International Trucks LT/RH/LoneStar RH613/LT625 Models Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for International / Navistar Trucks LT/RH/LoneStar RH613 4x2, RH613 6x4, RH613 6x2, LT625 4x2, LT625 6x4, LT625 6x2, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

International / Navistar Trucks LT / RH/ LoneStar RH613 4x2, RH613 6x4, RH613 6x2, LT625 4x2, LT625 6x4, LT625 6x2 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 5,157 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

0000001602 - Exhaust After-treatment System with SCR EPA 10 (Supersedes S07005), Revision 10 Aftertreatment.pdf

0000002122 - ELECTRICAL CIRCUIT DIAGRAM MANUAL (ProStar + and LoneStar Models Built June 14, 2010 and After).pdf

0000002122 - ProStar and LoneStar Series Built June 14, 2010 and After Electrical Circuit Diagrams (Supersedes S08344 and S08371).pdf

0000002221 - Heat Ventilation Air Conditioning (HVAC) System for 2010 (Supersedes S16047) Service Manual.pdf

0000002323 - Day Cab and Sleeper Cab Service Manual for LoneStar & ProStar (Supersedes S16044).pdf

0000002881 - LoneStar Radiator _ Cooling System Service Manual (Supersedes S12025).pdf

0000003161 - Hood, Grille, Fenders, and Bumper (Supersedes S09011) Service Manual.pdf

0000018822 - International LT _ RH and LoneStar Series Interactive Schematics Built Before 12_1_16 Circuit Diagrams.pdf

0000018825 - International LT _ RH and LoneStar Series Interactive Schematics Built 12_1_16 – 1_14_19 Revision 4Circuit Diagrams1_29_2020 12_00_00 AM.pdf

0000018828 - International LT _ RH and LoneStar Series Interactive Schematics (Built 1_15_19 – 12_31_20), Revision 7 Circuit Diagrams.pdf

0000628059 - 9900, PayStar, ProStar, TranStar, WorkStar Heavy Duty (HD) Radiator _ Cooling System (EPA 10 SCR) Revision 1 (Supersedes 0000001601, 0000001843 and 0000002222) Service Manual.pdf

0000885380 (Apr 2018) - Service Manual 2017–2020 LT_RH_LoneStar Technician Manual (Service & Diagnostics) - RH613 4x2, RH613 6x4, RH613 6x2, LT625 4x2, LT625 6x4, LT625 6x2.pdf

0000885380 (Feb 2020) - 2017-2020 International LT _ RH and LoneStar Technician Manual (Service and Diagnostics) (RH613 4x2_6x4_6x2, LT625 4x2_6x4_6x2).pdf

0000885380 (Nov 2019) - 2017-2020 International LT _ RH and LoneStar Technician Manual (Service and Diagnostics) (RH613 4x2_6x4_6x2, LT625 4x2_6x4_6x2).pdf

4328434 - New Truck Processing Manual.pdf

S03015 - 2007 MY ProStar _ LoneStar MAXXPOWER Front Air Suspension (Oct 2009) Manual.pdf

S05018 - LoneStar Steering Column Assembly, Tilt _ Telescoping (Oct 2011) Service Manual.pdf

S07003 - Exhaust Aftertreatment and Diesel Particulate Filter (DPF) (Oct 2009) Aftertreatment.pdf

S08319 - Inverter_Charger Power System (Sept 2003) Service Manual.pdf

S08327 - 2007 - 2010 Body Controller (BC) Diagnostic Trouble Codes Service Manual.pdf

S08339 - 2007 MY ProStar _ LoneStar Chassis (Built January, 2007 and After) Electrical Circuit Diagrams Manual.pdf

S08354 - 2007 MY ProStar _ LoneStar Models Built After January 2007 Electrical System Troubleshooting GuideManual.pdf

S08358 - Auto Start_Stop Troubleshooting (July 2011) Service Manual.pdf

S08360 - ProStar _ LoneStar Models Built After June 2010 Electrical System Troubleshooting Guide Manual.pdf

S09015 - Hood, Grille, Fenders and Bumper (Dec 2009) Service Manual.pdf

S11018 - Hydraulic Clutch Service Manual.pdf

S12041 - Radiator _ Cooling System Service Manual (2012).pdf

S12049 - Radiator _ Cooling System Service Manual (Latin American Market) (2012).pdf

S16039 - Heat Ventilation Air Conditioning (HVAC) System and TXV System For 2007 ProStar & LoneStar Service Manual.pdf

S16043 - 12V DC No Idle HVAC System (16UZL) Service Manual.pdf

MAIN SECTIONS

Table of Contents.......3

Safety Terminology.......6

Safety Instructions.......6

Work Area.......6

Safety Equipment.......6

Protective Measures.......6

Vehicle.......6

Engine.......7

Fire Prevention.......7

Batteries.......7

Compressed Air.......7

Tools.......7

Fluids Under Pressure.......8

Fuel.......8

Removal of Tools, Parts, and Equipment.......8

Frame.......9

1. Frame and Bumper.......11

Deck Plate.......11

Overview.......11

Front Bumper.......12

Overview.......12

One-piece Stationary Bumper.......13

Three-piece Stationary Bumper.......13

Removal.......14

Overview.......14

Special Tools.......14

Equipment Conditions.......14

Removal Procedure.......14

Follow-On Procedure.......14

Installation.......15

Overview.......15

Special Tools.......15

Equipment Conditions.......15

Installation Procedure.......15

Follow-On Procedure.......16

Tool Box.......17

Overview.......17

Tow Hook.......18

Overview.......18

2. Frame and Bumper - LoneStar.......20

Front Bumper.......20

Overview.......20

Front Axle.......21

1. Front Non-Driving Axle.......23

Dana Spicer.......23

Overview.......23

Kingpin.......25

Removal.......25

Overview.......25

Special Tools.......25

Equipment Conditions.......25

Removal Procedure.......26

Follow-On Procedure.......27

Installation.......28

Overview.......28

Special Tools.......28

Torque Specifications.......28

Equipment Conditions.......28

Installation Procedure.......29

Follow-On Procedure.......30

Kingpin.......31

Removal.......31

Overview.......31

Special Tools.......31

Equipment Conditions.......31

Removal Procedure.......32

Follow-On Procedure.......33

Installation.......34

Overview.......34

Special Tools.......34

Torque Specifications.......34

Equipment Conditions.......34

Installation Procedure.......35

Follow-On Procedure.......36

Wheel Seals.......36

Removal.......36

Overview.......36

Special Tools.......36

Equipment Conditions.......37

Removal Procedure.......38

Follow-On Procedure.......39

Installation.......40

Overview.......40

Special Tools.......40

Equipment Conditions.......40

Installation Procedure.......41

Follow-On Procedure.......43

Hendrickson.......45

Overview.......45

Meritor.......47

Overview.......47

Front Suspension.......49

1. Suspension Systems.......51

Air Ride.......51

Overview.......51

Mono Leaf Spring.......53

Overview.......53

Parabolic Taper Leaf Spring.......54

Overview.......54

Brakes.......57

1. Air Brakes.......59

Bendix ABS Air Brakes.......59

4-Channel.......59

Overview.......59

4-Channel with Automatic Traction Control.......62

Overview.......62

4-Channel with Electronic Stability and Automatic Traction Control.......64

Overview.......64

6-Channel.......66

Overview.......66

6-Channel with Automatic Traction Control.......69

Overview.......69

6-Channel with Electronic Stability and Automatic Traction Control.......71

Overview.......71

ABS Module.......73

Removal.......73

Overview.......73

Special Tools.......73

Equipment Conditions.......73

Removal Procedure.......74

Follow-On Procedure.......75

Installation.......76

Overview.......76

Special Tools.......76

Torque Specifications.......76

Equipment Conditions.......76

Installation Procedure.......77

Follow-On Procedure.......78

Steering Angle Sensor.......79

Removal.......79

Overview.......79

Special Tools.......79

Equipment Conditions.......79

Removal Procedure.......80

Follow-On Procedure.......82

Installation.......83

Overview.......83

Special Tools.......83

Torque Specifications.......83

Equipment Conditions.......83

Installation Procedure.......84

Follow-On Procedure.......86

Wheel Speed Sensor.......87

Removal.......87

Overview.......87

Special Tools.......87

Equipment Conditions.......87

Removal Procedure.......88

Follow-On Procedure.......88

Installation.......89

Overview.......89

Special Tools.......89

Torque Specifications.......89

Equipment Conditions.......89

Installation Procedure.......90

Follow-On Procedure.......90

Yaw Rate Sensor.......91

Removal.......91

Overview.......91

Special Tools.......91

Equipment Conditions.......91

Removal Procedure.......92

Follow-On Procedure.......92

Installation.......93

Overview.......93

Special Tools.......93

Equipment Conditions.......93

Installation Procedure.......94

Follow-On Procedure.......94

Meritor Wabco ABS Air Brakes.......95

4-Channel.......95

Overview.......95

4-Channel with Automatic Traction Control.......97

Overview.......97

4-Channel with Electronic Stability and Automatic Traction Control.......98

Overview.......98

6-Channel.......100

Overview.......100

6-Channel with Automatic Traction Control.......102

Overview.......102

6-Channel with Electronic Stability and Automatic Traction Control.......103

Overview.......103

Air Brake Systems.......105

Hand Control Valve.......105

Overview.......105

Spring Brake Modulator Valve.......106

Overview.......106

Tractor.......107

Overview.......107

Air Modulator Valve.......108

Removal.......108

Overview.......108

Special Tools.......108

Equipment Conditions.......108

Removal Procedure.......109

Follow-On Procedure.......109

Installation.......110

Overview.......110

Special Tools.......110

Torque Specifications.......110

Equipment Conditions.......110

Installation Procedure.......111

Follow-On Procedure.......111

ATR-6 Valve.......112

Removal.......112

Overview.......112

Special Tools.......112

Equipment Conditions.......112

Removal Procedure.......113

Follow-On Procedure.......113

Installation.......114

Overview.......114

Special Tools.......114

Torque Specifications.......114

Equipment Conditions.......114

Installation Procedure.......115

Follow-On Procedure.......115

Foot Valve.......116

Removal.......116

Overview.......116

Special Tools.......116

Equipment Conditions.......116

Removal Procedure.......117

Follow-On Procedure.......117

Installation.......118

Overview.......118

Special Tools.......118

Torque Specifications.......118

Equipment Conditions.......118

Installation Procedure.......119

Follow-On Procedure.......119

R-12 Relay Valve.......120

R-12 Relay Valve Removal.......120

Overview.......120

Special Tools.......120

Equipment Conditions.......120

Removal Procedure.......121

Follow-On Procedure.......121

R-12 Relay Valve Installation.......122

Overview.......122

Special Tools.......122

Torque Specifications.......122

Equipment Conditions.......122

Installation Procedure.......123

Follow-On Procedure.......123

Quick Release Valve.......124

Removal.......124

Overview.......124

Special Tools.......124

Equipment Conditions.......124

Removal Procedure.......125

Follow-On Procedure.......125

Installation.......126

Overview.......126

Special Tools.......126

Torque Specifications.......126

Equipment Conditions.......126

Installation Procedure.......127

Follow-On Procedure.......127

Disc Brakes.......128

Front .......128

Overview.......128

Caliper Removal.......129

Overview.......129

Special Tools.......129

Equipment Condition.......129

Removal Procedure.......129

Follow-On Procedure.......129

Caliper Installation.......130

Overview.......130

Special Tools.......130

Equipment Condition.......130

Installation Procedure.......130

Follow-On Procedure.......130

Rear.......132

Overview.......132

Caliper Removal.......133

Overview.......133

Special Tools.......133

Equipment Condition.......133

Removal Procedure.......133

Follow-On Procedure.......133

Caliper Installation.......134

Overview.......134

Special Tools.......134

Equipment Condition.......134

Installation Procedure.......134

Follow-On Procedure.......134

Slack Adjusters.......136

Front Axle.......136

Overview.......136

Rear Axle.......138

Overview.......138

2. Air Systems.......140

Air Compressors.......140

Cummins 18.7 CFM.......140

Overview.......140

Knorr-Bremse 31.8 CFM.......141

Overview.......141

Wabco 37.4 CFM.......142

Overview.......142

Air Compressor 21.0 CFM.......143

Overview.......143

Bendix 15.9 CFM.......144

Overview.......144

Air Dryer Bendix AD-IS.......145

Overview.......145

Air Dryer Meritor Wabco System Save 1200 Plus.......146

Overview.......146

Air Dryer Auxiliary Bendix Air Dryer.......147

Overview.......147

Air Tank.......148

Overview.......148

Standard Location.......149

Overview.......149

Drain Valves.......150

Heated Drain Valves.......150

Overview.......150

3. Trailer.......151

Trailer Connections.......151

Air Brakes - Trailer Connections.......151

Overview.......151

Electrical Connection.......153

Overview.......153

Steering.......155

1. Steering Column and Steering Wheel.......157

Steering Column - Tilting.......157

Overview.......157

Steering Column - Tilting and Telescoping.......158

Overview.......158

Steering Wheel.......159

Overview.......159

Special Tools.......160

Removal.......161

Overview.......161

Special Tools.......161

Equipment Conditions.......161

Removal Procedure.......161

Follow-On Procedure.......162

Installation.......163

Overview.......163

Special Tools.......163

Equipment Conditions.......163

Installation Procedure.......163

Follow-On Procedure.......164

Steering Wheel Switches.......165

Removal.......165

Overview.......165

Special Tools.......165

Equipment Conditions.......165

Removal Procedure.......165

Follow-On Procedure.......166

Installation.......167

Overview.......167

Special Tools.......167

Equipment Conditions.......167

Installation Procedure.......167

Follow-On Procedure.......168

2. Power Steering System.......169

Oil Cooler.......169

Remote Mounted Power Steering Oil Cooler.......169

Overview.......169

Power Steering Gear.......170

Ross PCF60.......170

Overview.......170

Ross THP60.......171

Overview.......171

Sheppard HD94.......172

Overview.......172

Reservoir.......174

Removal.......174

Overview.......174

Special Tools.......174

Equipment Conditions.......174

Removal Procedure.......174

Follow-On Procedure.......175

Installation.......176

Overview.......176

Special Tools.......176

Torque Specifications.......176

Equipment Conditions.......176

Installation Procedure.......176

Follow-On Procedure.......177

Power Steering Pump Bleed.......178

Overview.......178

Special Tools.......178

Equipment Conditions.......178

System Bleed Procedure.......178

Follow-on Procedure.......179

Power Steering Pump Flow Test.......180

Overview.......180

Special Tools.......180

Equipment Condition.......180

Test Setup.......180

Test Procedure.......180

Follow-On Procedure.......181

Drivelines.......183

1. Drive Shaft.......185

Dana Spicer.......185

Overview.......185

Universal Joint.......187

Removal.......187

Overview.......187

Special Tools.......187

Equipment Conditions.......187

Removal Procedure.......188

Follow-On Procedure.......188

Installation.......189

Overview.......189

Special Tools.......189

Equipment Conditions.......189

Installation Procedure.......190

Follow-On Procedure.......190

Driveline Service & Troubleshooting.......191

Operational Checkout Procedure.......192

Overview.......192

Center Bearing Inspection.......195

Overview.......195

Special Tools.......195

Equipment Condition.......195

Inspection Procedure.......195

Follow-On Procedure.......195

Driveline Angle Measurement.......196

Overview.......196

Special Tools.......196

Equipment Conditions.......196

Measurement Procedure.......196

Follow-On Procedure.......198

Driveline Vibration Diagnostics.......199

Overview.......199

Special Tools.......199

Equipment Condition.......199

Procedure.......199

Follow-On Procedure.......200

Exhaust.......201

1. Exhaust Systems.......203

Day Cab .......203

Horizontal.......203

Overview.......203

Horizontal with Vertical Tips.......204

Overview.......204

Vertical .......205

Overview.......205

Short Sleeper .......206

Horizontal.......206

Overview.......206

Vertical.......207

Overview.......207

Removal.......208

Overview.......208

Special Tools.......208

Equipment Conditions.......208

Removal Procedure.......208

Follow-On Procedure.......209

Installation.......210

Overview.......210

Special Tools.......210

Equipment Conditions.......210

Installation Procedure.......211

Follow-On Procedure.......211

Long Sleeper.......212

Horizontal.......212

Overview.......212

Vertical.......213

Overview.......213

Inhibit Regen Switch.......214

Overview.......214

2. Exhaust Systems - LoneStar.......215

Horizontal.......215

Overview.......215

3. Engine Brake.......216

Engine Compression Brake.......216

Cummins.......216

Overview.......216

Jacobs (A26).......217

Overview.......217

Engine Brake Switch.......218

Overview.......218

Electrical / Software.......219

1. Diagnostic Trouble Code (DTC) List.......225

2. 12 Volt System.......229

Overview.......229

Auto Start Stop.......230

Overview.......230

Overview.......231

Battery Box.......232

Overview.......232

Battery Box Locations.......234

Left Side Battery Box (Standard).......234

Auxiliary Battery Box (Between the Frame Rails).......235

Auxiliary Battery Box (Left Side Mounted).......236

Battery Disconnect.......237

Overview.......237

Special Tools.......237

Equipment Conditions.......237

Disconnect Procedure.......237

Follow-On Procedure.......238

Battery Reconnect.......239

Overview.......239

Special Tools.......239

Equipment Conditions.......239

Reconnect Procedure.......240

Follow-On Procedure.......240

Battery Disconnect Switch.......241

Overview.......241

Body Control Module.......242

Diagnostics.......242

Overview.......242

SPN 520274 FMI 6 - Ignition Grid: Current Above Normal or Grounded Circuit.......244

Overview.......244

Associated Faults.......244

Fault Facts.......244

Special Tools.......244

Possible Causes.......244

Body Control Module Electrical Test.......246

Overview.......246

Special Tools.......246

Equipment Conditions.......246

Test Setup.......246

Diamond Logic Builder.......252

Overview.......252

Selecting an Interface Cable.......253

Overview.......253

Special Tools.......253

Equipment Conditions.......253

Selection Procedure.......253

Follow-On Procedure.......254

Connecting to a Vehicle.......255

Overview.......255

Special Tools.......255

Equipment Conditions.......255

Connection Procedure.......255

Follow-On Procedure.......256

Activating Diagnostic Mode.......257

Overview.......257

Special Tools.......257

Equipment Conditions.......257

Activation Procedure.......257

Follow-On Procedure.......258

Starting a Session.......259

Overview.......259

Special Tools.......259

Equipment Conditions.......259

Starting Procedure.......259

Follow-On Procedure.......260

Viewing Fault Codes.......261

Overview.......261

Special Tools.......261

Equipment Conditions.......261

Viewing Procedure.......261

Follow-On Procedure.......261

Clearing Fault Codes.......262

Overview.......262

Special Tools.......262

Equipment Conditions.......262

Clearing Procedure.......262

Follow-On Procedure.......262

Modifying Signals Tab.......263

Overview.......263

Special Tools.......263

Equipment Conditions.......263

Modify Watched Signal Columns.......263

Modify Watched Signals.......264

Follow-On Procedure.......264

Programming Modules.......265

Overview.......265

Special Tools.......265

Equipment Conditions.......265

Programming Procedure.......265

Follow-On Procedure.......268

Input Not Recognized by Body Control Module.......269

Overview.......269

Special Tools.......269

Equipment Conditions.......269

Troubleshooting Procedure.......269

Follow-On Procedure.......270

Output Not Commanded by Body Control Module.......271

Overview.......271

Special Tools.......271

Equipment Conditions.......271

Troubleshooting Procedure.......271

Follow-On Procedure.......272

CAN Systems.......273

Overview.......273

Faults.......275

Short.......275

Terminating Resistor Failure.......275

Backbone Open.......275

Node Open.......276

Operational Checkout Procedure.......277

125K Low Speed.......278

Overview.......278

Overview.......278

Diagnostics.......280

250K Body.......282

Overview.......282

Diagnostics.......283

250K Cab.......285

Overview.......285

Diagnostics.......287

500K Powertrain.......289

Overview.......289

Diagnostics.......291

Tests.......293

Power and Ground Test.......293

Overview.......293

Tools Required.......293

Equipment Condition.......293

Test Setup.......293

Test Procedure.......293

Follow-On Procedure.......293

Module Communication Test.......294

Overview.......294

Tools Required.......294

Equipment Condition.......294

Test Setup.......294

Test Procedure.......294

Follow-On Procedure.......295

CAN Voltage Test.......296

Tools Required.......296

Equipment Condition.......296

Test Setup.......296

Test Procedure.......296

Follow-On Procedure.......296

CAN Resistance Test.......297

Tools Required.......297

Equipment Condition.......297

Test Setup.......297

Test Procedure.......297

Follow-On Procedure.......297

Clutch Switch.......298

Overview.......298

Electrical Load Control.......304

Overview.......304

Hood Switch.......308

Overview.......308

Key Switch.......311

Overview.......311

Starting and Charging System.......316

Operational Checkout Procedure.......317

Starting System.......318

Overview.......318

Battery Pack.......318

Starter.......318

Control.......318

No Click No Crank.......320

Overview.......320

Possible Causes.......320

Click No Crank.......322

Overview.......322

Possible Causes.......322

Low Cranking Speed.......324

Overview.......324

Possible Causes.......324

Starter Input Signal Not Sent.......325

Overview.......325

Key Switch and Grid Control.......325

Crank Inhibit.......325

GridCtrl_CrankInhibit.......325

Crank_Inhibit_Reason.......325

Lower_Clutch_Signal.......326

Neutral_Status_TCM.......326

Transmission_Engine_Crank_Enable (SPN 2900 - J1939 signal).......326

Hood_Switch.......326

Operational Checkout Procedure.......328

Overview.......328

Charging System.......332

Overview.......332

Battery Pack.......332

Alternator.......332

Red Battery Warning Light.......334

Overview.......334

Possible Causes.......334

Repeated Jump Starts.......336

Overview.......336

Possible Causes.......336

Voltmeter Reading High.......338

Overview.......338

Possible Causes.......338

Voltmeter Reading Low / Fluctuating.......339

Overview.......339

Possible Causes.......339

Tests.......341

Battery Test.......341

Overview.......341

Tools Required.......341

Equipment Condition.......341

Test Setup.......341

Test Procedure.......341

Expected Outcome.......342

Follow-On Procedure.......343

Electrical System Test.......344

Overview.......344

Tools Required.......344

Equipment Condition.......344

Test Setup.......344

Test Procedure.......344

Starter System Test Procedure.......347

Charging System Test Procedure.......348

Expected Outcome.......349

Follow-On Procedure.......349

Cable Drop Test.......350

Overview.......350

Tools Required.......350

Equipment Condition.......350

Test Setup.......350

Test Procedure.......350

Expected Outcome.......351

Follow-On Procedure.......351

Parasitic Draw Test.......352

Overview.......352

Tools Required.......352

Equipment Condition.......352

Test Setup.......352

Test Procedure.......353

Expected Outcome.......355

Follow-On Procedure.......355

Manual Engine Bar Test.......356

Overview.......356

Tools Required.......356

Equipment Condition.......356

Test Setup.......356

Test Procedure.......356

Expected Outcome.......356

Follow-On Procedure.......356

Starter Control Circuit Test.......357

Overview.......357

Tools Required.......357

Equipment Condition.......357

Test Setup.......357

Test Procedure.......357

Expected Outcome.......357

Follow-On Procedure.......357

Inspections.......358

Ring Gear Inspection.......358

Overview.......358

Tools Required.......358

Equipment Condition.......358

Inspection Procedure.......358

Expected Outcome.......359

Follow-On Procedure.......359

Electrical System Inspection.......360

Overview.......360

Tools Required.......360

Equipment Condition.......360

Inspection Procedure.......361

Expected Outcome.......363

Follow-On Procedure.......363

Neutral Confirmation.......364

Overview.......364

Automatic.......366

Overview.......366

Manual.......367

Overview.......367

Jump Start Stud.......369

Overview.......369

Power Inverter.......371

Overview.......371

Inverter Diagnostics.......371

Operational Checkout Procedure.......373

Inverter Inoperative.......375

Symptom Overview.......375

Symptom Facts.......375

Possible Causes.......375

Pin-Point Test - Inverter Inoperative.......377

Tools Required.......377

E01 - DC Input Under-Voltage Shutdown.......379

Fault Code Overview.......379

Fault Facts.......379

Possible Causes.......379

Pin-Point Test - E01.......381

Tools Required.......381

E02 - DC Input Over-Voltage Shutdown.......383

Fault Code Overview.......383

Fault Facts.......383

Possible Causes.......383

Pin-Point Test - E02.......385

Tools Required.......385

E03 - Inverter Output Overload.......386

Fault Code Overview.......386

Fault Facts.......386

Possible Causes.......386

E04 - Inverter Over-Temperature Shutdown.......388

Fault Code Overview.......388

Fault Facts.......388

Possible Causes.......388

E05 - DC Input Under-Voltage Warning.......390

Fault Code Overview.......390

Fault Facts.......390

Possible Causes.......390

Pin-Point Test - E05.......392

Tools Required.......392

E06 - Inverter Output Overload Warning.......394

Fault Code Overview.......394

Fault Facts.......394

Possible Causes.......394

E07 - Inverter Over-Temperature Warning.......396

Fault Code Overview.......396

Fault Facts.......396

Possible Causes.......396

E10 - Charger Output Over-Voltage Shutdown.......398

Fault Code Overview.......398

Fault Facts.......398

Possible Causes.......398

E11 - Battery Not Accepting Charge.......400

Fault Code Overview.......400

Fault Facts.......400

Possible Causes.......400

Pin-Point Test - E11.......402

Tools Required.......402

E12 - Transfer Relay Over-Temperature Shutdown.......404

Fault Code Overview.......404

Fault Facts.......404

Possible Causes.......404

3. Accessories.......406

Air Solenoid Pack.......406

Overview.......406

Cruise Control.......407

Overview.......407

Predictive Cruise Control.......411

Overview.......411

Operational Checkout Procedure.......415

Overview.......415

Predictive Cruise Control Module Diagnostics.......417

Pin-Point Tests - Predictive Cruise Control .......420

Tools Required.......420

Predictive Cruise Control GPS Antenna Diagnostics.......428

Differential Locking.......430

Overview.......430

Power Windows, Door Locks and Mirrors.......431

Power Door Locks and Windows.......431

Overview.......431

Heated Mirrors.......435

Overview.......435

Power Mirrors.......437

Overview.......437

Remote Keyless Entry.......439

Overview.......439

Remote Keyless Entry Fob Programming.......441

Overview.......441

Tools Required.......441

Equipment Condition.......441

Procedure.......441

Follow On Procedure.......441

Satellite Communication System.......442

Overview.......442

Steering Wheel Switches.......443

Left POD.......443

Overview.......443

Right POD.......445

Overview.......445

Theft Deterrent System.......447

Overview.......447

Operational Checkout Procedure.......450

Theft Deterrent System Not Responding.......451

Overview.......451

Fault Facts.......451

Possible Causes.......451

USB Receptacle.......453

Overview.......453

4. Brakes.......454

Bendix Air Brake System.......455

Anti-Lock Brake System (ABS).......455

Overview.......455

Inputs.......457

Outputs.......457

Operational Checkout Procedure.......459

Overview.......459

ABS Module Loss of Communication.......460

Overview.......460

Fault Facts.......460

Tools Required.......460

Possible Causes.......460

Automatic Traction Control (ATC) System.......463

Overview.......463

Inputs.......464

Outputs.......465

Electronic Stability Control (ESC) System.......466

Overview.......466

Inputs.......467

Outputs.......468

Meritor Wabco Air Brake System.......470

Anti-Lock Brake System (ABS).......470

Overview.......470

Inputs.......472

Outputs.......472

Automatic Traction Control (ATC) System.......474

Overview.......474

Inputs.......475

Outputs.......476

Electronic Stability Control (ESC) System.......477

Overview.......477

Inputs.......478

Outputs.......479

5. Collision Avoidance Systems.......480

Collision Mitigation System.......480

Bendix Wingman Advanced.......480

Overview.......480

Adaptive Cruise Control (ACC).......482

Alerts.......482

Collision Mitigation Braking.......482

Tech Tips.......484

Operational Checkout Procedure.......485

Overview.......485

Radar Sensor Loss of Communication.......487

Overview.......487

Fault Facts.......487

Tools Required.......487

Possible Causes.......487

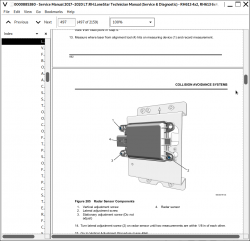

Radar Sensor Removal.......490

Special Tools.......490

Torque Specifications.......490

Equipment Conditions.......490

Removal Procedure.......490

Follow-On Procedure.......491

Radar Sensor Installation.......492

Special Tools.......492

Torque Specifications.......492

Equipment Conditions.......492

Installation Procedure.......492

Follow-On Procedure.......493

Radar Sensor Adjustment.......494

Special Tools.......494

Equipment Conditions.......494

Lateral Adjustment Procedure (Radar or Mounting Plate Not Replaced).......494

Lateral Adjustment Procedure (Radar or Mounting Plate Replaced).......496

Vertical Adjustment Procedure.......498

Follow-On Procedure.......500

Bendix Wingman Fusion.......501

Overview.......501

Adaptive Cruise Control (ACC).......503

Alerts.......503

Collision Mitigation Braking.......504

SafetyDirect Capability.......504

Stationary Vehicle Braking (SVB).......504

Tech Tips.......506

Operational Checkout Procedure.......507

Overview.......507

Camera Sensor Loss of Communication.......510

Overview.......510

Fault Facts.......510

Tools Required.......510

Possible Causes.......510

SafetyDirect Module Loss of Communication.......513

Overview.......513

Fault Facts.......513

Tools Required.......513

Possible Causes.......513

Camera Removal.......516

Special Tools.......516

Torque Specifications.......516

Equipment Conditions.......516

Removal Procedure.......516

Follow-On Procedure.......517

Camera Installation.......518

Special Tools.......518

Torque Specifications.......518

Equipment Conditions.......518

Installation Procedure.......518

Follow-On Procedure.......519

SafetyDirect Module High Roof Removal.......520

Special Tools.......520

Torque Specifications.......520

Equipment Conditions.......520

Removal Procedure.......520

Follow-On Procedure.......522

SafetyDirect Module High Roof Installation.......523

Special Tools.......523

Equipment Conditions.......523

Installation Procedure.......523

Follow-On Procedure.......525

SafetyDirect Module Low Roof Removal.......526

Special Tools.......526

Torque Specifications.......526

Equipment Conditions.......526

Removal Procedure.......526

Follow-On Procedure.......526

SafetyDirect Module Low Roof Installation.......527

Special Tools.......527

Torque Specifications.......527

Equipment Conditions.......527

Installation Procedure.......527

Follow-On Procedure.......527

Lane Departure System.......528

Bendix AutoVue 3G.......528

Overview.......528

6. Engine.......530

Cummins Diagnostics.......530

Table Of Contents.......530

Fault Code Diagnostics.......531

Fault Code List.......531

SPN 110 FMI 0 (Cummins FC 151) - Engine Coolant Temperature - Data Valid But Above Normal Operating Range - Most Severe Level.......533

Fault Overview.......533

Lamp Reaction.......533

Fault Fact.......533

Cummins Solutions.......533

Engine component coolant leaks.......533

Externally obstructed radiator.......533

Radiator shutters malfunctioning (If Equipped).......533

Fan Clutch operates incorrectly.......533

Stuck in - range Engine Coolant Temperature Sensor.......533

Thermostat is stuck open or closed.......533

Combustion gasses entering the cooling system.......533

Internally leaking EGR Cooler.......533

Engine Control Module (ECM) calibration revision history check.......533

SPN 111 FMI 3 (Cummins FC 195) - Coolant Level Sensor 1 Circuit - Voltage Above Normal or Shorted to High Source.......534

Fault Overview.......534

Lamp Reaction.......534

Fault Fact.......534

Cummins Solutions.......534

Fault Code 195 triggered by another Fault Code.......534

Engine Coolant Level sensor voltage circuit check (3 - wire sensor).......534

Malfunctioning Engine Coolant Level sensor circuit response (3 - wire).......534

Malfunctioning Engine Coolant Level sensor circuit response (2 - wire).......534

Engine Coolant Level sensor signal or return open circuit.......534

Engine Coolant Level sensor signal pin shorted to another pin.......534

SPN 111 FMI 18 (Cummins FC 197) - Coolant Level - Data Valid But Below Normal Operating Range - Moderately Severe Level.......535

Fault Overview.......535

Lamp Reaction.......535

Fault Fact.......535

Cummins Solutions.......535

Verify coolant loss complaint.......535

Missing or damaged Coolant Level Sensor.......535

Engine component coolant leaks.......535

Internally leaking EGR Cooler.......535

Engine Control Module (ECM) calibration revision history check.......535

SPN 111 FMI 1 (Cummins FC 235) - Coolant Level - Data Valid But Below Normal Operating Range - Most severe Level .......536

Fault Overview.......536

Lamp Reaction.......536

Fault Fact.......536

Cummins Solutions.......536

Verify coolant loss complaint.......536

Missing or damaged Coolant Level Sensor.......536

Engine component coolant leaks.......536

Internally leaking EGR Cooler.......536

Malfunctioning cooling system Pressure Cap.......536

Engine Control Module (ECM) calibration revision history check.......536

SPN 629 FMI 12 (Cummins FC 343) - Engine Control Module Warning Internal Hardware Failure - Bad Intelligent Device or Component.......537

Fault Overview.......537

Lamp Reaction.......537

Fault Fact.......537

Cummins Solutions.......537

Malfunctioning battery or battery cables.......537

Battery circuit fuse has open circuit.......537

Keyswitch input circuit check.......537

Malfunctioning charging system alternator.......537

Engine Control Module (ECM) calibration history check.......537

SPN 639 FMI 9 (Cummins FC 427) - J1939 Data Link - Abnormal Update Rate .......538

Fault Overview.......538

Lamp Reaction.......538

Fault Fact.......538

Cummins Solutions.......538

Incorrect ECM data link communications.......538

Engine Control Module (ECM) calibration revision history check.......538

SPN 168 FMI 16 (Cummins FC 442) - Battery 1 Voltage - Data Valid But Above Normal Operating Range - Moderately Severe Level.......539

Fault Overview.......539

Lamp Reaction.......539

Fault Fact.......539

Cummins Solutions.......539

Malfunctioning battery or battery cables.......539

Malfunctioning charging system alternator.......539

Engine Control Module (ECM) calibration revision history check.......539

SPN 3597 FMI 2 (Cummins FC 1117) - ECM Low Battery Voltage.......540

Fault Overview.......540

Lamp Reaction.......540

Fault Fact.......540

Cummins Solutions.......540

Battery Power Removed by Battery Power Disconnect Switch.......540

Low Battery Voltage.......540

Malfunctioning Battery or Battery Cables.......540

Battery Circuit Fuse has Open Circuit.......540

Keyswitch Input Circuit Check.......540

Intermittent Ground Connection.......540

Engine Control Module (ECM) Calibration Revision History Check.......540

ECM is Malfunctioning.......540

SPN 1761 FMI 1 (Cummins FC 1673) - Aftertreatment 1 Diesel Exhaust Fluid Tank Level - Data Valid But Below Normal Operating Range - Most Severe Level.......541

Fault Overview.......541

Associated Faults.......541

Fault Facts.......541

Possible Causes.......541

SPN 1761 FMI 3 (Cummins FC 1669) - Aftertreatment 1 Diesel Exhaust Fluid Tank Level Sensor Circuit - Voltage Above Normal or Shorted to High Source.......542

Fault Overview.......542

Associated Faults.......542

Fault Facts.......542

Possible Causes.......542

SPN 1761 FMI 4 (Cummins FC 1668) - Aftertreatment 1 Diesel Exhaust Fluid Tank Level Sensor Circuit - Voltage Below Normal or Shorted to Low Source.......543

Fault Overview.......543

Associated Faults.......543

Fault Facts.......543

Possible Causes.......543

SPN 1761 FMI 9 (Cummins FC 4677) Aftertreatment 1 Diesel Exhaust Fluid Tank Level - Abnormal Update Rate .......544

Fault Overview.......544

Associated Faults.......544

Fault Facts.......544

Possible Cause.......544

Pin-Point Tests (SPN 1761 FMI 9).......547

Tools Required.......547

SPN 1761 FMI 10 (Cummins FC 4769) - Aftertreatment 1 Diesel Exhaust Fluid Tank Level Sensor - Abnormal Rate of Change.......552

Fault Overview.......552

Associated Faults.......552

Fault Facts.......552

Possible Causes.......552

SPN 1761 FMI 11 (Cummins FC 4739) - Aftertreatment 1 Diesel Exhaust Fluid Tank Level Sensor - Root Cause Not Known.......553

Fault Overview.......553

Associated Faults.......553

Fault Facts.......553

Possible Causes.......553

SPN 1761 FMI 13 (Cummins FC 4732) - Aftertreatment 1 Diesel Exhaust Fluid Tank Level Sensor - Out of Calibration.......554

Fault Overview.......554

Associated Faults.......554

Fault Facts.......554

Possible Causes.......554

SPN 1761 FMI 17 (Cummins FC 3497) - Aftertreatment 1 Diesel Exhaust Fluid Tank Level - Data Valid But Below Normal Operating Range - Least Severe Level.......555

Fault Overview.......555

Associated Faults.......555

Fault Facts.......555

Possible Causes.......555

SPN 1761 FMI 18 (Cummins FC 3498) - Aftertreatment 1 Diesel Exhaust Fluid Tank Level - Data Valid But Below Normal Operating Range -Moderately Severe Level .......556

Fault Overview.......556

Associated Faults.......556

Fault Facts.......556

Possible Causes.......556

SPN 3031 FMI 2 (Cummins FC 1679) - Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature - Data Erratic, Intermittent, or Incorrect.......557

Fault Overview.......557

Associated Faults.......557

Fault Facts.......557

Possible Causes.......557

SPN 3031 FMI 3 (Cummins FC 1678) - Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature Sensor - Voltage Above Normal or Shorted to High Source .......558

Fault Overview.......558

Associated Faults.......558

Fault Facts.......558

Possible Causes.......558

SPN 3031 FMI 4 (Cummins FC 1677) - Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature Sensor - Voltage Below Normal or Shorted to Low Source.......559

Fault Overview.......559

Associated Faults.......559

Fault Facts.......559

Possible Causes.......559

SPN 3031 FMI 9 (Cummins FC 4572) - Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature - Abnormal Update Rate.......560

Fault Overview.......560

Associated Faults.......560

Fault Facts.......560

Possible Cause.......560

Pin-Point Tests (SPN 3031 FMI 9).......563

Tools Required.......563

SPN 3031 FMI 11 (Cummins FC 4737) - Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature - Root Cause Not Known.......568

Fault Overview.......568

Associated Faults.......568

Fault Facts.......568

Possible Causes.......568

SPN 3031 FMI 13 (Cummins FC 4731) - Aftertreatment 1 Diesel Exhaust Fluid Tank Temperature Sensor - Out of Calibration.......569

Fault Overview.......569

Associated Faults.......569

Fault Facts.......569

Possible Causes.......569

SPN 3364 FMI 2 (Cummins FC 3878) - Aftertreatment Diesel Exhaust Fluid Quality - Data Erratic, Intermittent, or Incorrect.......570

Fault Overview.......570

Associated Faults.......570

Fault Facts.......570

Possible Causes.......570

SPN 3364 FMI 3 (Cummins FC 1686) - Aftertreatment Diesel Exhaust Fluid Quality Sensor Circuit - Voltage Above Normal or Shorted to High Source.......571

Fault Overview.......571

Associated Faults.......571

Fault Facts.......571

Possible Cause.......571

SPN 3364 FMI 4 (Cummins 1685) - Aftertreatment Diesel Exhaust Fluid Quality Sensor Circuit - Voltage Below Normal or Shorted to Low Source.......573

Fault Overview.......573

Associated Faults.......573

Fault Facts.......573

Possible Cause.......573

SPN 3364 FMI 9 (Cummins FC 3868) - Aftertreatment Diesel Exhaust Fluid Quality - Abnormal Update Rate.......575

Fault Overview.......575

Associated Faults.......575

Fault Facts.......575

Possible Cause.......575

Pin-Point Tests (SPN 3364 FMI 9).......578

Tools Required.......578

SPN 3364 FMI 10 (Cummins FC 4277) - Aftertreatment Diesel Exhaust Fluid Quality - Abnormal Rate of Change .......583

Fault Overview.......583

Associated Faults.......583

Fault Facts.......583

Possible Causes.......583

SPN 3364 FMI 11 (Cummins FC 1715) - Aftertreatment Diesel Exhaust Fluid Quality - Root Cause Not Known.......585

Fault Overview.......585

Associated Faults.......585

Fault Facts.......585

Possible Causes.......585

SPN 3364 FMI 13 (Cummins FC 1714) - Aftertreatment Diesel Exhaust Fluid Quality - Out of Calibration.......586

Fault Overview.......586

Associated Faults.......586

Fault Facts.......586

Possible Causes.......586

SPN 3364 FMI 15 (Cummins FC 4842) - Aftertreatment Diesel Exhaust Fluid Quality - Data Valid But Above Normal Operating Range - Least Severe Level.......587

Fault Overview.......587

Associated Faults.......587

Fault Facts.......587

Possible Causes.......587

SPN 3364 FMI 18 (Cummins FC 3867) - Aftertreatment Diesel Exhaust Fluid Quality - Data Valid But Below Normal Operating Range - Moderately Severe Level.......589

Fault Overview.......589

Associated Faults.......589

Fault Facts.......589

Possible Causes.......589

SPN 3521 FMI 11 (Cummins FC 4768) - Aftertreatment 1 Diesel Exhaust Fluid Property - Root Cause Not Known.......591

Fault Overview.......591

Associated Faults.......591

Fault Facts.......591

Possible Causes.......591

SPN 3521 FMI 16 (Cummins FC 6765) - Aftertreatment Diesel Exhaust Fluid Property - Data Valid But Above Normal Operating Range - Moderately Severe Level.......592

Fault Overview.......592

Associated Faults.......592

Fault Facts.......592

Possible Causes.......592

SPN 3521 FMI 18 (Cummins FC 6766) - Aftertreatment Diesel Exhaust Fluid Property - Data Valid But Below Normal Operating Range - Moderately Severe Level.......594

Fault Overview.......594

Associated Faults.......594

Fault Facts.......594

Possible Causes.......594

SPN 3521 FMI 31 (Cummins FC 4235) - Aftertreatment 1 Diesel Exhaust Fluid Property- Condition Exists.......596

Fault Overview.......596

Associated Faults.......596

Fault Facts.......596

Possible Causes.......596

SPN 4096 FMI 31 (Cummins FC 3547) - Aftertreatment Diesel Exhaust Fluid Tank Empty - Condition Exists.......598

Fault Overview.......598

Associated Faults.......598

Fault Facts.......598

Possible Causes.......598

Tests and Inspections.......600

Overview.......600

DEF Head Unit Coolant Line Routing Inspection.......601

Overview.......601

Tools Required.......601

Equipment Condition.......601

Inspection Procedure.......601

Expected Outcome.......602

DEF Quality Test.......603

Overview.......603

Tools Required.......603

Equipment Condition.......603

Test Procedure.......603

Expected Outcome.......603

DEFTHV Coolant Flow Test.......604

Overview.......604

Tools Required.......604

Equipment Condition.......604

Test Setup.......604

Test Procedure.......604

Expected Outcome.......604

Engine Coolant Level Circuit Test.......605

Overview.......605

Tools Required.......605

Equipment Condition.......605

Test Setup.......605

Test Procedure.......605

ECM Battery Voltage Supply Test.......615

Overview.......615

Tools Required.......615

Equipment Condition.......615

Test Setup.......615

Test Procedure.......616

7. Exterior Lighting.......625

Air Cleaner Lighting - LoneStar.......625

Overview.......625

Air Shield Lighting.......626

Overview.......626

Brake Switch.......627

Overview.......627

Operational Checkout Procedure.......629

Overview.......629

Brake Switch Not Working.......631

Overview.......631

Fault Facts.......631

Possible Causes.......631

Pin-Point Test - Feature Code 0004092.......634

Tools Required.......634

SPN 597 FMI 0 - Brake Switch Input short to Power.......638

Overview.......638

Associated Faults.......638

Fault Facts.......638

Possible Causes.......638

Pin-Point Test - SPN 597 FMI 0 with Air Brakes 0004092.......640

Tools Required.......640

SPN 597 FMI 1 - Brake Switch Reading Below Normal Range.......644

Overview.......644

Associated Faults.......644

Fault Facts.......644

Possible Causes.......644

SPN 597 FMI 2 - Analog Brake Switch signal does not agree with Digital brake switch signal.......646

Overview.......646

Associated Faults.......646

Fault Facts.......646

Possible Causes.......646

Fog Lights.......648

Overview.......648

Operational Checkout Procedure.......650

Overview.......650

Input Diagnostics.......653

Overview.......653

Fault Facts.......653

Possible Causes.......653

Output Diagnostics - Not Illuminating.......655

Overview.......655

Fault Facts.......655

Possible Causes.......655

Pin-Point Test - Output Diagnostics - Not Illuminating.......660

Tools Required.......660

Output Diagnostics - Illuminating When Not Requested.......664

Overview.......664

Fault Facts.......664

Possible Causes.......664

Pin-Point Test - Output Diagnostics - Illuminating When Not Requested.......667

Tools Required.......667

SPN 2388 FMI 5 - Left Fog Light Open Circuit.......669

Overview.......669

Associated Faults.......669

Fault Facts.......669

Possible Causes.......669

Pin-Point Test - SPN 2388 FMI 5.......671

Tools Required.......671

SPN 2388 FMI 6 - Left Fog Light Short to Ground.......673

Overview.......673

Associated Faults.......673

Fault Facts.......673

Possible Causes.......673

Pin-Point Test - SPN 2388 FMI 6.......675

Tools Required.......675

SPN 4008 FMI 5 - Right Fog Light Open Circuit.......677

Overview.......677

Associated Faults.......677

Fault Facts.......677

Possible Causes.......677

Pin-Point Test - SPN 4008 FMI 5.......679

Tools Required.......679

SPN 4008 FMI 6 - Right Fog Light Short to Ground.......681

Overview.......681

Associated Faults.......681

Fault Facts.......681

Possible Causes.......681

Pin-Point Test - SPN 4008 FMI 6.......683

Tools Required.......683

Headlights.......685

Overview.......685

Operational Checkout Procedure.......687

Overview.......687

Special Tools.......690

Low Beam Diagnostics.......693

Overview.......693

Low Beam Input Diagnostics.......695

Overview.......695

Fault Facts.......695

Special Tools.......695

Possible Causes.......695

Low Beam Output Diagnostics - Not illuminating.......697

Overview.......697

Fault Facts.......697

Special Tools.......697

Possible Causes.......697

Low Beam Output Diagnostics - Illuminating When Not Requested.......702

Overview.......702

Fault Facts.......702

Special Tools.......702

Possible Causes.......702

SPN 2653 FMI 5 - Left Low Beam Open Circuit.......704

Overview.......704

Associated Faults.......704

Fault Facts.......704

Special Tools.......704

Possible Causes.......704

SPN 2653 FMI 6 - Left Low Beam Short to Ground.......706

Overview.......706

Associated Faults.......706

Fault Facts.......706

Special Tools.......706

Possible Causes.......706

SPN 2655 FMI 5 - Right Low Beam Open Circuit.......708

Overview.......708

Associated Faults.......708

Fault Facts.......708

Special Tools.......708

Possible Causes.......708

SPN 2655 FMI 6 - Right Low Beam Short to Ground.......710

Overview.......710

Associated Faults.......710

Fault Facts.......710

Special Tools.......710

Possible Causes.......710

High Beam Diagnostics.......711

Overview.......711

High Beam Input Diagnostics.......713

Overview.......713

Fault Facts.......713

Special Tools.......713

Possible Causes.......713

High Beam Output Diagnostics - Not Illuminating.......716

Overview.......716

Fault Facts.......716

Tools Required.......716

Possible Causes.......716

High Beam Output Diagnostics - Illuminating When Not Requested.......721

Overview.......721

Fault Facts.......721

Special Tools.......721

Possible Causes.......721

SPN 4011 FMI 5 - Left High Beam Open Circuit.......724

Overview.......724

Associated Faults.......724

Fault Facts.......724

Special Tools.......724

Possible Causes.......724

SPN 4011 FMI 6 - Left High Beam Short to Ground.......726

Overview.......726

Associated Faults.......726

Fault Facts.......726

Special Tools.......726

Possible Causes.......726

SPN 4012 FMI 5 - Right High Beam Open Circuit.......727

Overview.......727

Associated Faults.......727

Fault Facts.......727

Special Tools.......727

Possible Causes.......727

SPN 4012 FMI 6 - Right High Beam Short to Ground.......729

Overview.......729

Associated Faults.......729

Fault Facts.......729

Special Tools.......729

Possible Causes.......729

Lighting Control Module.......730

Overview.......730

Operational Checkout Procedure.......731

Overview.......731

Pin-Point Test - Operational Checkout Procedure.......733

Tools Required.......733

Marker / Park Lights.......734

Overview.......734

Operational Checkout Procedure.......738

Overview.......738

Park Light Input Diagnostics.......742

Overview.......742

Fault Facts.......742

Possible Causes.......742

Park Light Output Diagnostics - Not Illuminating.......744

Overview.......744

Fault Facts.......744

Possible Causes.......744

Pin-Point Test - Park Light Output - Not Illuminating.......747

Tools Required.......747

Park Light Output Diagnostics - Illuminating When Not Requested.......749

Overview.......749

Fault Facts.......749

Possible Causes.......749

Pin-Point Test - Park Light Output - Illuminating When Not Requested.......751

Tools Required.......751

SPN 2378 FMI 5 - Park Light Underccurrent.......753

Overview.......753

Associated Faults.......753

Fault Facts.......753

Possible Causes.......753

Pin-Point Test - SPN 2378 FMI 5.......755

Tools Required.......755

SPN 2378 FMI 6 - Park Light Overcurrent.......757

Overview.......757

Associated Faults.......757

Fault Facts.......757

Possible Causes.......757

Pin-Point Test - SPN 2378 FMI 6.......759

Tools Required.......759

SPN 4024 FMI 2 - Marker Light Interrupt Switch Failure.......761

Overview.......761

Associated Faults.......761

Fault Facts.......761

Possible Causes.......761

Stop / Turn Lights.......763

Overview.......763

Operational Checkout Procedure.......770

Overview.......770

Hazard Input Diagnostics.......775

Overview.......775

Possible Causes.......775

Pin-Point Test - Hazard Input Diagnostics.......778

Tools Required.......778

Turn Signal Input Diagnostics.......780

Overview.......780

Possible Causes.......780

Pin-Point Test - Turn Signal Input Diagnostics.......784

Tools Required.......784

Front Turn Lamps Not Illuminating.......792

Overview.......792

Possible Causes.......792

Pin-Point Test- Front Turn Lamp Output Not Illuminating.......796

Tools Required.......796

Front Turn Lamps Illuminating When Not Requested.......799

Overview.......799

Possible Causes.......799

Pin-Point Test - Front Turn Lamps Illuminating When Not Requested.......801

Tools Required.......801

Rear Turn Lamp Not Illuminating.......803

Overview.......803

Possible Causes.......803

Pin-Point Test - Stop and Turn Lamps- Rear Turn Lamp Not Illuminating.......806

Tools Required.......806

Rear Turn Lamps Illuminating When Not Requested.......809

Overview.......809

Possible Causes.......809

Pin-Point Test - Stop and Turn Lamps- Rear Turn Lamps Illuminating When Not Requested.......811

Tools Required.......811

SPN 2368 FMI 5 - Left Front Turn Lamp Undercurrent with Combined Stop and Turn Lamps.......813

Overview.......813

Associated Faults.......813

Fault Facts.......813

Possible Causes.......813

Pin-Point Test SPN 2368 FMI 5.......815

Tools Required.......815

SPN 2368 FMI 6 - Left Front Turn Lamp Overcurrent with Combined Stop and Turn Lamps.......817

Overview.......817

Associated Faults.......817

Fault Facts.......817

Possible Causes.......817

Pin-Point Test SPN 2368 FMI 6.......819

Tools Required.......819

SPN 2370 FMI 5 - Right Front Turn Lamp Undercurrent with Combined Stop and Turn Lamps.......821

Overview.......821

Associated Faults.......821

Fault Facts.......821

Possible Causes.......821

Pin-Point Test SPN 2370 FMI 5.......823

Tools Required.......823

SPN 2370 FMI 6 - Right Front Turn Lamp Overcurrent with Combined Stop and Turn Lamps.......825

Overview.......825

Associated Faults.......825

Fault Facts.......825

Possible Causes.......825

Pin-Point Test SPN 2370 FMI 6.......827

Tools Required.......827

SPN 2372 FMI 5 - Left Rear Turn Lamp Undercurrent .......829

Overview.......829

Associated Fault.......829

Fault Facts.......829

Possible Causes.......829

Pin-Point Test SPN 2372 FMI 5.......831

Tools Required.......831

SPN 2372 FMI 6 - Left Rear Turn Lamp Overcurrent .......833

Overview.......833

Associated Faults.......833

Fault Facts.......833

Possible Causes.......833

Pin-Point Test SPN 2372 FMI 6.......835

Tools Required.......835

SPN 2374 FMI 5 - Right Rear Turn Lamp Undercurrent .......837

Overview.......837

Associated Faults.......837

Fault Facts.......837

Possible Causes.......837

Pin-Point Test SPN 2374 FMI 5.......839

Tools Required.......839

SPN 2374 FMI 6 - Right Rear Turn Lamp Overcurrent .......841

Overview.......841

Associated Faults.......841

Fault Facts.......841

Possible Causes.......841

Pin-Point Test SPN 2374 FMI 6.......843

Tools Required.......843

8. HVAC.......845

On-Highway HVAC System.......845

Front HVAC System.......846

Overview.......846

A/C Refrigerant Flow.......848

General Operation of HVAC Electrical System.......850

Air Distribution.......851

Defrost.......851

Temperature.......851

Recirculation.......852

Panel / Floor.......852

Operational Checkout Procedure.......854

Overview.......854

Blower Not Working Properly.......857

Overview.......857

Fault Facts.......857

Special Tools.......857

Possible Causes.......857

HVAC System Air Not Cool After A/C Turned ON.......862

Overview.......862

Fault Facts.......862

Possible Causes.......862

HVAC System Air Not Warm After Heat Turned ON.......867

Overview.......867

Possible Causes.......867

SPN 876 FMI 5 - HVAC Compressor Clutch Engagement Undercurrent.......869

Overview.......869

Associated Faults.......869

Fault Facts.......869

Possible Causes.......869

SPN 876 FMI 6 - HVAC Compressor Clutch Engagement Overcurrent.......870

Overview.......870

Associated Faults.......870

Fault Facts.......870

Possible Causes.......870

SPN 1552 FMI 2 - Temperature Door Actuator Data Intermittent or Incorrect.......871

Overview.......871

Associated Faults.......871

Fault Facts.......871

Possible Causes.......871

SPN 2609 FMI 0 - PT Sensor - HVAC Pressure Sensor Reading Above Normal Range.......872

Overview.......872

Associated Faults.......872

Fault Facts.......872

Tools Required.......872

Possible Causes.......872

SPN 2609 FMI 1 - PT Sensor - HVAC Pressure Sensor Reading Below Normal Range.......874

Overview.......874

Associated Faults.......874

Fault Facts.......874

Tools Required.......874

Possible Causes.......874

SPN 2609 FMI 15 - PT Sensor - HVAC Low Pressure Protection (A/C Compressor Lockout).......877

Overview.......877

Associated Faults.......877

Fault Facts.......877

SPN 2609 FMI 16 - PT Sensor - HVAC High Pressure Protection.......878

Overview.......878

Associated Faults.......878

Fault Facts.......878

Possible Causes.......878

SPN 3981 FMI 2 - Defrost Door Actuator Data Intermittent or Incorrect.......880

Overview.......880

Associated Faults.......880

Fault Facts.......880

Possible Causes.......880

SPN 3984 FMI 2 - Recirculation Door Actuator Data Intermittent or Incorrect.......881

Overview.......881

Associated Faults.......881

Fault Facts.......881

Possible Causes.......881

SPN 3985 FMI 9 - HVAC Control Module Circuit Failed To Communicate With the Body Control Module.......882

Overview.......882

Associated Faults.......882

Fault Facts.......882

Possible Causes.......882

SPN 516636 FMI 19 - Error or Not Available is transmitted from Front HVAC Control Module.......883

Overview.......883

Associated Faults.......883

Fault Facts.......883

Tools Required.......883

Possible Causes.......883

SPN 516778 FMI 5 - Freeze Probe Open Circuit.......885

Overview.......885

Associated Faults.......885

Fault Facts.......885

Tools Required.......885

Possible Causes.......885

SPN 516778 FMI 6 - Freeze Probe Short to Ground.......886

Overview.......886

Associated Faults.......886

Fault Facts.......886

Tools Required.......886

Possible Causes.......886

SPN 516825 FMI 2 - Panel Door Actuator Data Intermittent or Incorrect.......888

Overview.......888

Associated Faults.......888

Fault Facts.......888

Possible Causes.......888

SPN 516826 FMI 2 - Floor Door Actuator Data Intermittent or Incorrect.......889

Overview.......889

Associated Faults.......889

Fault Facts.......889

Possible Causes.......889

SPN 516827 FMI 3 - Blower Motor Under Voltage Protection.......890

Overview.......890

Associated Faults.......890

Fault Facts.......890

Tools Required.......890

Possible Causes.......890

SPN 516827 FMI 4 - Blower Over Voltage Protection.......892

Overview.......892

Associated Faults.......892

Fault Facts.......892

Tools Required.......892

Possible Causes.......892

SPN 516827 FMI 7 - Blower Motor Not Responding (Blocked Rotor).......894

Overview.......894

Associated Faults.......894

Fault Facts.......894

Tools Required.......894

Possible Causes.......894

SPN 516827 FMI 31 - Blower Motor Over Temperature.......896

Overview.......896

Associated Faults.......896

Fault Facts.......896

Tools Required.......896

Possible Causes.......896

SPN 520465 FMI 2 - HVAC Control Module - Multiple Actuator Faults.......898

Overview.......898

Associated Faults.......898

Fault Facts.......898

Tools Required.......898

Possible Causes.......898

Sleeper / Rear HVAC System.......900

Overview.......900

A/C Refrigerant Flow.......903

Rear Air Distribution.......904

Sleeper HVAC Operational Checkout Procedure.......905

Overview.......905

Rear HVAC System Air Not Cool After A/C Turned ON.......910

Overview.......910

Fault Facts.......910

Possible Causes.......910

HVAC Tests.......912

Overview.......912

A/C Compressor Clutch Electrical Test.......914

Overview.......914

Tools Required.......914

Equipment Condition.......914

Test Setup.......914

Test Procedure.......914

Expected Outcome.......916

Follow On Procedure.......916

A/C System Restriction Test.......917

Overview.......917

Tools Required.......917

Equipment Condition.......917

Test Setup.......917

Test Procedure.......917

Expected Outcome.......917

Charge Quantity Measurement Test.......918

Overview.......918

Tools Required.......918

Equipment Condition.......918

Test Setup.......918

Test Procedure.......918

Expected Outcome.......918

Refrigerant Leak Test.......919

Overview.......919

Tools Required.......919

Equipment Condition.......919

Test Procedure Refrigerant Present.......920

No Refrigerant Present.......921

No Refrigerant Present - High Pressure Nitrogen.......922

Expected Outcome.......923

Follow-On Procedure.......923

Refrigerant Identification Test.......924

Overview.......924

Tools Required.......924

Equipment Condition.......924

Test Setup.......924

Test Procedure.......924

Expected Outcome.......924

Follow-On Procedure.......924

Static Refrigerant Pressure Test.......925

Overview.......925

Tools Required.......925

Equipment Condition.......925

Test Setup.......925

Test Procedure.......925

Expected Outcome.......926

Follow On Procedure.......926

Dynamic Refrigerant Pressure Test.......927

Overview.......927

Tools Required.......927

Equipment Condition.......927

Test Setup.......928

Test Procedure.......928

Expected Outcome.......930

Follow-On Procedure.......930

A/C Pressure Readings Indicating Problems.......931

Overview.......931

Tools Required.......931

Equipment Condition.......931

Low-Side Pressure Low, High-Side Pressure Low.......932

Possible Causes.......932

Low-Side Pressure Low, High-Side Pressure Normal or High.......933

Possible Causes.......933

High-Side and Low-Side Pressures Normal or Slightly Low, Duct Output Not Cold.......934

Possible Causes.......934

Low-Side Pressure Normal, High-Side Pressure High.......935

Possible Causes.......935

Low-Side Pressure High, High-Side Pressure Low.......936

Possible Causes.......936

Low-Side Pressure High, High-Side Pressure Normal.......937

Possible Causes.......937

Low-Side Pressure High, High-Side Pressure High.......938

Possible Causes.......938

High-Side Pressure Excessively High or Low.......938

A/C Compressor Compression Test.......939

Overview.......939

Tools Required.......939

Equipment Condition.......939

Test Procedure.......939

Expected Outcome.......939

HVAC Control Module and Actuator Calibration.......940

Overview.......940

Defrost Actuator Electrical Test.......941

Overview.......941

Fault Facts.......941

Possible Causes.......941

Pin-Point Test - Defrost Actuator Electrical Test.......944

Tools Required.......944

Floor Actuator Electrical Test.......949

Overview.......949

Fault Facts.......949

Possible Causes.......949

Pin-Point Test - Floor Actuator Electrical Test.......952

Tools Required.......952

Panel Actuator Electrical Test.......957

Overview.......957

Fault Facts.......957

Possible Causes.......957

Pin-Point Test - Panel Actuator Electrical Test.......960

Tools Required.......960

Recirculation Actuator Electrical Test.......965

Overview.......965

Fault Facts.......965

Possible Causes.......965

Pin-Point Test - Recirculation Actuator Electrical Test.......968

Tools Required.......968

Temperature Actuator Electrical Test.......973

Overview.......973

Fault Facts.......973

Possible Causes.......973

Pin-Point Test - Temperature Actuator Electrical Test.......976

Tools Required.......976

Blower Motor Electrical Input Test.......981

Overview.......981

Tools Required.......981

Equipment Condition.......981

Test Setup.......981

Test Procedure.......981

Expected Outcome.......981

Follow On Procedure.......981

HVAC Control Module Electrical Tests.......982

Overview.......982

Tools Required.......982

Equipment Condition.......982

Test Setup.......982

Test Procedure.......982

Expected Outcome.......984

Follow On Procedure.......984

Freeze Probe Electrical Test.......985

Overview.......985

Tools Required.......985

Equipment Condition.......985

Test Setup.......985

Test Procedure.......985

Expected Outcome.......986

Follow-On Procedure.......986

Heater Core Seal Leak Test.......987

Overview.......987

Tools Required.......987

Equipment Condition.......987

Test Setup.......987

Test Procedure.......988

Expected Outcome.......989

Follow On Procedure.......989

Low A/C Pressure Sensor Electrical Test.......990

Overview.......990

Tools Required.......990

Equipment Condition.......990

Test Setup.......990

Test Procedure.......990

Expected Outcome.......990

Follow On Procedure.......990

HVAC Pressure / Temperature Sensor Electrical Test.......991

Overview.......991

Tools Required.......991

Equipment Condition.......991

Test Setup.......991

Pressure / Temperature Test Procedure.......991

Expected Outcome.......993

Follow On Procedure.......993

HVAC Pressure / Temperature Sensor Functional Test.......994

Overview.......994

Tools Required.......994

Equipment Condition.......994

Test Setup.......994

Procedure.......994

Expected Outcome.......995

Sleeper HVAC Input Test.......996

Overview.......996

Tools Required.......996

Equipment Condition.......996

Test Setup.......996

Test Procedure.......997

Expected Outcome.......998

Follow On Procedure.......998

Rear A/C Request Test.......999

Overview.......999

Tools Required.......999

Equipment Condition.......999

Test Setup.......999

Test Procedure.......999

Expected Outcome.......1000

Follow On Procedure.......1000

Rear HVAC Control Module and Blend Door Actuator Calibration.......1001

Overview.......1001

Tools Required.......1001

Equipment Condition.......1001

Test Setup.......1001

Test Procedure.......1001

Expected Outcome.......1002

Follow-On Procedure.......1002

Rear Blend Door Actuator Electrical Test.......1003

Overview.......1003

Tools Required.......1003

Equipment Condition.......1003

Test Setup.......1003

Test Procedure.......1003

Expected Outcome.......1004

Follow-On Procedure.......1004

Rear Blend Door Movement Test.......1005

Overview.......1005

Tools Required.......1005

Equipment Condition.......1005

Test Setup.......1005

Test Procedure.......1005

Expected Outcome.......1005

Follow-On Procedure.......1005

Sleeper HVAC Blower Speed Switch Electrical Test.......1006

Overview.......1006

Tools Required.......1006

Equipment Condition.......1006

Test Setup.......1006

Test Procedure.......1006

Expected Outcome.......1008

Follow-On Procedure.......1008

Rear Blower Motor Electrical Test.......1009

Overview.......1009

Tools Required.......1009

Equipment Condition.......1009

Test Setup.......1009

Test Procedure.......1009

Expected Outcome.......1011

Follow-On Procedure.......1011

Rear HVAC Control Module Electrical Test.......1012

Overview.......1012

Tools Required.......1012

Equipment Condition.......1012

Test Setup.......1012

Test Procedure.......1012

Expected Outcome.......1013

Follow-On Procedure.......1013

Sleeper HVAC Temperature Control Switch Electrical Tests.......1014

Overview.......1014

Tools Required.......1014

Equipment Condition.......1014

Test Setup.......1014

Test Procedure.......1014

Expected Outcome.......1016

Rear Discharge Duct Temperature Sensor Electrical Test.......1017

Overview.......1017

Tools Required.......1017

Equipment Condition.......1017

Test Setup.......1017

Test Procedure.......1017

Expected Outcome.......1017

Follow-On Procedure.......1017

HVAC Inspections.......1018

Overview.......1018

HVAC System Inspection.......1019

Overview.......1019

Tools Required.......1019

Equipment Condition.......1019

Inspection Procedure.......1019

Expected Outcome.......1020

A/C System Internal Damage Inspection.......1021

Overview.......1021

Tools Required.......1021

Equipment Condition.......1021

Inspection Procedure.......1021

Expected Outcome.......1022

Rear HVAC System Inspection.......1023

Overview.......1023

Tools Required.......1023

Equipment Condition.......1023

Inspection Procedure.......1023

Expected Outcome.......1024

No Idle HVAC.......1025

Eberspaecher Auxiliary Heater.......1026

Overview.......1026

Regular Maintenance.......1027

Monthly.......1027

Every 1000 operating hours.......1028

Connecting EDiTH to heater.......1029

Starting and using EDiTH software.......1029

Reading fault codes.......1035

Clearing fault codes.......1035

Removing controller lock.......1036

Symptom Diagnostics.......1037

Overview.......1037

Fault Code Diagnostics.......1039

Overview.......1039

10 - Overvoltage / Shutdown.......1041

Fault Code Overview.......1041

11 - Undervoltage / Shutdown.......1042

Fault Code Overview.......1042

Pin-Point Tests.......1044

Tools Required.......1044

12 - Overheating.......1045

Fault Code Overview.......1045

14 - Possible Overheating Detected (Differential Evaluation).......1046

Fault Code Overview.......1046