Komatsu Wheeled Excavator PW200-7E0, PW220-7E0 Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Wheeled Excavator PW200-7E0, PW220-7E0, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Wheeled Excavator PW200-7E0, PW220-7E0 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,242 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

VEBM949100 - Wheeled Excavator PW200-7E0, PW220-7E0 Shop Manual.pdf

MAIN SECTIONS

PW200/220-7E0 VEBM949100...1

CONTENTS...3

FOREWORD...5

Safety...7

Safety notice...7

General precautions...7

Preparations for work...8

Precautions during work...8

List of revised pages...11

General...17

General...17

Structure and function...17

Testing, adjusting and troubleshooting...17

Disassembly and assembly...17

Maintenance standard...17

How to read the shop manual...18

Volumes...18

Distribution and updating...18

Filing method...18

Revised edition mark...18

Revisions...19

Symbols...19

Hoisting instructions...20

Hoisting...20

Coating materials...22

Standard tightening torque...24

Standard tightening torque of bolts and nuts...24

Tightening torque of hose nuts...25

Tightening torque of split flange bolts...25

Tightening torques for hoses (taper seal type and face seal type)...26

Tightening torque for 107 engine series (bolts and nuts)...26

Tightening torque for 107 engine series (eye joints)...27

Tightening torque for 107 engine series (tapered screws)...27

Electric wire code...28

Classification by thickness...28

Classification by color and code...28

Conversion tables...29

Method of using the conversion table...29

Temperature...34

Units...35

GENERAL...37

Specification dimension drawings...39

Dimensions...39

1 Piece boom...39

Dimensions...41

2 Piece boom...41

Working ranges...43

1 Piece boom...43

2 Piece boom...44

Specifications...45

PW200-7E0, PW220-7E0...45

Weight table...47

W200-7E0, PW220-7E0...47

1 Piece boom...48

2 Piece boom...49

Fuel, coolant and lubricants...50

STRUCTURE AND FUNCTION, MAINTENANCE STANDARD...53

Engine related parts...55

Radiator - Oil cooler - Charge air cooler...56

Power train...57

Swing circle...58

Swing machinery and motor...60

Swing motor...63

Operation of swing lock...66

Relief valve portion...67

Operation...67

Undercarriage...68

Transmission...70

Travel motor...73

Operation of travel motor...75

Clutch control circuit...78

Axle...80

Front axle...80

Rear Axle...82

Suspension lock cylinder...84

Circuit...84

Axle oscillation...85

Braking system...86

Brake/steer pump...88

Priority valve...89

Power brake valve...90

Accumulator for brake system...92

Steering system...93

Steering column...94

Orbitrol valve...95

Hydraulic equipment layout drawings...96

Hydraulic circuit diagram...98

Hydraulic tank...99

Hydraulic pump...100

HPV95 + 95 (PW200-7E0 )...100

LS valve...106

PC valve...106

Pilot pressure control (PPC) system...121

Control valve...122

PW200E0/220-7E0...122

CLSS...136

Outline of CLSS...136

Basic Principle...137

Main relief valve...139

Variable pressure compensation valve...140

Centre swivel joint...142

Travel PPC pedal...143

Work equipment - Swing PPC valve...145

Solenoid valves...150

Solenoid valve block...154

2 Position 3 way valve...154

2 Position 4 way valve...156

LS (PC)-EPC valve...158

Attachment EPC valve...161

Boom Safety valve...164

Hydraulic cylinder...166

PW200-7E0, PW200-7E0...166

Boom cylinder...166

Arm cylinder...166

Bucket cylinder...166

Adjust cylinder...167

Outrigger cylinder...168

Dozer cylinder...170

Work equipment...172

PW200-7E0/PW220-7E0...173

Work equipment...173

1. Dimension of arm...174

2. Dimension of bucket...176

Air conditioner...178

Air conditioner piping...178

Electrical wiring diagram...180

Electrical system...181

Engine control...181

Engine controller...183

CN-CE01...183

CN-CE01...184

CN-CE02...184

CN-CE03...185

Engine control system...188

Machine control system diagram...190

1. Engine and pump control function...192

2. Pump/valve control function...197

3. One-touch power maximizing function...199

4. Auto-deceleration function...201

5. Auto-warm-up/overheat and white smoke prevention function...203

6. Swing control function...205

7. Travel control function...207

8. ATT flow control, circuit selector function (option)...209

9. System component parts...210

Machine monitor system...213

Monitor panel...214

Monitor gauge displays...218

Keypad layout...221

Liquid crystal monitor adjustment switch...232

Overload warning device...238

Outline...238

Sensor...239

Coolant temperature sensor...240

Oil pressure switch...240

Rotation sensor...241

Boost pressure and temperature sensor...241

WIF (Water-In-Fuel detection) sensor...242

Engine oil level sensor...242

Coolant level sensor...243

Coolant temperature sensor...243

Hydraulic oil temperature sensor...244

Fuel level sensor...244

Air cleaner clogging sensor...245

Overload Caution sensor...245

Swing proximity sensor...245

Travel PPC sensor...245

PPC pressure sensor...246

Park brake pressure sensor...246

Brake accumulator low pressure sensor...246

Brake stop light sensor...246

1st attachment circuit hydraulic performance (main valve bypassed)...247

Travel circuit...248

Operational and control features...249

1. Travel motor...251

2. Travel pedal...259

3. Forward/neutral/reverse switch (F-N-R)...260

4. Forward/reverse travel solenoid...261

5. Travel/neutral solenoid...262

6. Travel creep solenoid...263

7. 2-stage relief solenoid...264

8. Hi/Lo solenoid valve...266

9. Back pressure solenoid...267

Steering system...268

Operating principles...268

Condition 1...269

Condition 2...269

Condition 3...270

Condition 4...270

Condition 5...271

Condition 6...271

OLS priority valve...272

Load sensing steering unit...272

Service brake and suspension system...278

Braking system...278

Operation...281

Quick coupler control valve...284

Specification...284

Operation...284

Shematic...285

ATT EPC valve assembly...286

KOMTRAX terminal system...287

KOMTRAX terminal...288

Standard value table for engine related parts...293

Standard value table for chassis related parts...294

Flow control characteristic of PC valve (STD)...307

TESTING AND ADJUSTING...291

Preparations for troubleshooting of electrical system...430

TESTING AND ADJUSTING...309

Measuring engine speed...311

Measuring intake air pressure (boost pressure)...313

Measurement of exhaust gas color...315

Adjusting valve clearance...317

Measuring compression pressure...319

Measurement of blow-by pressure...322

Measure engine oil pressure...324

Handling fuel system parts...325

Releasing residual pressure from fuel system...326

Measuring fuel pressure...327

Measuring fuel return rate and leakage...329

Bleeding air from fuel circuit...332

Checking fuel circuit for leakage...333

Checking and adjusting air conditioner compressor belt tension...335

Replacing the fan belt...336

Measurement of clearance in swing circle bearings...337

Inspection and adjustment of hydraulic oil pressure in hydraulic circuit for work equipment, swing and travel...338

Inspection and adjustment of control circuit oil pressure...343

Procedure for pressure reducing adjustment...345

Inspection and adjustment of pump pc (valve inlet) control oil pressure...346

Inspection and adjustment of pump ls valve control oil pressure...350

Measurement of solenoid valve output pressure...357

7 - Stage solenoid block...359

4 - Stage solenoid block...361

2 - Stage solenoid block...362

Measurement of PPC valve output pressure...363

Checking Proportional Control PPC Circuit...364

Adjustment of work equipment and swing PPC valve...365

Measuring and adjusting quick coupler control valve output pressure...366

Testing travel motor relief pressure...368

Measuring travel motor Relief pressure...368

Adjusting travel motor relief pressure...369

Testing propshaft speed...370

Measuring rotating speed of propshaft...370

Testing transmission clutch control circuit...371

Description...371

Inspection of locations of hydraulic drift of work equipment...373

Release of remaining pressure in hydraulic circuit...375

Measurement of oil leakage amount...377

Air bleeding of various parts...380

Inspection procedures for diode...382

Special function of monitor panel...384

Operation of operators menu and display (outline)...387

Table for failure code no...394

Operation and display of service menu...398

Way of switching to Service Menu...398

Table for monitoring items...401

Procedure for turning on KOMTRAX terminal...419

KOMTRAX terminal lamp indications...423

TESTING AND ADJUSTING...433

Troubleshooting...433

Points to remember when troubleshooting...435

Sequence of events in troubleshooting...437

Points to remember when carrying out maintenance...438

Points to remember when handling electric equipment...438

Points to remember when troubleshooting electric circuits...444

Points to remember when handling hydraulic equipment...444

Checks before troubleshooting...446

Classification and steps for troubleshooting...447

Steps for troubleshooting...447

Connector location chart and electrical circuit diagram by system...454

Connection table for connector pin numbers...479

T-boxes and T-adapters table...508

Information contained in troubleshooting table...515

Relative electrical circuit diagram...516

Failure code [6B2JMA] - Abnormality in travel PPC switch hydraulics...517

Failure code [989L00] - Engine controller lock caution 1...518

Failure code [989M00] - Engine controller lock caution 2...518

Failure code [989N00] - Engine controller lock caution 3...519

Failure code [AA10NX] - Air cleaner clogging...520

Failure code [AB00KE] - Charging voltage abnormally low...522

Failure code [B@BAZG] - Abnormally lowered engine oil pressure...524

Failure code [B@BAZK] - Abnormally lowered engine oil level...526

Failure code [B@BCNS] - Engine cooling water overheating...528

Failure code [B@BCZK] - Abnormally low radiator water level...530

Failure code [B@HANS] - Hydraulic oil overheating...532

Failure code [CA111] - EMC critical internal failure...534

Failure code [CA115] - Engine neutral and backup speed sensor error...535

Failure code [CA122] - Chg air press sensor high error...536

Failure code [CA123] - Chg air press sensor low error...538

Failure code [CA131] - Throttle sensor high error...540

Failure code [CA132] - Throttle sensor low error...542

Failure code [CA144] - Coolant temp sens high error...544

Failure code [CA145] - Coolant temp sens low error...546

Failure code [CA153] - Chg air temp sensor high error...548

Failure code [CA154] - Chg air temp sensor low error...550

Failure code [CA155] - Chg air temp high speed derate...552

Failure code [CA187] - Sens supply 2 volt low error...554

Failure code [CA221] - Ambient press sens high error...556

Failure code [CA222] - Ambient press sens low error...558

Failure code [CA227] - Sens supply 2 volt high error...560

Failure code [CA234] - Eng overspeed...562

Failure code [CA238] - Ne speed sens supply volt error...564

Failure code [CA271] - IMV/PCV1 short error...566

Failure code [CA272] - IMV/PCV1 open error...568

Failure code [CA322] - Inj #1 (L#1) open/short error...570

Failure code [CA323] - Inj #5 (L#5) open/short error...572

Failure code [CA324] - Inj #3 (L#3) open/short error...574

Failure code [CA325] - Inj #6 (L#6) open/short error...576

Failure code [CA331] - Inj #2 (L#2) open/short error...578

Failure code [CA332] - Inj #4 (L#4) open/short error...580

Failure code [CA342] - Calibration code incompatibility...582

Failure code [CA351] - Injectors drive circuit error...584

Failure code [CA352] - Sens supply 1 volt low error...586

Failure code [CA386] - Sens supply 1 volt high error...588

Failure code [CA428] - Water in fuel sensor high error...590

Failure code [CA429] - Water in fuel sensor low error...592

Failure code [CA435] - Eng oil press sw error...594

Failure code [CA441] - Battery voltage low error...596

Failure code [CA442] - Battery voltage high error...600

Failure code [CA449] - Rail press very high error...602

Failure code [CA451] - Rail press sensor high error...604

Failure code [CA452] - Rail press sensor low error...606

Failure code [CA488] - Chg air temp high torque derate...608

Failure code [CA553] - Rail press high error...608

Failure code [CA559] - Rail press low error...609

Failure code [CA689] - Eng ne speed sensor error...612

Failure code [CA731] - Eng bkup speed sens phase error...614

Failure code [CA757] - All continuous data lost error...616

Failure code [CA778] - Eng G speed sensor error...618

Failure code [CA1633] - KOMNET datalink timeout error...620

Failure code [CA2185] - Throttle sensor supply voltage high error...622

Circuit diagram related to fuel control dial...622

Failure code [CA2186] - Throttle sensor supply voltage low error...623

Circuit diagram related to fuel control dial...623

Failure code [CA2249] - Rail press very low error...624

Failure code [CA2311] - IMV solenoid error...626

Failure code [CA2555] - Grid htr relay volt high error...628

Failure code [CA2556] - Grid heater relay volt low error...630

Failure code [D110KB] - Short-circuiting in battery relay...632

Failure code [D19JKZ] - Personal code relay abnormality...634

Failure code [D862KA] - GPS antenna discon...636

Failure code [DA25KP] - Press. sensor power abnormality...638

Failure code [DA2RMC] - Pump comm. abnormality...640

Failure code [DA2SKA] - Disconnection of S-NET signal...642

Failure code [DA2SKQ] - Abnormality in inputting model code...644

Failure code [DA2SKQ] - Abnormality in inputting model code...646

Failure code [DAF0KT] - Abnormal data in error history...648

Failure code [DAFRMC] - Monitor comm. abnormality...650

Failure code [DDC3KZ] - Outrigger switch select abnormality...652

Failure code [DDHPAKP] - Abnormality in pump pressure sensor...654

Failure code [DDP4KX] - Abnormality in travel PPC pressure switch...656

Failure code [DDWCKZ] - Abnormality in travel direction control switch...658

Failure code [DFB1KZ] - Service lever potentio 1 abnormality...660

Failure code [DFB2KZ] - Service lever potentio 2 abnormality...662

Failure code [DFB3L8] - Service lever 1 potentio error...664

Failure code [DFB4L8] - Service lever 2 potentio error...665

Failure code [DGH2KB] - Hydr oil sensor short...667

Failure code [DH10KS] - Abnormality in pressure sensor power source...668

Failure code [DHPAKP] - Abnormality in F pump pressure sensor...670

Failure code [DHPAMA] - Abnormality in F pump pressure sensor...672

Failure code [DHPBMA] - Abnormality in R pump pressure sensor...674

Failure code [DHS5KX] - Abnormality in travel PPC sensor...676

Failure code [DHX1MA] - Abnormality in overload caution sensor...678

Failure code [DLE2MA] - Abnormality in engine rotation sensor in governor (pump controller system)...680

Failure code [DLT4KA] - Disconnection in transmission speed sensor in governor (pump controller syste)m)...682

Failure code [DW27KA] - Disconnection in transmission clutch solenoid...684

Failure code [DW27KB] - Short-circuiting in transmission clutch solenoid...686

Failure code [DW4CKA] - Disconnection in PPC lock solenoid...688

Failure code [DW4CKB] - PPC lock sol. S/C...690

Failure code [DW44KA] - Disconnection of travel F/R solenoid...692

Failure code [DW44KB] - Short-circuiting of travel F/R solenoid...694

Failure code [DW45KA] - Disconnection in swing parking brake solenoid...696

Failure code [DW4MKA] - Disconnection in creep solenoid...698

Failure code [DW4MKB] - Short-circuiting in creep solenoid...700

Failure code [DW91KA] - Disconnection in travel neutral solenoid...702

Failure code [DW91KB] - Short-circuiting in travel neutral solenoid...704

Failure code [DWK0KA] - Disconnection in 2-stage relief solenoid...706

Failure code [DWK0KB] - Short-circuiting in 2-stage relief solenoid...708

Failure code [DWK2KA] - Disconnection in 2-stage back pressure solenoid...710

Failure code [DWK2KB] - Short circuiting in 2-stage back pressure solenoid...712

Failure code [DXA0KA] - Disconnection in PC-EPC solenoid system...714

Failure code [DXE0KA] - Disconnection in LS-EPC solenoid system...716

Failure code [DXE0KB] - Short-circuiting in LS-EPC solenoid...718

Failure code [DXE4KA] - Service current EPC1 discon...720

Failure code [DXE4KB] - Service current EPC1 short...722

Failure code [DXE7KA] - Service current EPC2 disco...724

Failure code [DXE7KB] - Service current EPC2 short...726

Failure code [DXE8KA] - Service current EPC3 discon...728

Failure code [DXE8KB] - Service current EPC3 short...730

Failure code [DXE9KA] - Service current EPC4 discon...732

Failure code [DXE9KB] - Service current EPC4 short...734

Failure code [DY20KA] - Wiper working abnormality...736

Failure code [DY20MA] - Wiper parking abnormality...738

Failure code [DY2CKB] - Washer drive S/C...740

Failure code [DY2DKB] - Wiper drive (for) S/C...742

Failure code [DY2EKB] - Wiper drive (rev) S/C...744

TESTING AND ADJUSTING...511

Troubleshooting when service code "Electrical system" and failure code "Mechanical system" are indicated...511

Information contained in troubleshooting table...749

Relative electrical circuit diagram...750

E-1 - Engine does not start (engine does not rotate)...751

E-5 - Auto-decelerator does not work...755

E-6 - Auto engine warm-up device does not work...757

E-7 - Preheater does not operate...758

E-8 - All work equipment, swing and travel do not move...760

E-9 - One-touch power max switch does not work...762

E-10 - No display in monitor panel at all...763

E-11 - Part of display on monitor panel is missing...764

E-12 - Monitor panel displays contents irrelevant to the model...764

E-13 - Fuel level monitor red lamp lights up while engine is running...765

E-14 - Engine coolant temperature gauge does not indicate normally...766

E-15 - Hydraulic oil temperature gauge does not display correctly...768

E-16 - Fuel gauge does not display correctly...769

E-17 - Swing lock monitor does not display correctly...770

E-18 - When the monitor switch is operated, no display appears...772

E-19 - Windshield wiper and window washer do not operate...774

E-20 - Alarm buzzer cannot be stopped...776

E-21 - "Boom/stabiliser RAISE" is not correctly displayed in monitor function...777

E-22 - "Boom/stabiliser LOWER" is not correctly displayed in monitor function...778

E-23 - "Arm DIGGING" is not correctly displayed in monitor function...779

E-24 - "Arm DUMPING" is not correctly displayed in monitor function...780

E-25 - "Bucket DIGGING" is not correctly displayed in monitor function...781

E-26 - "Bucket DUMPING" is not correctly displayed in monitor function...782

E-27 - "SWING" is not correctly displayed in monitor function...784

E-28 - "TRAVEL" is not correctly displayed in monitor function...786

E-29 - "2 piece boom" is not correctly displayed in monitor function...788

E-30 - Air conditioner does not work...790

E-31 - Travel reverse alarm does not sound...792

E-32 - KOMTRAX system does not operate normally...794

TESTING AND ADJUSTING...747

Troubleshooting of electrical system (E-Mode)...747

Information contained in troubleshooting table...799

Radio cassette and telephone socket...800

PPC lock circuit...802

Brake light circuit...804

Undercarriage attachments - Mode selection...806

Undercarriage attachments - Front left outrigger...808

Undercarriage attachments - Front right outrigger...810

Undercarriage attachments - Rear left outrigger...812

Undercarriage attachments - Rear right outrigger...814

Heated seat does not warm up...816

Suspension lock...818

Lower wiper does not work (optional fitment)...820

Work lights (operator cab front left)...822

Work lights (operator cab front right)...823

Work lights (operator cab rear)...824

Work lights (boom, arm and counterweight)...826

Cab and counterweight beacon light...828

Air seat compressor (option - air suspension seat)...830

Operator cab interior light...832

Cigar lighter...834

Park brake (not activating)...836

Park brake (displayed symbol)...838

RH PPC lever clamshell roller switch pushed to the LH position...840

RH PPC lever clamshell roller switch pushed to the RH position...842

RH PPC lever clamshell roller switch pushed to the RH or LH position...844

Horns...846

Swing lock - Normal operation...848

Swing lock - Emergency operation...850

Neutral start (engine)...852

Neutral start (engine) contd (A)...853

Neutral start (engine) contd (B)...854

Neutral start (engine) contd (C)...855

Emergency travel control - Forward...858

Emergency travel control - neutral...860

Emergency travel control - Reverse...863

Emergency travel control - Reverse contd...864

Driving lights - Main beam...866

Driving lights - Main beam flash...868

Driving lights - Main beam dipped...870

Driving lights - Position lights...872

Driving lights - Position lights contd (1) and (2)...874

Indicators - Right hand...876

Indicators - Left hand...878

Hazard warning lights...880

Hazard warning lights contd (A)...882

Swing lock proximity switch...884

TESTING AND ADJUSTING...797

Troubleshooting of electrical system (Error checking of items without monitor codes)...797

System chart for hydraulic and mechanical systems...889

Information contained in troubleshooting table...893

H-1 - All work equipment lacks power, or travel and swing speeds are slow...894

H-2 - Engine speed sharply drops or engine stalls...895

H-3 - No work equipment, travel or swing move...896

H-4 - Abnormal noise is heard from around hydraulic pump...897

H-5 - Auto-decelerator does not work...898

H-6 - Fine control mode does not function...899

H-7 - Boom moves slowly or lacks power...900

H-8 - Arm moves slowly or lacks power...901

H-9 - Bucket moves slowly or lacks power...902

H-10 - Work equipment does not move in its single operation...903

H-11 - Work equipment hydraulic drift is too fast...904

H-12 - Work equipment has big time lag...905

H-13 - Other work equipment moves when relieving single circuit...906

H-14 - One-touch power max. switch does not operate...907

H-15 - In compound operation, work equipment with larger load moves slowly...908

H-16 - In swing and boom RAISE operation, boom moves slowly...909

H-17 - In swing and travel, travel speed drops sharply...910

H-18 - Travel speed does not switch...911

H-19 - Travel speed does not shift, or it is too slow or fast...912

H-20 - Machine does not swing...913

H-21 - Swing acceleration is poor, or swing speed is slow...914

H-22 - Excessive overrun when stopping swing...915

H-23 - There is big shock when stopping swing...916

H-24 - There is loud abnormal noise caused when stopping swing...917

H-25 - Swing natural drift is too big...918

H-26 - Swing speed is faster than specified swing speed...919

Troubleshooting of engine (S-mode)...920

Method of using troubleshooting chart...920

S-1 - Starting performance is poor...923

S-2 - Engine does not start...924

S-3 - Engine does not pick up smoothly...927

S-4 - Engine stops during operations...928

S-5 - Engine does not rotate smoothly...929

S-6 - Engine lack output (or lacks power)...930

S-7 - Exhaust smoke is black (incomplete combustion)...931

S-8 - Oil consumption is excessive (or exhaust smoke is blue)...932

S-9 - Oil becomes contaminated quickly...933

S-10 - Fuel consumption is excessive...934

S-11 - Oil is in coolant (or coolant spurts back or coolant level goes down)...935

S-12 - Oil pressure drops...936

S-13 - Oil level rises (entry of coolant/fuel)...937

S-14 - Coolant temperature becomes too high (overheating)...938

S-15 - Abnormal noise is made...939

S-16 - Vibration is excessive...940

TESTING AND ADJUSTING...887

Troubleshooting of hydraulic and mechanical system (H-Mode)...887

How to read this manual...945

Removal and installation of assemblies...945

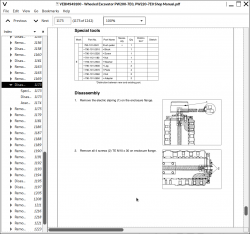

Special tools...945

Removal of parts...946

Installation of parts...946

Sketches of special tools...946

Coating materials list...947

Special Tools...950

Sketches of special tools...953

E1 push tool...953

E5 push tool...953

F2 push tool...954

List of tools...955

Precautions when performing operation...956

Removal and installation of starting motor...960

Removal...960

Installation...960

Removal and installation of fuel pump assembly...961

Removal...961

Installation...964

Removal and installation of fuel injector assembly...965

Special tools...965

Removal...965

Installation...970

Removal and installation of engine front seal...974

Special tools...974

Removal...974

Installation...976

Removing and installation of engine rear seal...977

Special tools...977

Removal...977

Installation...978

Removal and installation of cylinder head assembly...980

Special tools...980

Removal...980

Installation...988

Removal and installation of combination cooler...995

Removal...995

Installation...998

Removal and installation of engine and hydraulic pump assemblies...999

Special tools...999

Removal...999

Installation...1004

Removal and installation of fuel cooler assembly...1006

Removal...1006

Installation...1006

Removal and installation of transmission and travel motor...1007

Removal...1007

Installation...1009

Disassembly and assembly of transmission...1010

Special tools...1010

Disassembly...1010

Removal of travel motor...1010

Installation of travel motor...1011

Removal of transmission input shaft...1012

Installation of transmission input shaft...1022

Removal of output shaft...1023

Installation of output shaft...1026

Removal of pump shaft...1027

Installation of pump shaft...1029

Disassembly and assembly of travel motor assembly...1030

Disassembly...1031

Assembly...1033

Removal and installation of swing motor and swing machinery assembly...1035

Removal...1035

Installation...1036

Disassembly and assembly of swing motor and swing machinery assembly...1037

Special tools...1037

Disassembly...1037

Assembly...1040

Removal and installation of front axle...1046

Removal...1046

Installation...1047

Disassembly and assembly of front axle...1048

Disassembly of steering cylinder...1048

Assembly of steering cylinder...1053

Disassembly of epicyclic reduction gear and brake...1060

Assembly of epicyclic reduction gear and brake...1066

Disassembly of joint box...1075

Assembly of joint box...1082

Disassembly of beam trumpet and differential unit...1090

Assembly of beam trumpet and differential unit...1095

Disassembly of pinion group...1102

Assembly of pinion group...1105

Toe-in adjustment...1114

Removal and installation of rear axle...1116

Removal...1116

Installation...1117

Disassembly and assembly of rear axle...1118

Special tools...1118

Removal of epicyclic reduction gear and brake...1118

Installation of epicyclic reduction gear and brake...1125

Disassembly of beam trumpet and differential unit...1135

Installation of beam trumpet and differential unit...1139

Disassembly of pinion group...1140

Installation of pinion group...1144

Removal and installation of propshaft...1152

Removal...1152

Installation...1152

Removal and installation of wheel...1153

Removal...1153

Installation...1153

Removal and installation of suspension lock cylinder...1154

Removal...1154

Installation...1154

Disassembly and assembly of suspension lock cylinder...1155

Change rod seal...1155

Removal and installation of outrigger...1156

Removal...1156

Installation...1157

Disassembly and assembly of outrigger...1158

Disassembly...1158

Assembly...1159

Removal and installation of dozer blade...1160

Removal...1160

Installation...1160

Disassembly and assembly of dozer blade...1161

Disassembly...1161

Assembly...1162

Removal and installation of swing circle assembly...1163

Removal...1163

Installation...1163

Removal and installation of revolving frame assembly...1165

Removal...1165

Installation...1168

Removal and installation of centre swivel joint...1169

Removal...1169

Installation...1172

Disassembly and assembly of centre swivel joint...1173

Special tools...1173

Disassembly...1173

Assembly...1174

Removal and installation of hydraulic tank...1175

Removal...1175

Installation...1178

Removal and installation of fuel tank...1179

Removal...1179

Installation...1180

Removal and installation of control valve...1181

Removal...1181

Installation...1185

Removal and installation of LS select valve assembly...1186

Removal...1186

Installation...1186

Removal and installation of LS shuttle valve assembly...1187

Removal...1187

Installation...1187

Removal and installation of pressure compensation valve assembly...1188

Removal...1188

Installation...1188

Removal and installation of main relief valve assembly...1189

Removal...1189

Installation...1189

Removal and installation of LS control EPC valve assembly...1190

Removal...1190

Installation...1190

Removal and installation of EPC solenoid valve assembly...1191

Removal...1191

Installation...1191

Removal and installation of PPC valve block assembly...1192

Removal...1192

Installation...1192

Removal and installation of manifold block assembly...1193

Removal...1193

Installation...1193

Removal and installation of oil seal in hydraulic pump input shaft...1194

Special tools...1194

Removal...1194

Installation...1194

Disassembly and assembly of work equipment PPC valve...1195

Assembly...1196

Disassembly and assembly of hydraulic cylinder...1197

Special tools...1197

Disassembly of arm and bucket cylinders...1198

Assembly...1200

Removal and installation of monoboom work equipment...1205

Special tools...1205

Removal...1205

Installation...1207

Removal and installation of 2 piece boom work equipment...1208

Special tools...1208

Removal...1208

Installation...1210

Removal and installation of air conditioner unit...1211

Special tools...1211

Removal...1211

Installation...1215

Removal and installation of counterweight...1216

Removal...1216

Installation...1217

Removal and installation of operator cab assembly...1218

Removal...1218

Installation...1220

Removal and installation of monitor assembly...1221

Removal...1221

Installation...1222

Removal and installation of governor/pump controller assembly...1223

Removal...1223

Installation...1224

Removal and Installation of KOMTRAX terminal...1225

Removal...1225

Installation...1225

DISASSEMBLY AND ASSEMBLY...941

OTHER...1227

Lubrication...1229

Hydraulic circuit diagram (1/3)...1233

Hydraulic circuit diagram (2/3)...1234

Hydraulic circuit diagram (3/3)...1235

Electrical circuit diagram (1/7)...1236

Electrical circuit diagram (2/7)...1237

Electrical circuit diagram (3/7)...1238

Electrical circuit diagram (4/7)...1239

Electrical circuit diagram (5/7)...1240

Electrical circuit diagram (6/7)...1241

Electrical circuit diagram (7/7)...1242