier Roller - Install

Track Carrier Roller - Remove

Track - Connect - Press Fit Master Pin

Track Roller - Install

Track Roller - Remove

Track - Separate - Press Fit Master Pin

Travel Motor - Assemble

Travel Motor - Disassemble

Travel Motor - Install

Travel Motor - Remove

Upper Frame and Undercarriage Frame - Connect

Upper Frame and Undercarriage Frame - Separate

Window Wiper Motor - Remove and Install - Lower

Window Wiper Motor - Remove and Install - Upper

UENR1513 - Specifications (324E Excavator Machine System)

Accumulator (Pilot) (1)

Accumulator (Pilot) (2)

Air Cleaner (1)

Air Cleaner (2)

Air Conditioner Lines

Auxiliary Hydraulic Lines (1)

Auxiliary Hydraulic Lines (2)

Auxiliary Hydraulic Lines (3)

Auxiliary Hydraulic Lines (4)

Auxiliary Hydraulic Lines (5)

Auxiliary Hydraulic Lines (6)

Auxiliary Hydraulic Lines - Stick

Auxiliary Pump Drive and Mounting

Blower Motor

Boom - 10.2 m (33.46 ft)

Boom - 5.3 m (17.39 ft)

Boom - 5.9 m (19.36 ft) (1)

Boom - 5.9 m (19.36 ft) (2)

Boom Cylinder (1)

Boom Cylinder (2)

Boom Cylinder Lines (1)

Boom Cylinder Lines (2)

Boom Cylinder Lines (3)

Boom Cylinder Lines (4)

Boom Cylinder Lines (5)

Boom Cylinder Lines (6)

Boom Cylinder Lines (7)

Boom Cylinder Lines (8)

Boom - Fore Boom Group - 3.3 m (10.83 ft)

Boom Lines (1)

Boom Lines (2)

Boom Lines (3)

Boom Lines (4)

Boom Lines (5)

Boom Lines (6)

Boom Lines (7)

Boom Lines (8)

Boom Lines (9)

Boom - Stub Boom - 2.8 m (9.19 ft)

Bucket Adjuster (1)

Bucket Adjuster (2)

Bucket Cylinder (1)

Bucket Cylinder (2)

Bucket Cylinder (3)

Bucket Cylinder Lines (1)

Bucket Cylinder Lines (2)

Bucket Cylinder Lines (3)

Bucket Linkage (1)

Bucket Linkage (2)

Bucket Linkage (3)

Bucket Linkage - CB1 Family

Bucket Sidecutter

Cab - Air Duct

Cab - Front Window Guard

Cab

Cab - Protection Visor (1)

Cab - Protection Visor (2)

Check Valve (Hydraulic Oil Cooler Bypass)

Check Valve

Control Manifold (Pilot Oil)

Control Valve (Auxiliary) (1)

Control Valve (Auxiliary) (2)

Control Valve

Control Valve - Regeneration (1)

Control Valve - Regeneration (2)

Control Valve (Stick Lowering) (1)

Control Valve (Stick Lowering) (2)

Counterweight Mounting

Cylinder Guard

Drift Reduction Valve - Boom Lowering

Drift Reduction Valve

Ether Starting Aid

Fasteners - Final Drive and Mounting Group

Final Drive

Front Idler

Front Lines (1)

Front Lines (2)

Front Lines (3)

Front Lines (4)

Fuel Lines

Fuel Tank

Grease Lines (1)

Grease Lines (2)

Grease Lines (3)

Grease Lines - Stick

Handle Control (Travel) (1)

Handle Control (Travel) (2)

Heater and Air Conditioner Mounting

Hoist Solenoid Valve - Boom Lowering

Hydraulic Oil Cooler Lines Group

Hydraulic Pedal Control (Auxiliary) (1)

Hydraulic Pedal Control (Auxiliary) (2)

Hydraulic Pedal Control (Auxiliary) (3)

Hydraulic Tank and Filter

Hydraulic Tank Mounting

Joystick Control (1)

Joystick Control (2)

Joystick Control (3)

Liquid Level Sensor (Water Separator)

Main Control Valve

Main Hydraulic Pump

Manifold and Reducing Valve (Pilot Oil)

Oil Filter (Hydraulic) - Case Drain

Oil Filter (Hydraulic)

Oil Filter (Return)

Pilot Lines (1)

Pilot Lines (2)

Pilot Lines (3)

Pilot Lines - Joystick and Pedals

Pilot Oil Filter and Relief Valve

Pilot Valve (Auxiliary)

Pilot Valve (Joystick)

Pilot Valve (Travel)

Pressure Reducing Valve (Boom Priority)

Pressure Sensor

Pressure Switch (Refrigerant Pressure Cutoff)

Pump Coupling

Pump Head (Main) - Driven

Pump Head (Main) - Drive

Pump Lines (Main) - Hydraulic Oil Cooler Lines

Pump Lines

Recoil Spring

Refrigerant Compressor

Relief Valve (Line)

Relief Valve (Main) - Heavy Lift

Relief Valve (Negative Flow Control) - Auxiliary, Combined Function

Relief Valve (Negative Flow Control)

Return Lines - Boom Lowering Control

Return Lines - Smart Boom (1)

Return Lines - Smart Boom (2)

Rollover Protective Structure (ROPS) Mounting

Selector Valve (Control Pattern Change)

Shuttle Valve (Pilot Lines)

Solenoid Valve - Load Sensing

Solenoid Valve (Proportional Reducing) (1)

Solenoid Valve (Proportional Reducing) (2)

Solenoid Valve (Quick Coupler)

Solenoid Valve (Work Tool, 4-Function)

Sprocket

Stick - 2.5 m (8.20 ft) (1)

Stick - 2.5 m (8.20 ft) (2)

Stick - 2.5 m (8.20 ft) (3)

Stick - 2.95 m (9.678 ft) (1)

Stick - 2.95 m (9.678 ft) (2)

Stick - 2.95 m (9.678 ft) (3)

Stick - 2.95 m (9.678 ft) (4)

Stick - 7.9 m (25.92 ft)

Stick Cylinder (1)

Stick Cylinder (2)

Stick Cylinder Lines (1)

Stick Cylinder Lines (2)

Stick Cylinder Lines (3)

Stick Cylinder Lines - Long Reach

Stick Lines (1)

Stick Lines (2)

Stick Lines (3)

Stick Lines - Coupler Lines Group

Stick Lines - Long Reach

Swing Cushion Valve - Fine Swing

Swing Cushion Valve

Swing Drive Mounting

Swing Drive

Swing Gear and Bearing

Swing Motor

Swivel

Track Carrier Roller

Track

Track Roller (Single Flange) (1)

Track Roller (Single Flange) (2)

Travel Counterbalance Valve

Travel Motor and Mounting

Travel Motor Guard

Travel Motor Lines

Travel Motor

Upper Frame

UENR1514 - Systems Operation (324E & 329E Excavators Hydraulic System)

Accumulator (Pilot)

Boom Drift Reduction Valve

Boom Hydraulic System

Bucket Hydraulic System

Bypass Valve (Return) - Bypass Check Valve

Check Valve (Load)

Check Valve (Return Makeup) - Slow Return Check Valve

Control Valve (Boom Lowering)

Control Valve (Stick Lowering)

Control Valve (Straight Travel)

Cylinders (Boom, Stick and Bucket)

Displacement Change Valve

Electronic Control System

Final Drive

Gear Pump (Pilot)

General Information

Graphic Color Codes

Hydraulic Filter (Pilot)

Hydraulic Oil Cooler

Hydraulic Tank and Filter

Main Control Valve

Main Hydraulic Pump

Main Hydraulic System

Negative Flow Control System

Oil Filter (Return) - Case Drain Filter

Oil Makeup (Swing System)

Oil Makeup (Travel System)

Pilot Hydraulic System

Pilot Valve (Joystick)

Pilot Valve (Swing Parking Brake)

Pilot Valve (Travel)

Pump Control (Main Hydraulic) - Main Pump Regulator

Relief Valve (Cushion Crossover) - Anti-Reaction Valves

Relief Valve (Line)

Relief Valve (Main) - Heavy Lift

Relief Valve (Main)

Relief Valve (Pilot)

Relief Valve (Swing)

Return Hydraulic System

SmartBoom Hydraulic System

Solenoid Valve (Fine Swing) - If Equipped

Solenoid Valve (Hydraulic Lockout)

Solenoid Valve (Proportional Reducing) - Power Shift System

Stick Drift Reduction Valve

Stick Hydraulic System

Swing Drive

Swing Hydraulic System

Swing Motor

Swivel

Travel Counterbalance Valve

Travel Hydraulic System

Travel Motor

Travel Parking Brake

UENR1515 - Testing & Adjusting (324E Excavator Hydraulic System)

Accumulator (Pilot) - Test and Charge

Cylinder Drift - Check - Empty Bucket

Cylinder Drift - Check - Loaded Bucket

Cylinder Speed - Check

Engine Performance - Test - Engine Speed

Gear Pump (Pilot) - Test

General Testing and Adjusting Information

Machine Drift on a Slope - Check

Main Hydraulic Pump Air - Purge

Main Pump (Flow) - Test - Constant Horsepower Flow Control

Main Pump (Flow) - Test - Hydraulic Power

Operational Checks

Overload Warning - Set - If Equipped

Pump Control (Negative Flow) - Adjust

Pump Control (Negative Flow) - Test

Pump Control (Output Flow) - Adjust

Relief Valve (Crossover) - Test and Adjust

Relief Valve (Line) - Test and Adjust

Relief Valve (Main) - Test and Adjust

Relief Valve (Pilot) - Test and Adjust

Relief Valve (Swing) - Test and Adjust

Solenoid Valve (Proportional Reducing) - Calibrate - Boom Down Regeneration

Solenoid Valve (Proportional Reducing) - Calibrate - Negative Flow Control

Solenoid Valve (Proportional Reducing) - Calibrate - Power Shift Pressure

Specifications

Swing Bearing Movement - Measure

Swing Motor - Test - Measurement of Case Drain Oil

Swing Speed and Overswing on Level Ground - Check

Swing Speed and Swing Drift on a Slope - Check

System Pressure - Release

Travel Motor - Test - Measurement of Case Drain Oil

Travel on Level Ground - Test - Optional Test

Travel on Level Ground - Test

Visual Inspection

UENR1516 - Schematic (324E Excavator Hydraulic System)

UENR1517 - Schematic (324E, 329E & 329E MHPU Excavator Electrical System)

UENR1518 - Testing & Adjusting (320E, 323F, 324E, 326F, 329E, 329F & 330F Excavators Long Reach Front)

Cylinder Speed - Test and Adjust - 320E 323F

Cylinder Speed - Test and Adjust - 324E 326F

General Information

Overload Warning - Set - If Equipped

Relief Valve (Line) - Test and Adjust - 320E 323F

Relief Valve (Line) - Test and Adjust - 324E 326F

Specifications - 320E 323F

Specifications - 320E

Specifications - 324E 326F

UENR1525 - Testing & Adjusting (329E Excavator Hydraulic System)

Accumulator (Pilot) - Test and Charge

Cylinder Drift - Check - Empty Bucket

Cylinder Drift - Check - Loaded Bucket

Cylinder Speed - Check

Engine Performance - Test - Engine Speed

Gear Pump (Pilot) - Test

General Testing and Adjusting Information

Machine Drift on a Slope - Check

Main Hydraulic Pump Air - Purge

Main Pump (Flow) - Test - Constant Horsepower Flow Control

Main Pump (Flow) - Test - Hydraulic Power

Operational Checks

Overload Warning - Set - If Equipped

Pump Control (Negative Flow) - Adjust

Pump Control (Negative Flow) - Test

Pump Control (Output Flow) - Adjust

Relief Valve (Crossover) - Test and Adjust

Relief Valve (Line) - Test and Adjust

Relief Valve (Main) - Test and Adjust

Relief Valve (Pilot) - Test and Adjust

Relief Valve (Swing) - Test and Adjust

Solenoid Valve (Proportional Reducing) - Calibrate - Boom Down Regeneration

Solenoid Valve (Proportional Reducing) - Calibrate - Negative Flow Control

Solenoid Valve (Proportional Reducing) - Calibrate - Power Shift Pressure

Specifications

Swing Bearing Movement - Measure

Swing Motor - Test - Measurement of Case Drain Oil

Swing Speed and Overswing on Level Ground - Check

Swing Speed and Swing Drift on a Slope - Check

System Pressure - Release

Travel Motor - Test - Measurement of Case Drain Oil

Travel on Level Ground - Test - Optional Test

Travel on Level Ground - Test

Visual Inspection

UENR1526 - Schematic (329E Excavator & 329E MHPU Hydraulic System)

UENR2176 - Schematic (329E Excavator Hydraulic System - Attachment)

UENR2177 - Schematic (329E Excavator Hydraulic System - Attachment)

UENR2178 - Schematic (329E Excavator Hydraulic System - Attachment)

UENR2179 - Schematic (329E Excavator Hydraulic System - Attachment)

UENR2180 - Schematic (329E Excavator Hydraulic System - Attachment)

UENR2181 - Schematic (329E Excavator Hydraulic System - Attachment)

UENR2182 - Schematic (329E Excavator Hydraulic System - Attachment)

UENR2184 - Schematic (320E, 324E & 329E Excavators Hydraulic System - Attachment)

UENR2188 - Schematic (324E & 329E Excavators Hydraulic System - Attachment)

UENR2189 - Schematic (329E Excavator Hydraulic System - Attachment)

UENR2190 - Schematic (329E Excavator Hydraulic System - Attachment)

UENR2191 - Schematic (329E Excavator Hydraulic System - Attachment)

UENR2192 - Schematic (329E Excavator Hydraulic System - Attachment)

UENR2193 - Schematic (329E Excavator Hydraulic System - Attachment)

UENR2194 - Schematic (320E, 324E & 329E Excavators Hydraulic System - Attachment)

UENR2195 - Schematic (320E, 324E & 329E Excavators Hydraulic System - Attachment)

UENR3249 - Schematic (324E, 329E Excavator & 329E MHPU Electrical System)

UENR3884 - Schematic (324E, 329E Excavator & 329E MHPU Electrical System)