John Deere 670GLC Excavator Operator's Manual (OMT293264 OMT352329 OMT364685x19)

Complete Operator's Manual for John Deere 670GLC Excavators.

OMT293264 - John Deere 670GLC Excavator Operator's Manual.pdf

omt293265 - John Deere Excavadora 670GLC (Spanish).pdf

omt293266 - John Deere Excavatrice 670GLC (French).pdf

omt293262 - John Deere Excavadora 470GLC (Spanish).pdf

OMT352329 - John Deere 470GLC, 670GLC, and 870GLC Excavator Operator's Manual.pdf

omt350708 - John Deere 470GLC, 670GLC y 870GLC Excavadora (Spanish).pdf

omt350710 - John Deere Escavadeiras 470GLC, 670GLC, e 870GLC (Portuguese).pdf

OMT364685x19 - John Deere 670GLC Excavator Operator's Manual.pdf

omt364685x63 - John Deere Excavadora 670GLC (Spanish).pdf

omt364685x28 - John Deere Excavatrice 670GLC (French).pdf

PRODUCT DETAILS:

Total Pages: 1,231 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English etc.

omt293264 - John Deere 670GLC Excavator Operator's Manual

TABLE OF CONTENTS....2

Section 1-1: Safety—Safety and Operator Conveniences....27

Safety and Operator Convenience Features....28

Section 1-2: Safety—General Precautions....29

Recognize Safety Information....30

Follow Safety Instructions....31

Operate Only If Qualified....32

Wear Protective Equipment....33

Avoid Unauthorized Machine Modifications....34

Add Cab Guarding for Special Uses....35

Inspect Machine....36

Stay Clear of Moving Parts....37

Avoid High-Pressure Fluids....451

Avoid High-Pressure Oils....39

Work In Ventilated Area....40

Avoid Static Electricity Risk When Refueling....41

Prevent Fires....43

In Case of Machine Fire....44

Prevent Battery Explosions....45

Handle Chemical Products Safely....46

Handle Starting Fluid Safely....47

Decommissioning — Proper Recycling and Disposal of Fluids and Components....48

Exhaust Filter Ash Handling and Disposal....49

Prepare for Emergencies....50

Clean Debris from Machine....51

Section 1-3: Safety—Operating Precautions....52

Use Steps and Handholds Correctly....53

Start Only From Operator's Seat....54

Use and Maintain Seat Belt....55

Prevent Unintended Machine Movement....56

Avoid Work Site Hazards....57

Keep Riders Off Machine....59

Avoid Backover Accidents....60

Inspect and Maintain ROPS....61

Travel Safely....62

Prevent Acid Burns....63

Avoid Machine Tip Over....65

Use Special Care When Lifting Objects....67

Add and Operate Attachments Safely....68

Section 1-4: Safety—Maintenance Precautions....69

Park and Prepare for Service Safely....70

Service Cooling System Safely....71

Remove Paint Before Welding or Heating....72

Make Welding Repairs Safely....73

Drive Metal Pins Safely....74

Clean Exhaust Filter Safely....75

Section 1-5: Safety—Safety Signs....79

Safety Signs....79

Safety Signs Installed on Hydraulic Coupler—If Equipped....80

Section 2-1: Operation—Operator's Station....81

Pedals, Levers, and Panels....82

Switch Panel....84

Switch Panel Functions....85

Rear Left Panel....88

Horn....89

Power Boost Button....90

Pilot Shutoff Lever....91

Engine Stop Switch....92

Left Console....93

Travel Alarm and Travel Alarm Cancel Switch....94

Seat Heater Switch....95

Boom Mode Switch....96

Reversing Fan Switch....97

Counterweight Removal or Install Switch—If Equipped....99

Rear Light Switch—If Equipped....101

Right Console....102

Exhaust Filter Parked Cleaning Switch....103

Right Enable Switch—If Equipped....105

Cab Heater and Air Conditioner....106

Selecting Display Between Celsius and Fahrenheit....109

Operating the AM/FM Radio....110

Fire Extinguisher Mounting Location....112

Secondary Exit Tool....113

Cab Dome Light Switch....114

Opening Upper Front (Secondary Exit) Window....115

Removing and Storing the Lower Front Window....117

Opening Cab Door Window....119

Opening and Closing the Polycarbonate Type Roof Exit Cover....120

Adjusting the Mechanical Suspension Seat....121

Adjusting the Air Suspension Seat—If Equipped....123

Adjusting Pilot Control Lever Console Height....125

Section 2-2: Operation—Monitor Operation....126

Monitor....127

Monitor Functions....129

Monitor Start-Up....132

Main Menu....134

Main Menu—Alarm List....136

Main Menu—Air Conditioner....143

Main Menu—Radio....146

Main Menu—Work Mode....149

Main Menu—Setting Menu....151

Main Menu—Setting Menu—Date and Time....153

Main Menu—Setting Menu—Attachment Name Input....155

Main Menu—Setting Menu—Auto-Shutdown....156

Main Menu—Setting Menu—Auto Exhaust Filter Cleaning....157

Main Menu—Setting Menu—Sub Meter Selection....159

Main Menu—Setting Menu—Rear View Camera Monitor....161

Main Menu—Setting Menu—Display Item Selection....163

Main Menu—Setting Menu—Brightness Adjustment....165

Main Menu—Setting Menu—Language....166

Main Menu—Setting Menu—Unit Selection....167

Main Menu—Setting Menu—Main Menu Sequence Change....169

Main Menu—Information Menu....170

Main Menu—Information Menu—Operation....172

Main Menu—Information Menu—Maintenance....174

Main Menu—Information Menu—Troubleshooting....176

Main Menu—Information Menu—Monitoring....177

Section 2-3: Operation—Operating the Machine....178

Before Starting Work....179

Operator's Daily Machine Check Before Starting....180

Starting Engine....543

Cold Weather Start Aid....183

Cold Weather Warmup....184

Travel Pedals and Levers....186

Exhaust Filter....188

Exhaust Filter Parked Cleaning....191

Control Lever Pattern Operation....194

Control Lever Pattern Conversion....196

Operating in Water and Mud....198

Driving Up a Steep or Slippery Slope....199

Lifting....200

Towing Machine....201

Lower Boom With Engine Stopped....202

Parking the Machine....204

Lifting the Machine....206

Counterweight Removal With Hydraulic Removal Option—If Equipped....207

Counterweight Installation With Hydraulic Removal Option—If Equipped....218

Locking the Hydraulic Coupler to the Attachment—If Equipped....229

Unlocking the Hydraulic Coupler From the Attachment—If Equipped....232

Section 3-1: Maintenance—Machine....234

Required Emission-Related Information....235

Diesel Fuel....236

Diesel Fuel Specifications....238

Lubricity of Diesel Fuel....239

Handling and Storing Diesel Fuel....240

Biodiesel Fuel....241

Testing Diesel Fuel....243

Supplemental Diesel Fuel Additives....244

Fuel Filters....245

Minimizing the Effect of Cold Weather on Diesel Engines....246

Alternative and Synthetic Lubricants....248

Mixing of Lubricants....249

Lubricant Storage....250

John Deere Break-In Plus™ Engine Oil—Interim Tier 4, Final Tier 4, Stage IIIB, and Stage IV....251

Diesel Engine Oil — Interim Tier 4, Final Tier 4, Stage IIIB, Stage IV, and Stage V....252

Engine Oil and Filter Service Intervals—Interim Tier 4 and Stage III B Engines....254

Oil Filters....255

Hydraulic Oil....256

Swing Gear Case and Travel Gear Case Oils....258

Pump Drive Gear Case Oil....259

Track Adjuster, Working Tool Pivot, Swing Bearing, and Swing Bearing Gear Grease....260

Diesel Engine Coolant (engine without wet sleeve cylinder liners)....262

Water Quality for Mixing with Coolant Concentrate....264

Drain Intervals for Diesel Engine Coolant....265

John Deere COOL-GARD™ II Coolant Extender....266

Supplemental Coolant Additives....267

Operating in Warm Temperature Climates....268

Additional Information About Diesel Engine Coolants and John Deere COOL-GARD™ II Coolant Extender....269

Testing Coolant Freeze Point....271

Disposing of Coolant....273

Section 3-2: Maintenance—Periodic Maintenance....274

Service Machine at Specified Intervals....275

Check the Hour Meter Regularly....276

Prepare Machine for Maintenance....277

Open Engine Cover for Service....279

Open Access Doors for Service....280

Fuel Tank....281

Hydraulic Breaker and Crusher Attachments....282

Fluid Analysis Program Test Kits and 3-Way Coolant Test Kit....283

Service Intervals....284

Required Parts....286

Section 3-3: Maintenance—As Required....288

Drain Fuel Tank Sump....289

Remove and Clean Fuel Tank Inlet Screen....290

Clean Radiator Air Inlet Screen....291

Check and Adjust V-Belts....294

Clean Rear Camera Lens....297

Check and Clean Air Cleaner Dust Unloader Valve....298

Drain Primary Fuel Filter and Water Separators....299

Drain Final Fuel Filter and Water Separators....300

Check Windshield Washer Fluid Level....301

Check and Adjust Track Sag....302

Check Coolant....353

Section 3-4: Maintenance—Every 10 Hours or Daily....307

Check Coolant Level in Recovery Tank....308

Check Engine Oil Level....311

Check Hydraulic Oil Level....314

Lubricate Working Tool Pivots and Links....475

Lubricate Hydraulic Coupler—If Equipped....317

Section 3-5: Maintenance—Every 50 Hours....318

Lubricate Front End Pin Joints....319

Section 3-6: Maintenance—Every 100 Hours....322

Inspect and Re-Torque Track Hardware....323

Section 3-7: Maintenance—Every 250 Hours....325

Check Battery Electrolyte Level and Terminals....326

Check Swing Gear Case Oil Level....330

Check Travel Gear Case Oil Level....331

Check Pump Drive Gear Case Oil Level....332

Drain Hydraulic Tank Sump....333

Take Engine Oil Sample....335

Section 3-8: Maintenance—Every 500 Hours....336

Lubricate Swing Bearing Gear....337

Drain and Refill Engine Oil and Replace Filters....339

Check Air Intake Hoses....341

Replace Primary Fuel Filter and Water Separators....342

Replace Final Fuel Filter and Water Separators....344

Lubricate Swing Bearing....346

Clean Cab Fresh Air and Cab Recirculating Air Filters....347

Take Fluid Samples....349

Section 3-9: Maintenance—Every 1000 Hours....350

Drain and Refill Swing Gear Case Oil....351

Check Coolant....353

Replace Air Conditioner V-Belt....354

Adjust Engine Valve Lash....355

Replace Air Cleaner Elements....356

Drain and Refill Pump Drive Gear Case Oil....358

Replace Pilot System Oil Filter....360

Replace Hydraulic Tank Cap Breather Element....362

Replace Hydraulic Tank Oil Filter....364

Replace Pump Case Drain Filter....367

Section 3-10: Maintenance—Every 2000 Hours....369

Drain and Refill Travel Gear Case Oil....370

Section 3-11: Maintenance—Every 4000 Hours....372

Drain and Refill Hydraulic Tank Oil and Clean Suction Screen....373

Drain Cooling System....377

Cooling System Fill and Deaeration Procedure....380

Section 3-12: Maintenance—Every 4500 Hours....381

Service Exhaust Filter....382

Section 4-1: Miscellaneous—Machine....383

Bleed Fuel System....384

Bleed Air From Hydraulic System....550

Do Not Service or Adjust Injection Nozzles or High Pressure Fuel Pump....388

Do Not Service Control Valves, Cylinders, Pumps, or Motors....389

Precautions for Alternator and Regulator....390

Using Booster Batteries—24-Volt System....391

Handling, Checking, and Servicing Batteries Carefully....392

Using Battery Charger....395

Replacing Batteries....397

Welding On Machine....398

Welding Near Electronic Control Units....399

Keep Electronic Control Unit Connectors Clean....400

Clean the Machine Regularly....401

Adding 12-Volt Accessories....402

JDLink™ Machine Monitoring System (MMS)—If Equipped....403

Replacing Fuses....404

Replacing Bucket Teeth....408

Replacing Bucket Tooth Tip—Heavy-Duty Bucket....410

Replacing Bucket Teeth—TK Series....412

Bucket Remove and Install....413

Track Sag General Information....420

Check Track Shoe Hardware....421

Hardware Torque Specifications....422

Unified Inch Bolt and Screw Torque Values....423

Metric Bolt and Screw Torque Values....425

Section 4-2: Miscellaneous—Transporting....427

Transporting the Machine by Trailer....428

Types of Packings for Transportation....431

Packing Dimensions and Weights for Transportation....432

Retracting or Extending the Side Frame....476

Retracting the Side Frame....440

Extending the Side Frame....476

Section 4-3: Miscellaneous—Machine Assembly....447

Precautions for Assembling....448

Precautions for Lifting Work....449

Precautions for Operating Machine....450

Avoid High-Pressure Fluids....451

Installation Sequence....452

Installing Boom Cylinders....453

Installing Boom....458

Connecting Hoses Between Boom and Machine....461

Connecting Boom Cylinder Rod....464

Installing Arm....466

Connecting Arm Cylinder Rod....468

Connecting Bucket Cylinder Hoses....471

Installing Bucket....473

Lubricate Working Tool Pivots and Links....475

Extending the Side Frame....476

Checking Hydraulic Oil Level....477

Installing Counterweight (With Hydraulic Removal Option)....478

Installing Counterweight (Without Hydraulic Removal Option)....479

Section 4-4: Miscellaneous—Operational Checkout....482

Operational Checkout....482

Section 4-5: Miscellaneous—Troubleshooting....541

Troubleshooting Procedure....542

Engine....543

Electrical System....547

Hydraulic System....550

Hydraulic Counterweight....552

Section 4-6: Miscellaneous—Storage....553

Prepare Machine for Storage....554

Monthly Storage Procedure....556

Section 4-7: Miscellaneous—Machine Numbers....558

Record Product Identification Number (PIN)....559

Record Engine Serial Number....560

Record Travel Motor Serial Numbers....561

Record Swing Motor Serial Numbers....562

Hydraulic Pump Serial Numbers....563

Record Hydraulic Coupler Serial Number—If Equipped....564

Keep Proof of Ownership....565

Keep Machines Secure....566

Section 4-8: Miscellaneous—Specifications....567

Engine Specifications....568

Drain and Refill Capacities....569

Machine Specifications....570

Working Ranges....572

Lift Capacity—Arm: 3.6 m (11 ft 10 in.); Bucket: 2.9 m³ (3.8 yd³); Shoe: 650 mm (26 in.)....575

Lift Capacity—Arm: 4.2 m (13 ft 9 in.); Bucket: 2.5 m³ (3.3 yd³); Shoe: 650 mm (26 in.)....577

Lift Capacity—Arm: 5.3 m (17 ft 5 in.); Bucket: 2.0 m³ (2.6 yd³); Shoe: 650 mm (26 in.)....579

Lift Capacity—BE-Arm: 2.9 m (9 ft 6 in.); Bucket: 3.5 m³ (4.6 yd³); Shoe: 650 mm (25 in.)....582

Lift Capacity—Arm: 3.6 m (11 ft 10 in.); Bucket: 2.9 m³ (3.8 yd³); Shoe: 750 mm (30 in.)....584

Lift Capacity—Arm: 4.2 m (13 ft 9 in.); Bucket: 2.5 m³ (3.3 yd³); Shoe: 750 mm (30 in.)....586

Lift Capacity—Arm: 5.3 m (17 ft 5 in.); Bucket: 2.0 m³ (2.6 yd³); Shoe: 750 mm (30 in.)....589

Lift Capacity—BE-Arm: 2.9 m (9 ft 6 in.); Bucket: 3.5 m³ (4.6 yd³); Shoe: 750 mm (30 in.)....592

Lift Capacity—Arm: 3.6 m (11 ft 10 in.); Bucket: 2.9 m³ (3.79 yd³); Shoe: 900 mm (36 in.)....594

Lift Capacity—Arm: 4.2 m (13 ft 9 in.); Bucket: 2.5 m³ (3.27 yd³); Shoe: 900 mm (36 in.)....596

Lift Capacity—Arm: 5.3 m (17 ft 5 in.); Bucket: 2.0 m³ (2.6 yd³); Shoe: 900 mm (36 in.)....599

Lift Capacity—BE-Arm: 2.9 m (9 ft 6 in.); Bucket: 3.5 m³ (4.58 yd³); Shoe: 900 mm (36 in.)....602

omt352329 - John Deere 470GLC, 670GLC, and 870GLC Excavator Operator's Manual....616

TABLE OF CONTENTS....616

Section S: Safety....645

Recognize Safety Information....647

Follow Safety Instructions....648

Operate Only If Qualified....649

Wear Protective Equipment....650

Avoid Unauthorized Machine Modifications....651

Add Cab Guarding for Special Uses....652

Inspect Machine....653

Stay Clear of Moving Parts....654

Avoid High-Pressure Fluids....1050

Avoid High-Pressure Oils....656

Work In Ventilated Area....657

Prevent Fires....658

Prevent Battery Explosions....659

Handle Chemical Products Safely....660

Decommissioning — Proper Recycling and Disposal of Fluids and Components....661

Prepare for Emergencies....662

Clean Debris from Machine....663

Use Steps and Handholds Correctly....664

Start Only From Operator's Seat....665

Use and Maintain Seat Belt....886

Prevent Unintended Machine Movement....667

Avoid Work Site Hazards....668

Keep Riders Off Machine....670

Avoid Backover Accidents....671

Inspect and Maintain ROPS....672

Avoid Machine Tip Over....673

Use Special Care When Lifting Objects....675

Add and Operate Attachments Safely....676

Park and Prepare for Service Safely....677

Service Cooling System Safely....678

Remove Paint Before Welding or Heating....679

Make Welding Repairs Safely....680

Drive Metal Pins Safely....681

Safety Signs....682

Safety Signs Installed on Hydraulic Coupler—If Equipped....694

MEMO....1361

Section 1: Operator’s Station....697

Components Name....699

Getting ON/OFF the Machine....700

Cab Features (Std. Model)....702

Cab Features (with Attachment)....704

Multi Function Monitor....706

Basic Screen....707

How to Use Screens....708

Security Functions (Optional)....715

Alarm Occurrence Screen....719

Remedy....722

Main Menu....727

Air Conditioner....729

Radio....732

Work Mode....955

Mail (Optional)....736

Setting Menu....740

Date and Time....742

Attachment Adjust....753

Attachment Name Input....756

Auto-Lubrication....760

Password Change (Optional)....763

Sub Meter....768

Rear View Camera Monitor (Optional)....771

Brightness Adjustment....774

Language Settings....778

Lists of Display Language....781

Unit Selection....785

Display Item Selection (Rear View Camera OFF)....789

Main Menu Sequence Change....793

Information Menu....796

Operation....798

Maintenance....811

Monitoring....819

Switch Panel....822

Switch Panel (for Optional Equipment)....832

Key Switch....837

Power Boost Switch....959

Horn Switch....839

Cigar Lighter....840

Cab Light Switch....842

Installing Fire Extinguisher (Optional)....843

Pilot Control Shut-Off Lever....947

Engine Stop Handle....845

Fuse Box....847

Auto Air Conditioner....850

Tips for Optimal Air Conditioner Usage....859

AM/FM Radio Operation....861

Audio Input (Optional)....869

Cab Door Release Lever....871

Opening/Closing and Removing Cab Inside Window....872

Opening/Closing Upper Front (Secondary Exit) Window....873

Removing and Storing Lower Front Window....876

Opening Side Windows....877

Opening/Closing Overhead Window....878

Opening/Closing Overhead Window (Clear Hatch: If Equipped)....879

Secondary Exit....881

Adjusting Operator's Seat....882

Installation and Adjustment of Mirrors....885

Seat Belt....886

Battery Disconnect Switch (Optional)....888

MEMO....1361

Section 2: Break-In....894

Observe Engine Operations Closely....895

Every 10 Hours or Daily....896

After the First 50 Hours....897

After the First 100 Hours....898

MEMO....1361

Section 3: Operating The Engine....901

Inspect Machine Daily Before Starting....902

Before Starting Engine....903

Starting the Engine....905

Check Instruments After Starting....912

Using Booster Batteries....914

Stopping the Engine....916

Section 4: Driving The Machine....919

Drive the Machine Carefully....920

Steering the Machine Using Pedals....921

Steering the Machine Using Levers....923

Travel Mode Switch....960

Travel Alarm (Optional)....926

Operating on Soft Ground....927

Raise One Track Using Boom and Arm....928

Towing Machine a Short Distance....929

Operating in Water or Mud....931

Parking the Machine on Slopes....932

Parking the Machine....933

MEMO....1361

Section 5: Operating the Machine....937

Control Lever (ISO Pattern)....938

Control Lever (HITACHI Pattern) (Optional)....940

Attachment Pedal (Hydraulic Breaker) (Optional)....942

Attachment Pedal (Hydraulic Crusher) (Optional)....945

Pilot Control Shut-Off Lever....947

Warming Up Operation....949

Engine Speed Control....951

Auto-Idle....952

Work Mode....955

Power Boost Switch....959

Mode Switch....960

Operating Backhoe....962

Precaution for Arm Roll-In/Bucket Roll-In Combined Operation....964

Grading Operation....965

Do Not Strike the Ground with Bucket Teeth....966

Avoid Hammer Work....967

Avoid Abusive Operation....968

Avoid Side Load the Bucket....969

Do Not Use Wide Track Shoes on Rough Ground....970

Object Handling—If Equipped....971

Counterweight Removal With Hydraulic Removal Option—If Equipped....974

Counterweight Installation With Hydraulic Removal Option—If Equipped....985

Hydraulic Breaker and Hydraulic Crusher....996

Precautions for Breaker Operation....1001

Precautions for Crusher Operation....1013

How to Lower Boom In Case of Emergency and When Engine Stops....1016

Precautions for After Operations....1018

MEMO....1361

Section 6: Transporting....1021

Transporting the Machine by Trailer....1022

Types of Packings for Transportation—470GLC....1025

Packing Dimensions and Weights for Transportation—470GLC....1026

Types of Packings for Transportation—670GLC....1030

Packing Dimensions and Weights for Transportation—670GLC....1031

Types of Packings for Transportation—870GLC....1036

Packing Dimensions and Weights for Transportation—870GLC....1037

Retracting or Extending the Side Frame—670GLC and 870GLC ONLY....1092

Retracting the Side Frame—670GLC and 870GLC ONLY....1044

Extending the Side Frame—670GLC and 870GLC ONLY....1092

Precautions for Assembling....1047

Precautions for Lifting Work....1048

Precautions for Operating Machine....1049

Avoid High-Pressure Fluids....1050

Installation Sequence....1051

Installing Boom Cylinders....1052

Installing Boom....1057

Connecting Hoses Between Boom and Machine....1060

Connecting Boom Cylinder Rod....1066

Installing Arm....1068

Connecting Arm Cylinder Rod....1070

Connecting Bucket Cylinder Hoses....1073

Bucket Remove and Install—470GLC....1075

Bucket Remove and Install—670GLC and 870GLC ONLY....1084

Lubricate Working Tool Pivots and Links....1091

Extending the Side Frame—670GLC and 870GLC ONLY....1092

Checking Hydraulic Oil Level....1097

Installing Counterweight (With Hydraulic Removal Option)....1098

Installing Counterweight (Without Hydraulic Removal Option)....1099

Section 7: Maintenance....1101

Correct Maintenance and Inspection Procedures....1103

Check the Hour Meter Regularly....1105

Use Correct Fuels and Lubricants....1106

Alternative and Synthetic Lubricants....1107

Hydraulic Oil....1108

Swing Gear Case and Travel Gear Case Oils....1110

Track Adjuster, Working Tool Pivot, Swing Bearing, and Swing Bearing Gear Grease....1111

Diesel Engine Coolant (engine without wet sleeve cylinder liners)....1113

Lubricant Storage....1115

Mixing of Lubricants....1116

Diesel Fuel....1117

Handling and Storing Diesel Fuel....1119

Testing Diesel Fuel....1120

Minimizing the Effect of Cold Weather on Diesel Engines....1121

Diesel Engine Oil....1123

Engine Oil and Filter Service Intervals — Tier 2 and Stage II Engines....1125

Operating in Warm Temperature Climates....1127

Disposing of Coolant....1128

Layout....1129

Maintenance Guide Table....1134

Preparations for Inspection and Maintenance....1138

Hood and Access Covers....1140

Maintenance Guide....1147

A. Greasing....1152

Automatic/Manual Lubrication (Optional)....1158

Lubricator (Optional)....1165

B. Engine....1170

C. Transmission....1178

D. Hydraulic System Inspection and Maintenance of Hydraulic Equipment....1187

E. Fuel System....1210

F. Air Cleaner....1223

G. Cooling System....1229

H. Air Conditioner....1238

I. Electrical System....1243

J. Miscellaneous....1249

J. Miscellaneous Continued....1277

Unified Inch Bolt and Screw Torque Values....1324

Metric Bolt and Screw Torque Values....1326

Section 9: Maintenance Under Special Environmental Conditions....1329

Maintenance Under Special Environmental Conditions....1329

MEMO....1361

Section 10: Storage....1332

Storing the Machine....1333

Removing the Machine From Storage....1334

Section 11: Troubleshooting....1336

Troubleshooting....1336

Section 12: Specifications....1342

Specifications 470GLC....1343

Working Ranges 470GLC....1345

Shoe Types and Applications 470GLC....1347

Bucket Types and Applications 470GLC....1348

Specifications 670GLC....1349

Working Ranges 670GLC....1351

Shoe Types and Applications 670GLC....1353

Bucket Types and Applications 670GLC....1354

Specifications 870GLC....1355

Working Ranges 870GLC....1357

Shoe Types and Applications 870GLC....1359

Bucket Types and Applications 870GLC....1360

MEMO....1361

omt364685x19 - John Deere 670GLC Excavator Operator's Manual....1372

TABLE OF CONTENTS....1372

Section 1-1: Safety—Safety and Operator Conveniences....1405

Safety and Operator Convenience Features....1406

Section 1-2: Safety—General Precautions....1407

Recognize Safety Information....1408

Follow Safety Instructions....1409

Operate Only If Qualified....1410

Wear Protective Equipment....1411

Avoid Unauthorized Machine Modifications....1412

Control Pattern Selector—If Equipped....1413

Add Cab Guarding for Special Uses....1414

Inspect Machine....1415

Stay Clear of Moving Parts....1416

Avoid High-Pressure Fluids....1851

Avoid High-Pressure Oils....1418

Work In Ventilated Area....1419

Avoid Static Electricity Risk When Refueling....1420

Prevent Fires....1422

In Case of Machine Fire....1423

Prevent Battery Explosions....1424

Handle Chemical Products Safely....1425

Handle Starting Fluid Safely....1426

Decommissioning — Proper Recycling and Disposal of Fluids and Components....1427

Prepare for Emergencies....1428

Clean Debris from Machine....1429

Section 1-3: Safety—Operating Precautions....1430

Use Steps and Handholds Correctly....1431

Start Only From Operator's Seat....1432

Use and Maintain Seat Belt....1433

Prevent Unintended Machine Movement....1434

Avoid Work Site Hazards....1435

Keep Riders Off Machine....1437

Avoid Backover Accidents....1438

Avoid Machine Tip Over....1439

Inspect and Maintain ROPS....1441

Travel Safely....1442

Prevent Acid Burns....1443

Use Special Care When Lifting Objects....1445

Add and Operate Attachments Safely....1446

Section 1-4: Safety—Maintenance Precautions....1447

Park and Prepare for Service Safely....1448

Service Cooling System Safely....1449

Remove Paint Before Welding or Heating....1450

Make Welding Repairs Safely....1451

Drive Metal Pins Safely....1452

Section 1-5: Safety—Safety Signs and Other Instructions....1454

Safety Signs and Other Instructions....1454

Safety Signs Installed on Hydraulic Coupler—If Equipped....1464

Section 2-1: Operation—Operator's Station....1465

Pedals, Levers, and Panels....1466

Switch Panel....1468

Switch Panel Functions....1469

Rear Left Panel....1471

Horn....1472

Power Boost Button....1473

Pilot Shutoff Lever....1474

Engine Stop Switch....1475

Left Console....1476

Travel Alarm and Travel Alarm Cancel Switch....1477

Seat Heater Switch....1478

Boom Mode Switch....1479

Reversing Fan Switch....1480

Counterweight Removal or Install Switch—If Equipped....1482

Rear Light Switch—If Equipped....1484

Right Console....1485

Aftertreatment Device Regeneration Switch....1486

Right Enable Switch—If Equipped....1488

Cab Heater and Air Conditioner....1489

Selecting Display Between Celsius and Fahrenheit....1492

Operating the AM/FM Radio....1493

Fire Extinguisher Mounting Location....1495

Alternative Exit Tool....1496

Cab Dome Light Switch....1497

Opening Upper Front (Alternative Exit) Window....1498

Removing and Storing the Lower Front Window....1500

Opening Cab Door Window....1502

Opening and Closing the Polycarbonate-Type Roof Exit Cover....1503

Adjusting the Air Suspension Seat....1504

Adjusting Pilot Control Lever Console Height....1506

Section 2-2: Operation—Monitor Operation....1507

Monitor....1508

Monitor Functions....1510

Aftertreatment Indicators Overview....1513

Monitor Start-Up....1516

Main Menu....1517

Main Menu—Alarm List....1519

Main Menu—Air Conditioner....1527

Main Menu—Radio....1530

Main Menu—Work Mode....1533

Main Menu—Setting Menu....1535

Main Menu—Setting Menu—Date and Time....1537

Main Menu—Setting Menu—Attachment Name Input....1539

Main Menu—Setting Menu—Auto-Shutdown....1540

Main Menu—Setting Menu—Aftertreatment Device Regeneration Inhibit....1541

Main Menu—Setting Menu—Sub Meter Selection....1543

Main Menu—Setting Menu—Rear View Camera Monitor....1545

Main Menu—Setting Menu—Display Item Selection....1547

Main Menu—Setting Menu—Brightness Adjustment....1549

Main Menu—Setting Menu—Language....1550

Main Menu—Setting Menu—Unit Selection....1551

Main Menu—Setting Menu—Main Menu Sequence Change....1553

Main Menu—Information Menu....1554

Main Menu—Information Menu—Operation....1556

Main Menu—Information Menu—Maintenance....1558

Main Menu—Information Menu—Troubleshooting....1560

Main Menu—Information Menu—Monitoring....1561

Section 2-3: Operation—Operating the Machine....1562

Before Starting Work....1563

Inspect Machine Daily Before Starting....1564

Battery Disconnect Switch....1566

Starting Engine....1946

Cold Weather Start Aid....1569

Cold Weather Warm-Up....1570

Travel Pedals and Levers....1573

Aftertreatment Device....1575

Aftertreatment Device Regeneration....1578

Selective Catalytic Reduction (SCR) System Overview....1581

Control Lever Pattern Operation....1583

Mechanical Control Lever Pattern Selector—If Equipped....1585

Control Lever Pattern Conversion....1586

Operating in Water and Mud....1588

Driving Up a Steep or Slippery Slope....1589

Lifting....1591

Recovering the Machine....1593

Lower Boom With Engine Stopped....1595

Parking the Machine....1597

Lifting the Machine....1599

Counterweight Removal With Hydraulic Removal Option—If Equipped....1601

Counterweight Installation With Hydraulic Removal Option—If Equipped....1611

Locking the Hydraulic Coupler to the Attachment—If Equipped....1622

Unlocking the Hydraulic Coupler From the Attachment—If Equipped....1625

Section 3-1: Maintenance—Machine....1627

Required Emission-Related Information....1628

Diesel Fuel....1629

Diesel Fuel Specifications....1631

Lubricity of Diesel Fuel....1632

Handling and Storing Diesel Fuel....1633

Biodiesel Fuel....1634

Testing Diesel Fuel....1635

Supplemental Diesel Fuel Additives....1636

Fuel Filters....1637

Minimizing the Effect of Cold Weather on Diesel Engines....1638

Diesel Exhaust Fluid (DEF) — Use in Selective Catalytic Reduction (SCR) Equipped Engines....1640

Refilling Diesel Exhaust Fluid (DEF) Tank....1641

Testing Diesel Exhaust Fluid (DEF)....1643

Storing Diesel Exhaust Fluid (DEF)....1644

Disposal of Diesel Exhaust Fluid (DEF)....1645

Alternative and Synthetic Lubricants....1646

Mixing of Lubricants....1647

Lubricant Storage....1648

John Deere Break-In Plus™ Engine Oil—Interim Tier 4, Final Tier 4, Stage IIIB, and Stage IV....1649

Diesel Engine Oil — Interim Tier 4, Final Tier 4, Stage IIIB, Stage IV, and Stage V....1650

Engine Oil and Filter Service Intervals — Interim Tier 4, Final Tier 4, Stage IIIB, Stage IV, and Stage V Engines....1652

Oil Filters....1654

Hydraulic Oil....1655

Swing Gear Case and Travel Gear Case Oils....1657

Pump Drive Gear Case Oil....1658

Track Adjuster, Working Tool Pivot, Swing Bearing, and Swing Bearing Gear Grease....1659

Diesel Engine Coolant (engine without wet sleeve cylinder liners)....1661

Water Quality for Mixing with Coolant Concentrate....1663

Operating in Warm Temperature Climates....1664

Testing Coolant Freeze Point....1665

Disposing of Coolant....1667

Section 3-2: Maintenance—Periodic Maintenance....1668

Service Machine at Specified Intervals....1669

Check the Hour Meter Regularly....1670

Prepare Machine for Maintenance....1671

Open Engine Cover for Service....1673

Open Access Doors for Service....1674

Fuel Tank....1675

Hydraulic Breaker and Crusher Attachments....1676

Fluid Analysis Program Test Kits and 3-Way Coolant Test Kit....1677

Service Intervals....1678

Required Parts....1680

Section 3-3: Maintenance—As Required....1682

Drain Fuel Tank Sump....1683

Remove and Clean Fuel Tank Inlet Screen....1684

Clean Radiator Air Inlet Screen....1685

Check and Adjust V-Belts....1688

Clean or Replace Diesel Exhaust Fluid (DEF) Tank Inlet Screen....1691

Clean Rear Camera Lens....1693

Drain Primary Fuel Filter and Water Separators....1694

Drain Primary Water Separators....1695

Check Windshield Washer Fluid Level....1697

Check and Adjust Track Sag....1698

Section 3-4: Maintenance—Every 10 Hours or Daily....1701

Check Coolant Level in Recovery Tank....1702

Check Engine Oil Level....1705

Check Hydraulic Tank Oil Level....1708

Lubricate Working Tool Pivots and Links....1875

Lubricate Hydraulic Coupler—If Equipped....1711

Section 3-5: Maintenance—Every 50 Hours....1712

Lubricate Front End Pin Joints....1713

Section 3-6: Maintenance—Every 100 Hours....1715

Inspect and Re-Torque Track Hardware....1716

Section 3-7: Maintenance—Every 250 Hours....1718

Check Battery Electrolyte Level and Terminals....1719

Check Swing Gear Case Oil Level....1723

Check Travel Gear Case Oil Level....1724

Check Pump Drive Gear Case Oil Level....1725

Drain Water and Sediment From Hydraulic Tank Sump....1726

Take Engine Oil Sample....1728

Section 3-8: Maintenance—Every 500 Hours....1729

Lubricate Swing Bearing Gear....1730

Drain and Refill Engine Oil and Replace Filters....1732

Check Air Intake Hoses....1734

Replace Primary Fuel Filter and Water Separators....1735

Replace Final Fuel Filters....1737

Lubricate Swing Bearing....1738

Clean Cab Fresh Air and Cab Recirculating Air Filters....1739

Take Fluid Samples....1741

Section 3-9: Maintenance—Every 1000 Hours....1742

Drain and Refill Swing Gear Case Oil....1743

Check Coolant Condition....1745

Replace Air Conditioner V-Belt....1747

Adjust Engine Valve Lash....1748

Replace Air Cleaner Elements....1749

Drain and Refill Pump Drive Gear Case Oil....1751

Replace Pilot System Oil Filter....1753

Replace Hydraulic Tank Oil Filters....1755

Replace Pump Case Drain Filter....1758

Section 3-10: Maintenance—Every 2000 Hours....1760

Drain and Refill Travel Gear Case Oil....1761

Replace Primary Water Separators....1763

Section 3-11: Maintenance—Every 4000 Hours....1765

Drain and Refill Hydraulic Tank Oil and Clean Suction Screen....1766

Replace Hydraulic Tank Vent Cap Filter....1770

Drain Cooling System....1772

Cooling System Fill and Deaeration Procedure....1774

Section 3-12: Maintenance—Every 4500 Hours....1776

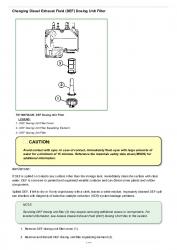

Access Diesel Exhaust Fluid (DEF) Dosing Unit Filter....1777

Changing Diesel Exhaust Fluid (DEF) Dosing Unit Filter....1778

Replace Diesel Exhaust Fluid (DEF) Inlet Bag Filter....1780

Section 4-1: Miscellaneous—Machine....1781

Bleed Fuel System....1782

Bleed Air From Hydraulic System....1954

Bleed Coolant System....1786

Do Not Service or Adjust Injection Nozzles or High-Pressure Fuel Pump....1787

Do Not Service Control Valves, Cylinders, Pumps, or Motors....1788

Precautions for Alternator and Regulator....1789

Handling, Checking, and Servicing Batteries Carefully....1790

Using Battery Charger....1793

Using Booster Batteries—24-Volt System....1795

Replacing Batteries....1796

Fluid Sampling Test Ports....1797

Welding on Machine....1798

Keep Electronic Control Unit Connectors Clean....1799

Clean the Machine Regularly....1800

Adding 12-Volt Accessories....1801

JDLink™ Machine Monitoring System (MMS)—If Equipped....1802

Replacing Fuses....1803

Replacing Bucket Teeth....1807

Replacing Bucket Tooth Tip—Heavy-Duty Bucket....1809

Replacing Bucket Teeth—TK Series....1811

Bucket Remove and Install....1812

Track Sag General Information....1819

Check Track Shoe Hardware....1820

Hardware Torque Specifications....1821

Unified Inch Bolt and Screw Torque Values....1822

Metric Bolt and Screw Torque Values....1824

Section 4-2: Miscellaneous—Transporting....1826

Transporting the Machine by Trailer....1827

Types of Packings for Transportation....1830

Packing Dimensions and Weights for Transportation....1831

Retracting or Extending the Side Frame....1876

Retracting the Side Frame....1840

Extending the Side Frame....1876

Section 4-3: Miscellaneous—Machine Assembly....1847

Precautions for Assembling....1848

Precautions for Lifting Work....1849

Precautions for Operating Machine....1850

Avoid High-Pressure Fluids....1851

Installation Sequence....1852

Installing Boom Cylinders....1853

Installing Boom....1858

Connecting Hoses Between Boom and Machine....1861

Connecting Boom Cylinder Rod....1864

Installing Arm....1866

Connecting Arm Cylinder Rod....1868

Connecting Bucket Cylinder Hoses....1871

Installing Bucket....1873

Lubricate Working Tool Pivots and Links....1875

Extending the Side Frame....1876

Checking Hydraulic Oil Level....1877

Installing Counterweight (With Hydraulic Removal Option)....1878

Installing Counterweight (Without Hydraulic Removal Option)....1879

Section 4-4: Miscellaneous—Operational Checkout....1882

Operational Checkout....1882

Section 4-5: Miscellaneous—Troubleshooting....1944

Troubleshooting Procedure....1945

Engine....1946

Electrical System....1950

Hydraulic System....1954

Hydraulic Counterweight....1957

Section 4-6: Miscellaneous—Storage....1958

Prepare Machine for Storage....1959

Monthly Storage Procedure....1961

Preparing Engine for Long-Term Storage....1963

Removing Engine From Long-Term Storage....1965

Section 4-7: Miscellaneous—Machine Numbers....1966

Record Product Identification Number (PIN)....1967

Record Engine Serial Number....1968

Record Travel Motor Serial Numbers....1969

Record Swing Motor Serial Numbers....1970

Record Hydraulic Pump Serial Numbers....1971

Record Hydraulic Coupler Serial Number—If Equipped....1972

Keep Proof of Ownership....1973

Keep Machines Secure....1974

Section 4-8: Miscellaneous—Specifications....1975

Engine Specifications....1976

Drain and Refill Capacities....1977

Machine Specifications....1978

Working Ranges....1980

Lift Capacity—Arm: 3.6 m (11 ft 10 in); Boom: 7.8 m (25 ft 7 in); Bucket: 2.9 m³ (3.8 yd³); Shoe: 650 mm (26 in)....1982

Lift Capacity—Arm: 4.2 m (13 ft 9 in); Boom: 7.8 m (25 ft 7 in); Bucket: 2.5 m³ (3.3 yd³); Shoe: 650 mm (26 in)....1984

Lift Capacity—Arm: 5.3 m (17 ft 5 in); Boom: 7.8 m (25 ft 7 in); Bucket: 2.0 m³ (2.6 yd³); Shoe: 650 mm (26 in)....1986

Lift Capacity—BE-Arm: 2.9 m (9 ft 6 in); Boom: 6.8 m (22 ft 4 in); Bucket: 3.5 m³ (4.6 yd³); Shoe: 650 mm (25 in)....1988

Lift Capacity—Arm: 3.6 m (11 ft 10 in); Boom: 7.8 m (25 ft 7 in); Bucket: 2.9 m³ (3.8 yd³); Shoe: 750 mm (30 in)....1990

Lift Capacity—Arm: 4.2 m (13 ft 9 in); Boom: 7.8 m (25 ft 7 in); Bucket: 2.5 m³ (3.3 yd³); Shoe: 750 mm (30 in)....1992

Lift Capacity—Arm: 5.3 m (17 ft 5 in); Boom: 7.8 m (25 ft 7 in); Bucket: 2.0 m³ (2.6 yd³); Shoe: 750 mm (30 in)....1994

Lift Capacity—BE-Arm: 2.9 m (9 ft 6 in); Boom: 6.8 m (22 ft 4 in); Bucket: 3.5 m³ (4.6 yd³); Shoe: 750 mm (30 in)....1996

Lift Capacity—Arm: 3.6 m (11 ft 10 in); Boom: 7.8 m (25 ft 7 in); Bucket: 2.9 m³ (3.8 yd³); Shoe: 900 mm (36 in)....1998

Lift Capacity—Arm: 4.2 m (13 ft 9 in); Boom: 7.8 m (25 ft 7 in); Bucket: 2.5 m³ (3.3 yd³); Shoe: 900 mm (36 in)....2000

Lift Capacity—Arm: 5.3 m (17 ft 5 in); Boom: 7.8 m (25 ft 7 in); Bucket: 2.0 m³ (2.6 yd³); Shoe: 900 mm (36 in)....2002

Lift Capacity—BE-Arm: 2.9 m (9 ft 6 in); Boom: 6.8 m (22 ft 4 in); Bucket: 3.5 m³ (4.6 yd³); Shoe: 900 mm (36 in)....2004

John Deere 670GLC Excavator Operator's Manual (OMT293264 OMT352329 OMT364685x19)