John Deere 1720, 1725 SeedStar 16 Row Planter Diagnosis and Tests Service Technical Manual (TM118219)

Complete Diagnosis & Tests Technical Manual with electrical wiring diagrams for John Deere SeedStar 16 Row Planters Models 1720, 1725 Planter (Frame, and Hydraulics) , with technical information to maintain, diagnose, and service like professional mechanics.

John Deere 1720, 1725 SeedStar 16 Row Planter (SN.745101-) workshop Diagnosis & Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm118219 - 1720, 172516 Row Planter (SN745101 - XXXXXX) SeedStarTM, Frame, and Hydraulics Diagnosis and Tests Technical Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,143 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MAIN SECTIONS

Foreword

General Information

Acronym Table

How to Use This Manual

Safety

Lubricants

Accessing Diagnostic Addresses and Codes

Recommended Tools for Diagnostics

Diagnostic Information for Electrical Components

Diagnostic Information for Hydraulic Components

Maintaining Hydraulic Systems and Components

Basic Diagnostics

Standard Torque Chart Procedures

Diagnostic Trouble Codes

Accessing Diagnostic Trouble Codes

PM1 - Planter Main 1 Codes

PM2 - Planter Main 2 Codes

Observable Symptoms and System Diagnostics

Observable Symptoms

Electrical System

Theory of Operation

Schematics

Diagnostics

Electrical Control Units

Accessing Diagnostic Addresses

Diagnostic Addresses by Control Unit

Diagnostics

Electrical Component Information

Assembly Connectors

Sensor Connectors

Light Connectors

Fuse Connectors

Battery Connectors

Relay Connectors

Motor Connectors

Resistor Connectors

Switch Connectors

Harness Interconnects

Solenoid Connectors

Hydraulic System

Theory of Operation

Schematics

Diagnostics

Hydraulic Component Information

Cylinders

Filters

Assemblies

Oil Coolers

Motors

Orifices

Reservoirs

Valves

Couplers

Solenoid Valves

Pneumatic System

Theory of Operation

Schematics

Diagnostics

Pneumatic Component Information

Accumulators

Sensors

Check Valves

Filters

Assemblies

Motors

Pumps

Reservoirs

Switches

Valves

Couplers

Solenoid Valves

tm118219 - 1720, 172516 Row Planter (SN745101 - XXXXXX) SeedStar™, Frame, and Hydraulics Diagnosis and Tests

Table of Contents

Foreword

Section 210: General Information

Group 10: Acronym Table

Acronym Table

Group 05A: How to Use This Manual

Information is Available in Sections, Groups and Subgroups

Group 05B: Safety

Work In Ventilated Area

Recognize Safety Information

Avoid Backover Accidents

Prevent Machine Runaway

Avoid Contact with Agricultural Chemicals

Clean Vehicle of Hazardous Pesticides

Use a Safety Chain

Work in Clean Area

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Prepare for Emergencies

In Case of Fire

Use Safety Lights and Devices

Avoid High-Pressure Fluids

Use Proper Lifting Equipment

Illuminate Work Area Safely

Live With Safety

Service Machines Safely

Support Machine Properly

Freeing a Mired Machine

Protect Against Noise

Remove Paint Before Welding or Heating

Park Machine Safely

Prevent Acid Burns

Follow Safety Instructions

Follow Safety Instructions

Use Proper Tools

Keep Riders Off Machine

Service Tires Safely

Stay Clear of Rotating Drivelines

Construct Dealer-Made Tools Safely

Practice Safe Maintenance

Understand Signal Words

Replace Safety Signs

Prevent Battery Explosions

Protect Against High Pressure Spray

Service Tires Safely

Avoid Heating Near Pressurized Fluid Lines

Tow Loads Safely

Transport Towed Equipment at Safe Speeds

Observe Maximum Transport Speed

Wear Protective Clothing

Precautions for Welding

Handle Agricultural Chemicals Safely

Service and Operate Chemical Sprayers Safely

Relieve Hydraulic Pressure Safely

Use Steps and Handholds Correctly

Group 05C: Lubricants

Grease

Gear Oil

Alternative and Synthetic Lubricants

Lubricant Storage

Group 05D: Accessing Diagnostic Addresses and Codes

Accessing Diagnostic Addresses

Accessing Diagnostic Trouble Codes

Group 05E: Recommended Tools for Diagnostics

Recommended Tools

Group 05F: Diagnostic Information for Electrical Components

Electrical Designators

Visually Inspect Electrical System

Group 05G: Diagnostic Information for Hydraulic Components

Hydraulic Designators

Troubleshooting Tips

Visually Inspect Hydraulic System

Group 05H: Maintaining Hydraulic Systems and Components

Hydraulic Components

Oil Storage and Filling

Oil Filtration

Group 05I: Basic Diagnostics

Seven Basic Steps

Troubleshooting Unresolved Problems

Group 05J: Standard Torque Chart Procedures

Unified Inch Bolt and Screw Torque Values

Metric Bolt and Screw Torque Values

Section 211: Diagnostic Trouble Codes

Group 10A: Accessing Diagnostic Trouble Codes

Accessing Diagnostic Trouble Codes

Group 10C: PM1 - Planter Main 1 Codes

PM1 000084.09 - Wheel Speed Not Detected On CAN Bus

PM1 000609.12 - Planter Module 2 Not Responding

PM1 000629.14 - Planter Disabled, Cycle Power

PM1 001859.09 - Radar Speed Not Detected On CAN Bus

PM1 001859.10 - Ground Speed and Tractor Speed Conflict

PM1 001859.14 - Minimum Speed Not Reached At End Of Quickstart

PM1 003509.03 - 5 Volt Sensor Supply Voltage High

PM1 003509.04 - 5 Volt Sensor Supply Voltage Low

PM1 003510.03 - 8 Volt Sensor Supply Voltage High

PM1 003510.04 - 8 Volt Sensor Supply Voltage Low

PM1 005109.12 - Planter Module 3 Not Responding

PM1 005117.01 - EPM 1 Input Voltage Low

PM1 005117.02 - EPM 1 Not Responding To Setup

PM1 005117.12 - EPM 1 Offline

PM1 005117.18 - EPM 1 Low Voltage On Inputs

PM1 005118.01 - EPM 2 Input Voltage Low

PM1 005118.02 - EPM 2 Not Responding To Setup

PM1 005118.12 - EPM 2 Offline

PM1 005118.18 - EPM 2 Low Voltage On Inputs

PM1 520328.02 - Seed Detected On Row 1 While Deactivated

PM1 520328.12 - Row 1 Clutch Failed

PM1 521037.03 - Vacuum 1 Sensor Voltage High

PM1 521037.04 - Vacuum 1 Sensor Voltage Low

PM1 521037.17 - Vacuum 1 Pressure Low

PM1 521124.03 - Vacuum 2 Sensor Voltage High

PM1 521124.04 - Vacuum 2 Sensor Voltage Low

PM1 521124.17 - Vacuum 2 Pressure Low

PM1 521633.07 - VRD 1 Frequency Low

PM1 521633.10 - VRD 1 Frequency Abnormal

PM1 521726.07 - VRD 2 Frequency Low

PM1 521726.10 - VRD 2 Frequency Abnormal

PM1 521883.07 - VRD 3 Frequency Low

PM1 521883.10 - VRD 3 Frequency Abnormal

PM1 522260.02 - Motion Sensor Speed and Tractor Speed Conflict

PM1 522260.10 - Motion Sensor Responding When No Active Tractor Speed

PM1 522336.02 - Seed Detected On Row 16 While Deactivated

PM1 522336.12 - Row 16 Clutch Failed

PM1 522337.02 - Seed Detected On Row 15 While Deactivated

PM1 522337.12 - Row 15 Clutch Failed

PM1 522338.02 - Seed Detected On Row 14 While Deactivated

PM1 522338.12 - Row 14 Clutch Failed

PM1 522339.02 - Seed Detected On Row 13 While Deactivated

PM1 522339.12 - Row 13 Clutch Failed

PM1 522342.02 - Seed Detected On Row 12 While Deactivated

PM1 522342.12 - Row 12 Clutch Failed

PM1 522346.02 - Seed Detected On Row 11 While Deactivated

PM1 522346.12 - Row 11 Clutch Failed

PM1 522347.02 - Seed Detected On Row 10 While Deactivated

PM1 522347.12 - Row 10 Clutch Failed

PM1 522348.02 - Seed Detected On Row 9 While Deactivated

PM1 522348.12 - Row 9 Clutch Failed

PM1 522349.02 - Seed Detected On Row 8 While Deactivated

PM1 522349.12 - Row 8 Clutch Failed

PM1 522351.02 - Seed Detected On Row 7 While Deactivated

PM1 522351.12 - Row 7 Clutch Failed

PM1 522352.02 - Seed Detected On Row 6 While Deactivated

PM1 522352.12 - Row 6 Clutch Failed

PM1 522353.02 - Seed Detected On Row 5 While Deactivated

PM1 522353.12 - Row 5 Clutch Failed

PM1 522354.02 - Seed Detected On Row 4 While Deactivated

PM1 522354.12 - Row 4 Clutch Failed

PM1 522355.02 - Seed Detected On Row 3 While Deactivated

PM1 522355.12 - Row 3 Clutch Failed

PM1 522356.02 - Seed Detected On Row 2 While Deactivated

PM1 522356.12 - Row 2 Clutch Failed

PM1 522941.11 - Selected Ground Speed Source is Wheel

PM1 522941.14 - Selected Ground Speed Source is Manual

PM1 522942.09 - Planting Parameters Satisfied Before Controller Initialized

PM1 523111.14 - Reset System Parameters

PM1 523170.31 - Row 16 Seed Sensor Not Responding

PM1 523171.31 - Row 15 Seed Sensor Not Responding

PM1 523172.31 - Row 14 Seed Sensor Not Responding

PM1 523173.31 - Row 13 Seed Sensor Not Responding

PM1 523174.31 - Row 12 Seed Sensor Not Responding

PM1 523175.31 - Row 11 Seed Sensor Not Responding

PM1 523176.31 - Row 10 Seed Sensor Not Responding

PM1 523177.31 - Row 9 Seed Sensor Not Responding

PM1 523178.31 - Row 8 Seed Sensor Not Responding

PM1 523179.31 - Row 7 Seed Sensor Not Responding

PM1 523180.31 - Row 6 Seed Sensor Not Responding

PM1 523181.31 - Row 5 Seed Sensor Not Responding

PM1 523182.31 - Row 4 Seed Sensor Not Responding

PM1 523183.31 - Row 3 Seed Sensor Not Responding

PM1 523184.31 - Row 2 Seed Sensor Not Responding

PM1 523185.31 - Row 1 Seed Sensor Not Responding

PM1 523194.31 - Rows Not Planting

PM1 523319.03 - ECU Power Voltage High

PM1 523319.04 - ECU Power Voltage Low

PM1 523328.11 - Height Sensor Not Calibrated

PM1 523328.14 - Height Sensor Below Normal Operating Range

PM1 523436.31 - Watchdog Reset For Seed Monitor

PM1 523651.11 - Internal Stack Overflow

PM1 523652.03 - High Current Power Voltage High

PM1 523652.04 - High Current Power Voltage Low

PM1 523705.31 - Watchdog Reset For Seed Monitor And VRD

PM1 523773.03 - CAN High Voltage High

PM1 523773.04 - CAN High Voltage Low

PM1 523774.03 - CAN Low Voltage High

PM1 523774.04 - CAN Low Voltage Low

PM1 524054.14 - Specified Area Has Been Planted

PM1 524055.11 - Stored NOVRAM Value Abnormal

Group 10D: PM2 - Planter Main 2 Codes

PM2 000609.02 - Seed Monitor Not Responding

PM2 000609.12 - Seed Monitor Offline

PM2 000629.12 - Watchdog Timed Out

PM2 000639.12 - Implement CAN Bus Lost Message

PM2 000639.14 - Implement CAN Bus Excessive Errors

PM2 000705.13 - Node 1 Sensor Calibration Error

PM2 000705.19 - Node 1 Downforce Sensor Error

PM2 000706.13 - Node 2 Sensor Calibration Error

PM2 000706.19 - Node 2 Downforce Sensor Error

PM2 000707.13 - Node 3 Sensor Calibration Error

PM2 000707.19 - Node 3 Downforce Sensor Error

PM2 001231.12 - Left CAN Bus Lost Message

PM2 001231.14 - Left CAN Bus Excessive Errors

PM2 001235.12 - Right CAN Bus Lost Message

PM2 001235.14 - Right CAN Bus Excessive Errors

PM2 001351.14 - Compressor Motor Time Limit Exceeded

PM2 003509.03 - 5 Volt Sensor Supply Voltage High

PM2 003509.04 - 5 Volt Sensor Supply Voltage Low

PM2 005111.02 - Node 1 Message Missing

PM2 005111.12 - Node 1 Missing

PM2 005111.19 - Node 1 Accelerometer Fault

PM2 005112.02 - Node 2 Message Missing

PM2 005112.12 - Node 2 Missing

PM2 005112.19 - Node 2 Accelerometer Fault

PM2 005113.02 - Node 3 Message Missing

PM2 005113.12 - Node 3 Missing

PM2 005113.19 - Node 3 Accelerometer Fault

PM2 521087.03 - Increase Solenoid Feedback Voltage High

PM2 521087.05 - Increase Solenoid Current Low

PM2 521087.06 - Increase Solenoid Current High

PM2 521092.03 - Exhaust Solenoid Feedback Voltage High

PM2 521092.05 - Exhaust Solenoid Current Low

PM2 521092.06 - Exhaust Solenoid Current High

PM2 521130.03 - Row Unit Downforce Sensor Signal Voltage High

PM2 521130.06 - Row Unit Downforce Sensor Signal Voltage Low

PM2 521130.13 - Row Unit Downforce Sensor Zero Error

PM2 521938.03 - Right Address Feedback Voltage High

PM2 521938.05 - Right Address Line Open

PM2 521938.06 - Right Address Current High

PM2 521939.03 - Row Unit Downforce Sensor Signal Voltage High

PM2 521939.06 - Row Unit Downforce Sensor Signal Voltage Low

PM2 521939.13 - Row Unit Downforce Sensor Zero Error

PM2 521940.03 - Exhaust Solenoid Feedback Voltage High

PM2 521940.05 - Exhaust Solenoid Current Low

PM2 521940.06 - Exhaust Solenoid Current High

PM2 521941.03 - Increase Solenoid Feedback Voltage High

PM2 521941.05 - Increase Solenoid Current Low

PM2 521941.06 - Increase Solenoid Current High

PM2 523219.03 - High Current Power Voltage High

PM2 523219.04 - High Current Power Voltage Low

PM2 523219.05 - High Current Power Not Detected

PM2 523319.03 - ECU Power Voltage High

PM2 523319.04 - ECU Power Voltage Low

PM2 523685.03 - Left Address Feedback Voltage High

PM2 523685.05 - Left Address Line Open

PM2 523685.06 - Left Address Current High

Section 212: Observable Symptoms and System Diagnostics

Group 10: Observable Symptoms

Auxiliary Hydraulics Observable Symptoms

CAN Bus Observable Symptoms

CCS Agitator Observable Symptoms

CCS Blower Observable Symptoms

Electronic Control Unit (ECU) Power and Ground Observable Symptoms

Enhanced Monitoring Observable Symptoms

Fold Observable Symptoms

Height and Motion Sensors Observable Symptoms

High Current Power and Ground Observable Symptoms

Lift Assist and Wing Lift Observable Symptoms

Lighting - CCS Fill Lights Observable Symptoms

Lighting - Transport Lights - CCS Observable Symptoms

Lighting - Transport Lights - non-CCS Observable Symptoms

Pneumatic Downforce Observable Symptoms

Population Observable Symptoms

Rate Controller Observable Symptoms

Row Command Observable Symptoms

Seed Monitoring Observable Symptoms

Vacuum Observable Symptoms

Variable Rate Drive Observable Symptoms

Section 240: Electrical System

Group 05: General Information

General Information

Intermittent Fault Diagnostics

Circuit Load Test

Group 20: Theory of Operation

Auxiliary Hydraulics Electrical Theory of Operation

Auxiliary Power Electrical Theory of Operation

CAN Bus Electrical Theory of Operation

CCS Agitator Electrical Theory of Operation

CCS Blower Electrical Theory of Operation

CCS Tank Low Warning Electrical Theory of Operation

Electronic Control Unit (ECU) Power and Ground Electrical Theory of Operation

Enhanced Monitoring Electrical Theory of Operation

Height and Motion Sensors Electrical Theory of Operation

High Current Power and Ground Electrical Theory of Operation

Lighting - CCS Fill Lights Electrical Theory of Operation

Lighting - Transport Lights - CCS Electrical Theory of Operation

Lighting - Transport Lights - non-CCS Electrical Theory of Operation

Pneumatic Downforce Electrical Theory of Operation

Rate Controller Electrical Theory of Operation

Row Command Electrical Theory of Operation

Seed Monitoring Electrical Theory of Operation

Vacuum Electrical Theory of Operation

Variable Rate Drive Electrical Theory of Operation

Group 30: Schematics

Auxiliary Hydraulics Electrical Schematic

Auxiliary Power Electrical Schematic

CAN Bus Electrical Schematic

CCS Agitator Electrical Schematic

CCS Blower Electrical Schematic

CCS Tank Low Warning Electrical Schematic

Electronic Control Unit (ECU) Power and Ground Electrical Schematic

Enhanced Monitoring Electrical Schematic

Height and Motion Sensors Electrical Schematic

High Current Power and Ground Electrical Schematic

Lighting - CCS Fill Lights Electrical Schematic

Lighting - Transport Lights - CCS Electrical Schematic

Lighting - Transport Lights - non-CCS Electrical Schematic

Pneumatic Downforce Electrical Schematic

Rate Controller Electrical Schematic

Row Command Electrical Schematic

Seed Monitoring Electrical Schematic

Vacuum Electrical Schematic

Variable Rate Drive Electrical Schematic

Group 50: Diagnostics

Auxiliary Hydraulics Electrical Diagnostics

CAN Bus Electrical Diagnostics

CCS Agitator Electrical Diagnostics

CCS Blower Electrical Diagnostics

Electronic Control Unit (ECU) Power and Ground Electrical Diagnostics

Enhanced Monitoring Electrical Diagnostics

Height and Motion Sensors Electrical Diagnostics

High Current Power and Ground Electrical Diagnostics

Lighting - CCS Fill Lights Electrical Diagnostics

Lighting - Transport Lights - CCS Electrical Diagnostics

Lighting - Transport Lights - non-CCS Electrical Diagnostics

Pneumatic Downforce Electrical Diagnostics

Rate Controller Electrical Diagnostics

Row Command Electrical Diagnostics

Seed Monitoring Electrical Diagnostics

Vacuum Electrical Diagnostics

Variable Rate Drive Electrical Diagnostics

Section 245: Electrical Control Units

Group 10A: Accessing Diagnostic Addresses

Accessing Diagnostic Addresses

Group 10B: Diagnostic Addresses by Control Unit

Planter Main 1 (PM1) Addresses

Planter Main 2 (PM2) Addresses

Group 50: Diagnostics

EPM 1 Diagnostic Test

EPM 2 Diagnostic Test

Planter Main 1 (PM1) Control Unit Test

Planter Main 2 (PM2) Control Unit Test

Section 249: Electrical Component Information

Group 40XA: Assembly Connectors

XA4 - Flasher Module Connector

XA6 - Disconnects Console Connector

XA8-1 - Rate Controller J1 Connector

XA8-2 - Rate Controller J2 Connector

XA8-3 - Rate Controller J3 Connector

XA10 - Implement CAN Secondary Terminator Connector

XA11-1 - Planter Main 1 Control Unit A1 Connector

XA11-2 - Planter Main 1 Control Unit B Connector

XA12-1 - Planter Main 2 Control Unit J1 Connector

XA12-2 - Planter Main 2 Control Unit J2 Connector

XA12-3 - Planter Main 2 Control Unit J3 Connector

XA12-4 - Planter Main 2 Control Unit MMC Power Connector

XA15 - Left CAN Primary Terminator Connector

XA16 - Left CAN Secondary Terminator Connector

XA17 - Left CAN Diagnostic Connector

XA18 - Right CAN Primary Terminator Connector

XA19 - Right CAN Secondary Terminator Connector

XA20 - Right CAN Diagnostic Connector

XA21-1 - EPM 1 J1 Connector

XA21-2 - EPM 1 J2 Connector

XA21-3 - EPM 1 J3 Connector

XA22-1 - EPM 2 J1 Connector

XA22-2 - EPM 2 J2 Connector

XA22-3 - EPM 2 J3 Connector

XA31 - Node 1 Connector

XA32 - Node 2 Connector

XA33 - Node 3 Connector

XA95 - ISO Implement Connector

Group 40XB: Sensor Connectors

XB14 - Motion Sensor Connector

XB31 - Node 1 Downforce Sensor Connector

XB32 - Node 2 Downforce Sensor Connector

XB33 - Node 3 Downforce Sensor Connector

XB41 - Left Bin Level Sensor Connector

XB42 - Right Bin Level Sensor Connector

XB51 - VRD 1 Speed Sensor Connector

XB52 - VRD 2 Speed Sensor Connector

XB53 - VRD 3 Speed Sensor Connector

XB61 - Vacuum 1 Pressure Sensor Connector

XB62 - Vacuum 2 Pressure Sensor Connector

XB71 - Air Pressure Sensor Connector

XB101 - XB116 - Seed Sensors Connectors

Group 40XE: Light Connectors

XE23 - Left Side Light Connector

XE24 - Left Amber Light - non-CCS Connector

XE25 - Left Red Light - non-CCS Connector

XE26 - Right Red Light - non-CCS Connector

XE27 - Right Amber Light - non-CCS Connector

XE28 - Right Side Light Connector

XE41 - Rear Fill Light Connector

XE42 - Front Fill Light Connector

XE44 - Left Amber Light - CCS Connector

XE45 - Left Red Light - CCS Connector

XE46 - Right Red Light - CCS Connector

XE47 - Right Amber Light - CCS Connector

Group 40XF: Fuse Connectors

XF6 - Disconnects Console Fuse Connector

XF7 - Battery Adapter Fuse Connector

XF21 - EPM 1 Fuse Connector

XF22 - EPM 2 Fuse Connector

Group 40XG: Battery Connectors

XG7-1 - Tractor Battery Positive Terminal Connector

XG7-2 - Tractor Battery Negative Terminal Connector

Group 40XK: Relay Connectors

XK7 - Battery Adapter Relay Connector

XK40 - Agitator Relay Connector

XK70 - Compressor Relay Connector

Group 40XM: Motor Connectors

XM41-1 - Left Agitator Motor Power Connector

XM41-2 - Left Agitator Motor Ground Connector

XM42-1 - Right Agitator Motor Power Connector

XM42-2 - Right Agitator Motor Ground Connector

XM70 - Compressor Motor Connector

Group 40XR: Resistor Connectors

XR1 - Height Resistor Connector

Group 40XS: Switch Connectors

XS15 - Height Switch 1 Connector

XS16 - Height Switch 2 Connector

XS17 - Row Switch Connector

XS40 - Fill Light Switch Connector

XS41 - Clean Out Switch Connector

XS44 - Auxiliary Hydraulics Switch Connector

XS70 - Tank Pressure Switch Connector

Group 40XX: Harness Interconnects

XX6 - Disconnects Console to Backbone Harness Interconnect

XX7 - Battery to Backbone Harness Interconnect

XX9 - Unswitched Power to Backbone Harness Interconnect

XX10 - Lighting and Accessory Outlet

XX11 - Backbone to SMVR Harness Interconnect

XX12 - Auxiliary Power Interconnect

XX14 - Backbone to Motion Sensor Harness Interconnect

XX15 - Backbone to Height Switch 1 Harness Interconnect

XX16 - Backbone to Height Switch 2 Harness Interconnect

XX17 - Backbone to Row Switch Harness Interconnect

XX18-1 - Backbone to Rate Controller Harness Interconnect 1

XX18-2 - Backbone to Rate Controller Harness Interconnect 2

XX19-1 - Backbone to Implement CAN Terminator Harness Interconnect

XX19-2 - High Current Power Out Interconnect

XX20-1 - Backbone to EPM Harness Interconnect 1

XX20-2 - Backbone to EPM Harness Interconnect 2

XX25 - Backbone to Left Lighting Harness - non-CCS Interconnect

XX26 - Backbone to Right Lighting Harness - non-CCS Interconnect

XX31 - Backbone to Node 1 Harness Interconnect

XX32 - Backbone to Node 2 Harness Interconnect

XX33 - Backbone to Node 3 Harness Interconnect

XX41 - Backbone to CCS Cradle Harness Interconnect

XX43 - CCS Cradle to Ladder Harness Interconnect

XX44 - Auxiliary Hydraulics Jumper Harness Interconnect

XX45 - CCS Cradle to Left Lighting Harness - CCS Interconnect

XX46 - CCS Cradle to Right Lighting Harness - CCS Interconnect

XX51 - Backbone to VRD 1 Harness Interconnect

XX52 - Backbone to VRD 2 Harness Interconnect

XX53 - Backbone to VRD 3 Harness Interconnect

XX70 - Backbone to Compressor Harness Interconnect

XX71 - Backbone to Downforce Manifold Harness Interconnect

XX101 - XX116 - Backbone to Row Unit Harnesses Interconnects

Group 40XY: Solenoid Connectors

XY41 - CCS Blower Solenoid Connector

XY51 - VRD 1 Solenoid Connector

XY52 - VRD 2 Solenoid Connector

XY53 - VRD 3 Solenoid Connector

XY71 - Fill Solenoid Connector

XY72 - Exhaust Solenoid Connector

XY101 - XY116 - Row Clutch Connectors

Section 270: Hydraulic System

Group 20: Theory of Operation

Auxiliary Hydraulics Hydraulic Theory of Operation

CCS Blower Hydraulic Theory of Operation

Fold Hydraulic Theory of Operation

Lift Assist and Wing Lift Hydraulic Theory of Operation

Markers Hydraulic Theory of Operation

Vacuum Hydraulic Theory of Operation

Variable Rate Drive Hydraulic Theory of Operation

Group 30: Schematics

Auxiliary Hydraulics Hydraulic Schematic

CCS Blower Hydraulic Schematic

Fold Hydraulic Schematic

Lift Assist and Wing Lift Hydraulic Schematic

Markers Hydraulic Schematic

Vacuum Hydraulic Schematic

Variable Rate Drive Hydraulic Schematic

Group 50: Diagnostics

Auxiliary Hydraulics Hydraulic Diagnostics

CCS Blower Hydraulic Diagnostics

Fold Hydraulic Diagnostics

Vacuum Hydraulic Diagnostics

Variable Rate Drive Hydraulic Diagnostics

Section 279: Hydraulic Component Information

Group 40C: Cylinders

C1 - Left Wing Lift Cylinder

C2 - Right Wing Lift Cylinder

C3 - Left Assist Cylinder

C4 - Right Assist Cylinder

C5 - Left Fold Cylinder

C6 - Right Fold Cylinder

C7 - Left Marker Cylinder

C8 - Right Marker Cylinder

Group 40F: Filters

F11 - Auxiliary Filter

Group 40G: Assemblies

G1 - Fold Manifold

G2 - Lift Manifold

G41 - CCS Blower Motor Case

Group 40H: Oil Coolers

H41 - CCS Oil Cooler

Group 40M: Motors

M41 - CCS Blower Motor

M51 - VRD 1 Motor

M52 - VRD 2 Motor

M53 - VRD 3 Motor

M61 - Vacuum 1 Motor

M62 - Vacuum 2 Motor

Group 40O: Orifices

O5-1 - Left Fold Rod Orifice

O5-2 - Left Fold Piston Orifice

O6-1 - Right Fold Rod Orifice

O6-2 - Right Fold Piston Orifice

O7-1 - Left Marker Rod Orifice

O7-2 - Left Marker Piston Orifice

O8-1 - Right Marker Rod Orifice

O8-2 - Right Marker Piston Orifice

O41 - CCS Motor Orifice

O61 - Vacuum 1 Orifice

O62 - Vacuum 2 Orifice

Group 40R: Reservoirs

R41 - CCS Blower Reservoir

Group 40V: Valves

V4 - Fold Flow Divider Valve

V5 - Fold Piston Thermal Relief Valve

V6 - Fold Rod Thermal Relief Valve

V7 - Marker Sequence Valve

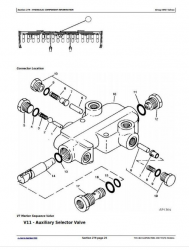

V11 - Auxiliary Selector Valve

V41 - CCS Flow Control Valve

V51 - VRD 1 Pressure Sense Valve

V52 - VRD 2 Pressure Sense Valve

V53 - VRD 3 Pressure Sense Valve

V61 - Vacuum 1 Flow Control Valve

V62 - Vacuum 2 Flow Control Valve

Group 40X: Couplers

X11P - Auxiliary Pressure Coupler

X11R - Auxiliary Return Coupler

Group 40Y: Solenoid Valves

Y41 - CCS Solenoid Valve

Y51 - VRD 1 Solenoid Valve

Y52 - VRD 2 Solenoid Valve

Y53 - VRD 3 Solenoid Valve

Section 280: Pneumatic System

Group 20: Theory of Operation

Downforce Pneumatic Theory of Operation

Group 30: Schematics

Downforce Pneumatic Schematics

Group 50: Diagnostics

Downforce Pneumatic Diagnostics

Section 289: Pneumatic Component Information

Group 40A: Accumulators

A101 - A116 - Row Air Springs

Group 40B: Sensors

B70 — Tank Pressure Gauge

B71 - Air Pressure Sensor

Group 40D: Check Valves

D70 - Compressor Outlet Check Valve

Group 40F: Filters

F70 - Compressor Inlet Filter

F71 - Manifold Inlet Filter

Group 40G: Assemblies

G70 - Pneumatic Downforce Manifold

G71 - Compressor Assembly

Group 40M: Motors

M8 - Compressor Motor

Group 40P: Pumps

P70 - Compressor

Group 40R: Reservoirs

R71 - Air Tank

Group 40S: Switches

S70 - Tank Pressure Switch

Group 40V: Valves

V70 - Condensate Drain

V71 - Pressure Increase Valve

V72 - Pressure Decrease Valve

V75 - Fill Valve

V77 - Relief Valve 1

V78 - Relief Valve 2

V80 - Front Shutoff Valve

Group 40X: Couplers

X70 - Tank Gauge Coupler

X71 - Main Gauge Coupler

X73 - Exhaust Vent

Group 40Y: Solenoid Valves

Y71 - Fill Solenoid

Y72 - Exhaust Solenoid

John Deere 1720, 1725 SeedStar 16 Row Planter Diagnosis and Tests Service Technical Manual (TM118219)