John Deere Residential Mowers Z425, Z435, Z445, Z465 EZtrak Diagnostic and Repair Technical Manual (TM113019)

Complete service repair manual with electrical wiring diagrams for John Deere Residential Mowers Z425, Z435, Z445, Z465 EZtrak (SN.100001-), with workshop information to maintain, diagnose, repair, and service like professional mechanics.

John Deere Residential Mowers Z425, Z435, Z445, Z465 EZtrak workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM113019 - John Deere Residential Mowers Z425, Z435, Z445, Z465 EZtrak Technical Manual (Diagnostics and Repair).PDF

TM113019 - John Deere Residential Mowers Z425, Z435, Z445, Z465 EZtrak Technical Manual (Diagnostics and Repair).EPUB

Total Pages: 906 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality) & EPUB/MOBI/AZW for Kindle/iPad/iPhone/Android.

Language: English

MAIN SECTIONS

Foreword

General Information

Safety

General Specifications

Fuel and Lubricants

Machine Specifications

Engine Repair B&S

Repair Engine Twin Cylinder

Engine Repair Kawasaki

Specifications

Tools and Materials

Repair

Electrical Repair

Component Location

Wiring Harness

Power Train Repair

Component Location

Repair

Attachments Repair

Component Location

Repair

Miscellaneous Repair

Component Location

Repair

Engine Diagnosis, Tests, and Adjustments B&S

Diagnosis

Tests and Adjustments

Engine Diagnosis, Tests, and Adjustments Kawasaki

Component Location

General Information

Theory of Operation

Diagnostics

Tests and Adjustments

Electrical Diagnosis, Tests, and Adjustments

Theory of Operation

Diagnosis

Tests and Adjustments

Wiring Schematics

Connector Information

Power Train Diagnosis, Tests, and Adjustments

Theory of Operation

Diagnosis

Tests and Adjustments

Attachments Diagnosis, Tests, and Adjustments

Diagnosis

Tests and Adjustments

Service Tools and Kits

tm113019 - Z425, Z435, Z445, and Z465 EZtrak Mower (S.N. 100001-)

Table of Contents

Foreword

Section 10: General Information

Group 05: Safety

Recognize Safety Information

Understand Signal Words

Follow Safety Instructions

Practice Safe Maintenance

Use Proper Tools

Handle Fluids Safely—Avoid Fires

Drain Gasoline When Storing Machine

Prevent Acid Burns

Prevent Battery Explosions

Handling Batteries Safely

Prepare for Emergencies

Park Machine Safely

Support Machine Properly

Wear Protective Clothing

Work in Clean Area

Service Machines Safely

Work In Ventilated Area

Illuminate Work Area Safely

Replace Safety Signs

Use Proper Lifting Equipment

Service Tires Safely

Decommissioning: Proper Recycling and Disposal of Fluids and Components

Protect Against High Pressure Spray

Live With Safety

Group 10: General Specifications

Service Recommendations for O-Ring Boss Fittings

Service Recommendations For Flat Face O-Ring Seal Fittings

Metric Cap Screw Torque Values—Grade 7

Metric Bolt and Screw Torque Values

Unified Inch Bolt and Screw Torque Values

Group 15: Fuel and Lubricants

Summary of References

Gasoline Engine Oil

Oil Filters

Gasoline Fuel for 4-Cycle Engines

Transaxle Oil

Grease

Mixing of Lubricants

Alternative and Synthetic Lubricants

Lubricant Storage

Gasoline and Engine Storage

Carburetor Cleaning

Carburetor Cleaning Methods

Group 20: Machine Specifications

Machine Specifications (S.N. -130000)

Machine Specifications (S.N. 130001—15000)

Machine Specifications (S.N. 150001-170000)

Machine Specifications (S.N. 170001- )

Product Identification Number Location

Section 20: Engine Repair B&S

Group 10: Repair Engine Twin Cylinder

Summary of References

Essential or Recommended Tools

Service Equipment and Tools

Specifications

Remove and Install Air Cleaner

Remove and Install Upper Blower Housing (ELS)

Remove and Install Upper Blower Housing (Cyclonic)

Remove Two Barrel Carburetor

Install Two Barrel Carburetor

Repair Two Barrel Carburetor

Assemble Two Barrel Carburetor

Remove Engine (S.N. -130000)

Install Engine (S.N. -130000)

Remove Engine (S.N. 130001- )

Install Engine (S.N. 130001- )

Remove Cylinder Air Guides

Install Cylinder Air Guides

Remove Cylinder Head

Install Cylinder Head

Inspect and Repair Cylinder Head

Remove Valve

Inspect and Repair Valve

Lap Valves

Install Valve

Remove Piston, Rings and Rod

Check Piston Ring End Gap

Inspect Piston and Rod

Assemble Piston and Rod

Install Piston and Rod

Inspect Cylinder Bore

Hone Cylinder Bore

Clean Cylinder Bore

Resize Cylinder Bore

Remove Flywheel

Install Flywheel

Remove and Install Stator

Remove and Inspect Crankshaft and Camshaft

Crankshaft and Camshaft Component Location

Install Crankshaft and Camshaft

Inspect Magneto Bearing

Inspect PTO and Cam Bearing

Service Breather Valve

Remove Oil Pump

Install Oil Pump

Inertia Starting Motor Components

Remove and Install Starting Motor

Disassemble Inertia Starting Motor

Assemble Inertia Starting Motor

Replace Inertia Pinion Gear

Section 25: Engine Repair Kawasaki

Group 05: Specifications

Specifications

Group 10: Tools and Materials

Other Material

Service Equipment and Tools

Group 15: Repair

Summary of References

Replace Fuel Filter, FS730V

Remove and Install Fuel Pump, FS730V

Remove and Install Muffler, FS730V

Remove Engine, FS730V

Install Engine, FS730V

Remove and Install Carburetor, FS730V

Disassemble and Assemble Carburetor, FS730V

Remove and Install Intake Manifold, FS730V

Remove and Install Crankcase Breather, FS730V

Remove and Install Blower Housing, FS730V

Remove and Install Ignition Coil, FS730V

Remove and Install Flywheel, FS730V

Remove and Install Stator, FS730V

Remove and Install Rocker Arm Cover, FS730V

Remove and Install Rocker Arm and Push Rod, FS730V

Inspect Rocker Arm and Push Rod, FS730V

Remove Cylinder Head, FS730V

Disassemble and Assemble Cylinder Head, FS730V

Install Cylinder Head, FS730V

Inspect Cylinder Head and Valves, FS730V

Analyze Valves, FS730V

Valve Seats Reconditioning, FS730V

Lap Valve, FS730V

Remove and Install Crankcase Cover, FS730V

Crankcase Cover Disassembly, Inspection, and Assembly, FS730V

Disassemble and Assemble Governor, FS730V

Remove and Install Camshaft and Tappets, FS730V

Camshaft and Tappets Inspection, FS730V

Remove and Install Piston and Connecting Rod, FS730V

Disassemble Piston and Connecting Rod, FS730V

Piston and Connecting Rod Inspection, FS730V

Check Piston Ring End Gap, FS730V

Assemble and Install Piston and Connecting Rod, FS730V

Analyze Piston Ring Wear, FS730V

Analyze Piston Wear, FS730V

Remove and Install Crankshaft, FS730V

Crankshaft Inspection, FS730V

Check Connecting Rod-to-Crankshaft Clearance, FS730V

Inspect Crankshaft and Connecting Rod Wear, FS730V

Replace Oil Seal, FS730V

Deglaze Cylinder Bore, FS730V

Resize Cylinder Bore, FS730V

Remove and Install Starting Motor, FS730V

Disassemble and Assemble Starting Motor, FS730V

Section 30: Electrical Repair

Group 10: Component Location

Electrical Component Location

Group 20: Wiring Harness

Summary of References

Wiring Harness Legend

W1 Main Wiring Harness (S.N. -120000)

W1 Main Wiring Harness Color Codes (S.N. -120000)

W1 Main Wiring Harness, with B&S Engines (S.N. 120001- )

W1 Main Wiring Harness Color Codes, with B&S Engines (S.N. 120001- )

W1 Main Wiring Harness, Z445, Z465 (S.N. 150001- )

W1 Main Wiring Harness Color Codes, Z445, Z465 (S.N. 150001- )

W2 Engine Wiring Harness

W3 Lighting Kit Wiring Harness

Section 40: Power Train Repair

Group 10: Component Location

Summary of References

Steering Control Components

Transmission Serviceable Components (S.N. -130000)

Transmission Serviceable Components (S.N. 130001- )

Transmission Components (S.N. -130000)

Group 20: Repair

Summary of References

Specifications

Other Material

Replace Transaxle Filter (S.N. -130000)

Drain and Replace Transaxle Oil (S.N. 130001- )

Remove and Install Transaxle (S.N. -130000)

Remove and Install Transaxle (S.N. 130001- )

Remove and Install Traction Drive Belt (S.N. -130000)

Remove and Install Traction Drive Belt (S.N. 130001- )

Replace Input Shaft Seal (S.N. -130000)

Replace Input Shaft Seal (S.N. 130001- )

Replace Bypass Seal (S.N. -130000)

Replace Bypass Seal (S.N. 130001- )

Replace Axle Seal (S.N. -130000)

Replace Axle Seal (S.N. 130001- )

Replace Control Shaft Seal (S.N. -130000)

Replace Control Shaft Seal (S.N. 130001- )

Replace Brake Lever Seal (S.N. 130001- )

Remove and Install Transaxle Case Plug (S.N. 130001- )

Section 50: Attachments Repair

Group 10: Component Location

Summary of References

Lift Assembly, 48 and 54 Decks

Lift Components, 48 and 54 Decks

Lift Assembly, 62C

Lift Components, 62C

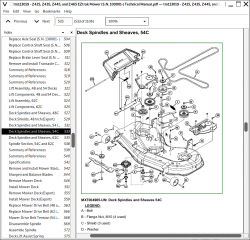

Deck Spindles and Sheaves, 48C

Deck Shields, 48 Inch (Export)

Deck Spindles and Sheaves, 54 Inch

Deck Spindles and Sheaves, 54C

Deck Spindles and Sheaves, 62C

Spindle Section, 54C and 62C

Group 20: Repair

Summary of References

Specifications

Remove and Install Mower Blades

Sharpen and Balance Blades

Remove Mower Deck

Install Mower Deck

Remove Mower Deck (Export)

Install Mower Deck (Export)

Replace Mower Drive Belt (48 and 54 in. Mowers)

Replace Mower Drive Belt (62 in. Mowers)

Mower Drive Belt Tension (54 in. Deck)

Disassemble Spindle

Assemble Spindle

Deck Lift Assist Spring

Section 60: Miscellaneous Repair

Group 10: Component Location

Summary of References

Fuel System Components

Park Brake Components (S.N. -130000)

Park Brake Components (S.N. 130001- )

Muffler and Heat Shield (S.N. -120000)

Muffler and Heat Shield (S.N. 120001-50000)

Muffler and Heat Shields (S.N. 150001- )

Seat and Pan Components

Group 20: Repair

Summary of References

Specifications

Remove and Install Seat

Remove and Install Seat Platform

Remove and Instal Control Console

Remove and Install Control Panel

Remove and Install Foot Plate

Remove Engine Guards (S.N. -130000)

Remove Engine Guards (S.N. 130001- )

Front Caster Wheels

Repair Park Brake (S.N. -130000)

Repair Park Brake (S.N. 130001- )

Section 220: Engine Diagnosis, Tests, and Adjustments B&S

Group 10: Diagnosis

Diagnose Engine Starting, V-Twin

Diagnose Carburetor, Air and Fuel, V-Twin

Engine Will Not Crank, V-Twin

Engine Cranks But Will Not Start, V-Twin

Engine Runs Erratically, V-Twin

Engine Runs Then Dies, V-Twin

Engine Backfires or Misses, V-Twin

Engine Overheats, V-Twin

Engine Has Loss of Power, V-Twin

Group 20: Tests and Adjustments

Summary of References

Specifications

Service Equipment and Tools

Adjust Throttle and Choke Cable, V-Twin

Adjust Governor - Static, V-Twin

Adjust Governor - Dynamic, V-Twin

Test Crankcase Vacuum, V-Twin

Test Cylinder Leakdown, V-Twin

Test Cylinder Balance, V-Twin

Adjust Armature Air Gap, V-Twin

Adjust Valve Clearance, V-Twin

Test Engine Oil Pressure, V-Twin

Test Fuel Shut Off Solenoid

Section 225: Engine Diagnosis, Tests, and Adjustments Kawasaki

Group 10: Component Location

Summary of References

Engine Block

Valves and Governor

Intake and Carburetor Components

Group 20: General Information

Cleaning Carburetors

Cleaning Methods

Fuel

Group 30: Theory of Operation

Engine Oil Flow Chart

Lubrication System Operation

Governor Operation

Crankcase Breather Operation

Automatic Compression Release (ACR) Operation

Cooling System Operation

Ignition System Operation

Carburetor Operation

Group 40: Diagnostics

Engine Troubleshooting

Kawasaki, Diagnose Carburetor Air and Fuel

Kawasaki, Diagnose Carburetor

Kawasaki, Diagnose Starting

Kawasaki, Diagnose Starting Motor

Group 50: Tests and Adjustments

Summary of References

Check and Adjust Choke, FS730V

Check and Adjust Throttle Cable, FS730V

Adjusting Governor — Static, FS730V

Adjust Slow Idle Speed, FS730V

Adjust Fast Idle Speed, FS730V

Cylinder Compression Test, FS730V

Cylinder Leak-Down Test, FS730V

Check and Adjust Valve Clearance, FS730V

Fan Screen Check and Adjustment, FS730V

Ignition Coil Air Gap Check and Adjustment, FS730V

Testing Spark, FS730V

Spark Plug Gap Adjustment, FS730V

Testing Engine Oil Pressure, FS730V

Test Fuel Pump, FS730V

Test Crankcase Vacuum, FS730V

Section 230: Electrical Diagnosis, Tests, and Adjustments

Group 10: Theory of Operation

Summary of References

Power Circuit Operation (S.N. -120000)

Cranking Circuit Operation (S.N. -120000)

Ignition Interlock Circuit Operation (S.N. -120000)

Fuel Shutoff Circuit Operation (S.N. -120000)

PTO Circuit Operation (S.N. -120000)

Charging Circuit Operation (S.N. -120000)

Headlight Circuit Operation (option) (S.N. -120000)

Hour Meter Circuit Operation (S.N. -120000)

Power Circuit Operation, with B&S Engines (S.N. 120001- )

Cranking Circuit Operation, with B&S Engines (S.N. 120001- )

Ignition Interlock Circuit Operation, with B&S Engines (S.N. 120001- )

Fuel Shutoff Circuit Operation, with B&S Engines (S.N. 120001- )

PTO Circuit Operation, with B&S Engines (S.N. 120001- )

Charging Circuit Operation, with B&S Engines (S.N. 120001- )

Headlight Circuit Operation, with B&S Engines (option) (S.N. 120001- )

Hour Meter Circuit Operation, with B&S Engines (S.N. 120001- )

Power Circuit Operation, Z445, Z465 (S.N. 150001- )

Cranking Circuit Operation, Z445, Z465 (S.N. 150001- )

PTO Circuit Operation, Z445, Z465 (S.N. 150001- )

Hour Meter Circuit Operation, Z445, Z465 (S.N. 150001- )

Interlock Circuit Operation, Z445, Z465 (S.N. 150001- )

Charging Circuit Operation, Z445, Z465 (S.N. 150001- )

Fuel Shutoff Circuit Operation, Z445, Z465 (S.N. 150001- )

Headlight Circuit Operation, Z445, Z465 (option) (S.N. 150001- )

Group 20: Diagnosis

Diagnose Power Circuit (S.N. -120000)

Diagnose Cranking Circuit (S.N. -120000)

Diagnose Ignition Interlock Circuit (S.N. -120000)

Diagnose Fuel Shutoff Circuit (S.N. -120000)

Diagnose PTO Circuit (S.N. -120000)

Diagnose Charging Circuit (S.N. -120000)

Diagnose Headlight Circuit (S.N. -120000)

Diagnose Hour Meter Circuit (S.N. -120000)

Diagnose Power Circuit, with B&S Engines (S.N. 120001- )

Diagnose Cranking Circuit, with B&S Engines (S.N. 120001- )

Diagnose Ignition Interlock Circuit, with B&S Engines (S.N. 120001- )

Diagnose Fuel Shutoff Circuit, with B&S Engine (S.N. 120001- )

Diagnose PTO Circuit, with B&S Engines (S.N. 120001- )

Diagnose Charging Circuit, with B&S Engines (S.N. 120001- )

Diagnose Headlight Circuit, with B&S Engines (S.N. 120001- )

Diagnose Power Circuit, Z445, Z465 (S.N. 150001- )

Diagnose Ignition Interlock Circuit, Z445, Z465 (S.N. 150001- )

Diagnose Fuel Shutoff Circuit, Z445, Z465 (S.N. 150001- )

Diagnose Cranking Circuit, Z445, Z465 (S.N. 150001- )

Diagnose PTO Circuit, Z445, Z465 (S.N. 150001- )

Diagnose Charging Circuit, Z445, Z465 (S.N. 150001- )

Diagnose Hour Meter Circuit, Z445, Z465 (S.N. 150001- )

Diagnose Headlight Circuit, Z445, Z465 (S.N. 150001- )

Group 30: Tests and Adjustments

Summary of References

Specifications

Service Equipment and Tools

Ground Circuit Test

Battery Voltage and Specific Gravity Tests

Battery Charge

Battery Load Test

Spark Test

Regulated Voltage Test

Regulated Amperage Test

Voltage Regulator/Rectifier Test, Kawasaki

Starting Motor Amperage Draw Test: Loaded, B&S

Starting Motor Amperage Draw Test: No Load, B&S

Starting Motor Amperage Draw Test: Loaded, Kawasaki

Starting Motor Amperage Draw Test: No-Load, Kawasaki

Test Starting Solenoid, Kawasaki

Stator Output Test, B&S

Stator Output Test, Kawasaki

Flywheel Stator Magnets Test

Flywheel Ignition Magnet Test

Diode Test

PTO Switch Test (S.N. 110001-)

Electric PTO Clutch Test

Key Switch Test

Start Relay Test

Relay Test

Fuel Shutoff Solenoid Test, B&S

Fuel Shutoff Solenoid Test, Kawasaki

Seat Switch Test

Headlight Switch Test

Park Brake and Neutral Switch Test

Group 40: Wiring Schematics

Summary of References

Schematic Legend

Main Electrical Schematic (S.N. -120000)

Main Electrical Schematic, with B&S Engines (S.N. 120001- )

Main Electrical Schematic, Z445, Z465 (S.N. 150001- )

Group 50: Connector Information

Summary of References

Load Center (S.N. -120000)

Load Center, with B&S Engines (S.N. 120001- )

Load Center, Z445, Z465 (S.N. 150001- )

Hour Meter Connector

Key Switch Connector

Left Handle Neutral Switch Connector

Right Handle Neutral Switch Connector

Park Brake Switch Connector

Seat Switch Connector

PTO Switch Connector

Light Switch Connector

Headlight Connector

Engine Connector

PTO Clutch Connector

Start Relay Connectors

Regulator/Rectifier Connectors

Section 240: Power Train Diagnosis, Tests, and Adjustments

Group 10: Theory of Operation

Summary of References

Drive Operation (S.N. -130000)

Drive Operation (S.N. 130001- )

Transaxle Operation

Group 20: Diagnosis

Transaxle Checks

Machine Does Not Achieve Full Speed

Machine Will Not Move

Noisy Operation

Wheel Will Not Rotate

Wheel Rotates One Direction Only

Group 30: Tests and Adjustments

Summary of References

Specifications

Adjust Tracking

Adjust Neutral Creep

Adjust Return To Neutral (RTN) (S.N. -130000)

Adjust Motion Control Levers

Adjust Park Brake

Section 250: Attachments Diagnosis, Tests, and Adjustments

Group 10: Diagnosis

Mower Blade Does Not Rotate

Mower Deck Vibrates

Mower Deck Cuts Unevenly or with Striping

Mower Belt Slips or Jumps Off Sheaves

Group 20: Tests and Adjustments

Summary of References

Adjust Mower Level

Section 299: Service Tools and Kits

Group 10: Service Tools

Service Equipment and Tools

John Deere Residential Mowers Z425, Z435, Z445, Z465 EZtrak Diagnostic and Repair Technical Manual (TM113019)