John Deere Tractor 6100E, 6110E, 6125E, 6415, 6615 Diagnosis and Tests Service Technical Manual (TM800319)

John Deere Tractor 6100E, 6110E, 6125E, 6415, 6615 Diagnosis and Tests Service Technical Manual (TM800319)

tm800319 - 6415 Classic, 6615 Classic, 6100E, 6110E and 6125E Tractors (Up to Serial Number -500000) — Diagnostic Technical Manual.pdf

Complete Diagnosis & Tests Technical Manual with electrical wiring diagrams for John Deere Tractor 6415, 6615, 6100E, 6110E, 6125E (South America), with all the workshop information to maintain, diagnose, repair, rebuild like professional mechanics.

John Deere South America Tractors 6415 Classic, 6615 Classic, 6100E, 6110E, 6125E workshop Diagnosis & Tests technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,032 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MAIN SECTIONS

Foreword

Safety

Safety Information

General Information

Safety Measures

General References

Diagnostic Trouble Codes

BCU Diagnostic Trouble Codes

Observable Symptoms

Electrical System

SyncroPlus Transmission

Drive Systems

Steering and Brakes

System Diagnosis

Electronic Components

Engine

Operational Checks

Tests and Adjustments

Fuel System, Air Intake and Cooling

Tests and Adjustments

Theory of Operation

Electrical System - 6415 and 6615

How To Use Diagnostic Information

Fuse Box

Starting and Charging Circuit

Panel Warning Lights

Lights and Tail Lights

Work Lights

Horn

Accessories Socket

Reverse Light and Backup Alarm

Trailer Connector

BCU - Turn Signal and Hazard Warning Lights

BCU - Brakes

BCU - Service Connector

BCU - PTO

BCU - Engine Speed Sensor

BCU - Front-Wheel Drive

BCU - Differential Lock

Component Tests

Connectors

Electrical System - 6110E and 6125E

How To Use Diagnostic Information

Fuse Box

Starting and Charging Circuit

Panel Warning Lights

Lights and Tail Lights

Work Lights

Horn

Accessories Socket

Reverse Light and Backup Alarm

Trailer Connector

BCU - Turn Signal and Hazard Warning Lights

BCU - Brakes

BCU - Service Connector

BCU - PTO

BCU - Engine Speed Sensor

BCU - Front-Wheel Drive

BCU - Differential Lock

Component Tests

Connectors

Electronic Control Units

Operation and General Information on Diagnostics

Data BUS Systems, Operation

BCU - Basic Control Unit

SyncroPlus Transmission

Preliminary Checks

Operational Check

Tests and Adjustments

Operation

Range Box

Drive Systems

Operational Check

Tests and Adjustments

Operation

Steering and Brakes

Preliminary Checks

Operational Check

Tests and Adjustments

Operation

Hydraulic System

Operational Check

Tests and Adjustments

Operation

Special Tools (Dealer-Fabricated)

Special Tools (Dealer-Fabricated)

tm800319 - 6415 Classic, 6615 Classic, 6100E, 6110E and 6125E Tractors (Up to Serial Number -500000) — Diagnostic Technical Manual

Table of Contents

Foreword

Section 205: Safety

Group 05: Safety Information

Recognize Safety Information

Follow Safety Instructions

Replace Safety Signs

Wear Protective Clothing

Prevent Battery Explosions

Avoid Static Electricity Risk When Refueling

Service Tires Safely

Keep ROPS Installed Properly

Park Machine Safely

Handle Fluids Safely—Avoid Fires

Handle Fuel Safely—Avoid Fires

Prepare for Emergencies

Work in Clean Area

Prevent Machine Runaway

Work In Ventilated Area

Avoid High-Pressure Fluids

Use Proper Lifting Equipment

Illuminate Work Area Safely

Use Proper Tools

Live With Safety

Section 210: General Information

Group 05: Safety Measures

Safety Measures on Electronic Control Units

Group 15: General References

General References—Summary

Unified Inch Bolt and Cap Screw Torque Values

Metric Bolt and Cap Screw Torque Values

Hydraulic System Unified Inch Fitting Torques

Hydraulic system metric fitting torques

Component Identification Table

Diagnostic Diagram and Information on Symbols in DiagramHow to use an Electrical Diagram

Electrical Diagram Symbols

Wire Numbers and Color Codes

Troubleshooting Unsolved Problems

Electrical System Visual Inspection

Circuit Malfunctions

Seven Steps Electrical Test Procedure

Hydraulic System — Circuit Symbols

Section 211: Diagnostic Trouble Codes

Group BCU: BCU Diagnostic Trouble Codes

BCU 000168.16 - System Voltage Too High (Engine Running)

BCU 000168.17 - System Voltage Too Low (Engine Speed Over 1500 rpm)

BCU 000168.18 - System Voltage Too Low (Engine Speed Up to 1500 rpm)

BCU 000186.02 - PTO Speed Sensor, Electrical Circuit Fault

BCU 000186.17 - PTO speed is not registered

BCU 000190.02 - Engine Speed Sensor, Circuit Fault

BCU 000629.12 - Control Unit, Internal Error

BCU 000639.12 - Control Unit, Internal Error

BCU 000639.13 - 29-bit CAN BUS, High Error Rate

BCU 000639.14 - 29-bit CAN BUS, Very High Error Rate

BCU 000639.19 - 29-bit CAN BUS, Very High Error Rate

BCU 000746.31 - Differential Lock Solenoid Valve, Circuit Fault

BCU 000980.07 - PTO, Switch Error

BCU 299780.07 - Malfunction at Turn Signal Switch

BCU 302001.31 - OPERATOR INFORMATION 250-Hour Service

BCU 302002.31 - OPERATOR INFORMATION 500-Hour Service

BCU 302003.31 - OPERATOR INFORMATION 750-Hour Service

BCU 302004.31 - OPERATOR INFORMATION 1500-Hour Service

BCU 302071.31 - OPERATOR INFORMATION Turn PTO switch OFF

BCU 302073.31 - PTO Solenoid, Circuit Fault

BCU 302077.31 - INFORMATION FOR OPERATOR: Sit on seat or Disengage PTO

BCU 302080.31 - Differential Lock, Switch Error

BCU 302082.31 - OPERATOR INFORMATION Actuate Front-Wheel Drive Switch

BCU 302085.31 - Front Wheel Drive, Switch Error

BCU 302086.31 - Front-Wheel Drive Clutch Solenoid, Circuit Fault

BCU 302089.31 - OPERATOR INFORMATION Turn PTO switch OFF

BCU 302106.31 - Control Unit, Internal Error

BCU 302131.31 - Fault in Turn Signal Circuit

BCU 302132.31 - Defective Hazard Warning Light Fuse F113 and/or F114

BCU 302133.31 - PTO, Switch Error

BCU 302135.31 - Remote-control PTO, Error left-hand switch

BCU 302136.31 - Remote-control PTO, Error right-hand switch

BCU 302139.31 - INFORMATION FOR OPERATOR: PTO may be engaged via remote-control switch

BCU 302240.31 - Control Unit Connected to Wrong Wiring Harness Connector

BCU 303047.03 - System Voltage Too High

Section 212: Observable Symptoms

Group 40: Electrical System

Control Unit(s) Not Displayed

Diagnostic Mode Cannot Be Entered or Connection Problems with Service ADVISOR (Cab Tractors)

Diagnostic Mode Can Not Be Accessed or Connection Problems with Service ADVISOR™ (Open operator's station)

Problems with the Battery

Problems with the Starter Motor

Problems with the Horn — Optional

Group 50: SyncroPlus Transmission

Problems with SyncroPlus Transmission

Group 56: Drive Systems

Problems with the PTO

Group 60: Steering and Brakes

Problems with the Brakes

Problems with the Steering

Section 213: System Diagnosis

Group 45: Electronic Components

29-bit CAN BUS - Check (Cab Tractors)

Section 220: Engine

Group 10: Operational Checks

Safety

Preliminary Engine Testing

Group 15: Tests and Adjustments

Dynamometer test

Section 230: Fuel, Air Intake and Cooling Systems

Group 15: Tests and Adjustments

Tests and Adjustments—Summary of References

Safety Information

Explanation of Checks

Safety

Special Tools

Identifying Cooling System Type

Specifications

Testing Air Intake System

Checking Cooling System for Leaks (Only A-Type Cooling System)

Testing Temperature at Which the Thermostat Opens

Hand Throttle Lever and Accelerator Pedal Adjustment

Accelerator Pedal Adjustment

Group 20: Theory of Operation

Component Description - Summary of References

Fuel System - Description

Air Intake System - Theory of Operation

Automatic Drive Belt Tensioner - Theory of Operation

Section 240: Electrical System - 6415 and 6615

Group 05: How To Use Diagnostic Information

Electrical System Visual Inspection

Diagnostic Diagram and Information on Symbols in DiagramHow to use an Electrical Diagram

Electrical Schematic Symbols

Know the System

Ask the Operator

Group 10: Fuse Box

Theory of Operation

Electrical Diagram

Group 10A: Starting and Charging Circuit

Theory of Operation

Electrical Diagram

Group 10B: Panel Warning Lights

Theory of Operation

Electrical Diagram

Group 10C: Lights and Tail Lights

Theory of Operation

Electrical Diagram

Group 10D: Worklights

Theory of Operation

Electrical Diagram

Group 10E: Horn

Theory of Operation

Electrical Diagram

Group 10F: Accessory Socket

Theory of Operation

Electrical Diagram

Group 10G: Reverse Light and Backup Alarm

Theory of Operation

Electrical Diagram

Group 10H: Trailer Connector

Theory of Operation

Electrical Diagram

Group 10J: BCU - Turn Signal and Hazard Warning Lights

Theory of Operation

Electrical Diagram

Group 10K: BCU - Brakes

Theory of Operation

Electrical Diagram

Group 10L: BCU - Service Connector

Theory of Operation

Electrical Diagram

Group 10M: BCU - PTO

Theory of Operation

Electrical Diagram

Group 10N: BCU - Engine Speed Sensor

Theory of Operation

Electrical Diagram

Group 10O: BCU - Front-Wheel Drive

Theory of Operation

Electrical Diagram

Group 10P: BCU - Differential Lock

Theory of Operation

Electrical Diagram

Group 15: Component Tests

Starter Motor and Charging Circuit

Instrument Panel

Horn - Optional

Lighting Circuits

Work Lights

Electronic Hitch Control

PTO

BCU (Forward)

Differential Lock

Hazard Warning Lights Unit

Brake System

Group 20: Connectors

A01 - Fuse and relay box

B01 - Engine speed sensor

B02 - Sender for air cleaner restriction warning light

B03 - Fuel gauge sensor unit

B04 - Sender for engine oil pressure indicator light

B07 - Transmission oil filter pressure sensor

B08 - Coolant temperature sensor

B29 - Transmission oil temperature sensor

B30 - Hydrostatic oil temperature sensor

B31 - Transmission oil pressure sender

B36 - Neutral start switch

B48 - Backup alarm switch

B88 - Brake switch

E01 - Right-hand front light

E02 - Left-hand front light

E15-R - Right-hand rear working light

E15-L - Left-hand rear working light

E21 - License plate light

F13 - Main fuse

F14 - Main fuse

G01 - Battery

G02 - Alternator

H01 - Horn

K01 - Starter relay

K24 - Injection pump shut-off valve

K28 - Backup alarm

M01 - Starter motor

P24-1 - Instrument panel

P24-2 - Instrument panel

P24-3 - Instrument panel

S01 - Starter switch

S04 - Horn switch

S08 - Turn signal switch

S09 - Light switch

S10 - Full/low beam light switch

S21 - PTO switch

S22 - Differential lock switch

S42 - Light switch

S59 - Front lights switch

S63 - Front-wheel drive switch

S92-2 - Rear work lights switch

S106 - Hazard warning lights switch

X05 - Trailer connector

X06 - Accessories socket

X21 - Connector (W07 and W08)

X37 - Connector (W05 and W07)

X67 - Connector (W05 and W06)

X106 - Tail, brake and turn signal lights (right-hand)

X107 - Tail, brake and turn signal lights (left-hand)

X234 - Connector (W08 and W31)

X286 - Connector (W08 and W28)

X287 - Connector (W08 and W30)

X288 - Connector (W02 and W08)

X289 - Connector (W02 and W08)

X411 - Connector (W02 and W04)

X473 - Connector (W01 and W08)

X504 - Connector (W08 and W09)

X505 - Connector (W08 and W09)

X547 - Connector (W02 and W03)

X571 - Service connector (CAN Bus)

X616-1 Basic control unit (BCU)

X616-2 Basic control unit (BCU)

X616-3 Basic control unit (BCU)

XGND1 - Platform ground wire

XGND2 - Platform ground wire

XGND9 - Engine grounding

XGND26 - Grounding point

Y03 - Front-wheel drive solenoid valve

Y04 - PTO Solenoid

Y05 - Differential lock solenoid valve

Section 241: Electrical System - 6100E, 6110E and 6125E (Up to Serial Number -500000)

Group 05: How To Use Diagnostic Information

Electrical System Visual Inspection

Diagnostic Diagram and Information on Symbols in DiagramHow to use an Electrical Diagram

Electrical Schematic Symbols

Know the System

Ask the Operator

Group 10: Fuse Box

Theory of Operation

Electrical Diagram

Group 10A: Starting and Charging Circuit

Theory of Operation

Electrical Diagram

Group 10B: Panel Warning Lights

Theory of Operation

Electrical Diagram

Group 10C: Lights and Tail Lights

Theory of Operation

Electrical Diagram

Group 10D: Worklights

Theory of Operation

Electrical Diagram

Group 10E: Horn

Theory of Operation

Electrical Diagram

Group 10F: Accessory Socket

Theory of Operation

Electrical Diagram

Group 10G: Reverse Light and Backup Alarm

Theory of Operation

Electrical Diagram

Group 10H: Trailer Connector

Theory of Operation

Electrical Diagram

Group 10J: BCU - Turn Signal and Hazard Warning Lights

Theory of Operation

Electrical Diagram

Group 10K: BCU - Brakes

Theory of Operation

Electrical Diagram

Group 10L: BCU - Service Connector

Theory of Operation

Electrical Diagram

Group 10M: BCU - PTO

Theory of Operation

Electrical Diagram

Group 10N: BCU - Engine Speed Sensor

Theory of Operation

Electrical Diagram

Group 10O: BCU - Front-Wheel Drive

Theory of Operation

Electrical Diagram

Group 10P: BCU - Differential Lock

Theory of Operation

Electrical Diagram

Group 15: Component Tests

Starting Motor and Charging Circuit

Instrument Panel

Horn - Optional

Lighting Circuits

Work Lights

Electronic Hitch Control

PTO

BCU (Forward)

Differential Lock

Hazard Warning Lights Unit

Brake System

Group 20: Connectors

A01 - Fuse and relay box

B01 - Engine speed sensor

B02 - Sender for air cleaner restriction warning light

B03 - Fuel gauge sensor unit

B04 - Sender for engine oil pressure indicator light

B06 - PTO Speed Sensor

B07 - Transmission oil filter pressure sensor

B08 - Coolant temperature sensor

B29 - Transmission oil temperature sensor

B30 - Hydrostatic oil temperature sensor

B31 - Transmission oil pressure sender

B36 - Neutral start switch

B49 - Reverse Travel Switch

B88 - Brake switch

E01 - Right-hand front light

E02 - Left-hand front light

E15-R - Right-hand rear working light

E15-L - Left-hand rear working light

E21 - License plate light

E67 - Reverse Light (if equipped)

F13 - Main fuse

F14 - Main fuse

G01 - Battery

G02 - Alternator

H01 - Horn

H67 - Backup Alarm

K01 - Starter relay

K24 - Injection pump shut-off valve

M01 - Starter motor

P24-1 - Instrument panel

P24-2 - Instrument panel

P24-3 - Instrument panel

S01 - Starter switch

S04 - Horn switch

S08 - Turn signal switch

S09 - Light switch

S10 - Full/low beam light switch

S21 - PTO switch

S22 - Differential lock switch

S59 - Front lights switch

S63 - Front-wheel drive switch

S92-2 - Rear work lights switch

S106 - Hazard warning lights switch

X05 - Trailer connector

X06 - Accessories socket

X106 - Tail, brake and turn signal lights (right-hand)

X107 - Tail, brake and turn signal lights (left-hand)

X108 - Clearance and turn signal light (right-hand)

X109 - Clearance and turn signal light (left-hand)

X234 - Connector (W08 and W31)

X286 - Connector (W08 and W28)

X287 - Connector (W08 and W30)

X288 - Connector (W02 and W08)

X289 - Connector (W02 and W08)

X411 - Connector (W02 and W04)

X473 - Connector (W01 and W08)

X504 - Connector (W08 and W09)

X505 - Connector (W08 and W09)

X547 - Connector (W02 and W03)

X571 - Service connector (CAN Bus)

X616-1 Basic control unit (BCU)

X616-2 Basic control unit (BCU)

X616-3 Basic control unit (BCU)

XGND1 - Platform ground wire

XGND2 - Platform ground wire

XGND9 - Engine grounding

XGND26 - Grounding point

Y03 - Front-wheel drive solenoid valve

Y04 - PTO Solenoid

Y05 - Differential lock solenoid valve

Section 245: Electronic Control Units

Group 05: Operation and General Information on Diagnostics

Special Tools

General Operation and Entering the Program Mode

Calling up Addresses and Diagnostic Trouble Codes

Electronic Control Units — Summary of Addresses

Group 20: Data BUS Systems, Operation

Data BUS systems — Summary of References

Data BUS systems

CAN BUS Systems

CAN-BUS Systems on Cab and Open Operator's Station Tractors

CAN BUS Systems – Plug Layout

Group BCU: BCU - Basic Control Unit

BCU — Basic Control Unit — Summary of References

Test Procedure in the Case of Occasional BCU Circuit Problems

PTO Speed Sensor Test (B06) - Tractors with Open Operator's Station

Circuit Test for PTO Switch (S21) - Open Operator's Station

Circuit Test for Front-Wheel Drive Switch (S63) - Open Operator's Station

Circuit Test for Differential Lock Switch (S22) - Open Operator's Station

Circuit Test for Turn Signal Switch (S08) - Open Operator's Station

Circuit Test for Engine Speed Sensor (B01) - Open Operator's Station

Circuit Test for PTO Solenoid Valve (Y04) - Open Operator Station

Circuit Test for Front-Wheel Drive Solenoid Valve (Y03) - Open Operator Station

Circuit Test for Differential Lock Solenoid Valve (Y05) - Open Operator Station

Circuit Test for Hazard Warning Lights Switch (S106)

BCU — Theory of Operation (Basic Functions)

Section 250: SyncroPlus Transmission

Group 05: Preliminary Checks

Special Tools

Introductory Checks for Transmission and Hydraulic Diagnosis

Group 10: Operational Check

SyncroPlus Transmission — Operational Check

Group 15: Tune-Up

SyncroPlus Transmission—System Check

SyncroPlus Transmission—Checking System Pressure

SyncroPlus Transmission—Adjusting System Pressure

SyncroPlus Transmission—Checking Components Dependent on System Pressure

SyncroPlus™ Transmission—Checking Filter Relief Valve

SyncroPlus Transmission—Checking the Engagement Override Valve and Clutch Pedal Valve

SyncroPlus Transmission—Checking the Modulation of the Clutch Pedal Valve

SyncroPlus Transmission—Checking Lube Oil Pressure

SyncroPlus Transmission—Checking Cooling System

SyncroPlus Transmission—Checking Flow Rate

SyncroPlus Transmission—Checking Cooler Relief Valve

SyncroPlus Transmission—Checking the Transmission Oil Filter

SyncroPlus Transmission—Layout of Test Ports and Sending Units

SyncroPlus Transmission—Checking and Adjusting the Shift Units

SyncroPlus Transmission—Adjusting the Park Lock

SyncroPlus Transmission—Checking and Adjusting the Linkage on the Range Transmission

SyncroPlus Transmission — Checking and Adjusting Shift Drive

SyncroPlus Transmission—Checking and Adjusting the Neutral Start Switch

SyncroPlus Transmission—Adjusting the Clutch Pedal

Group 20: Operating

SyncroPlus Transmission — Summary of References

SyncroPlus Transmission —Cross-sectional View

SyncroPlus Transmission—Lubrication system

SyncroPlus Transmission—Shifter Linkage

SyncroPlus Transmission—Synchronization

SyncroPlus Transmission—Operation of Transmission Oil Circuit (including Diagram)

Clutch Components PermaClutch

Transmission Hydraulic Circuit

Transmission Oil Circuit

Perma Clutch II Module—Exploded View

Perma Clutch II Module—Cross-sectional View

Clutch Activation

Perma Clutch II Module—Power Flow

Perma Clutch II Module—Transmission Oil Pump

Perma Clutch II Module—Hydraulic Circuit Diagram

Perma Clutch II Module—Description of Various Valves and Components

Perma Clutch II Module—Operation of Pressure Regulating Valve and Filter Relief Valve

Perma Clutch II Module—Operation of Clutch Pedal Valve and Engagement Override Valve

Perma Clutch II Module—Operation of Cooling System

Function of Centrifugal Valve and Suction Valve

Description of Gear Shift—Cross-sectional View

Description of Gear Shift—Power Flow

Gear Shift— Neutral Start Switch

Creeper Transmission— Cross-sectional View and Operation

Creeper Transmission—Power Flow

Group 25: Range Box

Range Transmission - Cross-Sectional View

Range Transmission - Power Flows

Range Transmission - Park Lock

Section 256: Drive Systems

Group 10: Operational Check

Special Tools

Drive Systems—Operational Check

Group 15: Tests and Adjustments

Drive Systems—System Check

Checking Pressure at the Front-Wheel Drive Clutch

Checking Pressure at Hydraulic Differential Lock

Checking Pressure at PTO

Drive Systems—Test Result Table

Group 20: Operation

Drive Systems—Summary of References

Front-Wheel Drive Clutch—Cross-Sectional View

Front-Wheel Drive Clutch—Oil Flow and Power Flow

Front-Wheel Drive Clutch—Cooling and Lubrication

Differential—Cross-Sectional View

Differential—Power Flows

Differential—Oil Flows

Final Drives—Operation and Cross-Sectional View

PTO Options—Description

PTO Options—PTO Modulating Valve and Solenoid Valve

PTO Options—PTO Brake and PTO Clutch

PTO Options—Power Flows

Section 260: Steering and Brakes

Group 05: Preliminary Checks

Tests & Adjustments—Summary of References

Preliminary Checks – Steering System

Preliminary Checks – Brake System

Group 10: Operational Check

Operational Checkout (Summary of References)

Safety Information

Check Steering

Checking Brakes

Group 15: Tests and Adjustments

Tests & Adjustments—Summary of References

Special Tools

Specification

Checking Steering Valve

Checking Brake System

Bleeding the Rear Brakes

Adjusting Brake Pedals and Switches

Group 20: Operating

Operation —Summary of References

Description of Steering Valves, Operation

Operation of Brake Piston, Plate and Disks

Brake released

Initial Braking

Brake Engaged

Rear Wheel Brakes, Operation

Section 270: Hydraulic System

Group 10: Operational Check

Special Tools

Reference 270-10-001, Hydraulic System - Operational Check

Group 15: Tests and Adjustments

Reference 270-15-001, Safety Measures for Hydraulic Checks

Reference 270-15-010, Warming Hydraulic System Oil

Reference 270-15-020, Hydraulic System — Oil Pressure Testing Points

Reference 270-15-030, Checking Hydraulic System

Reference 270-15-040, Hydraulic System — Test Result Table

Reference 270-15-050, Hydraulic System — Checking and Adjusting System Oil Pressure

Reference 270-15-060, Hydraulic System — Checking and Adjusting SC Oil Pressure at Steering Valve

Reference 270-15-061, Hydraulic System — Checking SC Oil Pressure at Cart Brake Valve

Reference 270-15-070, Hydraulic System — Checking Steering Oil Pressure

Reference 270-15-080, Hydraulic System — Checking Lubrication Oil Pressure

Reference 270-15-090, Hydraulic Pump — Checking Delivery Rate

Reference 270-15-100, Selective Control Valves — Check for Leaks at Valve Spools

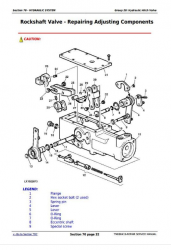

Reference 270-15-110, Rockshaft Valve — Checking and Adjusting Pressure-Relief Valve

Reference 270-15-120, Rockshaft Valve — Checking for Leaks

Reference 270-15-130, Checking and Adjusting Rockshaft Control

Reference 270-15-140, Rockshaft — Adjusting Control Lever Friction

Group 20: Operation

Reference 270-20-001, Hydraulic System — Summary of References

Reference 270-20-010, Hydraulic System — Description

Reference 270-20-020, Hydraulic System — Operation

Reference 270-20-030, Hydraulic System — Symbolic View

Reference 270-20-040, Hydraulic System — Schematic View

Reference 270-20-050, Hydraulic System — Three-Dimensional View

Reference 270-20-060, Hydraulic System — Description of Hydraulic Pump

Reference 270-20-110, Hydraulic System — Lube Priority Valve

Reference 270-20-120, Hydraulic System — Operation of Priority Valve

Reference 270-20-130, Rockshaft — Description

Reference 270-20-140, Rockshaft — Operation of Rockshaft Control

Reference 270-20-150, Rockshaft — Operation of Rockshaft Control Valve

Reference 270-20-160, Selective Control Valves — Description

Reference 270-20-170, Selective Control Valves — Operation

Reference 270-20-180, Couplers — Description

Section 299: Special Tools (Dealer-Fabricated)

Group 05: Special Tools (Dealer-Fabricated)

Special Tools (Dealer-Fabricated) — Summary

Retainer Tool

Adjustment Tool

DFRW2—Needle Valve Test Hose Assembly

DFLX10 and DFLX11—Test Harnesses

DFLX12—Special Tool for 11-bit and 29-bit CAN BUS

DFLX14—Solenoid Valve Test Harness