John Deere Compact Utility Tractors Models 3032E, 3036E, 3038E Service Technical Manual (TM127919)

All Inclusive Diagnosis, Operation, Tests, Repair Service manual with electrical wiring diagrams for John Deere Compact Utility Tractors Models 3032E, 3036E, and 3038E (SN. from 610000), with workshop information to maintain, diagnose, repair, and service like professional mechanics.

TM127919 - John Deere 3032E, 3036E, 3038E (SN.610000-) Tractors All Inclusive Technical Service Manual (Diagnostic & Repair) (August 2014).pdf

TM127919 - John Deere 3032E, 3036E, 3038E (SN.610000-) Tractors All Inclusive Technical Service Manual (Diagnostic & Repair) (August 2014).epub

Total Pages: 1,454 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTIONS

Foreword

Safety

Safety

Specifications and Information

General Specifications

Fuel and Lubricants

Serial Number Locations

Diagnostic Trouble Codes

General References

Instrument Cluster Control (ICC) Diagnostic Trouble Codes

Engine Control Unit (ECU) Diagnostic Trouble Codes

Engine-Diesel

Specifications

Component Location

Theory of Operation

Diagnostics

Tests and Adjustments

Repair

Electrical

General Information

Specifications

Component Location

Schematics and Harnesses

Operation and Diagnostics

Tests and Adjustments

Repair

Electrical - 3036E

Component Location

Schematics and Harnesses

Operation and Diagnostics

Electronic Control Units

General References

Theory of Operation

Programing and Calibrations

Test and Adjustments

Diagnostic Addresses

Power Train

Specifications

Component Location

Theory of Operation

Diagnostics

Troubleshooting

Tests and Adjustments

Repair

Hydraulics

Specifications

Component Location and Schematics

Theory of Operation

Troubleshooting

Tests and Adjustments

Repair

Steering

Specifications

Component Location

Theory of Operation

Diagnostics

Tests and Adjustments

Repair

Brakes

Specifications

Component Location

Theory of Operation

Diagnostics

Tests and Adjustments

Repair

Miscellaneous

Specifications

Component Location

Repair

tm127919 - 3025E, 3032E, 3036E, and 3038E Compact Utility Tractors Diagnostic and Repair Manual

Table of Contents

Foreword

Section 10: General Information

Group 05A: Safety

Recognize Safety Information

Understand Signal Words

Follow Safety Instructions

Prepare for Emergencies

Wear Protective Clothing

Protect Against Noise

Handle Fuel Safely—Avoid Fires

Handle Starting Fluid Safely

Fire Prevention

In Case of Fire

Keep ROPS Installed Properly

Use Foldable ROPS and Seat Belt Properly

Stay Clear of Rotating Drivelines

Use Steps and Handholds Correctly

Read Operator’s Manuals for ISOBUS Controllers

Use Seat Belt Properly

Operating the Tractor Safely

Avoid Backover Accidents

Limited Use in Forestry Operation

Operating the Loader Tractor Safely

Keep Riders Off Machine

Instructional Seat

Use Safety Lights and Devices

Use a Safety Chain

Transport Towed Equipment at Safe Speeds

Towing Trailers/Implements Safely

Use Caution on Slopes, Uneven Terrain, and Rough Ground

Freeing a Mired Machine

Avoid Contact with Agricultural Chemicals

Handle Agricultural Chemicals Safely

Handling Batteries Safely

Avoid Heating Near Pressurized Fluid Lines

Remove Paint Before Welding or Heating

Handle Electronic Components and Brackets Safely

Practice Safe Maintenance

Avoid Hot Exhaust

Clean Exhaust Filter Safely

Work In Ventilated Area

Support Machine Properly

Prevent Machine Runaway

Park Machine Safely

Transport Tractor Safely

Service Cooling System Safely

Service Accumulator Systems Safely

Service Tires Safely

Service Front-Wheel Drive Tractor Safely

Tightening Wheel Retaining Bolts/Nuts

Avoid High-Pressure Fluids

Do Not Open High-Pressure Fuel System

Store Attachments Safely

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Group 05B: General References

Deliver Safely

Information Available in Sections, Groups and Subgroups

Glossary of Terms

Trademarks

Group 05C: Technical Specific References

Metric Bolt and Screw Torque Values

Unified Inch Bolt and Screw Torque Values

Metric Cap Screw Torque Values—Grade 7

Gasket Sealant Application

Service Recommendations For Flat Face O-Ring Seal Fittings

Service Recommendations for O-Ring Boss Fittings

Group 05D: Fuel and Lubricants

Diesel Fuel

Handling and Storing Diesel Fuel

Diesel Engine Oil

Diesel Engine Break-In Oil

Alternative and Synthetic Lubricants

Lubricant Storage

Mixing of Lubricants

Grease

Transmission and Hydraulic Oil

Diesel Engine Coolant (engine with wet sleeve cylinder liners)

Group 05E: Serial Number Locations

Serial Numbers

Machine Product Identification Number

Engine Serial Number

Section 20: Engine Repair

Group 05: Engine

Glow Plug Removal and Installation

Rocker Cover Removal and Installation

Rocker Arm Assembly

Engine Removal and Installation

Cylinder Head and Valves Removal and Installation

Cylinder Head and Valves Disassembly and Assembly

Valve Seats

Valve Recession

Valve Guides

Valve Springs

Grind Valve Seats

Lap Valves

Measure Piston-To-Cylinder Head Clearance

Piston and Connecting Rod

Piston Inspection

Cylinder Bore

Crankshaft Front Oil Seal

Crankshaft Rear Oil Seal

Crankshaft and Main Bearings

Flywheel and Coupling

Camshaft

Camshaft Followers

Timing Gear Cover

Idler Gear

Timing Gear Cover Mounting Plate

Oil Pan and Strainer

Oil Pump

Group 10: Cooling System

Radiator Removal and Installation—3036E

Radiator Removal and Installation—3032E, 3038E

Thermostat Removal and Installation

Water Pump Removal and Installation

Section 30: Fuel, Air Intake, and Exhaust Repair

Group 05: Fuel

Fuel Filter and Water Separator

Secondary Fuel Filter

Fuel Injection Pump

Fuel Injection Nozzles

Fuel Tank Removal and Installation

Group 10: Air Intake

Intake Manifold

Group 20: Exhaust

Muffler Removal and Installation

Diesel Particulate Filter Removal and Installation

Exhaust Pipe Removal and Installation-Downward Exhaust

Exhaust Pipe Removal and Installation-Vertical Exhaust

Turbocharger Removal and Installation

Exhaust Manifold

Section 40: Electrical Repair

Group 05: Battery, Starter and Alternator

Battery Removal and Installation

Starting Motor Removal and Installation

Starting Motor Disassembly and Assembly

Starting Motor Inspection/Test

Alternator Removal and Installation

Alternator Disassembly and Assembly

Group 10: Electrical System Components

Engine Control Unit (ECU) Removal and Installation

Section 50: Drive System and Transmissions Repair

Group 05: Separation

Machine Splitting (Rear)

Machine Splitting (Front)

Group 10: Power Train

Speed Range Gears

Group 15: MFWD

MFWD Output Assembly

MFWD Removal and Installation

MFWD Final Drive Cover

MFWD Spindle Shaft

MFWD Differential (—Oct 2013)

MFWD Differential (Oct 2013— )

Group 20: Differential

Rear Axles

Axle Housing Disassembly and Assembly

Differential Removal and Installation

Group 25: PTO

PTO Drive Shaft and Gears

PTO Clutch Removal and Installation

PTO Clutch Disassembly and Assembly

Section 60: Steering and Brake Repair

Group 05: Steering

Steering Cylinder Removal and Installation MFWD

Steering Wheel Removal and Installation

Steering Control Unit (SCU) Removal and Installation

Tie Rod Removal and Installation MFWD

Group 10: Brake

Power Train Brake Assembly

Brake Pedal Assembly Removal and Installation

Brake Assembly

Section 70: Hydraulics Repair

Group 05: Hydraulic Pump and Filter

Hydraulic Gear Pump Removal

Hydraulic Gear Pump and Drive Removal

Hydraulic Gear Pump and Reduction

Group 10: Rockshaft

Rockshaft Removal and Installation

Rockshaft Disassembly and Assembly

Rockshaft Lift Arms Removal and Installation

Section 80: Miscellaneous Repair

Group 05: Hood and Side Panels

Hood Removal and Installation

Group 10: Fenders

Rear Fenders Removal and Installation

Group 15: Wheels

Front Wheel Removal and Installation

Rear Wheel Removal and Installation

Section 90: Operator’s Station Repair

Group 05: Seat and Support

Seat and Seat Support Removal and Installation

Group 10: Control Console

Control Panel Removal and Installation

Group 15: Roll-Gard

Roll Over Protection System (ROPS)

Group 20: Operator Station Components

Operator’s Foot Decks

Section 211: Diagnostic Trouble Codes

Group 05: General References

Diagnostic Trouble Codes - Summary of References

Diagnostic Trouble Codes Overview

Recall, Record, and Clear Codes

Erroneous Diagnostic Trouble Codes

Group ICC: Instrument Cluster Control (ICC) Diagnostic Trouble Codes

ICC 000000.00-999999.99 - ICC Diagnostic Trouble Codes

Group ECU: Engine Control Unit (ECU) Diagnostic Trouble Codes

ECU - Non-Tractor ECU Codes

ECU 000000.00-999999.99 - ECU Diagnostic Trouble Codes

Section 212: Observable Symptoms and System Diagnostics

Group 05: General References

Observable Symptoms and System Diagnostics - Summary of References

Group 20: Engine System Diagnostics

Engine Diagnosis

Group 30: Fuel, Air Intake, Exhaust, and Cooling System Diagnostics

Fuel and Air System Diagnosis

Group 40: Electrical System Diagnostics

Starting System Diagnosis

Charging System Diagnosis

Group 45: Electronic Control Unit System Diagnostics

CAN System Diagnosis

Group 50: Drive Systems and Transmission System Diagnostics

MFWD System Diagnosis

Power Train System Diagnosis

Differential Lock System Diagnosis

Rear PTO System Diagnosis

Group 60: Steering and Brakes System Diagnostics

Rear Brake System Diagnosis

Steering System Diagnosis

Group 70: Hydraulic System Diagnostics

Hydraulic System Diagnosis

SCV / Hitch System Diagnosis

Section 220: Engine Operation, Test, and Adjustments

Group 05: General References

Engine Operation, Test and Adjustments—Summary of References

Engine Information

Install Test Equipment 20-1

Install Test Equipment 20-2

Group 10: Calibrations, Preliminary Checks and Operational Checks

Engine—Preliminary Checks

Engine—Operational Checks

Group 20: Theory of Operation

Lubrication System Theory of Operation

Group 50: Tests and Adjustments

Fan and Alternator Drive Belt Adjustment

Cylinder Compression Test

Cylinder Leakage Test

Valve Clearance Adjustment

Valve Lift Check

Engine Oil Pressure Test

Engine Oil Consumption

Crankshaft End Play Check

Timing Gear Backlash Check

Camshaft End Play Check

Connecting Rod Side Play Check

Connecting Rod Bearing Clearance Check

Crankshaft Main Bearing Clearance Check

Section 230: Fuel , Air Intake, Exhaust, and Cooling Operation, Test, and Adjustments

Group 05: General References

Fuel, Air Intake, Exhaust, and Cooling Operation, Test, and Adjustments—Summary of References

Install Test Equipment 30-1

Install Test Equipment 30-2

Group 10: Calibrations, Preliminary Checks and Operational Checks

Air Intake Operational Checks

Cooling Operational Checks

Fuel Operational Checks

Turbocharger Operational Checks

Group 20: Theory of Operation

Fuel System Theory of Operation

Cooling System Theory of Operation

Air Intake System Theory of Operation

Turbocharger Theory of Operation

Group 40: Component and Connector Information

Air Cleaner and Intake Component Overview—3025E

Air Cleaner and Intake Component Overview—3032E

Air Cleaner and Intake Component Overview—3036E

Air Cleaner and Intake Component Overview—3038E

Fuel Supply Component Overview—3025E

Fuel Supply Component Overview—3032E and 3038E

Fuel Supply Component Overview—3036E

Turbocharger Component Overview

Group 50: Tests and Adjustments

Check Air Intake System

Check for Intake and Exhaust Restrictions

Throttle Rod Adjustment

Slow Idle Adjustment

Fuel System Leakage Test

Bleed Fuel System

Fuel Pump Supply Pressure Test

Injection Pump Timing

Fuel Injection Nozzle Test

Check for Exhaust Air Leaks (Turbocharger)

Turbocharger Oil Seal Leak Check

Turbocharger Waste Gate Test

Turbocharger Inspection

Cooling System Pressure Test

Radiator Cap Pressure Test

Thermostat Opening Test

Section 240A: Electrical General and Theory of Operation

Group 05: General References

Electrical General and Theory of Operation - Summary of References

Electrical Designators

Electrical Procedure

Circuit Malfunctions

Circuit Types

Relay Circuit Types

Electrical Schematic Symbols

Reading Wiring Functional Schematics

Wiring Diagram and Schematic Information

Troubleshooting Unresolved Electrical/Electronic Problems

Visually Inspect Electrical System

Using a Probe Light

Using a Digital Multimeter

Group 20A: Key Switch, Starter and Alternator Theory of Operation

Cranking Circuit Theory of Operation

Glow Plug Circuit Theory of Operation

Charging Circuit Theory of Operation

Power Circuit Theory of Operation

Group 20B: Instrument Cluster Control (ICC) Theory of Operation

Instrument Cluster Control (ICC) Theory of Operation

PTO Circuit Theory of Operation

Group 20C: Engine Control Unit (ECU) Theory of Operation

Fuel Supply Circuit Theory of Operation

Group 20D: Lights, Turn Signals, Cruise Control Theory of Operation

Lighting Circuit Theory of Operation

Cruise Control Circuit Theory of Operation

Section 240B: Electrical Schematics

Group 05: General References

Electrical Schematics - Summary of References

Group 30AA: Key Switch, Starter and Alternator—with ECU (SE1A)

Key Switch, Starter and Alternator—with ECU Schematic (SE1A)

Group 30AB: Key Switch, Starter and Alternator—without ECU (SE1B)

Key Switch, Starter and Alternator—without ECU Schematic (SE1B)

Group 30BA: Instrument Cluster Control—with ECU (SE2A)

Instrument Cluster Control—with ECU Schematic (SE2A)

Group 30BB: Instrument Cluster Control—without ECU (SE2B)

Instrument Cluster Control—without ECU Schematic (SE2B)

Group 30CA: Engine Control Unit (ECU)—3032E, 3038E (SE3A)

Engine Control Unit (ECU) Schematic—3032E, 3038E (SE3A)

Group 30CB: Engine Control Unit (ECU)—3025E (SE3B)

Engine Control Unit (ECU) Schematic—3025E (SE3B)

Group 30DA: Lights and Turn Signals—with ECU (SE4A)

Lights and Turn Signals—with ECU Schematic (SE4A)

Group 30DB: Lights and Turn Signals—with ECU (SE4B)

Lights and Turn Signals—without ECU Schematic (SE4B)

Group 30EA: Cruise Control (SE5)

Cruise Control Schematic (SE5)

Group 30FA: Electrical Harness Diagrams

W100 Chassis Harness Diagram—3032E, 3038E

W101 Chassis Harness Diagram—3025E

W102 Chassis Harness Diagram—3036E

W200 Cruise Control Harness Diagram

Section 240C: Electrical Components and Connectors

Group 05: General References

Electrical Components and Connectors - Summary of References

Group 40AA: Key Switch, Starter and Alternator—with ECU (SE1A)

F21 Inline Fuse (250A)—with ECU

F22 Alternator Fuse

F23 Load Center Fuse

F24 Glow Plugs Fuse

G01 Battery—with ECU

G02 Alternator—with ECU

K02 Starter Relay—with ECU

K03 Glow Plug Relay—with ECU

M01 Starter Motor—with ECU

M02 Fuel Pump Motor—with ECU

R01 Glow Plug—with ECU

R02 Glow Plug—with ECU

R03 Glow Plug—with ECU

S01 Key Switch—with ECU

Group 40AB: Key Switch, Starter and Alternator—without ECU (SE1B)

G01 Battery—without ECU

G02 Alternator—without ECU

M01 Starter Motor—without ECU

R01 Glow Plug—without ECU

R02 Glow Plug—without ECU

R03 Glow Plug—without ECU

S01 Key Switch—without ECU

Group 40BA: Instrument Cluster Control—with ECU (SE2A)

A01 Instrument Cluster Control (ICC)

A01-J1 Instrument Cluster Control (ICC) Connector—with ECU

A01-J2 Instrument Cluster Control (ICC) Connector—with ECU

A01-J3 Instrument Cluster Control (ICC) Connector—with ECU

B04 Engine Oil Pressure Switch—with ECU

S03 Turn Signal Switch—with ECU

S04 Transmission Neutral Switch—with ECU

S05 PTO Switch—with ECU

S38 Seat Switch—with ECU

S39 Park Brake Switch

S47 Roll/Display Mode Switch

X19 Service Advisor Connector

Group 40BB: Instrument Cluster Control—without ECU (SE2B)

A01 Instrument Cluster Control (ICC)—without ECU

A01-J1 Instrument Cluster Control (ICC) Connector—without ECU

A01-J2 Instrument Cluster Control (ICC) Connector—without ECU

A01-J3 Instrument Cluster Control (ICC) Connector—without ECU

B02 Engine Coolant Temp Switch—without ECU

B04 Engine Oil Pressure Switch—without ECU

S04 Transmission Neutral Switch—without ECU

S05 PTO Switch—without ECU

S38 Seat Switch—without ECU

Y02 Fuel Shutoff Solenoid—without ECU

Y03 Rear PTO Solenoid—without ECU

Group 40CA: Engine Control Unit (ECU)—3032E, 3038E (SE3A)

ECU—3032E, 3038E

ECU-J1 Connector—3032E, 3038E

ECU-J2 Connector—3032E, 3038E

F08 Inline Fuse (10A)—with ECU

B12 DPF Inlet Temperature Sensor

B13 DPF Intermediate Temperature Sensor

B14 DPF Differential Pressure Switch

P03 Hand Throttle Switch—3032E, 3038E

S48 DPF Regeneration Switch

Group 40CB: Engine Control Unit (ECU)—3025E (SE3B)

ECU—3025E

ECU Connector—3025E

B10 Throttle Sensor

B11 Coolant Temperature Sensor

B15 Revolution Sensor

K27 Main Battery Relay

Y05 EGR Valve

Y06 Rack Actuator

Y08 Cold Start Device

Group 40DA: Lights and Turn Signals—with ECU (SE4A)

E01 LH Headlight—with ECU

E02 RH Headlight—with ECU

E03 Left Tail/Turn/Warning Light—with ECU

E04 Right Tail/Turn/Warning Light—with ECU

E05 LH Work Light—with ECU

E06 RH Work Light—with ECU

S02 Light Switch—with ECU

Group 40DB: Lights and Turn Signals—Without ECU (SE4B)

E01 LH Headlight—Without ECU

E02 RH Headlight—Without ECU

E05 LH Work Light—Without ECU

E06 RH Work Light—Without ECU

E07 Right Front Turn Signal, Tail Light, and Hazard Light—Without ECU

E11 Left Rear Turn Signal and Hazard Light—Without ECU

E13 Left Front Turn Signal, Tail Light, and Hazard Light—Without ECU

E16 Right Rear Turn Signal and Hazard Light—Without ECU

E18 License Plate Light—Without ECU

H02 Horn

S02 Light Switch—Without ECU

S07 Turn Signal Switch—Without ECU

S11 Horn Switch

S13 Hazard Light Switch—Without ECU

S42 Brake Switch—Without ECU

Group 40EA: Cruise Control (SE5)

K08 Cruise Control Relay

K09 Cruise Control Relay

M03 Cruise Control Magnet

S42 Brake Switch—With ECU

S46 Cruise Control Switch

Group 40ZA: Fuses and Relays

Load Center—3032E, 3038E

Load Center—3025E

Load Center—3036E

Group 40ZB: Ground Points

W01 Chassis Ground

Group 40ZC: Interconnects

X03 Cruise Control Interconnect

Group 40ZD: Harnesses

W100 Chassis Harness Location—3032E, 3038E

W101 Chassis Harness Location—3025E

W102 Chassis Harness Location—3036E

W200 Cruise Control Harness Location

Section 240D: Electrical Tests and Adjustments

Group 05: General References

Electrical Tests and Adjustments - Summary of References

How to Use Electrical Tests and Adjustments Information

Group 50: Tests and Adjustments

Connector Test

Diode Test

Fuse Test

Light Test

Miscellaneous Component Test

Motor Test

Pump Test

Relay Test

Resistor Test

Sensor Test

Solenoid Test

Switch Test

Alternator Circuit Test

Battery Inspection Test

Open Circuit Load Test

CAN Network Voltage Checks

ECU—Engine Control Unit Test

ICC—Instrument Cluster Control Unit Test

Section 245: Electronic Control Units

Group 05: General References

Electronic Control Units—Summary of References

Control Unit Addresses—Access

Entering Diagnostic and Calibration Modes

VIN Security Fault Diagnosis

Servicing Electronic Control Units

Welding Near Electronic Control Units

Keep Electronic Control Unit Connectors Clean

Group 10: Calibrations, Preliminary Checks and Operational Checks

Programming Control Units

Group 20: Theory of Operation

CAN Bus Theory of Operation

CAN Bus Message Structure

Group 40: Component and Connector Information

Control Unit Connectors and Components

Group 50: Test and Adjustments

Troubleshooting Control Unit Programming

Troubleshooting Unresolved Problems

Control Unit Messaging Errors

Troubleshooting Electronic Controllers

CAN Communication Fault Checks

Monitoring CAN Bus Traffic Data

Group ICC: Instrument Cluster Control (ICC)

Diagnostic Addresses—Instrument Cluster Control (ICC)

Instrument Cluster Control (ICC) Configuration and Calibration

Group ECU: Engine Control Unit (ECU)

Diagnostic Addresses—Engine Control Unit (ECU)

Section 250: Drive System and Transmission Operation, Test, and Adjustments

Group 05A: General References

Drive System and Transmission Operation, Test, and Adjustments—Summary of References

Group 10: Calibrations, Preliminary Checks and Operational Checks

Transmission—Preliminary Checks

Transmission—Operational Checks

PTO - Preliminary Checks

PTO - Operational Checks

Differential and MFWD - Preliminary Checks

Differential and MFWD - Operational Checks

Group 20: Theory of Operation

Range Transmission Theory of Operation

Differential Power Flow and Lock Theory of Operation

MFWD Power Theory of Operation

Power Transmission - Rear PTO Theory of Operation

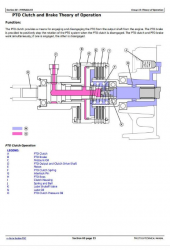

PTO Clutch and Brake Theory of Operation

Group 30: Schematics

Steering System and Hydrostatic Schematic

PTO System Schematic

Group 40: Component and Connector Information

Drive Pedals and Linkage Component Overview

Transmission Oil Pump Component Overview

Transmission and Swash Plate Component Overview

Transmission Housing Component Overview

Drive/Pinion Shaft Component Overview

Differential Assembly Component Overview

Rear Axle and Final Drive Component Overview

PTO Clutch and Brake Assembly Component Overview

PTO Rear Shaft Component Overview

Front Drive Component Overview (For MFWD)

MFWD Front Axle Housing and Differential Component Overview (—OCT 2013)

MFWD Front Axle Housing Component Overview (OCT 2013—)

Differential Component Overview (OCT 2013—)

Axle Housing Component Overview

Axle Housing Component Overview (OCT 2013—)

Group 50: Tests and Adjustments

Control Pedal Adjustment

Charge Pump Pressure Test and Adjustment

Differential Pinion Shaft Adjustment

Differential Backlash Adjustment

PTO Clutch Pressure Test

MFWD Driveline Test

Section 260: Steering and Brakes Operation, Test, and Adjustments

Group 05A: General References

Steering and Brakes Operation, Test, and Adjustments—Summary of References

Group 10A: Calibrations, Preliminary Checks and Operational Checks—Steering

Steering - Preliminary Check

Steering - Operational Check

Group 10B: Calibrations, Preliminary Checks and Operational Checks—Brakes

Brakes - Preliminary Check

Brakes - Operational Check

Group 20A: Theory of Operation—Steering

Steering Theory of Operation

Group 20B: Theory of Operation—Brakes

Brakes Theory of Operation

Group 30A: Schematics—Steering

Steering System Schematic

Group 40A: Component and Connector Information—Steering

Steering Component Overview

Group 40B: Component and Connector Information—Brakes

Brake and Differential Lock Linkage Component Overview

Brake and Axle Housing Component Overview

Brake Pedal and Linkage Component Overview

Brake Assembly Component Overview

Group 50A: Tests and Adjustments—Steering

Steering Pressure Test

Steering Pressure Check

Steering System Test

Toe-in Adjustment MFWD

Group 50B: Tests and Adjustments—Brakes

Brake and Differential Lock Adjustment

Section 270: Hydraulics Operation, Test, and Adjustments

Group 05A: General References

Hydraulics Operation, Test, and Adjustments—Summary of References

Group 10: Calibrations, Preliminary Checks and Operational Checks

Hydraulics - Preliminary Check

Hydraulics - Operational Check

Group 20: Theory of Operation

Hydraulic Theory of Operation

Rockshaft Theory of Operation

Group 30: Schematics

Rockshaft and SCV System Schematic

Group 40: Component and Connector Information

Rockshaft and Lift Arms Component Overview

Rockshaft Control Valve Component Overview

Group 50: Tests and Adjustments

Heating Hydraulic Oil

Hydraulic System Bleed Procedure

Rate of Drop and Stop Valve Adjustment

Lift Arms Adjustment

System Pressure and Flow Test

System Pressure Adjustment

Charge Pressure Test

Rockshaft Lift Cycle Test

Rockshaft Leakage Test

Rockshaft Position Feedback Linkage Adjustment

Rockshaft Surge Relief Test

Section 299: Service Tools

Group 05A: General References

Special Tools - Summary of References

Group 05C: Dealer Fabricated and Service Tools

DFRW20 Compressor Holding Fixture

John Deere Compact Utility Tractors Models 3032E, 3036E, 3038E Service Technical Manual (TM127919)