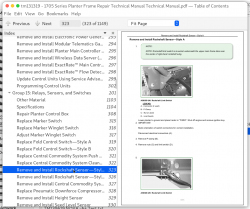

John Deere 1705, 1715, 1725, 1735, 1755, 1765, 1775, 1785, 1795 Planter Frame Repair Service Manual (TM131319)

Complete Repair Service Technical Manual for John Deere 1705, 1715, 1725, 1735, 1755, 1765, 1775, 1785, 1795 Planter Frame, with all the workshop information to maintain, repair, and rebuild like professional mechanics.

John Deere 1705, 1715, 1725, 1735, 1755, 1765, 1775, 1785, 1795 Planter Frame workshop technical manual (repair) includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm131319 - 1705 Series Planter Frame Repair Technical Manual Technical Manual.pdf

tm131319 - 1705 Series Planter Frame Repair Technical Manual Technical Manual.epub

PRODUCT DETAILS:

Total Pages: 1,149 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MAIN SECTIONS

Foreword

General Information

Safety

Lubricants

General Information

Vacuum System

Vacuum System

Central Commodity System

Seed Tanks and Manifolds

Seed Delivery Hose

Central Commodity System Fan

Electrical

Connector Repair

Control Units

Relays, Sensors, and Switches

Lighting Repair

Batteries

Generator

Drives

Specifications

Seed Drive Transmissions

Half Width Disconnect

Drill Shafts

Variable Rate Drive

Charging System Drive

Hitch and Frame

Repair and Welding

Hitch Pads

Wheel Module Repair

Row Markers

Loading Platform and Hitch

Rockshafts

Lift Assist

Hydraulics

General Information

Motors

Cylinders

Valve Block

Valves

Miscellaneous

Fertilizer and Pesticide Systems

Liquid Fertilizer System

Variable Rate Fertilizer

Pesticide System

Pneumatic Down Force

General Information

Pneumatic Down Force

Active Pneumatic Down Force

Miscellaneous

Polyethylene Tank Repair

Dealer Fabricated Tools

TABLE OF CONTENTS................1

Section 10: General Information................18

Group 05: Safety................18

Recognize Safety Information................21

Understand Signal Words................22

Handle Fluids Safely—Avoid Fires................23

Prevent Battery Explosions................24

Handling Batteries Safely................25

Prevent Acid Burns................27

Prepare for Emergencies................29

Avoid Harmful Asbestos Dust................30

Practice Safe Maintenance................31

Avoid High-Pressure Fluids................33

Park Machine Safely................34

Support Machine Properly................35

Wear Protective Clothing................36

Handle Agricultural Chemicals Safely................37

Work in Clean Area................39

Service Machines Safely................40

Work In Ventilated Area................41

Illuminate Work Area Safely................42

Replace Safety Signs................43

Use Proper Lifting Equipment................44

Remove Paint Before Welding or Heating................45

Avoid Heating Near Pressurized Fluid Lines................46

Service Accumulator Systems Safely................877

Service Tires Safely................48

Use Proper Tools................49

Construct Dealer-Made Tools Safely................50

Decommissioning — Proper Recycling and Disposal of Fluids and Components................51

Live With Safety................52

Servicing Electronic Control Units................53

Welding Near Electronic Control Units................54

Precautions for Welding................572

Keep Electronic Control Unit Connectors Clean................57

Group 10: Lubricants................19

Multipurpose Grease................59

Multipurpose Extreme Pressure (EP) Grease................60

Gear Oil................61

Alternative and Synthetic Lubricants................62

Lubricant Storage................63

Group 15: General Information................19

Unauthorized Modifications................65

Specifications—1705, 1705 Twin Row, 1715, and 1735................66

Dimensions—1705, 1705 Twin Row, 1715, and 1735................69

Specifications—1725, 1725NT, 1725C, 1725 CCS, and 1725 CCS Twin Row................70

Dimensions—1725, 1725NT, 1725 CCS, and 1725 CCS Twin Row................74

Specifications—1755 and 1785................75

Dimensions—1755 and 1785................78

Specifications—1765 and 1765NT................79

Dimensions—1765 and 1765NT................81

Specifications—1775NT 12 Row................82

Dimensions—1775NT 12 Row................85

Specifications—1775NT 16 Row................87

Dimensions—1775NT 16 Row................90

Specifications—1775NT 24 Row................92

Dimensions—1775NT 24 Row................95

Specifications—1795................98

Dimensions—1795................103

Sealants and Adhesives Cross-Reference Chart................105

Metric Bolt and Screw Torque Values................107

Unified Inch Bolt and Screw Torque Values................109

Face Seal Fittings Assembly and Installation—All Pressure Applications................111

Metric Face Seal Fitting Torque Chart—Standard Pressure Applications................112

SAE Face Seal Fitting Torque Chart—Standard Pressure Applications................114

External Hexagon Port Plug Torque Chart................116

Section 20: Vacuum System................118

Group 05: Vacuum System................118

Specifications................1104

Adjust Vacuum Gauge................121

Vacuum Manifold Blower System................122

Vacuum Manifold System Exploded View................123

Vacuum Manifold System Exploded View—With Dust Suppression System................124

Inspect and Adjust Vacuum Coupler Bell—1795................125

Clean Vacuum Manifold System................127

Repair Vacuum Monitoring Assembly —Two Vacuum Gauges................128

Repair Vacuum Monitoring Assembly with SeedStar™................130

Remove and Install Vacuum Blower Assembly—Style A................132

Disassemble and Assemble Vacuum Blower Assembly—Style A................134

Remove and Install Vacuum Blower Assembly—Style B................139

Disassemble and Assemble Vacuum Blower Assembly—Style B................140

Section 30: Central Commodity System................144

Group 05: Seed Tanks and Manifolds................144

Other Material................1103

Specifications................1104

Remove and Install Seed Tanks................148

Remove and Install Refuge Plus Third Tank................152

Tank Repair................906

Seal Central Commodity System Tanks To Prevent Water Leakage................156

Remove and Install Seed Agitator Motor Assembly................159

Remove and Install Seed Delivery Manifold Seal................162

Remove and Install Seed Delivery Manifold Nozzle................171

Repair Central Commodity System Seed Tank Manifold................177

Remove and Install Seed Tank Lid Ring and Seal................179

Group 10: Seed Delivery Hose................144

Other Material................1103

Remove and Install Seed Delivery Hose................187

Repair Seed Delivery Hose................188

Group 15: Central Commodity System Fan................144

Specifications................1104

Remove and Install Central Commodity System Blower Fan................192

Repair Central Commodity System Blower Fan Assembly................196

Section 40: Electrical................200

Group 05: Connector Repair................200

Essential or Recommended Tools................1133

Other Material................1103

Installation of Repair Wire Assembly (RWA)................213

Use Electrical Insulating Compound................222

Using High-Pressure Washers................223

Connector Information................224

Repair Procedure R-A................225

Repair Procedure R-B................230

Repair Procedure R-C................235

Repair Procedure R-D................240

Repair Procedure R-E................243

Repair Procedure R-F................247

Repair Procedure R-G................251

Repair Procedure R-I................254

Repair Procedure R-J................257

Repair Procedure R-K................262

Repair Procedure R-M................265

Repair Procedure R-N................269

Repair Procedure R-T................273

Repair Procedure R-AA................274

Repair Procedure R-AE................275

Replace Fold-Unfold Circuit Diode................279

Remove and Install Frame Control Harness................281

Group 10: Control Units................200

Remove and Install Electronic Power Generation (EPG) Control Unit................293

Remove and Install Modular Telematics Gateway (MTG) Control Unit................294

Remove and Install Planter Main Controller (PMC)................295

Remove and Install Wireless Data Server (WDS) Control Unit................296

Remove and Install ExactRate™ Main Control Unit................297

Remove and Install ExactRate™ Flow Detection Module................298

Update Control Units Using Service Advisor™................299

Programming Control Units................302

Group 15: Relays, Sensors, and Switches................201

Other Material................1103

Specifications................1104

Repair Planter Control Box................308

Replace Marker Switch................315

Replace Marker Winglet Switch................316

Adjust Marker Winglet Switch................317

Replace Fold Control Switch—Style A................319

Replace Fold Control Switch—Style B................320

Replace Central Commodity System Push Button Shut-Off Switch................321

Replace Central Commodity System Cleanout Switch................322

Remove and Install Rockshaft Sensor—Style A................323

Remove and Install Rockshaft Sensor—Style B................326

Remove and Install Central Commodity System Loading Platform Light Switch................327

Replace Pneumatic Downforce Compressor Pressure Switch................328

Remove and Install Height Sensor................329

Remove and Install Seed Level Sensor................330

Remove and Install Wheel Speed Sensor (Style A)................332

Remove and Install Wheel Speed Sensor (Style B)................334

Remove and Install Hopper Level Sensor................335

Remove and Install Liquid Fertilizer Sensor................336

Remove and Install Pneumatic Downforce Pressure Sensor................337

Remove and Install Active Pneumatic Downforce Pressure Sensor................338

Remove and Install Active Pneumatic Downforce Pressure Switch................339

Remove and Install Variable Rate Fertilizer Pump Speed Sensor................340

Remove Variable Rate Fertilizer Cam Position Sensor................341

Install Variable Rate Fertilizer Cam Position Sensor................342

Remove and Install Variable Rate Drive Motor Speed Sensor................344

Remove and Install Lift Assist Steering Position Sensor................345

Remove and Install Generator Speed Sensor—Style A................346

Remove and Install Generator Speed Sensor—Style B................347

Remove and Install Generator Current Sensor................348

Remove and Install Generator Motor Pressure Sensor................349

Remove and Install ExactEmerge Fuse Box................350

Remove and Install Battery Fuse................351

Remove and Install Temperature Sensor—Tractor Power Generation................354

Remove and Install Frame Weight Distribution Switch................355

Remove and Install ExactRate™ System Pressure Sensor................356

Remove and Install ExactRate™ Nozzle Pressure Sensor................357

Remove and Install ExactRate™ Pump Speed Sensor................358

Remove and Install ExactRate™ Flowmeter................359

Remove and Install ExactRate™ Keypad................360

Relay Identification................361

Group 20: Lighting Repair................202

Repair Red Warning Lamp................366

Repair Amber Warning Lamp................368

Repair Red Warning Lamp—CCS................370

Repair Amber Warning Lamp—CCS................371

Red and Amber Warning Lamps—1705 Twin Row................372

Red and Amber Warning Lamps—1725 CCS................373

Group 25: Batteries................202

Essential or Recommended Tools................1133

Specifications................1104

Prevent Damage to Electrical Systems................377

Remove and Install Control Unit Battery................378

Remove and Install ExactEmerge Batteries................380

Charging Batteries................385

Connecting Battery Cables................387

Group 30: Generator................202

Other Material................1103

Specifications................1104

Remove and Install Generator................392

Remove and Install Generator—Tractor Power Generation................394

Remove and Install Generator Splined Coupler—Tractor Power Generation................397

Group 35: Miscellaneous................202

Remove and Install ExactRate™ DC to DC Inverter................399

Calibrate ExactRate™ Nozzle Pressure Sensor................400

Calibrate ExactRate™ Flowmeter................406

Calibrate ExactRate™ System Pressure Sensor................409

Calibrate ExactRate™ Solution Pump................413

Section 50: Drives................417

Group 05: Specifications................1104

Drive Chain Specifications................1104

Shear Pin Specifications................1104

Sprocket Specifications................1104

Spur Gear Specifications................1104

Group 10: Seed Drive Transmissions................417

Specifications................1104

Seed Drive Transmission Exploded View—1705, 1715, 1725 and 1755................437

Seed Drive Transmission Exploded View—1705 Twin Row................439

Seed Drive Transmission Exploded View—1705 Twin Row with Variable Rate Drive................554

Seed Drive Transmission Exploded View—1735................443

Seed Drive Transmission Exploded View—1765................446

Seed Drive Transmission Exploded View—1775NT................448

Seed Drive Transmission Exploded View—1775NT 24 Row................452

Seed Drive Transmission Exploded View—1785................454

Seed Drive Transmission Exploded View—1795................456

Remove and Install Seed Drive Transmission—1775NT................458

Remove and Install Seed Drive Transmission—1775NT 24 Row................464

Remove and Install Seed Drive Transmission—1795................466

Adjust Seed Drive Transmission—1775NT................467

Adjust Contact Link—1775NT 24 Row................468

Adjust Contact Link—1795................470

Check and Adjust Transmission Spur Gear Backlash................471

Disassemble and Assemble Tire Contact Seed Transmission................473

Disassemble and Assemble Ground Driven Seed Transmission................496

Group 15: Half Width Disconnect................417

Other Material................1103

Specifications................1104

Remove and Install Half Width Disconnect Clutch................502

Disassemble and Assemble Half Width Disconnect Clutch................504

Group 20: Drill Shafts................417

Specifications................1104

Remove and Install Outer Wing Drill Shaft................521

Remove and Install Inner Wing Drill Shaft................523

Remove and Install Center Frame Drill Shaft................525

Remove and Install Upper Jackshaft................527

Remove and Install Lower Jackshaft................529

Align Drill Shaft Coupler and Flex Shaft................531

Align Drill Shaft Couplers—1795 38 cm (15 in.) Row................535

Align Drill Shaft Couplers—1795 51 cm (20 in.) Row................538

Sprocket Location Drawings—1775NT................541

Sprocket Location Drawings—1795................544

Group 25: Variable Rate Drive................554

Variable Rate Drive................554

Group 30: Charging System Drive................418

Other Material................1103

Specifications................1104

Remove and Install Generator Belt................558

Remove and Install Generator Belt Tensioner................560

Disassemble and Assemble Generator Gearbox—Tractor Power Generation................561

Remove and Install Generator Gearbox Check Valve—Tractor Power Generation................564

Check Generator Gearbox Oil Level—Tractor Power Generation................566

Section 60: Hitch and Frame................567

Group 05: Repair and Welding................572

Frame Repair................571

Welding................572

Emergency Crack Repair................573

Emergency “T” Joint Repair................574

Skip Welding................575

Stress Relief (Normalizing)................576

Group 10: Hitch Pads................567

Other Material................1103

Specifications................1104

Remove and Install Hitch Pads—1775NT................580

Remove and Install Hitch Pads—1795................586

Group 15: Wheel Module Repair................567

Other Material................1103

Specifications................1104

Center Frame Wheel Module Exploded View—1705, 1715, 1725, and 1735................594

Center Frame Wheel Module Exploded View—1755................596

Drive Wheel Hub Exploded View—1705, 1715, 1725, and 1735................597

Center Frame Wheel Module Exploded View—1775NT................599

Wing Wheel Module Exploded View—1775NT................601

Remove and Install Center Frame Wheel Assembly—1775NT................603

Remove and Install Wing Wheel Assembly—1775NT................606

Center Frame Wheel Module Exploded View—1795................609

Wing Wheel Module Exploded View—1795................611

Remove and Install Center Frame Wheel Assembly—1795................613

Remove and Install Wing Wheel Assembly—1795................616

Axle and Hub Assembly (8-Bolt)................619

Axle and Hub Assembly (6-Bolt)................621

Adjust Tire Scraper................623

Group 20: Row Markers................567

Specifications................1104

Remove and Install Row Marker................626

Remove and Install Row Marker—1775NT 24 Row (Style A)................631

Remove and Install Row Marker—1775NT 24 Row (Style B)................633

Disassemble and Assemble Row Marker Disk and Arms—1725NT................637

Disassemble and Assemble Row Marker Disk and Arms................640

Disassemble and Assemble Row Marker Pivot................642

Disassemble and Assemble Row Marker Disk and Arms—1775NT 24 Row (Style A)................644

Disassemble and Assemble Row Marker Disk and Arms—1775NT 24 Row (Style B)................646

Replace Marker Breakaway Bolt................649

Replace Marker Breakaway Bolt—1775NT 24 Row (Style A)................651

Replace Marker Breakaway Bolt—1775NT 24 Row (Style B)................652

Replace Marker Breakaway Bolt—1725NT................653

Adjust Marker Length................654

Adjust Marker Length—1795................656

Adjust Marker Disk................658

Adjust Marker Cable—1775NT 24 Row................659

Group 25: Loading Platform and Hitch................568

Remove and Install Loading Platform Steps—1775NT................664

Remove and Install Tow-Behind Hitch—1795................668

Remove and Install Loading Platform—1795................670

Remove and Install Loading Platform with Hitch—1795 24R20................672

Remove and Install Loading Platform without Hitch—1795 24R20................674

Group 30: Rockshafts................568

Other Material................1103

Specifications................1104

Remove and Install Rockshaft................679

Shim Rockshaft................686

Group 35: Lift Assist................568

Other Material................1103

Specifications................1104

Lift Assist—8 and 12 Row Planters................692

Lift Assist—16 Row Planter................694

Disassemble and Assemble Lift Assist Wheel Tail Yoke—1725 CCS................696

Disassemble and Assemble Lift Assist Wheel Tail Yoke—1725 CCS Twin Row................701

Remove and Install Lift Assist Steering Cylinder Yoke................708

Remove and Install Lift Assist Steering Cylinder Bracket................709

Remove and Install Lift Assist Wheel Offset Frame — 1725 CCS Twin Row................711

Lift Assist Exploded View—1735 (9, 11, 13 and 15 Row)................717

Disassemble and Assemble Lift Assist Wheels—1725 CCS and 1725 CCS Twin Row................720

Disassemble and Assemble Stack Fold Frame Lift—1705 and 1725................722

Section 70: Hydraulics................724

Group 00: General Information................724

Relieve Hydraulic System Pressure................728

Replacing Hydraulic Hoses................729

Group 05: Motors................724

Other Material................1103

Specifications................1104

Inspect Vacuum Blower Motor................734

Repair Vacuum Blower Motor................735

Inspect Central Commodity System Blower Motor................741

Remove and Install Central Commodity System Blower Motor................743

Repair Central Commodity System Blower Motor................749

Repair Air Compressor Drive Motor................755

Remove and Install Generator Motor................765

Group 10: Cylinders................724

Essential or Recommended Tools................1133

Specifications................1104

Remove and Install Main Frame Wheel Cylinder................770

Remove and Install Main Frame Wheel Cylinder—1775NT 24 Row................773

Remove and Install Frame Weight Distribution Cylinders—1775NT 24 Row................776

Remove and Install Wing Downforce Cylinders—1725 CCS ExactEmerge™................779

Remove and Install Wing Wheel Cylinder................781

Remove and Install Wing Fold Cylinder................783

Remove and Install Marker Cylinder................785

Remove and Install Marker Cylinder—1725NT................788

Remove and Install Marker Cylinders—1775NT 24 Row (Style A)................790

Remove and Install Marker Cylinders—1775NT 24 Row (Style B)................794

Remove and Install Rockshaft Cylinder—1795................798

Remove and Install Main Frame Lift Cylinders— 1705 and 1725................800

Remove and Install Master Cylinder................802

Disassemble and Assemble Master Cylinder................805

John Deere Hydraulic Cylinder Repair—Use CTM................823

Group 15: Valve Block................725

Essential or Recommended Tools................1133

Valve and Port Locations—1775NT 12 Row................826

Valve and Port Locations—1775NT 16 Row................829

Valve and Port Locations—1775NT 24 Row (Style A)................832

Valve and Port Locations—1775NT 24 Row (Style B)................835

Valve and Port Locations—1795................838

Valve and Port Locations—1725................841

Adjust Wing Downforce—1725 CCS ExactEmerge™................843

Drawbar Hitch Valve Block Exploded View (if equipped)—1775NT................845

Wing Valve Block—1775NT 24 Row................846

Remove and Install Frame Weight Distribution Valve Block—1775NT 24 Row................848

Disassemble and Assemble Frame Weight Distribution Valve Block—1775NT 24 Row................849

Group 20: Valves................725

Specifications................1104

Remove and Install Solenoid Valves................853

Inspect Solenoid Valve Body................855

Remove and Install Cartridge Valves................856

Remove and Install Rockshaft Solenoid Valve Assembly................857

Repair Rockshaft Valve Assembly................858

Remove and Install Rephasing Valve Assembly................859

Repair Rephasing Valve Assembly—1775NT................861

Repair Rephasing Valve Assembly—1795................864

Flush Power Generation Motor Valve................865

Remove and Install Power Generation Motor Valve................867

Flow Control Valve................869

Group 25: Miscellaneous................725

Essential or Recommended Tools................1133

Specifications................1104

Remove and Install Hydraulic Oil Cooler................874

Remove and Install Hydraulic Oil Filter Assembly................876

Service Accumulator Systems Safely................877

Remove and Install Air Compressor Motor Accumulator................878

Remove and Install Frame Weight Distribution Accumulator................879

Charge Frame Weight Distribution Accumulator................880

Accumulator Pre-Charge Pressure Correction for Ambient Air Temperature................882

Section 80: Fertilizer and Pesticide Systems................883

Group 05: Liquid Fertilizer System................883

Essential or Recommended Tools................1133

Other Material................1103

Specifications................1104

Flush Liquid Fertilizer System................891

Remove and Install Fertilizer Tank................893

Replace Fertilizer Tank Fitting................895

Tank Repair................906

Tighten Liquid Fertilizer Hose Clamps................907

Adjust Pump Number Setting................908

Fertilizer Pump Drive Assembly................909

Adjust Fertilizer Drive Contact Link................912

Fertilizer Pump Exploded View................913

Remove and Install Fertilizer Pump................915

Fertilizer Pump Repair................917

Priming and Initial Start Up of Pump................931

Fertilizer Pump Lubrication................932

Remove and Install Fertilizer Flow Divider................933

Disassemble and Assemble Fertilizer Flow Divider................934

Remove and Install Liquid Fertilizer Block Manifold................936

Repair Liquid Fertilizer Block Manifold................939

Remove and Install Liquid Fertilizer In-Line Orifice................941

Remove and Install Liquid Fertilizer Coupler................943

Remove and Install Liquid Fertilizer Check Valve................945

Remove and Install Liquid Fertilizer Delivery Tube................947

Frame Mounted Single-Disk Fertilizer Opener................952

Remove and Install Fertilizer Opener Disk Seals and Bearing—1795 24R20................958

Frame Mounted Single-Disk Fertilizer Opener—1795 24R20................960

Repair Double Disk Fertilizer Opener................964

Unit Mounted Double-Disk Fertilizer Opener................967

Group 10: Variable Rate Fertilizer................883

Other Material................1103

Specifications................1104

Remove and Install Variable Rate Fertilizer Pump................972

Variable Rate Fertilizer Pump Exploded View................974

Variable Rate Fertilizer Pump Repair................976

Replace Variable Rate Drive Pump Crankcase Seal................990

Group 15: Pesticide System................884

Other Material................1103

Specifications................1104

Pesticide Tanks—General Information................997

Remove and Install Pesticide Tank— Wing Mounted................998

Remove and Install Pesticide Tank—Hitch Mounted................1001

Remove and Install Pesticide Tank Shut-Off Valve— 265 L (70 gal.) Tank................1004

Repair Pesticide Tanks— 265 L (70 gal.) Tank................1006

Repair Pesticide Tank— 852 L (225 gal.) Tank................1009

Repair Pesticide Tank—1136 L (300 gal.) Tank................1011

Repair Pesticide Tank—1703 L (450 gal.) Tank................1013

Group 20: Dry Fertilizer................884

Other Material................1103

Specifications................1104

Disassemble and Assemble Dry Fertilizer Distribution Tower................1018

Disassemble and Assemble Dry Fertilizer Single Disk Opener................1020

Group 25: ExactRate™ Liquid Fertilizer System................884

Essential or Recommended Tools................1133

Other Material................1103

Specifications................1104

Clean ExactRate™ Liquid Fertilizer System Components................1028

Remove and Install ExactRate™ Solution Pump Assembly................1029

Disassemble and Assemble ExactRate™ Solution Pump Assembly................1031

Disassemble and Assemble ExactRate™ Solution Pump................1034

Disassemble and Assemble ExactRate™ Shutoff Valve................1036

Disassemble and Assemble ExactRate™ Tube Assembly................1038

Remove and Install ExactRate™ Nozzle Assembly................1040

Disassemble and Assemble ExactRate™ Nozzle Assembly................1043

Disassemble and Assemble ExactRate™ Nozzle Solenoid Assembly................1045

Frame Mounted ExactRate™ Single-Disk Opener................1050

Prime and Start the ExactRate™ Solution Pump................1056

Section 90: Pneumatic Downforce................1059

Group 00: General Information................1059

Depressurize Pneumatic Downforce System................1063

Adjust and Inspect Pneumatic Downforce................1066

Group 05: Pneumatic Downforce................1059

Essential or Recommended Tools................1133

Other Material................1103

Specifications................1104

Install Pneumatic Downforce Air Pressure Gauges................1073

Remove and Install Pneumatic Downforce Control Valve................1075

Disassemble and Assemble Pneumatic Downforce Control Valve................1078

Remove and Install Pneumatic Downforce Control Valve Poppet................1080

Remove and Install Pneumatic Downforce Air Reservoir................1091

Pneumatic Downforce Air Compressor—Exploded View................1092

Cab-Mounted Pneumatic Downforce Air Compressor—Exploded View................1094

Remove and Install Pneumatic Downforce Air Compressor................1096

Remove and Install Air Compressor Filter................1099

Remove and Install Air Compressor Isolators................1101

Group 10: Active Pneumatic Downforce................1059

Other Material................1103

Specifications................1104

Remove and Install Hydraulically Driven Air Compressor Filter................1105

Remove and Install Hydraulically Driven Air Compressor................1107

Disassemble and Assemble Hydraulically Driven Air Compressor................1111

Remove and Install Active Pneumatic Downforce Air Reservoir................1119

Remove and Install Pneumatic Downforce Control Manifold (S.N. 765101—XXXXXX)................1120

Disassemble and Assemble Pneumatic Downforce Control Manifold (S.N. 765101—XXXXXX)................1121

Disassemble and Assemble Pneumatic Downforce Manifold Segment (S.N. 765101—XXXXXX)................1124

Remove and Install Pneumatic Downforce In-Line Orifice................1127

Pneumatic Downforce In-Line Orifice Identification and Location................1128

Section 100: Miscellaneous................1131

Group 05: Polyethylene Tank Repair................906

Essential or Recommended Tools................1133

Repair Polyethylene Plastic................1134

Install RIVNUT® Threaded Inserts................1140

Section 199: Dealer Fabricated Tools................1143

Group 05: Dealer Fabricated Tools................1143

DFAXT1—Set Screw Wrench................1145

DFHX1709A—Master Cylinder Assembly Fixture................1146

John Deere 1705, 1715, 1725, 1735, 1755, 1765, 1775, 1785, 1795 Planter Frame Repair Service Manual (TM131319)