John Deere Hay and Forage Draper Platforms Models 625D, 630D, 635D, 640D Repair Service Technical Manual (TM103919)

Complete technical manual with electrical wiring diagrams for John Deere 625D, 630D, 635D and 640D Draper Platform, with all the workshop information to maintain, diagnose, repair, service, and rebuild like professional mechanics.

John Deere 625D, 630D, 635D and 640D Draper Platform workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm103919 - 625D, 630D, 635D and 640D Draper Platforms Repair Technical Manual.pdf

PRODUCT DETAILS:

Total Pages: 562 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English

MAIN SECTIONS

Foreword

General

Safety

Identification

Specifications

Lubrication

Cutterbar

Platform Cutterbar

Feed Drum, Reel And Top Auger

Feed Drum Repair

Reel Repair

Top Auger Repair

Electrical

Components

Harness and Connector Repair

Drives

Gear Cases

Drivelines

Knife Drive

Draper Belt

Draper Belt Assembly

Deck Shift

Hydraulics

Cylinders

Motors and Pump

Valves

Multi-Coupler

Accumulator

Frame

Transport

tm103919 - 625D, 630D, 635D and 640D Draper Platforms Repair

Table of Contents

Foreword

Section 10: General

Group 05: Safety

Recognize Safety Information

Understand Signal Words

Avoid High-Pressure Fluids

Service Accumulator Systems Safely

Park Machine Safely

Follow Safety Instructions

Prepare for Emergencies

Wear Protective Clothing

Use Proper Tools

Use Safety Lights and Devices

Use Proper Lifting Equipment

Avoid Contact With Moving Parts

Avoid Contact With Cutterbar

Service Machines Safely

Replace Safety Signs

Avoid Heating Near Pressurized Fluid Lines

Protect Against Noise

Practice Safe Maintenance

Avoid Harmful Asbestos Dust

Work In Ventilated Area

Illuminate Work Area Safely

Service Tires Safely

Support Machine Properly

Work in Clean Area

Remove Paint Before Welding or Heating

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Live With Safety

Group 10: Identification

Serial Number

Group 15: Specifications

General Specifications

Dimensions

Hydraulic Specifications

Platform Weights

Metric Bolt and Screw Torque Values

Unified Inch Bolt and Screw Torque Values

Face Seal Fittings Assembly and Installation—All Pressure Applications

Metric Face Seal and O-Ring Stud End Fitting Torque Chart—Standard Pressures

SAE Face Seal and O-Ring Stud End Fitting Torque Chart—Standard Pressures

Group 20: Lubrication

Draper Main Gear Case

Grease

Section 20: Cutterbar

Group 05: Platform Cutterbar

Other Material

Specifications

Remove Knife Head Bearing

Repair Knife Head Bearing

Install Knife Head Bearing

Remove Knife Head

Install Knife Head

Remove Knife Assembly

Install Knife Assembly

Knife Hold-Down Clearance

Replacing Knife Sections

Adjust Knife System

Cutterbar Knife Timing

Section 30: Feed Drum, Reel And Top Auger

Group 05: Feed Drum Repair

Specifications

Remove and Install Feed Drum

Disassemble and Assemble Feed Drum Fingers, Cranks And Shafts

Adjust Feed Drum Finger Timing

Group 10: Reel Repair

Service Equipment and Tools

Specifications

Remove and Install Single Reel

Remove and Install Split Reel

Disassemble and Assemble Reel

Disassemble and Assemble Split Reel Coupler

Remove and Install Reel Roller Bearing

Remove and Install Left-Hand Reel Support Slide Assembly

Remove and Install Right-Hand Reel Support Slide Assembly

Disassemble and Assemble Reel Support Slide Assembly

Adjust Pickup Finger Pitch

Group 15: Top Auger Repair

Specifications

Remove and Install Top Augers

Remove and Install Top Auger Bearings

Section 40: Electrical

Group 05: Components

Specifications

Remove and Install Hazard Warning Light and Bracket Assembly

Remove and Install Transport Lights

Light Bulb Replacement

Remove and Install Reel Speed Sensor

Remove and Install Draper Belt Speed Sensor

Remove and Install Control Block Pressure Sensor

Group 10: Harness and Connector Repair

Essential or Recommended Tools

Other Material

Wiring Harness Routing—Right-Hand Side

Wiring Harness Routing—Left-Hand Side

Use Electrical Insulating Compound

Using High-Pressure Washers

Connector Identification

Electrical Connector / Wiring Harness Handling and Repair

Installation of Repair Wire Assembly (RWA)

Repair Procedure R-A

Repair Procedure R-B

Repair Procedure R-C

Repair Procedure R-E

Repair Procedure R-G

Section 50: Drives

Group 05: Gear Cases

Essential or Recommended Tools

Other Material

Specifications

Remove and Install Main Drive Gear Case

Disassemble and Assemble Main Drive Gear Case

Remove and Install Center Feed Gear Case

Disassemble and Assemble Center Feed Gear Case

Remove and Install 90° Gear Case (Left-Hand Side)

Remove and Install 90° Gear Case (Right-Hand Side)

Disassemble and Assemble 90° Gear Case

Remove and Install 90° Gear Case With Belt Drive Pump

Disassemble and Assemble 90° Gear Case With Belt Drive Pump

Group 10: Drivelines

Other Material

Remove and Install Backshaft

Remove and Install 90° Gear Case Drive Shaft

Remove and Install Feed Drum Slip Clutch

Group 15: Knife Drive

Essential Or Recommended Tools

Other Material

Specifications

Remove and Install Knife Drive Belt

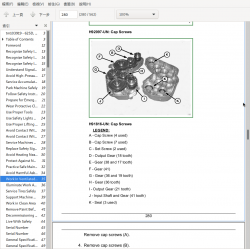

Knife Drive Gear Case—Exploded View

Remove and Install Knife Drive Gear Case

Disassemble and Assemble Knife Drive Gear Case

Section 60: Draper Belt

Group 05: Draper Belt Assembly

Specifications

Remove and Install Side Belt Assembly

Remove and Install Side Belt Drive Roller

Remove and Install Side Belt Idler Roller

Remove and Install Center Draper Belt Drive Roller

Remove and Install Center Belt Idler Roller

Group 10: Deck Shift

Specifications

Remove and Install Deck Shift Drive Sprocket

Remove and Install Manual Deck Shift Drive Bearings

Remove and Install Deck Shift Chain

Deck Shift Chain Tensioner Exploded View

Section 70: Hydraulics

Group 05: Cylinders

Specifications

Remove and Install Reel Lift Cylinders—Single Reel

Remove and Install Reel Lift Cylinder—Split Reel

Remove and Install Reel Lift Supply Cylinders—Split Reel

Remove and Install Reel Fore/Aft Cylinders

Remove and Install Frame Float Cylinders

Remove and Install Wheel Cylinders

Remove and Install Cutterbar Tilt Cylinder

Disassemble and Assemble 150 Series Hydraulic Cylinders

Rephase Reel Fore/Aft Cylinders

Rephase Reel Lift Cylinders

Bleeding Reel Lift Cylinder System

Group 10: Motors and Pump

Specifications

Remove and Install Reel Drive Motor

Remove and Install Left-Hand and Right-Hand Draper Drive Motors—Style A

Remove and Install Left-Hand and Right-Hand Draper Drive Motors—Style B

Remove and Install Belt Drive Pump

Remove and Install Top Auger Drive Motor

Remove and Install Deck Shift Motor

Group 15: Valves

Specifications

Remove and Install Header Control Block

Disassemble and Assemble Header Control Block

Remove and Install Pump Control Block

Disassemble and Assemble Pump Control Block

Remove and Install Reel Phasing Valve Block

Top Auger Flow Control Valve Exploded View

Deck Shift Valve Block Disassemble and Assemble—Left-Hand Side

Deck Shift Valve Block Disassemble and Assemble—Right-Hand Side

Remove and Install Check Valve Block

Disassemble and Assemble Check Valve Block

Group 20: Multi-Coupler

Specifications

Remove and Install Multi-Coupler Hydraulic Connectors

Disassemble and Assemble Multi-Coupler Cartridge

Group 25: Accumulator

Specifications

Relieve Hydraulic System Pressure

Accumulator (General Information)

Remove and Install Accumulator—Style A

Remove and Install Accumulator—Style B

Checking Accumulator Pressure—Style A

Checking Accumulator Pressure—Style B

Section 80: Frame

Group 05: Transport

Specifications

Other Material

Gauge Wheel—Exploded View

Remove and Install Front Transport and Gauge Wheel Assembly

Front Transport Wheel Assembly—Exploded View

Left Rear Transport Wheel Assembly—Exploded View

Right Rear Transport Wheel Assembly—Exploded View

Remove and Install Rear Transport Wheel Assembly

John Deere Hay and Forage Draper Platforms Models 625D, 630D, 635D, 640D Repair Service Technical Manual (TM103919)