Toyota Powered Pallet Stacker 7SM/7SLL Series Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Toyota Powered Pallet Stacker Models 7SM08F, 7SM10, 7SM12, 7SM12F, 7SM12S, 7SM16D, 7SLL12.5, 7SLL16, 7SLL13.5S, 7SLL12.5F, 7SLL16F, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Toyota Powered Pallet Stacker 7SM/7SLL Series workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,460 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

202184-040 - Toyota Powered Pallet Stacker 7SM10/12, 7SM12S Series Service Manual.pdf

202185-040 - Toyota Powered Pallet Stacker 7SM Series Service Manual.pdf

202187-040 - Toyota Powered Pallet Stacker 7SM12F, 7SM16D Service Manual.pdf

226306-040 (2005) - Toyota Powered Pallet Stacker 7SM10, 7SM12, 7SM12S Service Manual.pdf

226306-040 (2006) - Toyota Powered Pallet Stacker 7SM10, 7SM12, 7SM12S Service Manual.pdf

226307-040 - Toyota Powered Pallet Stacker 7SM12F, 7SM16D Service Manual.pdf

229102-040 - Toyota Powered Pallet Stacker 7SM12F, 7SM16D Service Manual.pdf

229735-040 (2005) - Toyota Powered Pallet Stacker 7SM08F Service Manual (Valid from serial number 904519-).pdf

229735-040 (2006) - Toyota Powered Pallet Stacker 7SM08F Service Manual (Valid from serial number 904519-).pdf

230087-040 - Toyota Powered Pallet Stacker 7SLL12.5, 7SLL16, 7SLL13.5S, 7SLL12.5F, 7SLL16F Service Manual.pdf

MAIN SECTIONS

202184-040 - Toyota Powered Pallet Stacker 7SM1012, 7SM12S Series Service Manual...1

Contents...3

Technical data 7...3

Introduction Maintenance 11...3

1 Safety regulations with maintenance work 11...3

2 Cleaning and washing 13...3

3 Safe lifting 14...3

Preventive maintenance 15...3

1 Maintenance schedule 15...3

2 Lubrication schedule 20...3

Oil and grease specification 21...3

Tools 23...3

1 Super Seal connectors 23...3

Support arm chassis 27...3

1 General 27...3

2 Main components 28...3

3 Maintenance 28...3

4 Adjustment of the support arm width 29...3

5 Exchange of support arms 30...3

Electric drive motor 31...3

1 Component parts 31...3

2. Service/Repairs 33...3

3 Technical data 35...3

Drive unit/gear 37...4

1 Component parts 38...4

2 Leakage from top cover 40...4

3 Changing of the drive shaft’s sealing ring 40...4

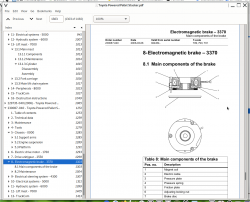

Electro magnetic brake 43...4

1 Main components of the brake 43...4

2 Maintenance 44...4

Steering 47...4

1 Component parts, tiller arm 47...4

2 Adjustments 48...4

3 Tiller arm handle 49...4

Electrical systems 55...4

1 Electrical parts 55...4

2 List of symbols and electrical wiring diagram 57...4

3 Functional description 64...4

4 Hour meter 66...4

5 Fault codes 66...4

6 Parameters 71...4

7 Part numbers 80...4

8 Transistor panel 81...4

9 Diagnostic and troubleshooting 82...4

10 Technical specifications – Curtis 1243 84...4

Hydraulic system 85...4

1 Hydraulic diagram and components 85...4

Control/computer equipment 89...5

1 General 89...5

2 Connection 89...5

3 Layout 90...5

4 Function 92...5

5 Specifications 100...5

Battery charger (Inbuilt) 101...5

1 General 101...5

2 Charging 101...5

3 Troubleshooting and service 102...5

4 Technical data 102...5

5 Charging settings 103...5

Technical data...7

Model...7

7SM10...7

7SM12...7

7SM12S...7

Introduction Maintenance...11

1 Safety regulations with maintenance work...11

WARNING!...11

WARNING!...12

WARNING!...12

NOTE!...12

CAUTION!...12

2 Cleaning and washing...13

NOTE!...13

2.1 External cleaning...13

NOTE!...13

2.2 Cleaning the motor compartment...13

NOTE!...13

2.3 Electrical components...13

NOTE!...13

3 Safe lifting...14

WARNING!...14

Preventive maintenance...15

1 Maintenance schedule...15

Pos. No...15

Work to carry out...15

2 Lubrication schedule...20

Pos no...20

Service point...20

Interval/Running hours...20

Lubricant...20

Oil and grease specification...21

Lubticant...21

Specification...21

Application area...21

Tools...23

1 Super Seal connectors...23

Figure...23

Number...23

Application...23

1.1 AMP connectors...24

Figure...24

Number...24

Application...24

1.2 Other tools...25

Figure...25

Number...25

Application...25

Support arm chassis...27

1 General...27

2 Main components...28

3 Maintenance...28

4 Adjustment of the support arm width...29

Warning!...29

5 Exchange of support arms...30

Electric drive motor...31

1 Component parts...31

Pos...31

Description...31

Note...31

1.1 Dismantling of motor from truck...32

1.2 Assembling...32

2. Service/Repairs...33

2.1 Dismantling of motor...33

2.2 Assembling of motor...34

2.3 Cleaning...34

3 Technical data...35

Drive unit/gear...37

1 Component parts...38

Pos...38

Description...38

Note...38

1.1 Technical data...39

Type of truck...39

7SM10/12, 7SM12S...39

2 Leakage from top cover...40

3 Changing of the drive shaft’s sealing ring...40

3.1 Dismantling...40

3.2 Assembling...41

Electro magnetic brake...43

1 Main components of the brake...43

2 Maintenance...44

2.1 Basic Adjustment of gap...44

2.2 Exchange of brake disc...45

Steering...47

1 Component parts, tiller arm...47

Pos...48

Description...48

Note...48

2 Adjustments...48

2.1 Adjusting of brake microswitch...48

3 Tiller arm handle...49

Pos...49

Description...49

Note...49

3.1 Dismantling/Assembling...51

NOTE!...51

Change from ignition key to keyboard (2)...51

Change from keyboard to ignition key (2)...51

Changing of signal button/switch (9, 10)...52

Changing of lift/lowering button (13)...53

Changing of pushbutton (16)...53

Electrical systems...55

1 Electrical parts...55

2 List of symbols and electrical wiring diagram...57

Symbol...57

Description...57

Function...57

Notes...57

2.1. Elschema 1 (5)...59

2.2. Elschema 2(5)...60

2.3. Elschema 3(5)...61

2.4. Elschema 4(5)...62

2.5. Elschema 5(5)...63

3 Functional description...64

3.1 Starting the truck...64

3.2 Driving...64

3.3 Neutral speed reduction...64

3.4 Picture 3...64

3.5 Neutral speed reduction on slopes...65

3.6 Braking...65

3.7 Lifting the forks...65

3.8 Lowering the forks...65

3.9 Horn...65

4 Hour meter...66

5 Fault codes...66

Code...67

C19...67

Code...67

C20...67

Code...67

C28...67

Code...67

C29...67

Code...67

C41...67

Code...68

C42...68

Code...68

C43...68

Code...68

E101...68

Code...68

E104...68

Code...68

E106...68

Code...69

E107...69

Code...69

E108...69

Kod...69

E110...69

Code...69

E140...69

Code...69

E141...69

Code...69

E150...69

Code...70

E151...70

Code...70

E157...70

Code...70

E159...70

Code...70

E160...70

Code...70

E200...70

Code...70

E201...70

Code...71

E202...71

Code...71

E214...71

6 Parameters...71

NOTE !...71

6.1 Driver parameters...72

Parameter...72

Name...72

Unit...72

Min...72

Max...72

Step...72

Std...72

Description...72

6.2 Service parameters...73

Parameter...73

Name...73

Unit...73

Min...73

Max...73

Step...73

Std...73

Description...73

6.3 Parameter description...74

Parameter 1...74

Parameter 2...74

Parameter 3...74

Parameter 4...74

Parameter 5...74

Parameter 10...74

Parameter 14...74

Parameter 20...75

Parameter 21...75

Value...76

Function...76

Battery (Ah)...76

WARNING !...76

Parameter 25...76

Parameter 28...77

Parameter 39...77

Service display...77

Flashing symbol...78

Displayed data...78

Segment...78

Function...78

Segment...79

Function...79

Segment...79

Function...79

Segment...80

Function...80

7 Part numbers...80

8 Transistor panel...81

8.1 General...81

9 Diagnostic and troubleshooting...82

9.1 Error codes and troubleshooting...82

STATUS LED...82

Handheld terminal display...82

Explanation...82

Possible cause...82

9.2 Resetting errors...83

Error...83

Reset when...83

9.3 Safety...83

WARNING!...83

10 Technical specifications – Curtis 1243...84

Value...84

Unit...84

Explanation...84

Hydraulic system...85

1 Hydraulic diagram and components...85

1.1 Main components...86

Pos No...86

Description...86

Remark...86

1.2 Description...86

1.2.1 Lift...86

1.2.2 Lowering...86

1.2.3 Operating pressure...86

1.2.4 Relief valve...86

1.2.5. Pressure switch...87

Control/computer equipment...89

1 General...89

2 Connection...89

3 Layout...90

3.1 Main window...90

3.2 Nodes...90

3.2.1 Icons...91

Icon...91

Description...91

3.3 Tool buttons...91

3.4 Information window...92

3.5 Status bar...92

4 Function...92

4.1 Connection...92

4.2 Disconnection...92

4.3 Downloading program...93

4.3.1 Normal downloading...93

4.3.2 Downloading in old versions of logic card...93

4.3.3 Emergency downloading...94

NOTE!...94

4.4 Truck report...95

4.5 Parameters...96

NOTE!...96

4.6 Diagnostics...97

NOTE!...97

4.6.1 Analogue...97

4.6.2 Temperature...98

NOTE!...98

4.6.3 Digital...98

4.7 Other functions...99

4.7.1 Save to file...99

4.7.2 Download from file...99

4.7.3 Reset CAN adapter...99

4.7.4 Delete error code log...99

4.7.5 Reset hour meter...99

4.7.6 Read error code log...99

4.7.7 Adjust date and time...99

NOTE!...99

4.7.8 Adjusting the hour meter on older cards...99

4.8 Help...100

4.8.1 About TruckCom...100

4.9 Exit...100

5 Specifications...100

5.1 CAN interface...100

5.2 Installation...100

5.3 To uninstall...100

Battery charger (Inbuilt)...101

1 General...101

2 Charging...101

3 Troubleshooting and service...102

4 Technical data...102

5 Charging settings...103

5.1 Freely ventilated batteries...103

Switch...103

Batterysize...103

Output current...103

I2 current...103

Max current maintenance...103

5.2 Valve regulated batteries...103

Switch...103

Batterysize...103

Output current...103

I2 current...103

Max current maintenance...103

202185-040 - Toyota Powered Pallet Stacker 7SM Series Service Manual...105

Contents...107

Electrical systems 5...107

1 Electrical diagram 7SM10/12, 7SM12S 1(5) 5...107

2 Electrical diagram 7SM12F, 7SM16D 1(5) 10...107

3 Component identification 15...107

4 Error codes and troubleshooting 19...107

5 Fault codes 20...107

6 Parameters 22...107

7 Part numbers 27...107

Hydraulic diagram and components 29...107

1 Main components 7SM10/12/12S 29...107

2 Main components 7SM12F/16D 30...107

Tightening torque 33...107

1 Basic Adjustment of gap 34...107

Oil and grease specification 35...107

Preventive maintenance 37...107

1 Maintenance schedule 37...107

2 Lubrication schedule 42...107

Lifting points 43...107

Electrical systems...109

1 Electrical diagram 7SM10/12, 7SM12S 1(5)...109

Electrical diagram 7SM10/12, 7SM12S 2(5)...110

Electrical diagram 7SM10/12, 7SM12S 3(5)...111

Electrical diagram 7SM10/12, 7SM12S 4(5)...112

Electrical diagram 7SM10/12, 7SM12S 5(5)...113

2 Electrical diagram 7SM12F, 7SM16D 1(5)...114

Electrical diagram 7SM12F, 7SM16D 2(5)...115

Electrical diagram 7SM12F, 7SM16D 3(5)...116

Electrical diagram 7SM12F, 7SM16D 4(5)...117

Electrical diagram 7SM12F, 7SM16D 5(5)...118

3 Component identification...119

3.1 List of symbols...121

Symbol...121

Description...121

Function...121

Notes...121

4 Error codes and troubleshooting...123

WARNING!...123

STATUS LED...123

Handheld terminal display...123

Explanation...123

Possible cause...123

5 Fault codes...124

Code...124

Description...124

Possible fault reason...124

6 Parameters...126

NOTE !...126

6.1 Driver parameters...127

Parameter...127

Name...127

Unit...127

Min...127

Max...127

Step...127

Std...127

Description...127

6.2 Service parameters...128

Parameter...128

Name...128

Unit...128

Min...128

Max...128

Step...128

Std...128

Description...128

Parameter 21...128

Service display...129

Flashing symbol...129

Displayed data...129

Segment...129

Function...129

Segment...130

Function...130

Segment...130

Function...130

Segment...131

Function...131

7 Part numbers...131

Hydraulic diagram and components...133

1 Main components 7SM10/12/12S...133

Pos No...133

Description...133

Remark...133

2 Main components 7SM12F/16D...134

Pos No...134

Description...134

Remark...134

2.1 Description...135

2.1.1 Lift...135

2.1.2 Lowering...135

2.1.3 Operating pressure...135

2.1.4 Relief valve...135

2.1.5. Pressure switch...136

Tightening torque...137

1 Basic Adjustment of gap...138

Oil and grease specification...139

Lubticant...139

Specification...139

Application area...139

Preventive maintenance...141

1 Maintenance schedule...141

Pos. No...141

Work to carry out...141

2 Lubrication schedule...146

Pos no...146

Service point...146

Interval/Running hours...146

Lubricant...146

Lifting points...147

WARNING!...147

WARNING!...147

202187-040 - Toyota Powered Pallet Stacker 7SM12F, 7SM16D Service Manual...149

Contents...151

Technical data 5...151

Introduction Maintenance 9...151

Preventive maintenance 13...151

Oil and grease specification 21...151

Tools 23...151

Electric drive motor 27...151

Drive unit/gear 33...151

Electro magnetic brake 39...151

Steering 43...152

Electrical systems 51...152

Hydraulic system 81...152

Control/computer equipment 85...152

Battery charger (Inbuilt) 99...152

Technical data...153

Model...153

7SM12F...153

7SM16D...153

Introduction Maintenance...157

1 Safety regulations with maintenance work...157

WARNING!...157

WARNING!...158

WARNING!...158

NOTE!...158

CAUTION!...158

2 Cleaning and washing...159

NOTE!...159

2.1 External cleaning...159

NOTE!...159

2.2 Cleaning the motor compartment...159

NOTE!...159

2.3 Electrical components...160

NOTE!...160

3 Safe lifting...160

WARNING!...160

Preventive maintenance...161

1 Maintenance schedule...161

Pos. No...161

Work to carry out...161

2 Lubrication schedule...166

Pos no...166

Service point...166

Interval/Running hours...166

Lubricant...166

Oil and grease specification...169

Lubticant...169

Specification...169

Application area...169

Tools...171

1 Super Seal connectors...171

Figure...171

Number...171

Application...171

1.1 AMP connectors...172

Figure...172

Number...172

Application...172

1.2 Other tools...173

Figure...173

Number...173

Application...173

Electric drive motor...175

1 Component parts...175

Pos...175

Description...175

Note...175

1.1 Dismantling of motor from truck...176

1.2 Assembling...177

2 Service/Repairs...178

2.1 Dismantling of motor...178

2.2 Assembling of motor...179

2.3 Cleaning...179

3 Technical data...180

Type of machine...180

7SM12F, 7SM16D...180

Drive unit/gear...181

1 Component parts...182

Pos...182

Description...182

Note...182

1.1 Technical data...183

Type of truck...183

7SM12F, 7SM16D...183

2 Leakage from top cover...184

3 Changing of the drive shaft’s sealing ring...184

3.1 Dismantling...184

3.2 Assembling...185

Electro magnetic brake...187

1 Main components of the brake...187

2 Maintenance...188

2.1 Basic Adjustment of gap...188

2.2 Exchange of brake disc...189

Steering...191

1 Component parts, tiller arm...191

Pos...191

Description...191

Note...191

2 Adjustments...192

2.1 Adjusting of brake microswitch...192

3 Tiller arm handle...193

Pos...193

Description...193

Note...193

3.1 Dismantling/Assembling...195

NOTE!...195

Change from ignition key to keyboard (2)...195

Change from keyboard to ignition key (2)...195

Changing of signal button/switch (9, 10)...196

Changing of lift/lowering button (13)...197

Changing of pushbutton (16)...197

Electrical systems...199

1 Component identification...199

2 List of symbols and electrical wiring diagram...201

Symbol...201

Description...201

Function...201

Notes...201

2.1 Electrical diagram 1(5)...203

2.2 Electrical diagram 2(5)...204

2.3 Electrical diagram 3(5)...205

2.4 Electrical diagram 4(5)...206

2.5 Electrical diagram 5(5)...207

3 Functional description...208

3.1 Starting the truck...208

3.2 Driving...208

3.3 Neutral speed reduction...208

3.4 Picture 3...208

3.5 Neutral speed reduction on slopes...209

3.6 Braking...209

3.7 Lifting the forks...209

3.8 Lifting the support arms...209

3.9 Lowering the forks...209

3.10 Lowering the support arms...209

3.11 Horn...209

4 Hour meter...210

5 Fault codes...210

Code...211

C19...211

Code...211

C20...211

Code...211

C28...211

Code...211

C29...211

Code...211

C41...211

Code...212

C42...212

Code...212

C43...212

Code...212

E101...212

Code...212

E104...212

Code...212

E106...212

Code...213

E107...213

Code...213

E108...213

Code...213

E110...213

Code...213

E140...213

Code...213

E141...213

Code...213

E150...213

Code...214

E151...214

Code...214

E157...214

Code...214

E159...214

Code...214

E160...214

Code...214

E200...214

Code...214

E201...214

Code...215

E202...215

Code...215

E214...215

6 Parameters...215

NOTE !...215

6.1 Driver parameters...216

Parameter...216

Name...216

Unit...216

Min...216

Max...216

Step...216

Std...216

Description...216

6.2 Service parameters...217

Parameter...217

Name...217

Unit...217

Min...217

Max...217

Step...217

Std...217

Description...217

6.3 Parameter description...218

Parameter 1...218

Parameter 2...218

Parameter 3...218

Parameter 4...218

Parameter 5...218

Parameter 10...218

Parameter 14...218

Parameter 20...219

Parameter 21...219

Value...220

Function...220

Battery (Ah)...220

WARNING !...220

Parameter 25...220

Parameter 28...221

Parameter 39...221

Service display...221

Flashing symbol...222

Displayed data...222

Segment...222

Function...222

Segment...223

Function...223

Segment...223

Function...223

Segment...224

Function...224

7 Part numbers...224

8 Transistor panel...225

8.1 General...225

9 Diagnostic and troubleshooting...226

9.1 Error codes and troubleshooting...226

STATUS LED...226

Handheld terminal display...226

Explanation...226

Possible cause...226

9.2 Resetting errors...227

Error...227

Reset when...227

9.3 Safety...227

WARNING!...227

10 Technical specifications – Curtis 1243...228

Value...228

Unit...228

Explanation...228

Hydraulic system...229

1 Hydraulic diagram and components...229

1.1 Main components...229

Pos No...229

Description...229

Remark...229

1.2 Description...230

1.2.1 Lift...230

1.2.2 Lowering...230

1.2.3 Operating pressure...230

1.2.4 Relief valve...230

1.2.5. Pressure switch...231

Control/computer equipment...233

1 General...233

2 Connection...233

3 Layout...234

3.1 Main window...234

3.2 Nodes...234

3.2.1 Icons...235

Icon...235

Description...235

3.3 Tool buttons...235

3.4 Information window...236

3.5 Status bar...236

4 Function...236

4.1 Connection...236

4.2 Disconnection...237

4.3 Downloading program...237

4.3.1 Normal downloading...238

4.3.2 Downloading in old versions of logic card...238

4.3.3 Emergency downloading...238

NOTE!...238

4.4 Truck report...239

4.5 Parameters...240

NOTE!...240

4.6 Diagnostics...241

NOTE!...241

4.6.1 Analogue...241

4.6.2 Temperature...242

NOTE!...242

4.6.3 Digital...242

4.7 Other functions...243

4.7.1 Save to file...243

4.7.2 Download from file...243

4.7.3 Reset CAN adapter...243

4.7.4 Delete error code log...243

4.7.5 Reset hour meter...243

4.7.6 Read error code log...243

4.7.7 Adjust date and time...243

NOTE!...243

4.7.8 Adjusting the hour meter on older cards...244

4.8 Help...244

4.8.1 About TruckCom...244

4.9 Exit...244

5 Specifications...244

5.1 CAN interface...244

5.2 Installation...245

5.3 To uninstall...245

Battery charger (Inbuilt)...247

1 General...247

2 Charging...247

3 Troubleshooting and service...248

4 Technical data...248

5 Charging settings...249

5.1 Freely ventilated batteries...249

Switch...249

Batterysize...249

Output current...249

I2 current...249

Max current maintenance...249

5.2 Valve regulated batteries...249

Switch...249

Batterysize...249

Output current...249

I2 current...249

Max current maintenance...249

226306-040 (2005) - Toyota Powered Pallet Stacker 7SM10, 7SM12, 7SM12S Service Manual...251

1- Table of contents...253

2- Technical data - M4...259

3- Introduction Maintenance - P1...263

3.1 Safety regulations with maintenance work...263

3.2 Cleaning and washing...264

3.2.1 External cleaning...265

3.2.2 Cleaning the motor compartment...265

3.2.3 Electrical components...265

3.3 Safe lifting...266

4- Preventive maintenance - P2...267

4.1 Maintenance schedule...267

4.2 Lubrication schedule...272

5- Oil and grease specification - P3...273

6- Tools - P4...275

6.1 Super Seal connectors...275

6.2 AMP connectors...276

6.2.1 AMP Connectors, 040 series...277

6.3 Molex connectors...277