John Deere Front Mowers 1420, 1435, 1445, 1545, 1565 Series II Repair Service Manual (TM2147)

Complete All Inclusive Technical Manual with electrical wiring diagrams for John Deere Front Mower 1420, 1435, 1445, 1545, 1565 Series II, with workshop information to maintain, diagnose, repair, and rebuild like professional mechanics (Diagnosis, Operation, Tests, Repair, Service, Troubleshooting).

John Deere Front Mower 1420, 1435, 1445, 1545, 1565 Series II workshop technical service manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 2,122 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

tm2147 - Front Mower1420, 1435, 1445, 1545, 1565 Series II Technical Manual.pdf

tm2147 - Front Mower1420, 1435, 1445, 1545, 1565 Series II Technical Manual.epub

tm2147 - Front Mower1420, 1435, 1445, 1545, 1565 Series II

Table of Contents

Foreword

Section 10: Safety

Group 05: Safety

Recognize Safety Information

Understand Signal Words

Replace Safety Signs

Handle Fluids Safely—Avoid Fires

Prepare for Emergencies

Prevent Battery Explosions

Prevent Acid Burns

Wear Protective Clothing

Avoid High-Pressure Fluids

Avoid Heating Near Pressurized Fluid Lines

Service Machines Safely

Use Proper Tools

Park Machine Safely

Support Machine Properly

Use Proper Lifting Equipment

Work in Clean Area

Using High-Pressure Washers

Protect Against High Pressure Spray

Illuminate Work Area Safely

Work In Ventilated Area

WARNING: California Proposition 65 Warning

Remove Paint Before Welding or Heating

Avoid Harmful Asbestos Dust

Follow Tire Recommendations

Stay Clear of Rotating Drivelines

Service Cooling System Safely

Dispose of Waste Properly

Handle Chemical Products Safely

Live With Safety

Section 20: Specifications and Information

Group 05: Specifications

Engine

Drive Train

Brakes

Steering

Attachments

Group 10: General Information

Metric Bolt and Screw Torque Values

Metric Cap Screw Torque Values—Grade 7

Unified Inch Bolt and Screw Torque Values

Face Seal Fittings With Inch Stud Ends Torque

Face Seal Fittings With Metric Stud Ends Torque

O-Ring Face Seal Fittings

O-Ring Boss Fittings

Service Recommendations for STC Fittings

Using Proper Fuel

Engine Oil

Hydrostatic Transaxle Oil

4WD Rear Axle Oil

Grease

Recommended Engine Coolant

Machine Product Identification Number

Engine Serial Number

Group 15: Interlock System

Interlock System

Section 30: Engine

Group 05: Specifications

Specifications

Essential or Recommended Tools

Service Equipment and Tools

Other Material

Group 10: Diagnostics

Engine Diagnostics

Symptom: Starter Does Not Rotate

Symptom: Starter Rotates Slowly

Symptom: Starter Rotates But Does Not Crank

Symptom: Engine Cranks but Will Not Start

Symptom: Engine Malfunctions at Low RPM

Symptom: Engine Malfunctions at High RPM

Symptom: Excessive Oil Consumption

Symptom: Engine Overheats

Symptom: Excessive Fuel Consumption

Group 15: Tests and Adjustments

Check and Adjust Alternator Belt Tension

Adjust Throttle Cable and Governor

Adjust Choke Cable

Adjust Slow Idle Speed

Adjust Fast Idle Speed

Adjust Throttle Start Position Screw

Adjust Valve Clearance

Test Cooling System Pressure

Test Fuel Pump Pressure

Fuel Pump Flow Test

Oil Pressure Test

Test Cylinder Compression

Test Thermostat Opening

Test Radiator Cap Pressure

Radiator Bubble Test

Group 20: Repair

Remove and Replace Carburetor

Inspect Carburetor

Install High-Altitude Jet

Remove, Install, and Inspect Radiator

Remove and Install Thermostat

Remove and Install Coolant Pump (Thermostat Included)

Remove and Install Fuel Filter

Remove and Install Throttle and Choke Cable Assembly

Remove and Install Fuel Pump

Remove and Install Engine

Remove and Install Flywheel

Remove and Install Rocker Arm Cover

Rocker Arm and Push Rod

Remove and Install Cylinder Head

Remove and Install Exhaust Manifold

Remove and Install Intake Manifold

Recondition Cylinder Head, 3TG72

Oil Pan and Strainer

Oil Pressure Regulating Valve

Oil Pump

Remove and Install Timing Gear Cover

Check Timing Gear Backlash

Check Camshaft End Play

Camshaft

Remove, Inspect, and Install Governor

Remove and Install Piston and Connecting Rod

Connecting Rod Bearing Clearance

Check Connecting Rod Side Play

Cylinder Bore

Crankshaft and Main Bearings

Crankshaft Main Bearing Clearance Check

Crankshaft Rear Oil Seal

Section 35: Diesel Engine (3TNE74, 3TNV76, 3TNV80)

Group 05: Specifications

Specifications

Essential or Recommended Tools

Service Equipment and Tools

Other Material

Group 10: Diagnostics

Symptom: Engine Will Not Start

Symptom: Engine Starts but Does Not Continue Running - No Exhaust Smoke

Symptom: Engine Starts but Does Not Continue Running - Excess Exhaust Smoke

Symptom: Low Engine Output - Exhaust Color NORMAL

Symptom: Low Engine Output - Exhaust Color WHITE

Symptom: Low Engine Output - Exhaust Color BLACK

Symptom: Exhaust Color WHITE under Load

Symptom: Exhaust Color BLACK under Load

Symptom: Exhaust Temperature Too High

Symptom: Engine Runs Rough - Misfiring

Symptom: Engine Runs Rough - Uneven Combustion Sound

Symptom: Engine Runs Rough - Engine Surges DURING IDLING

Symptom: Engine Runs Rough - Engine Surges UNDER LOAD

Symptom: Engine Runs Rough - Excessive Engine Vibration

Symptom: Excessive Fuel Consumption

Symptom: Excessive Oil Consumption

Symptom: Fuel Oil in Crankcase

Symptom: Coolant in Crankcase

Symptom: Low Oil Pressure

Symptom: Engine Is Overheating

Symptom: Low Engine Coolant Temperature

Symptom: Low Compression

Starting Motor Troubleshooting Guide

Symptom: Starter Does Not Rotate

Symptom: Starter Rotates Slowly

Symptom: Starter Rotates but Does Not Rotate Engine

Group 15: Tests and Adjustments

Specifications

Check and Adjust Alternator Drive Belt Tension

Adjusting Valve Clearance

Check Valve Lift

Test Cylinder Compression (3TNE74, 3TNV76, 3TNV80)

Test Engine Oil Pressure

Leak Test Air Intake System

Test Fuel Pump Pressure

Leak Test Fuel System

Procedure for Bleeding Fuel System (S.N. -060000)

Priming Diesel Fuel System (S.N. 060001- )

Slow Idle Speed Adjustment

Adjust Throttle Cable

Test Fuel Injection System

Test Fuel Injection Nozzle

Adjust Injection Pump Timing (3TNE74)

Injection Pump Static Timing Check and Adjustment (3TNV76, 3TNV80)

Pressure Test Cooling System

Pressure Test Radiator Cap

Test Thermostat

Test Cylinder Leakdown

Fuel Transfer Pump Pressure Test

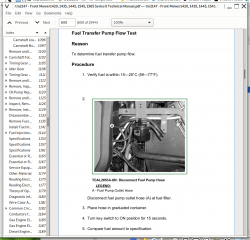

Fuel Transfer Pump Flow Test

Group 20: Repair

Remove and Install Alternator Drive Belt

Remove and Install Throttle Cable Assembly

Radiator Removal, Installation and Inspection

Remove and Install Air Filter Restriction Indicator

Remove and Install Air Cleaner Assembly

Remove and Install Muffler

Remove and Install Exhaust Pipe

Removal and Installation Exhaust Manifold

Removal and Installation Intake Manifold

Removal and Installation Intake Manifold (3TNV80)

Removal and Installation Thermostat

Remove and Install Temperature Coolant Switch

Removal and Installation Engine

Removal and Installation Rocker Arm Cover

Removal and Installation Rocker Arm Cover (3TNV80)

Remove and Install Rocker Arm Assembly

Disassemble and Assemble Rocker Arm

Removing and Installing Cylinder Head

Recondition Cylinder Head

Measure Piston-to-Cylinder Head Clearance

Removal and Installation Piston and Connecting Rod

Connecting Rod Side Play Check

Check Connecting Rod Bearing Clearance

Check Cylinder Bore

Check Crankshaft Rear Oil Seal

Crankshaft Front Oil Seal

Check Crankshaft and Main Bearings

Check Crankshaft Main Bearing Clearance

Crankshaft End Play Check

Removal and Installation Flywheel

Check Camshaft

Remove, Inspect, and Install Camshaft Follower

Removal and Installation Timing Gear Cover

Remove and Install Idler Gear

Remove and Install Timing Gear Housing

Remove and Install Oil Pan and Strainer

Oil Pump Repair

Oil Pump Repair (3TNV80)

Remove and Install Oil Pressure Regulating Valve

Remove and Install Water Pump (Thermostat Included)

Assemble Fuel Filter

Remove and Install Fuel Injection Pump

Remove and Install Fuel Injection Pump (3TNV80)

Remove, Inspect, and Install Fuel Injection Pump Camshaft

Remove and Install Fuel Control and Governor Linkage

Remove, Inspect, and Install Fuel Injection Nozzle

Remove and Install Fuel Shutoff Solenoid

Removal and Installation Fuel Pump

Removal and Installation Electric Fuel Pump

Section 35A: Diesel Engine (3TNV82A, 3TNV88)

Group 05: Specifications

Specifications

Essential or Recommended Tools

Service Equipment and Tools

Other Material

Group 10: Theory of Operation

Fuel and Air System Operation

Cooling System Operation

Lubrication System Operation

Group 15: Diagnostics

Diesel Engine Troubleshooting

Symptom: Engine Will Not Start

Symptom: Engine Starts But Does Not Continue Running - No Exhaust Smoke

Symptom: Engine Starts But Does Not Continue Running - Excess Exhaust Smoke

Symptom: Low Engine Output - Exhaust Color NORMAL

Symptom: Low Engine Output - Exhaust Color WHITE

Symptom: Low Engine Output - Exhaust Color BLACK

Symptom: Exhaust Color WHITE Under Load

Symptom: Exhaust Color BLACK Under Load

Symptom: Exhaust Temperature Too High

Symptom: Engine Runs Rough - Misfiring

Symptom: Engine Runs Rough - Uneven Combustion Sound

Symptom: Engine Runs Rough - Engine Surges DURING IDLING

Symptom: Engine Runs Rough - Engine Surges UNDER LOAD

Symptom: Engine Runs Rough - Excessive Engine Vibration

Symptom: Excessive Fuel Consumption

Symptom: Excessive Oil Consumption

Symptom: Fuel Oil in Crankcase

Symptom: Coolant in Crankcase

Symptom: Low Oil Pressure

Symptom: Engine Is Overheating

Symptom: Low Engine Coolant Temperature

Symptom: Low Compression

Starting Motor Troubleshooting Guide

Symptom: Starter Does Not Rotate

Symptom: Starter Rotates Slowly

Symptom: Starter Rotates But Does Not Crank

Group 20: Tests and Adjustments

Fan and Alternator Drive Belt Adjustment

Cylinder Compression Test

Slow Idle Adjustment

Throttle Cable Adjustment

Injection Pump Static Timing

Valve Clearance Adjustment

Checking Connecting Rod Side Play

Connecting Rod Bearing Clearance Check

Checking Crankshaft End Play

Crankshaft Main Bearing Clearance Check

Valve Lift Check

Camshaft End Play Check

Checking Timing Gear Backlash

Fuel Injection Nozzle Test

Thermostat Opening Test

Cylinder Pressure Leakage Test

Cooling System Pressure Test

Radiator Pressure Cap Test

Oil Pressure Test

Fuel Transfer Pump Pressure Test

Fuel Transfer Pump Flow Test

Fuel System Leakage Test

Bleed Fuel System (S.N. -060000)

Priming Diesel Fuel System (S.N. 060001- )

Group 25: Repair

Remove and Install Engine

Rocker Arm Cover Remove and Install

Service Rocker Arm Assembly

Remove and Install Glow Plug

Cylinder Head and Valves Removal and Installation

Cylinder Head and Valves Disassembly and Assembly

Valve Seats

Intake and Exhaust Valves

Valve Recession

Valve Guides

Valve Springs

Exhaust Manifold

Intake Manifold

Grind Valve Seats

Lap Valves

Check Piston-to-Cylinder Head Clearance

Piston and Connecting Rod

Piston Inspection

Cylinder Bore (3TNV82A, 3TNV88)

Crankshaft Rear Oil Seal (3TNV82A, 3TNV88)

Crankshaft Front Oil Seal (3TNV82A, 3TNV88)

Remove and Install Crankshaft and Main Bearings

Crankshaft Main Bearing Clearance Check (3TNV82A, 3TNV88)

Flywheel and Flex Plate

Remove and Install Camshaft

Inspect Camshaft

Remove and Install Camshaft Gear

Camshaft Followers

Timing Gear Cover

Idler Gear

Timing Gear Cover Mounting Plate

Remove and Install Oil Pan, Crankcase Extension, and Strainer

Remove, Inspect, and Install Oil Pump

Oil Pump Repair

Remove and Install Thermostat

Inspect, Remove, and Install Coolant Pump

Remove, Install and Inspect Radiator

Disassemble and Assemble Water Separator

Remove Fuel Injection Pump

Install Fuel Injection Pump

Fuel Injection Nozzles

Section 40: Electrical

Group 05: Specifications

Specifications

Group 10: Tools and Materials

Essential or Recommended Tools

Service Equipment and Tools

Other Material

Group 15: General Information

Reading Electrical Schematics

Theory of Operation Information

Diagnostic Information

Wire Color Abbreviation Chart

Common Circuit Tests

Conductors for 12 Volt Circuits

Group 20: Component Location

Gas Engine Electrical Components

Diesel Engine Electrical Components

Group 25: Schematics and Harnesses

Schematic and Wiring Harness Legend - 1420 Gas Engine

Schematic and Wiring Harness Legend - 1435, 1445, 1545, and 1565 Diesel Engine

Schematic - 1420 Gas Engine

Main Wiring Harness (W4) - 1420 Gas Engine

Pulser Wiring Harness (W5) - 1420 Gas Engine

Coil Pack Wiring Harness (W6) - 1420 Gas Engine

Headlight Harness (W7)

Schematic - 1435 Diesel Engine

Wire Harness - 1435 Diesel Engine

Schematic - 1445, 1545, 1565 Diesel Engine

Wire Harness - 1445, 1545, 1565 Diesel Engine

Headlight Harness (W7)

Group 30: Operation and Diagnostics

Use of Dielectric Grease

Unswitched Power Circuit Operation - 1420 Gas Engine

Switched Power Circuit Operation - 1420 Gas Engine

Power Circuit Schematic - 1420 Gas Engine

System: Power Circuit Diagnosis - 1420 Gas Engine

Unswitched Power Circuit Operation - 1435, 1445, 1545, 1565 Diesel Engine

Switched Power Circuit Operation - 1435, 1445, 1545, 1565 Diesel Engine

Power Circuit Schematic - 1435, 1445, 1545, 1565 Diesel Engine

System: Power Circuit Diagnosis - 1435, 1445, 1545, 1565 Diesel Engine

Cranking Circuit Operation

Cranking Circuit Schematic

System: Cranking Circuit Diagnosis - 1420 Gas Engine

System: Cranking Circuit Diagnosis - 1435, 1445, 1545, 1565 Diesel Engine

Charging Circuit Operation - 1420 Gas Engine

Charging Circuit Schematic - 1420 Gas Engine

System: Charging Circuit Diagnosis - 1420 Gas Engine

Charging Circuit Operation - 1435, 1445, 1545, 1565 Diesel Engine

Charging Circuit Schematic - 1435, 1445, 1545, 1565 Diesel Engine

System: Charging Circuit Diagnosis - 1435, 1445, 1545, 1565 Diesel Engine

Operator Presence and PTO Interlock Circuit Operation - 1420 Gas Engine

Operator Presence and PTO Interlock Circuit Schematics - 1420 Gas Engine

System: Operator Presence and PTO Interlock Circuit Diagnosis - 1420 Gas Engine

Operator Presence and PTO Interlock Circuit Operation - 1435, 1445, 1545, 1565 Diesel Engine

Operator Presence and PTO Interlock Circuit Schematic - 1435, 1445, 1545, 1565 Diesel Engine

System: Operator Presence and PTO Interlock Circuit Diagnosis - 1435, 1445, 1545, 1565 Diesel Engine

Engine Oil Pressure Light and Buzzer Circuit Operation - 1420 Gas Engine

Engine Oil Pressure Light and Buzzer Circuit Schematic - 1420 Gas Engine

System: Engine Oil Pressure Light and Buzzer Circuit Diagnosis - 1420 Gas Engine

Engine Oil Pressure Light and Buzzer Circuit Operation - 1435, 1445, 1545, 1565 Diesel Engine

Engine Oil Pressure Light and Buzzer Circuit Schematic - 1435, 1445, 1545, 1565 Diesel Engine

System: Engine Oil Pressure Light and Buzzer Circuit Diagnosis - 1435, 1445, 1545, 1565 Diesel Engine

Engine Coolant Temperature Light and Buzzer Circuit Operation - 1420 Gas Engine

Engine Coolant Temperature Light and Buzzer Circuit Schematic - 1420 Gas Engine

System: Engine Coolant Temperature Light and Buzzer Circuit Diagnosis - 1420 Gas Engine

Engine Coolant Temperature Light and Buzzer Circuit Operation - 1435, 1445, 1545, 1565 Diesel Engine

Engine Coolant Temperature Light and Buzzer Circuit Schematic - 1435, 1445, 1545, 1565 Diesel Engine

System: Engine Coolant Temperature Light and Buzzer Circuit Diagnosis - 1435, 1445, 1545, 1565 Diesel Engine

Hydraulic Oil Temperature Light Circuit Operation - 1420 Gas Engine

Hydraulic Oil Temperature Light Circuit Schematic - 1420 Gas Engine

System: Hydraulic Oil Temperature Light and Buzzer Circuit Diagnosis - 1420 Gas Engine

Hydraulic Oil Temperature Light Circuit Operation - 1435, 1445, 1545, 1565 Diesel Engine

Hydraulic Oil Temperature Light Circuit Schematic - 1435, 1445, 1545, 1565 Diesel Engine

System: Hydraulic Oil Temperature Light and Buzzer Circuit Diagnosis - 1435, 1445, 1545, 1565 Diesel Engine

Cold Start Operation - 1435, 1445, 1545, and 1565 Diesel Engine

Cold Start Circuit Schematic - 1435 Diesel Engine

Cold Start Circuit Schematic - 1445, 1545, 1565 Diesel Engine

System: Cold Start Circuit Diagnosis - 1435, 1445, 1545, 1565 Diesel Engine

Engine Ignition Circuit Operation - 1420 Gas Engine

Engine Ignition Circuit Schematic - 1420 Gas Engine

System: Engine Ignition Circuit Diagnosis - 1420 Gas Engine

Fuel Shutoff Solenoid Circuit Operation - 1420 Gas Engine

Fuel Shutoff Solenoid Circuit Schematic - 1420 Gas Engine

System: Fuel Shutoff Solenoid Circuit Diagnosis - 1420 Gas Engine

Fuel Shutoff Solenoid Circuit Operation - 1435, 1445, 1545, 1565 Diesel Engine

Fuel Shutoff Solenoid Circuit Schematic - 1435, 1445, 1545, 1565 Diesel Engine

System: Fuel Shutoff Solenoid Circuit Diagnosis - 1435, 1445, 1545, 1565 Diesel Engine

Cruise Control Circuit Operation

Cruise Control Circuit Schematic

System: Cruise Control Circuit Diagnosis

Group 35: Tests and Adjustments

Ground Circuit Test

Battery Test

Charge Battery

Battery Load Test

Unregulated Amperage Test

Regulated Voltage Output Test

Starting Motor Loaded Amperage Draw Test

Starting Motor No-Load Amperage Draw and RPM Test

Air Preheater Test

Relay Test

Key Switch Test

Brake Switch Test

Seat Switch Test

Engine Coolant Temperature Switch Test

Hydraulic Oil Temperature Switch Test

Engine Oil Pressure Switch Test

Glow Plug Test

Diode Pack AMT386 Test

Diode Pack AMT477 Test

Test Fuel Pump

PTO Switch Test

Headlight Switch Test

Cruise Control Switch Test

Cruise Control Magnet Test

Fuel Shutoff Solenoid Test - Diesel Engine

Fuel Shutoff Solenoid Test - Gas Engine

HVAC Switch Test

Blower Motor Switch Test

Group 40: Repair

Battery Removal and Installation

Alternator Removal and Installation - 1420 and 1435

Alternator Removal and Installation - 1445, 1545, 1565 Diesel Engine

Alternator Repair

Starting Motor Removal and Installation

Starting Motor Removal and Installation - 1565 Diesel Engine

Group 45: Cab

Schematic and Wiring Harness Legend - Gas Engine

Main Electrical Schematic

Cab Road Lights Schematics

W2 Front Road Lights Wiring Harness

W4 and W5 Front Position/Turn Lights Harness (LH and RH)

W3 Rear Road Lights Wiring Harness

W6 and W7 Rear Position/Turn Lights Harness (LH and RH)

W8 License Plate Light Wiring Harness

W9 Trailer Wiring Harness

Group 50: Cab Blower and Air Conditioner

Schematic and Wiring Harness Legend - Cab A/C and Blower

Schematic and Wiring Harness Legend - Cab Blower

Cab Air Conditioner and Blower Schematic

Cab Blower Schematic

Cab A/C Power Wiring Harness (W10)

Cab A/C Blower Wiring Harness (W11)

Cab Blower Power Wiring Harness (W12)

Cab Blower Wiring Harness (W13)

Cab Air Conditioner and Blower Circuit Operation

System: Cab Air Conditioner and Blower Circuit Diagnosis

Cab Blower Circuit Operation

System: Cab Blower Circuit Diagnosis

Group 55: MCS600 Plus

MCS600 Plus Controller

MCS Radiator Fan

MCS Hydraulic Circuit

MCS600 Plus Schematic

MCS600 Plus Components

System: MCS600 Plus Diagnosis

Section 50: Power Train

Group 05: Specifications

Specifications

Essential or Recommended Tools

Service Equipment and Tools

Fabricated Tools

Other Material

Group 10: Component Location

Transaxle Component Location (Single Speed Range)

Hydrostatic Pedal and Neutral Safety Linkage Component Location

4WD Component Location

Group 15: Diagnostics

Symptom: Differential Will Not Lock when Lock Pedal Is Pressed

Symptom: Machine Moves with Travel Pedals in Neutral

Symptom: Machine Will Not Move when Travel Pedals Are Pressed

Symptom: Machine Will Not Reach Full Speed

Symptom: PTO Turns with PTO Switch Off

Symptom: PTO Shaft Will Not Turn

Symptom: Rear Wheels Do Not Drive

Group 20: Tests and Adjustments

Test and Adjust Transaxle Neutral Creep

Adjust F-N-R Linkage

Adjust Differential Lock

Adjust 4WD Axle Pivot Pin Clearance

Group 25: Repair

Summary of References

Remove and Install Engine Drive Shaft

Remove and Install Transaxle

Separate and Install Hydrostatic and Differential Assemblies

Disassemble, Inspect, and Assemble Charge Pump

Disassemble, Inspect, and Assemble Hydrostatic Assembly

Disassemble, Inspect, and Assemble Differential Assembly

Disassemble, Inspect, and Assemble PTO

Remove and Install 4WD Drive Shaft

Remove and Install 4WD Gear Case

Disassemble, Inspect, and Assemble 4WD Gear Case

Remove and Install 4WD Axle

Disassemble, Inspect, and Assemble 4WD Axle

Section 55: Power Train (2 Speed)

Group 05: Specifications

Specifications

Essential or Recommended Tools

Group 10: Tools and Materials

Fabricated Tools

Other Material

Group 15: Component Location

Transaxle Component Location (1545 and 1565 2-Speed Range)

Hydrostatic Pedal and Neutral Safety Linkage Component Location (2 Speed)

4WD Component Location (2 Speed)

Group 20: Diagnostics

Symptom: Differential Will Not Lock when Lock Pedal Is Pressed

Symptom: Machine Moves with Travel Pedals in Neutral

Symptom: Machine Will Not Move when Travel Pedals Are Pressed

Symptom: Machine Will Not Reach Full Speed

Symptom: PTO Shaft Turns with PTO Switch Off

Symptom: PTO Shaft Will Not Turn

Symptom: Rear Wheel Do Not Drive

Group 25: Tests and Adjustments

Test and Adjust Transaxle Neutral Creep (2 Speed)

Adjust F-N-R Linkage (2 Speed)

Adjust Differential Lock (2 Speed)

Adjust 4WD Axle Pivot Pin Clearance

Group 30: Repair

Removal and Installation of Engine Driveshaft

Removal and Installation of Transaxle

Separate and Install Hydrostatic Assembly and Differential Assembly

Removal, Disassembly, Inspection, and Assembly of Hydraulic Pump

Disassembly, Inspection, and Assembly of Charge Pump

Removal, Inspection, and Installation of Two-Speed Range Transaxle

Four-Wheel Drive Output Unit - Removal, Inspection, and Assembly

Hydrostatic Assembly – Disassembly, Inspection, and Assembly

Disassembly, Inspection, and Assembly of Differential

Disassembly, Inspection, and Assembly of PTO

Removal and Installation of 4WD DriveShaft

Removal and Installation of 4WD Axle

Disassembly, Inspection, and Assembly of 4WD Axle

Section 60: Hydraulics

Group 05: Specifications

Specifications

Group 10: Tools and Materials

Essential or Recommended Tools

Group 15: Component Location

Hydraulic System Component Location

Auxiliary Hydraulic Kit Component Location

Steering System Hydraulic Hose Routing

Weight Transfer System Component Location

Lift System Hydraulic Hose Routing

Group 20: Schematics

Main Hydraulic Schematic Without Optional Auxiliary Valve (1400 Series)

Main Hydraulic Schematic Without Optional Auxiliary Valve (1500 Series)

Main Hydraulic Schematic With Optional Auxiliary Valve (1400 Series)

Main Hydraulic Schematic With Optional Auxiliary Valve (1500 Series)

Single Spool Auxiliary Hydraulic Kit Schematic

Double Spool Auxiliary Hydraulic Kit Schematic

MCS600 Plus Hydraulic Schematic

Group 25: Theory of Operation

Hydraulic System Operation

Lift Circuit Operation

Auxiliary Hydraulic Operation

MCS600 Plus Circuit Operation

Group 30: Diagnostics

System: Lift System

System: Auxiliary Hydraulic

System: Weight Transfer

Group 35: Tests and Adjustments

Hydraulic Oil Warm-Up Procedure

Hydraulic System Bleeding Procedure

Charge Pressure Relief Valve Test - 1400 Series

Charge Pressure Relief Valve Test - 1500 Series

Charge Pump Flow Test (1400 Series Only)

Hydraulic Pump Flow and Implement Relief Valve Test (1500 Series Only)

PTO Solenoid Valve Check

PTO Relief Valve Test

Implement Relief Valve Test (1400 Series Only)

MCS600 Plus Test

Group 40: Repair

Removal and Installation of Oil Cooler

Oil Cooler Inspection

Removal and Installation of Lift Lever

Removal and Installation of Implement Lift Valve

Disassembly and Assembly of Implement Lift Valve

Removal and Installation of Lift Cylinder

Removal and Installation of Auxiliary Hydraulic Valve

Disassembly, Inspection and Assembly of Auxiliary Hydraulic Valve

Removal and Installation of Steering Cylinder

Removal and Installation of Hydraulic Pump

Disassembly and Assembly of Hydraulic Pump

Section 70: Steering

Group 05: Specifications

Special or Required Tools

Specifications

Essential or Recommended Tools

Group 10: Component Location

Steering System Component Location

Group 15: Theory of Operation

Steering System Operation - Neutral

Steering System Operation - Power Turn

Steering System Operation - Manual Turn

Group 20: Diagnostics

Symptom: High Steering Effort in Both Directions

Symptom: Hydraulic Oil Foams

Symptom: Lost Motion in Steering Wheel

Symptom: Machine Continues to Turn after Steering Wheel Has Returned to Center Position

Symptom: Sluggish Steering Response

Symptom: Steering Not Driving Straight

Symptom: Steering Operation Reversed

Symptom: Steering Wheel Vibration

Group 25: Tests and Adjustments

Check and Adjust Steering Toe-In

Test Steering System Leakage

Test Steering Valve Leakage

Group 30: Repair

Remove and Install Steering Console Cover

Remove and Install Steering Valve

Remove and Install Steering Valve Bushing

Remove and Install Steering Column Repair Kit

Remove and Install Steering Cylinder

Section 80: Brakes

Group 05: Specifications

Specifications

Group 10: Component Location

Brake System Component Location

Group 15: Theory of Operation

Brake System Operation

Group 20: Brake System Diagnostics

Symptom: Machine Will Not Move

Symptom: Brake Will Not Engage or Hold Machine

Symptom: Excessive Brake Wear

Symptom: Machine Pulls to One Side

Group 25: Tests and Adjustments

Check and Adjust Turn Brake

Adjust Brake Switch

Group 30: Repair

Remove and Install Brake Linkage

Remove and Install Turn Brake Pedals

Remove and Install Master Brake Pedal

Remove and Install Park Brake Lock Lever Assembly

Section 90: Attachments

Group 05: Specifications

Specifications

Essential or Recommended Tools

Other Material

Group 10: Diagnostics

System: 60, 62 and 72-Inch Mower Deck

System: 7-Iron V-Flex Deck

System: 60-Inch Heavy-Duty Snowblower

Group 15: Tests and Adjustments

Mower Deck Level Check and Adjustment

Check V-Flex Deck Level

Check and Adjust 60, 62 and 72-Inch (Side Discharge) Mower Drive Belt Tension

Check and Adjust 72-Inch (Rear Discharge) Mower Deck Belt Tension

Check and Adjust V-Flex Deck Drive Belt Tension

Group 20: Repair

Rotate 60, 62 and 72-Inch (Side Discharge) Mower Deck

Rotate 72-Inch (Rear Discharge) Mower Deck S.N. (210001-211095)

Rotate 72-Inch (Rear Discharge) Mower Deck S.N. (215001 - )

Remove and Install 60, 62 and 72-Inch (Side Discharge) Mower Deck Belt Shields

Remove and Install 72-Inch Rear Discharge Mower Deck Belt Shield S.N. (210001-211095)

Remove and Install 72-Inch Rear Discharge Mower Deck Belt Shield S.N. (215001-)

Rotate V-Flex Mower Deck

Remove 60, 72-Inch (Side Discharge) and 62-Inch (Rear Discharge) Mower Deck Drive Belt

Install 60, 72-Inch (Side Discharge) and 62-Inch (Rear Discharge) Mower Deck Drive Belt

Remove 72-Inch (Rear Discharge) Mower Deck Drive Belt

Install 72-Inch (Rear Discharge) Mower Deck Drive Belt

Remove and Install V-Flex Mower Deck Belt Shields

Remove and Install V-Flex Mower Deck Drive Belts

Align Vertical Belt Drive

Remove and Install Mower Deck Blade

Mower Deck Blade - Sharpen

Mower Deck Blade - Balance

Remove and Install Mower Deck Spindle

Disassemble and Inspect Mower Deck Spindle

Remove and Install Mower Deck Drive Shaft

Mower Deck Drive Shaft Repair

Remove and Install Mower Deck Gearbox

Mower Deck Gearbox Repair

Caster Wheels, Yoke and Bearings

60-Inch Snowblower Gear Case Inspection

Snowblower Gear Assembly

Snowblower Main Case Inspection

Snowblower Main Case Assembly

Install Snowblower Rotor and Fan

Replacing Fan or Coupler

Install Rotor Assembly

Replace Rotor Bearing

Section 100: Miscellaneous

Group 05: Specifications

Specifications

Group 10: Tools and Materials

Other Material

Service Equipment and Tools

Essential or Recommended Tools

Group 15: Component Location

Air Conditioning Component Location

Group 20: Theory of Operation

Air Conditioning System Cycle

Refrigerant R134a

Compressor

Condenser

Receiver - Dryer

Expansion Valve

Evaporator

High - Low Pressure Switch

Air Conditioning - Heater Control Switch and Temperature Control Knob

Blower Speed Control Switch

Group 25: Air Conditioning Diagnostics

Symptom: Compressor Clutch Does Not Engage

Symptom: A.C. System Does Not Cool Properly

Group 30: Tests and Adjustments

Compressor Clutch Engagement Check

Static Pressure Check

System Cooling Check

Heater Valve Operation Check

Sight Glass Check

System Leak Check

Expansion Valve Operation Check

Internal Line Restriction Check

High/Low Pressure Switch Check

Group 35: Repair

Removal and Installation of Engine Cover

Removal and Installation of Engine Cover Latch

Removal and Installation of Operator’s Seat Platform

Removal and Installation of Front Wheel

Removal and Installation of Rear Wheel

Removal and Installation of Fuel Tank

Recovering and Recycling Air Conditioning Refrigerant

Removal and Installation of Receiver - Dryer

Removal and Installation of Condenser - Oil Cooler

Removal and Installation of Compressor

Defrost Evaporator

Removal and Installation of Evaporator

Service Expansion Valve

Expansion Valve Bench Test

Refrigerant Oil Information

Check Compressor Oil Charge

A.C. System General Information

Evacuate Air Conditioning System

Flush Air Conditioning System

Charge Air Conditioning System

Removal and Installation of Temperature Control Cable

Removal and Installation of Temperature Control Valve

Removal and Installation of Blower Motor

Removal and Installation of Heater Core

John Deere Front Mowers 1420, 1435, 1445, 1545, 1565 Series II Repair Service Manual (TM2147)