John Deere Tractors 6405, 6605 Diagnosis and Tests Service Technical Manual (TM4576)

Complete Diagnosis & Tests Technical Manual with electrical wiring diagrams for John Deere 2WD or MFWD Tractors Models 6405 and 6605, with all the shop information to maintain, diagnose, and rebuild like professional mechanics.

John Deere Tractors 6405, 6605 workshop Diagnostics & Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm4576 - 6405 and 6605 tractors Technical Manual - Diagnosis and Tests.pdf

tm4576 - 6405 and 6605 tractors Technical Manual - Diagnosis and Tests.epub

Total Pages: 1,304 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Foreword

Safety

Safety

Service Code Diagnosis

HCU Code Diagnostics

Observable Symptom

Electrical

Power Take-Off

Hitch

Engine

Tests

Fuel, Air Intake and Cooling Systems

System Diagnosis

Tests and Adjustments

Fuel System

Air Intake System

Cooling System

Cold Weather Starting Aids

Electrical System

General

System Diagrams (Operator's Station)

System Diagrams (Tractors with Cab)

Sub-System Diagnostics (Operator's Station)

Sub-System Diagnostics (Tractors with Cab)

Component Testing

Electronic Control Units

Operation and General Information on Diagnostics

HCU References

SYNCROPLUS Transmission

Operational Checkout

Troubleshooting

Tests and Adjustments

SyncroPlus Transmission Operation

Perma Clutch II

Gear Transmission

Creeper Transmission

Range Transmission

POWRREVERSER Transmission

Operational Checkout

Troubleshooting

Test and Adjustments

Power Reverser Operation

Power Reverser Module

Gear Transmission

Drive Systems

Operational Checks

System Diagnosis

Tests

Front-Wheel Drive Clutch

Differential

Final Drives

Rear PTO Options

Front PTO

Steering and Brakes

Operational Checks

System Diagnosis

System Tests

Hydrostatic Steering

Hydraulic Brakes

Hydraulic System

Operational Checkout

Hydraulic System Troubleshooting

Tests and Adjustments

HYDRAVANTAGE Hydraulic System and Components

Hydraulic Pump

Valves, Oil Cooler and Filter

Rockshaft

Selective Control Valves and Couplers

Independent Control Valve (ICV)

Operator's Cab

Operational Checkout

Air Conditioner Troubleshooting

Ventilation and Heater Troubleshooting

Air Conditioner Operation

Ventilation and Heating Operation

Special Tools (Dealer-Fabricated)

tm4576 - 6405 and 6605 tractors

Table of Contents

Foreword

Section 210: Safety

Group 05: Safety

Recognize Safety Information

“Important” - Information

“Note” - Information

Prevent Machine Runaway

Handle Fluids Safely-Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Avoid High-Pressure Fluids

Service Cooling System Safely

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Work In Ventilated Area

Wear Protective Clothing

Practice Safe Maintenance

Park Machine Safely

Use Proper Lifting Equipment

Construct Dealer-Made Tools Safely

Support Machine Properly

Work in Clean Area

Illuminate Work Area Safely

Service Machines Safely

Use Proper Tools

Service Tires Safely

Service Front-Wheel Drive Tractor Safely

Safety Information - Air Brake System

Avoid Eye Contact with Radar

Keep ROPS Installed Properly

Replace Safety Signs

Dispose of Waste Properly

Live With Safety

Section 211: Service Code Diagnosis

Group HCU: HCU Code Diagnostics

HCU 022-System Voltage not in Specification

HCU 027-Calibration not Successful

HCU 028-Calibration Memory Failure

HCU 029-Calibration Memory Failure

HCU 030-Insignificant Fault that has no Effect on Tractor Operation

HCU 041-Stepper Motor Circuit Open

HCU 042-Stepper Motor Circuit Open

HCU 043-Stepper Motor Circuit Shorted

HCU 044-Stepper Motor Circuit Shorted

HCU 045-Potentiometers and Position Sensor Supply Voltage Out of Range

HCU 046-Draft Sensor Supply voltage Out of Range

HCU 049-Quick Raise/Lower Rocker Switch Circuit

HCU 050-Stepper Motor Deadband out of range

HCU 051-Left Draft Sensor Signal Circuit

HCU 052-Right Draft Sensor Signal Circuit

HCU 053-Load/Depth Control Potentiometer Circuit

HCU 054-Hitch Control Lever Potentiometer Circuit

HCU 055-Hitch Position Sensor Circuit

HCU 056-Raise Limit Control Potentiometer

HCU 057-Rate-of-Drop Control Potentiometer Circuit

HCU 058-Remote Control Switch Circuit

HCU 239-Circuit fault during Calibration

HCU 241-Hitch Position Sensor Circuit fault during Calibration

HCU 242-Hitch Position Sensor Circuit fault during Calibration

HCU 250-Right Draft Sensor Circuit out of specification during calibration

HCU 251-Right Draft Sensor Circuit out of specification during calibration

HCU 252-Right Draft Sensor Circuit out of specification during calibration

HCU 253-Left Draft Sensor Circuit out of specification during calibration

HCU 254-Left Draft Sensor Circuit out of specification during calibration

HCU 255-Left Draft Sensor Circuit out of specification during calibration

Section 212: Observable Symptom

Group 40: Electrical

HCU Controller not Displayed

Group 56: Power Take-Off

Rear PTO Will Not Run

Rear PTO Will Not Stop Turning

PTO Slips Under Load

Group 70: Hitch

Hitch Does Not Work

Hitch Remote Control Does Not Work

Section 220: Engine

Group 10: Tests

Safety Measures

Preliminary Engine Tests

Dynamometer Test

Section 230: Fuel, Air Intake and Cooling Systems

Group 10: System Diagnosis

Fuel System

Cooling System

Group 15: Tests and Adjustments

General Information

Explanation of Checks

Safety Measures

Special Tools

Specifications

Testing the Air Intake System

Testing the Low-Pressure Switch in Air Intake System

Checking the Cooling System for Leaks

Checking Expansion Tank Cap

Test Thermostat Opening Temperature

Checking the Viscous Fan Drive

Checking the Fuel Transfer Pump

General Information on Diagnostics

Adjust Hand Throttle Lever and Accelerator Pedal

Group 20A: Fuel System

General Information

Description

Fuel Transfer Pump - Theory of Operation

Fuel Filter - Theory of Operation

Group 20B: Air Intake System

Air Cleaner - Theory of Operation

Group 20C: Cooling System

General Information

Description of Radiator

Automatic Drive Belt Tensioner - Theory of Operation

Viscous Fan Drive - Theory of Operation

Group 20D: Cold Weather Starting Aids

General Information

Electrical Starting Aid - Theory of Operation

Fuel Preheater - Theory of Operation

Coolant Heater - Theory of Operation

Section 240: Electrical System

Group 05: General

Electrical Circuit Malfunctions

Group 10: System Diagrams (Operator's Station)

Fuses

Component Designations on Functional Schematics and Wiring Harnesses

Section Designations on Functional Schematics

Wiring Harness Identification

Functional Schematic - Complete Tractor

W3 - Wiring Harness for 4-Cylinder Engine (AL117076)

W3 - Wiring Harness for 6-Cylinder Engine (AL117226)

Wiring Harness for Electrical Starting Aid (W27; AL119472)

Front Corner Worklight Wiring Harness (W14; AL81307)

Platform Wiring Harness (W4; AL117225) up to Serial Number 249394

Platform Wiring Harness (W4; AL119281) from Serial Number 249395

7-Pin Socket Wiring Harness (W28; AL150291)

3-Pin Socket Wiring Harness (W30; AL114896)

Front Part of Transmission Wiring Harness (W32; AL115344)

Rear Part of Transmission Wiring Harness (W33; AL116810)

W40 - Wiring Harness - Back-Up Alarm (AL117624)

W41 - Wiring Harness - Back-Up Alarm -Switch for SynchroPlus Transmission (AL114955)

Group 10A: System Diagrams (Tractors with Cab)

Fuses

Part Designations in Functional Schematic and Wiring Harnesses

Section Designations on Functional Schematics

Wiring Harness Identification

Functional Schematic (Complete Tractor)

W3 - Wiring Harness for 4-Cylinder Engine (AL150218)

W3 - Wiring Harness for 6-Cylinder Engine (AL150219)

Wiring Harness for Electrical Starting Aid (W27; AL119472)

Front PTO Wiring Harness (W39; AL110126)

W4 - Cab Wiring Harness (AL153711)

W30 - 3-Pin Socket Wiring Harness (AL114896)

W11 - Cab Roof Wiring Harness (AL153454)

W8 - Air Conditioner and Fan Wiring Harness (AL110589)

W13 - Transmission Wiring Harness (AL153957)

W40 - Wiring Harness - Back-Up Alarm (AL117624)

W41 - Wiring Harness - Back-Up Alarm -Switch for SynchroPlus Transmission (AL114955)

Group 15: Sub-System Diagnostics (Operator's Station)

Special or Essential Tools

SE1-Starting Motor and Charging Circuit, Functional and Diagnostic Schematic

SE2-Basic Informator, Functional and Diagnostic Schematic

SE3-Horn, Functional and Diagnostic Schematic

SE5-Rear PTO, Functional and Diagnostic Schematic

SE6-Lights, Functional and Diagnostic Schematic

SE7-Work Lights, Functional and Diagnostic Schematic

SE8-Front Loader Plug, Functional and Diagnostic Schematic

SE14-3-Pin- and 7-Pin Receptacle, Functional and Diagnostic Schematic

SE15-Electronic Hitch Control, Functional and Diagnostic Schematic

SE16A-Hazard Flashers and Turn Signals, Functional and Diagnostic Schematic (up to Serial No. 249394)

SE16A-Hazard Flashers and Turn Signals, Functional and Diagnostic Schematic (from Serial No. 249395)

SE16B-Front Wheel Drive, Functional and Diagnostic Schematic

SE16C-Differential Lock, Functional and Diagnostic Schematic

SE25-Back-Up Alarm, Functional and Diagnostic Schematic

Group 15A: Sub-System Diagnostics (Tractors with Cab)

Special or Essential Tools

SE1-Starter Motor and Charging Circuit

SE2-Instrument Panel

SE3-Horn

SE4-Operator's Seat

SE5A-Front PTO

SE5B-Rear PTO

SE6-Lighting Circuits

SE7-Work Light

SE9A-3- and 7-Pin Power Outlet Sockets

SE9B-Radio, Dome and Console Lights

SE10-Fan and Air Conditioner

SE11-Windshield Wiper and Washer

S13-Beacon

SE15-Electronic Hitch Control Unit (HCU)

SE16A-Hazard Warning Flasher and Turn Signal Lights

SE16C-Brake System

SE16D-Differential Lock

SE16E-Front Wheel Drive

SE25-Back-Up Alarm, Functional and Diagnostic Schematic

Group 25: Component Testing

Special or Essential Tools

Specifications

SE1-Starting Motor and Charging Circuit

SE2-Instrument Unit and Lighting

SE3-Horn

SE4-Operator Seat

SE5A-Front PTO

SE5 or SE5B-Rear PTO

SE6-Lighting Circuits

SE7-Work Light

SE9B-Radio, Dome and Shift Console Lights

SE10-Fan and Air Conditioner

SE11-Windshield Wiper and Washer

SE13-Beacon

SE15-Electronic Hitch Control (HCU)

SE16A-Hazard Flasher and Turn Signal Unit

SE16C-Braking System

SE16D or SE16C-Differential Lock

SE16E or SE16D-Front Wheel Drive

SE25-Back-Up Alarm

Section 245: Electronic Control Units

Group 05: Operation and General Information on Diagnostics

General Explanation of Testing Procedures for Electronic Control Unit HCU

Safety Measures

Essential Tools

Diagnosis with the Performance Monitor

Abbreviations Used in the Display

Entering Program Mode

Calling up and Deleting Service Codes

Identification of Electronic Control Unit (HCU)

Group HCU: HCU References

Service Code List

List of Diagnostic Addresses for Hitch Control Unit (HCU)

Calibration (HCU) - Rockshaft

Quick Reference, Calibration (HCU) - Rockshaft

Enabling Sway Dampening on HCU (Rockshaft)

HCU Beep Mode Test (HCU 02)

Quick Raise/Lower Rocker Switch (S24) Circuit Test

L.H. Draft Sensor (B20) Signal Circuit Test

R.H. Draft Sensor (B19) Signal Circuit Test

Load/Depth Control Potentiometer (B26) Signal Circuit Test

Hitch Height Control Potentiometer (B27) Signal Circuit Test

Position Sensor Potentiometer (B21) Signal Circuit Test

Raise-Limit Control Potentiometer (B27) Signal Circuit Test

Rate-of-Drop Control Potentiometer (B27) Signal Circuit Test

Remote Control Switch (S31) Circuit Test

Potentiometer (B21, B26 and B27) Supply Voltage Circuit Test

Draft Sensor (B19 and B20) Supply Voltage Circuit Test

Stepper Motor (M08) Circuit Test

HCU Power Supply Circuit Test

CCD - Circuit Test

Section 250: Transmission

Group 05: Operational Checkout

Checking If Perma Clutch II Separates Properly

Checking Perma Clutch II for Slippage

Checking the Slip Phase of Perma Clutch II

Checking the Transmission

Checking the Neutral Start Switch

Group 10: Troubleshooting

Essential Tools

Specifications

Safety Precautions

Explanation of System Diagnosis (Troubleshooting)

Hydraulic Oil Warm-Up

Connecting JT07115 Hydraulic Test Kit

Connecting the Sensocontrol© Testing Equipment

Layout of Test Ports and Sending Units

Preliminary Checks

Checking Gear and Range Engagement

Checking Clutch Operation

Transmission Oil Filter Check

Checking System (Engagement) Pressure

Adjusting System (Engagement) Pressure

Check Components Dependent on System (Engagement) Pressure

Checking the Filter Relief Valve

Testing the Engagement Override Valve and Clutch Pedal Valve

Checking the Modulation of the Clutch Pedal Valve

Checking Lubricating Oil Pressure

Checking the Clutch Cooling System

Checking the Flow Rate

Checking the Cooler Relief Valve

Group 15: Tests and Adjustments

Essential Tools

Specifications

Shift Linkage Test

Range Transmission Linkage Test

Adjusting Range Box Shifting

Gear Transmission Linkage Test

Adjusting Shift Linkage at Gear Transmission

Adjusting the Neutral Start Switch

Checking the Neutral Start Switch

Adjusting the Shift Linkage and Parking Lock

Clutch Pedal Adjustment

Group 20: SyncroPlus Transmission Operation

Layout of 12-Speed Transmission

Layout of 12-Speed Transmission with Creeper

Lubrication System

Shift Operation

Synchronization

Transmission Circuit Hydraulic Schematic

Transmission Circuit - Theory of Operation

Group 20A: Perma Clutch II

Exploded View of Perma Clutch II

Clutch Design

Power Flow, Clutch Pedal Depressed

Power Flow, Clutch Pedal Not Depressed

Theory of Operation - Transmission Oil Pump

Hydraulic Schematic of Perma Clutch II

Description of Valves and Other Hydraulic Components

Theory of Operation - Pressure Regulating and Filter Relief Valves

Theory of Operation - Clutch Pedal and Engagement Override Valves

Theory of Operation - Cooling

Group 20B: Gear Transmission

Gear Transmission Design

Power Flow in 1st Gear

Power Flow in 2nd Gear

Power Flow in 3rd Gear

Power Flow in Reverse Gear

Neutral Start Switch

Group 20C: Creeper Transmission

Layout of Creeper Transmission

Power Flow With Creeper Disengaged

Power Flow With Creeper Engaged

Group 20D: Range Transmission

Range Transmission

Layout

Power Flow in Range A

Power Flow in Range B

Power Flow in Range C

Power Flow in Range D

Parking Lock

Section 251: Transmission

Group 05: Operational Checkout

Before You Start

Checking the Neutral Start Switch

Neutral-to-Gear Modulation Check

Reverser Control Modulation Check

Gear Engagement Check

Range Engagement Check

Clutch Modulation Check

Transmission Creep Check

Clutch Engagement Check

Group 10: Troubleshooting

Essential Tools

Specifications

Safety Precautions

Explanation of Troubleshooting

Hydraulic Oil Warm-Up

Connecting the JT07115 Hydraulic Test Kit

Connecting the Sensocontrol© Testing Equipment

Layout of Test Ports and Sending Units

Preliminary Checks

Checking Gear and Range Engagement

Checking Forward/Reverse Modulation

Transmission Oil Filter Check

Checking System (Engagement) Pressure

Adjusting System (Engagement) Pressure

Checking Components Dependent on System (Engagement) Pressure

Checking the Filter Relief Valve

Checking the Engagement Override Valve and Clutch Pedal Valve

Checking the Disk Clutch and Disk Brake

Checking Lubricating Oil Pressure

Checking the Clutch Cooling System

Checking the Flow Rate

Checking the Cooler Relief Valve

Group 15: Test and Adjustments

Special Tool (Dealer-Manufactured)

Shift Linkage Test

Range Transmission Linkage Test

Adjusting Range Transmission Linkage

Gear Transmission Linkage Test

Adjusting Shift Linkage at Gear Transmission

Adjusting the Reverser Control Linkage

Adjusting the Shift Linkage and Parking Lock

Adjusting the Reverse Drive Lever

Clutch Pedal Adjustment

Group 20: Power Reverser Operation

Design of Power Reverser

Description of Transmission Oil Circuit

Group 20A: Power Reverser Module

Components

Design and Powerflow

Power Reverser Module - Sectional View

Theory of Operation - Transmission Oil Pump

Valves and Other Hydraulic Components

Power Reverser - Hydraulic Circuit Diagram

Description of Valves and Other Hydraulic Components

Theory of Operation - Pressure Regulating and Filter Relief Valves

Theory of Operation - Forward/Reverse Modulation

Theory of Operation - Clutch Pedal Valve

Theory of Operation - Engagement Override Valve

Theory of Operation - Cooling

Group 20B: Gear Transmission

Illustration of Gear Transmission

Design and Powerflow

Section 256: Drive Systems

Group 05: Operational Checks

Checking the Differential Lock

Checking the Front and Rear PTOs

Checking Front-Wheel Drive

Group 10: System Diagnosis

Front Wheel Drive

Differential

Hydraulic Pump Drive

Final Drives

Rear PTO

Front PTO

Group 15: Tests

Safety Precautions

Special or Essential Tools

Connecting the SensoControl Testing Equipment

Specifications

Hydraulic Oil Warmup

Testing Operating Pressure of FWD Clutch

Testing Operating Pressure of Hydraulic Differential Lock

Testing the Rear PTO

Testing the Front PTO

Testing the System Engagement Pressure

Group 20A: Front-Wheel Drive Clutch

Design

Oil and Power Flows With Front-Wheel Drive Engaged

Oil and Power Flows With Front-Wheel Drive Disengaged

Group 20B: Differential

Design

Power Flow When Moving Straight Ahead

Power Flow When Cornering

Oil Flow With Differential Lock Engaged

Oil Flow With Differential Lock Disengaged

Group 20C: Final Drives

Operation and Layout

Group 20D: Rear PTO Options

Description of Rear PTO Options

PTO Modulating Valve and Solenoid Valve

Operation of PTO Clutch and Brake

PTO Power Flow (540 rpm)

PTO Power Flow (540/1000 RPM, Reversible)

Group 20E: Front PTO

Front PTO Operation

Independent Hydraulic Circuit

Oil Cooler

Modulating Valve and Solenoid

Hydraulic Pump

Section 260: Steering and Brakes

Group 05: Operational Checks

Checking the Steering

Checking the Brakes

Group 10: System Diagnosis

Hydrostatic Steering

Hydraulic Brakes

Group 15: System Tests

Special or Essential Tools

Specifications

Steering Valve Hydraulic Connections

Checking Steering System

Testing and Adjusting Shock Valves

Checking Brake System

Bleeding the Brakes

Checking Brake Piston Travel

Checking Control Valve Opening Pressure

Adjusting Brake Pedals

Adjusting the Brake Switches

Checking Rear Brakes

Group 20A: Hydrostatic Steering

Description of Steering Valve

Operation of Metering Unit

Oil Flow in Steering System

Oil Flow - Neutral Position

Oil Flow - Emergency Steering

Group 20B: Hydraulic Brakes

Brake Valve Layout

Operation

Brake Valve - Sectional View

Hydraulic Circuit Diagram

Oil Flow During Brake Application

Rear Brake Operation

Section 270: Hydraulic System

Group 05: Operational Checkout

Operational Checkout Notes

Safety Precautions

Operational Checks

SCV Check

Rockshaft - Operational Checkout

Checking the Rockshaft Valve and the Stepper Motor of External Control Switch

Group 10: Hydraulic System Troubleshooting

Troubleshooting Notes, Hydraulic System

Safety Precautions

Special Tools

Connecting Test Equipment - Test Ports

Connecting the SensoControl Testing Equipment

Heating Up Hydraulic Oil

Test Specifications

Test Sequence

Hydraulic System Troubleshooting

Measuring Flow Rate of Hydraulic Pump

Information on System Diagnosis

Hydraulic System Test Result Log

Group 15: Tests and Adjustments

Explanation of the Hydraulic Tests

Safety Precautions

Special or Essential Tools

Heating Up Hydraulic Oil

Installing the Shuttle Valves

Remedy for Missing Shuttle Valve

Diagnosing Faults at the Selective Control Valves

Diagnosing Faults at Independent Control Valves

Checking Pressure Relief Valve of Rockshaft

Rockshaft Controls

Hitch Troubleshooting Tips

Testing, Calibrating and Adjusting the Hitch Control Unit (HCU)

List of Rockshaft/HCU Diagnostic and Calibration Procedures

Test Sequence

Additional Checks

Checking the Stepper Motor and Rockshaft Valve

Checking for Leaks at the Rockshaft Valve

Centering the Stepper Motor

Checking Depth to Which Raising and Lowering Valves Are Screwed In

Checking the Position Sensor

Checking and Adjusting the Draft SensorIf equipped

Group 20A: HYDRAVANTAGEHYDRAVANTAGE is a trademark of Deere & Company Hydraulic System and Components

Hydraulic Symbols (ISO 1219)

Description of the Hydraulics

HYDRAVANTAGEHYDRAVANTAGE is a trademark of Deere & Company Hydraulic System - Theory of Operation

Hydraulic System - Symbolic View

Hydraulic System - Schematic View

Hydraulic System - Three-Dimensional View

Group 20B: Hydraulic Pump

Description of Hydraulic Pump

Layout of Oil Lines

Hydraulic Pump - Theory of Operation

Group 20C: Valves, Oil Cooler and Filter

Hydraulic Oil Filter With Filter Relief Valve

Oil Cooler

Filter Screen

Lube Priority Valve

Shuttle Valves on HydraVantage Hydraulic System - Theory of Operation and Layout

Main Block With Inlet Priority Valve and By-Pass Valve

Inlet Priority Valve and By-Pass Valve - Theory of Operation

Group 20D: Rockshaft

Rockshaft Description

Rockshaft Operation

Rockshaft Valve - Theory of Operation

Position Sensor

Draft SensorsIf equipped

Control Console

Hitch Control Unit (HCU)

Direct Control of Rockshaft

Group 20E: Selective Control Valves and Couplers

Selective Control Valves

101 Series Selective Control Valve - Neutral Position

101 Series Selective Control Valve - Extend Position

101 Series Selective Control Valve - Retract Position

101 Series Selective Control Valve - Float Position

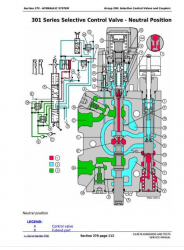

301 Series Selective Control Valve - Neutral Position

301 Series Selective Control Valve - Extend Position

301 Series Selective Control Valve - Retract Position

301 Series Selective Control Valve - Float Position

Couplers

Endplates on SCV Units - Summary

Group 20F: Independent Control Valve (ICV)

Independent Control Valve Description

Independent Control Valve - Sectional View

Oil Flow Through the Independent Control Valve

Special Endplate on R.h. Side

Section 290: Operator's Cab

Group 05: Operational Checkout

Test Sequence

Operational Checks on Air Conditioning and Heater

Group 10A: Air Conditioner Troubleshooting

Safety At Work

Handling Refrigerant

Safety Equipment

In an Emergency

Storage of Refrigerant Containers

R134A Refrigerant

Important Note

Special or Essential Tools

Special Tools

Specifications

Troubleshooting

Explanation of Checks

Air Conditioning System, Checks

Pressure Deviations

Group 10B: Ventilation and Heater Troubleshooting

Ventilation and Heater Troubleshooting

Group 20A: Air Conditioner Operation

Principle of Heat Exchange

R134A Refrigerant

Refrigerant Circuit Diagram

Description of How Refrigerant Circuit Functions

Compressor

Condenser

Receiver-Drier

Expansion Valve

Thermostat Switch

Evaporator

High/Low Pressure Switch

Knobs for Heating and Cooling

Group 20B: Ventilation and Heating Operation

Ventilation and Heating

Section 299: Special Tools (Dealer-Fabricated)

Group 05: Special Tools (Dealer-Fabricated)

Holding Tool

DFLX14 –– Solenoid Test Harness

John Deere Tractors 6405, 6605 Diagnosis and Tests Service Technical Manual (TM4576)