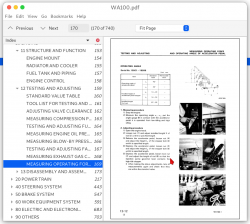

Komatsu WA100 Wheel Loader Repair Service Manual & Operation Maintenance Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu WA100 Wheel Loader, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu WA100 Wheel Loader workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEAM04160101 - Wheel Loader WA100-1, WA150-1 Operation & Maintenance Manual.pdf

SEBM04160105 - Wheel Loader WA100-1 Shop Manual.pdf

PRODUCT DETAILS:

Total Pages: 740 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

TABLE OF CONTENTS

SEAM04160101 - Wheel Loader WA100-1, WA150-1 Operation & Maintenance Manual...1

COVER...1

FOREWORD...2

BREAKING IN YOUR NEW MACHINE...3

CONTENTS...4

SAFETY HINTS...5

GENERAL LOCATIONS AND SPECIFICATIONS...12

INSTRUMENTS AND CONTROLS...13

CHECK BEFORE STARTING...35

OPERATING YOUR MACHINE...39

ADJUSTMENT OF WORK EQUIPMENT...47

HANDLING THE TIRES...49

TOWING...52

TRANSPORTATION...53

HANDLING OF BATTERY...54

COLD WEATHER OPERATION...57

PERIODIC MAINTENANCE...61

PRECAUTIONS FOR MAINTENANCE...62

MAINTENANCE TABLE...66

OIL FILLER AND LEVEL GAUGE POSITIONS...69

EVERY 50 HOURS SERVICE...70

EVERY 100 HOURS SERVICE...71

INITIAL 250 HOURS SERVICE...73

EVERY 250 HOURS SERVICE...73

EVERY 500 HOURS SERVICE...79

EVERY 1000 HOURS SERVICE...83

EVERY 2000 HOURS SERVICE...88

EVERY 4000 HOURS SERVICE...91

WHEN REQUIRED...92

ADJUSTMENT...103

TROUBLE SHOOTING GUIDE...105

STORAGE...108

SERVICE METER...110

MACHINE AND ENGINE SERIAL NUMBERS...111

FUEL,COOLANT AND LUBRICANTS...112

SEBM04160105 - Wheel Loader WA100-1 Shop Manual...115

COVER...115

CONTENTS...116

10 ENGINE...153

11 STRUCTURE AND FUNCTION...153

ENGINE MOUNT...154

RADIATOR AND COOLER...155

FUEL TANK AND PIPING...157

ENGINE CONTROL...158

12 TESTING AND ADJUSTING...159

STANDARD VALUE TABLE...160

TOOL LIST FOR TESTING AND ADJUSTING...161

ADJUSTING VALVE CLEARANCE...162

MEASURING COMPRESSION PRESSURE...163

TESTING AND ADJUSTING FUEL INJECTION TIMING...164

MEASURING ENGINE OIL PRESSURE AND TEMPERATURE...165

MEASURING BLOW-BY PRESSURE...166

TESTING AND ADJUSTING FAN BELT TENSION...167

MEASURING EXHAUST GAS COLOR...168

MEASURING OPERATING FORCE AND OPERATING ANGLE OF ACCELERATOR PEDAL...169

13 DISASSEMBLY AND ASSEMBLY...173

STARTING MOTOR...174

REMOVAL...174

INSTALLATION...174

ALTERNATOR...175

REMOVAL...175

INSTALLATION...175

FUEL INJECTION PUMP...176

REMOVAL...176

INSTALLATION...177

WATER PUMP...179

REMOVAL...179

INSTALLATION...180

NOZZLE HOLDER...181

REMOVAL (SERIAL NO.10001-19999)...181

INSTALLATION (SERIAL NO.10001-19999)...181

REMOVAL (SERIAL NO.20001-)...182

INSTALLATION (SERIAL NO.20001-)...182

CYLINDER HEAD...184

REMOVAL...184

INSTALLATION...190

RADIATOR...196

REMOVAL...196

INSTALLATION...199

ENGINE...202

REMOVAL...202

INSTALLATION...208

FUEL TANK...214

REMOVAL...214

INSTALLATION...215

20 POWER TRAIN...217

21 STRUCTURE AND FUNCTION...217

GENERAL...218

HYDRAULIC CIRCUIT FOR POWER TRAIN...220

HYDRAULIC CIRCUIT DIAGRAM FOR POWER TRAIN...221

FORWARD 1ST...222

TORQUE CONVERTER AND TRANSMISSION PIPING...224

TORQUE CONVERTER CHARGING PUMP...225

TORQUE CONVERTER...226

TORQUE CONVERTER OIL FILTER...228

TORQFLOW TRANSMISSION...230

CLUTCH PACK...233

TRANSMISSION CONTROL VALVE...242

MAIN REGULATOR VALVE...244

TORQUE CONVERTER OIL OUTLET VALVE...245

QUICK RETURN VALVE AND ACCUMULATOR...246

POWER MODULATING FUNCTION...248

ACCUMULATOR VALVE...252

ACTION OF THE CLUTCH CUT-OFF VALVE...253

DRIVE SHAFT...255

AXLE...256

DIFFERENTIAL...258

FINAL DRIVE...262

AXLE MOUNT...264

TIRE AND WHEEL...266

22 TESTING AND ADJUSTING...267

STANDARD VALUE TABLE...268

TOOL LIST FOR TESTING AND ADJUSTING...269

MEASURING ENGINE STALL SPEED...270

MEASURING OIL PRESSURE OF TORQUE CONVERTER AND TRANSMISSION...272

MEASURING SHIFT LEVER...274

MEASURING VALVE SPOOL OPERATING FORCE AND TRAVEL...275

TROUBLESHOOTING...277

PRECAUTIONS WHEN TROUBLESHOOTING...278

METHOD OF READING TROUBLESHOOTING TABLE...280

PREVENTING RECURRENCE OF TROUBLE...282

TROUBLESHOOTING TABLE...284

1. MACHINE DOES NOT MOVE OFF...284

2. MACHINE SPEED IS LOW, THRUST IS WEAK, GRADEABILITY FALLS OFF...286

3. LARGE SHOCK WHEN MOVING OFF OR CHANGING GEAR...288

4. LARGE TIME LAG WHEN MOVING OFF OR CHANGING GEAR...289

5. OIL TEMPERATURE IN TORQUE CONVERTER IS HIGH...290

23 DISASSEMBLY AND ASSEMBLY...291

TORQUE CONVERTER CHARGING PUMP...292

REMOVAL...292

INSTALLATION...292

TORQUE CONVERTER, TRANSMISSION...294

REMOVAL...294

INSTALLATION...304

TORQUE CONVERTER...312

DISASSEMBLY...312

ASSEMBLY...315

TRANSMISSION...318

DISASSEMBLY...318

ASSEMBLY...328

CLUTCH PACK...342

DISASSEMBLY...342

ASSEMBLY...350

TRANSMISSION VALVE...364

REMOVAL...364

INSTALLATION...366

TRANSMISSION CONTROL VALVE...368

DISASSEMBLY...368

ASSEMBLY...372

DRIVE SHAFT...378

DISASSEMBLY...378

ASSEMBLY...380

FRONT AXLE...382

REMOVAL...382

INSTALLATION...384

REAR AXLE...386

REMOVAL...386

INSTALLATION...390

DIFFERENTIAL...396

DISASSEMBLY...396

ASSEMBLY...400

AXLE HOUSING...410

DISASSEMBLY...410

ASSEMBLY...415

24 MAINTENANCE STANDARD...423

TRANSMISSION AND ENGINE MOUNT...424

TORQUE CONVERTER CHARGING PUMP...425

TORQUE CONVERTER...426

TRANSMISSION...428

TRANSMISSION CLUTCH ASSEMBLY...430

TRANSMISSION CONTROL VALVE...432

AXLE...434

DIFFERENTIAL...436

FINAL DRIVE...438

DRIVE SHAFT...439

AXLE MOUNT...440

40 STEERING SYSTEM...443

41 STRUCTURE AND FUNCTION...443

GENERAL...444

HYDRAULIC CIRCUIT FOR STEERING...446

HYDRAULIC CIRCUIT DIAGRAM FOR STEERING...447

OPERATIONS OF STEERING VALVE...448

STEERING VALVE (SERIAL NO. 10001-19999)...450

STEERING RELIEF VALVE...452

SAFETY VALVE (WITH SUCTION VALVE)...453

OPERATION OF DEMAND VALVE...455

TWO-WAY RESTRICTOR VALVE...456

STEERING VALVE (SERIAL NO. 20001-)...458

PRIORITY VALVE...466

STEERING COLUMN AND GEAR BOX...469

STEERING LINKAGE...470

STEERING CYLINDER...471

CENTER HINGE PIN...472

42 TESTING AND ADJUSTING...473

STANDARD VALUE TABLE...474

TOOL LIST FOR TESTING AND ADJUSTING...474

MEASURING STEERING WHEEL PLAY...475

MEASURING OPERATING FORCE OF STEERING WHEEL...476

OPERATING TIME OF STEERING WHEEL...477

TESTING STEERING LINKAGE...478

ADJUSTING STEERING LINKAGE...479

STEERING OIL PRESSURE...480

TROUBLESHOOTING...481

TROUBLESHOOTING TABLE...482

1. STEERING WHEEL DOES NOT TURN...482

2. STEERING WHEEL IS SLUGGISH...484

3. STEERING WHEEL MOVE UNSTEADILY OR IS SUBJECTED TO LARGE SHOCK...486

4. MACHINE TENDS TO TURN NATURALLY IN ONE PARTICULAR DIRECTION WHEN TRAVELING...486

5. LEFT AND RIGHT TURNING RADII ARE DIFFERENT...486

43 DISASSEMBLY AND ASSEMBLY...489

STEERING GEAR BOX...490

REMOVAL...490

INSTALLATION...491

DISASSEMBLY...492

ASSEMBLY...493

STEERING VALVE...496

REMOVAL...496

INSTALLATION...497

DISASSEMBLY...498

ASSEMBLY...500

PRIORITY VALVE...502

REMOVAL...502

INSTALLATION...503

STEERING VALVE...504

REMOVAL...504

INSTALLATION...505

STEERING CYLINDER...506

REMOVAL...506

INSTALLATION...506

DISASSEMBLY...508

ASSEMBLY...510

CENTER HINGE PIN...514

REMOVAL...514

INSTALLATION...524

44 MAINTENCE STANDARD...535

STEERING VALVE...536

STEERING CYLINDER MOUNT...538

STEERING CYLINDER...539

CENTER HINGE PIN...540

STEERING LINKAGE...542

STEERING COLUMN AND GEAR BOX...543

STEERING COLUMN...544

PRIORITY VALVE...545

50 BRAKE SYSTEM...547

51 STRUCTURE AND FUNCTION...547

GENERAL...548

BRAKE MASTER CYLINDER...550

BRAKE...552

PARKING BRAKE...554

BRAKE CALIPER...556

52 TESTING AND ADJUSTING...557

STANDARD VALUE TABLE...558

TOOL LIST FOR TESTING AND ADJUSTING...559

MEASURING BRAKE PEDAL...560

TESTING AND ADJUSTING OF BRAKE PEDAL LINKAGE...561

BRAKE PERFORMANCE...563

CHECKING BRAKE PISTON LEAKAGE...564

MEASURING WEAR OF BRAKE DISC...565

AIR BLEEDING FROM BRAKE LINE...566

PARKING BRAKE PERFORMANCE...567

CHECKING AND ADJUSTING PARKING BRAKE...568

MEASURING CLEARANCE...570

TROUBLESHOOTING...571

TROUBLESHOOTING TABLE...572

1. BRAKE IS INEFFECTIVE OR NOT VERY EFFECTIVE...572

2. BRAKE CANNOT BE RELEASED OR DRAGS...573

53 DISASSEMBLY AND ASSEMBLY...575

MASTER CYLINDER...576

REMOVAL...576

INSTALLATION...577

DISASSEMBLY...578

ASSEMBLY...579

PARKING BRAKE...580

REMOVAL...580

INSTALLATION...582

PARKING BRAKE PAD...584

REMOVAL...584

INSTALLATION...585

54 MAINTENANCE STANDARD...587

BRAKE MASTER CYLINDER...588

BRAKE...589

PARKING BRAKE...590

60 WORK EQUIPMENT SYSTEM...591

61 STRUCTURE AND FUNCTION...591

GENERAL...592

HYDRAULIC CIRCUIT (SERIAL NO.10001-19999)...594

HYDRAULIC CIRCUIT DIAGRAM (SERIAL NO.10001-19999)...595

HYDRAULIC CIRCUIT (SERIAL NO.20001-)...596

HYDRAULIC CIRCUIT DIAGRAM (SERIAL NO.20001-)...597

DUMP AND LIFT CONTROL LEVER LINKAGE...598

BUCKET LINKAGE...600

BUCKET POSITIONER AND BOOM KICK-OUT...602

HYDRAULIC TANK...603

OIL FILTER BYPASS VALVE...606

BREATHER...606

HYDRAULIC AND STEERING PUMP...607

MAIN CONTROL VALVE...608

RELIEF VALVE...610

SAFETY VALVE...611

SUCTION VALVE...612

HYDRAULIC CYLINDER...619

62 TESTING AND ADJUSTING...621

STANDARD VALUE TABLE...622

TOOL LIST FOR TESTING AND ADJUSTING...623

MEASURING DUMP AND LIFT CONTROL LEVERS...624

ADJUSTING DUMP AND LIFT CONTROL LEVERS...625

MEASURING DUMP AND LIFT CONTROL VALVE SPOOL TRAVEL...626

MEASURING HYDRAULIC PRESSURE...627

MEASURING LIFT ARM AND BUCKET...629

MEASURING HYDRAULIC DRIFT OF LIFT ARM AND BUCKET...630

ADJUSTING BUCKET POSITIONER...631

ADJUSTING BOOM KICK-OUT...632

TROUBLESHOOTING...633

TROUBLESHOOTING TABLE...634

1. LIFT ARM DOES NOT RISE...634

2. LIFT ARM MOVES SLOWLY OR DOES NOT HAVE SUFFICIENT LIFTING POWER...635

3. LIFT ARM MOVEMENT BECOMES SLOW AFTER IT REACHES A CERTAIN HEIGHT...636

4. BUCKET CANNOT BE HOLD DOWN WITH LIFT ARM CYLINDER...636

5. LIFT ARM HAS LARGE HYDRAULIC DRIFT...636

6. LIFT ARM MOVEMENT IS UNSTEADY DURING WORK...636

7. LIFT ARM DESCENDS MOMENTARILY WHEN CONTROL LEVER IS SHIFTED FROM "HOLD" TO "RAISE"...636

8. BUCKET DOES NOT TILT BACK...637

9. BUCKET MOVES SLOWLY OR HAS INSUFFICIENT TILT BACK POWER...638

10. BUCKET MOVEMENT BECOMES SLOW DURING TILT BACK...639

11. BUCKET CANNOT BE HELD DOWN BY THE BUCKET CYLINDER...639

12. BUCKET HAS LARGE HYDRAULIC DRIFT...639

13. BUCKET MOVES UNSTEADILY WHEN MACHINE TRAVELS UNDER LOAD...639

14. BUCKET DUMPS MOMENTARILY WHEN CONTROL LEVER IS SHIFTED FROM "HOLD" TO "TILT BACK"...639

15. CONTROL LEVERS OF LIFT ARM AND BUCKET MOVE STIFFLY AND SLUGGISHLY...640

63 DISASSEMBLY AND ASSEMBLY...641

HYDRAULIC TANK...642

REMOVAL...642

INSTALLATION...643

HYDRAULIC FILTER...644

REMOVAL...644

INSTALLATION...644

HYDRAULIC-STEERING PUMP...645

REMOVAL...645

INSTALLATION...645

MAIN CONTROL VALVE...646

REMOVAL...646

INSTALLATION...648

DISASSEMBLY...650

ASSEMBLY...652

DUMP CYLINDER...654

REMOVAL...654

INSTALLATION...656

LIFT CYLINDER...658

REMOVAL...658

INSTALLATION...659

LIFT AND DUMP CYLINDER...660

DISASSEMBLY...660

ASSEMBLY...662

WORK EQUIPMENT...666

REMOVAL...666

INSTALLATION...669

COUNTERWEIGHT...672

REMOVAL...672

INSTALLATION...672

64 MAINTENANCE STANDARD...673

MAIN CONTROL VALVE...674

DUMP CYLINDER...676

LIFT CYLINDER...677

WORK EQUIPMENT...678

BUCKET POSITIONER AND BOOM KICK-OUT...680

BUCKET...681

HYDRAULIC AND STEERING PUMP...682

80 ELECTRIC AND ELECTRONIC SYSTEM...683

81 STRUCTURE AND FUNCTION...683

CLUSTER GAUGE...684

PROXIMITY SWITCH...686

ENGINE STARTING CIRCUIT...688

ENGINE STOP CIRCUIT...689

PREHEATING CIRCUIT...690

PREHEATING WITH STARTING SWITCH...690

ELECTRICAL WIRING DIAGRAM...691

ELECTRICAL WIRING DIAGRAM CIRCUIT...692

SENSOR...694

83 DISASSEMBLY AND ASSEMBLY...699

INSTRUMENT PANEL...700

REMOVAL...700

INSTALLATION...701

90 OTHERS...703

91 STRUCTURE AND FUNCTION...703

CAB...704

AIR CONDITIONER (OPTION)...705

AIR CONDITIONER PIPING...705

AIR CONDITIONER WIRING DIAGRAM...706

AIR CONDITIONER ELECTRIC CIRCUIT...706

AIR CONDITIONER UNIT...707

AIR CONDITIONER COMPRESSOR...708

AIR CONDITIONER CONDENSOR...708

AIR CONDITIONER DRY RESERVOIR...709

93 DISASSEMBLY AND ASSEMBLY...711

CAB...712

REMOVAL...712

INSTALLATION...713

97 GEAR PUMP...715

GENERAL...715

GENERAL...716

PRINCIPLE OF OPERATION...717

PRESSURE LOADED TYPE GEAR PUMP...720

FIXED SIDE PLATE TYPE GEAR PUMP...722

SA SERIES...723

STRUCTURE...724

TESTING AND ADJUSTING...727

DISASSEMBLY...730

ASSEMBLY...734

MAINTENANCE STANDARD...739

Komatsu WA100 Wheel Loader Repair Service Manual & Operation Maintenance Manual