Komatsu Wheeled Excavator PW200-7K, PW220-7K Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Wheeled Excavator PW200-7K, PW220-7K, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Wheeled Excavator PW200-7K, PW220-7K workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,584 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

UEBM001901 - Wheeled Excavator PW200-7K, PW220-7K Shop Manual.pdf

UEAM002501 - Wheeled Excavator PW200-7KA, PW220-7KA Operation & Maintenance Manual.pdf

UEAM003700 - Wheeled Excavator PW200-7K, PW220-7K Operation & Maintenance Manual.pdf

MAIN SECTIONS

UEAM002501 - Wheeled Excavator PW200-7KA, PW220-7KA Operation & Maintenance Manual.....2

FOREWORD.....4

FOREWORD.....5

SAFETY INFORMATION.....7

SAFETY MESSAGES.....7

NOISE.....8

VIBRATION.....8

EMERGENCY STEERING.....9

INTRODUCTION.....10

INTENDED USE.....10

FEATURES.....10

BREAKING IN YOUR NEW MACHINE.....11

LOCATIONS OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR.....12

MACHINE SERIAL NO. PLATE POSITION.....12

ENGINE SERIAL NO. PLATE POSITION.....12

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR.....12

MACHINE SERIAL PLATES.....13

STANDARD SERIAL PLATE.....13

STANDARD SERIAL PLATE.....13

GERMANY SERIAL PLATE.....14

ITALIAN SERIAL PLATE.....14

SAFETY.....22

GENERAL PRECAUTIONS.....23

PRECAUTION DURING OPERATION.....29

BEFORE STARTING ENGINE.....29

OPERATING MACHINE.....30

TRANSPORTATION.....36

BATTERY.....37

TOWING.....38

BUCKET WITH HOOK OR BUCKET LINK WITH LIFTING EYE.....39

GENERAL PRECAUTIONS.....39

PRECAUTIONS FOR LIFTING OPERATION.....40

PRECAUTIONS FOR MAINTENANCE.....42

BEFORE CARRYING OUT MAINTENANCE.....42

DURING MAINTENANCE.....45

POSITION FOR ATTACHING SAFETY LABELS.....48

POSITION FOR ATTACHING SAFETY LABELS.....48

LIFTING CAPACITY CHART PW200-7K.....57

ONE PIECE BOOM Lift capacity tables for 2.5 metre undercarriage.....57

ONE PIECE BOOM Lift capacity tables for 2.75 metre undercarriage.....64

LIFTING CAPACITY CHART PW220-7K.....71

ONE PIECE BOOM Lift capacity tables for 2.75 metre undercarriage and heavy duty counterweight.....71

ONE PIECE BOOM Lift capacity tables for 2.75 metre undercarriage.....78

OPERATION.....86

GENERAL VIEW.....87

GENERAL VIEW OF MACHINE.....87

GENERAL VIEW OF CONTROLS AND GAUGES.....88

EXPLANATION OF COMPONENTS.....89

MACHINE MONITOR.....89

BASIC OPERATION OF MACHINE MONITOR.....90

BASIC CHECK ITEMS.....92

CAUTION ITEMS.....94

EMERGENCY STOP ITEMS.....98

METER DISPLAY PORTION.....101

METERS.....103

MONITOR SWITCHES.....106

SWITCHES.....121

CONTROL LEVERS, PEDALS.....129

FRONT WINDOW.....134

EMERGENCY EXIT FROM OPERATOR'S CAB.....138

DOOR LOCK.....139

CAP, COVER WITH LOCK.....140

METHOD OF OPENING AND CLOSING CAP WITH LOCK (For the fuel tank filler port).....140

METHOD OF OPENING AND CLOSING COVER WITH LOCK (cover with lock).....140

FUSE.....141

LUGGAGE TRAY.....142

ASHTRAY.....142

CUP HOLDER.....142

HOT AND COOL BOX.....142

CAB RADIO.....143

EXPLANATION OF COMPONENTS.....143

1.POWER SWITCH/VOLUME CONTROL KNOB (SW-VOLUME) BALANCE CONROL KNOB (Pull Bar).....143

2.TONE CONTROL KNOB (TONE).....144

3.FM/AM SELECTOR BUTTON (AM/FM).....144

4.DISPLAY SELECTOR BUTTON (TIME).....144

5.TUNING BUTTONS (TUNING) MANUAL TUNING (MANUAL).....144

6.PRESET BUTTONS (1,2,3,4,5,6) (PRESET STATION).....144

7.DISPLAY.....145

8.TIME CORRECTION BUTTON.....145

9.STEREO INDICATOR (ST).....145

METHOD OF OPERATION.....145

METHOD OF SETTING PRESET BUTTONS.....145

MANUAL TUNING.....146

AUTOMATIC TUNING.....146

SETTING CORRECT TIME.....146

PRECAUTION OF USE.....147

POWER PICK-UP PORT.....147

HANDLING AIR CONDITIONER.....148

GENERAL LOCATIONS OF CONTROL PANEL.....148

METHOD OF OPERATION.....152

PRECAUTIONS WHEN USING AIR CONDITIONER.....159

CHECK, MAINTAIN MACHINE EQUIPPED WITH AIR CONDITIONER.....160

OTHER FUNCTIONS.....160

FUSIBLE LINK.....161

CONTROLLER.....161

TOOL BOX.....162

REFUELLING PUMP.....162

WARNING LAMPS.....163

HANDLING ACCUMULATORS.....164

OPERATION.....165

CHECK BEFORE STARTING ENGINE.....165

WALK-AROUND CHECK.....165

CHECK BEFORE STARTING.....167

ADJUSTMENT BEFORE OPERATION OPERATORS SEAT (AIR SUSPENSION SEAT).....172

SEAT BELT.....174

ADJUSTMENT BEFORE OPERATION OPERATORS SEAT (MECHANICAL SEAT).....174

SEAT BELT.....175

OPERATIONS AND CHECKS BEFORE STARTING ENGINE.....176

STARTING ENGINE.....178

NORMAL STARTING.....178

STARTING IN COLD WEATHER.....179

OPERATIONS AND CHECKS AFTER STARTING ENGINE.....181

WARMING UP OPERATION.....181

IN COLD AREAS (AUTOMATIC WARMING-UP OPERATION).....184

MOVING MACHINE OFF.....187

MOVING MACHINE FORWARD.....187

STEERING.....190

TRAVELLING ON PUBLIC HIGHWAY.....191

STOPPING & PARKING.....192

STOPPING MACHINE (EMERGENCY).....193

SWINGING (Slewing the upper carriage).....194

OPERATION OF WORK EQUIPMENT.....195

WORKING MODE SELECTION.....197

PROHIBITIONS FOR OPERATION.....199

PRECAUTIONS FOR OPERATION.....200

PRECAUTIONS WHEN TRAVELLING UP OR DOWN HILLS.....201

HOW TO ESCAPE FROM MUD.....202

WHEN ONE SIDE IS STUCK.....202

WHEN BOTH SIDES ARE STUCK.....202

WORK POSSIBLE USING HYDRAULIC EXCAVATOR.....203

BACKHOE WORK.....203

SHOVEL WORK.....203

DITCHING WORK.....203

LOADING WORK.....204

LEVELLING WORK.....204

REPLACEMENT AND INVERSION OF BUCKET.....204

REPLACEMENT.....204

INVERSION.....205

STOPPING ENGINE.....206

CHECK AFTER FINISHING WORK.....206

CHECK AFTER STOPPING ENGINE.....207

LOCKING.....207

HANDLING THE WHEELS.....207

TRANSPORTATION.....211

LOADING, UNLOADING WORK.....211

PRECAUTIONS FOR LOADING.....213

HOW TO LIFT THE MACHINE.....214

PRECAUTIONS FOR TRANSPORTATION.....215

TRAVELLING POSTURE.....216

COLD WEATHER OPERATION.....217

PRECAUTIONS FOR LOW TEMPERATURE.....217

FUEL AND LUBRICANTS.....217

BATTERY.....218

PRECAUTIONS AFTER COMPLETION OF WORK.....219

AFTER COLD WEATHER.....219

LONG-TERM STORAGE.....220

BEFORE STORAGE.....220

DURING STORAGE.....220

AFTER STORAGE.....221

STARTING MACHINE AFTER LONG-TERM STORAGE.....221

TROUBLESHOOTING.....222

PHENOMENA THAT ARE NOT FAILURES.....222

METHOD OF TOWING MACHINE.....223

PRECAUTIONS ON PARTICULAR JOBSITES.....223

DISCHARGED BATTERY.....224

REMOVAL AND INSTALLATION OF BATTERY.....224

BATTERY CHARGES.....225

STARTING ENGINE WITH BOOSTER CABLES.....226

OTHER TROUBLE.....228

ELECTRICAL SYSTEM.....228

CHASSIS.....229

ENGINE.....230

ELECTRONIC CONTROL SYSTEM.....232

MAINTENANCE.....234

GUIDES TO MAINTENANCE.....235

OUTLINE OF SERVICE.....238

USE OF BIO-DEGRADEABLE OIL.....238

Filter changes.....238

Oil changes.....238

OUTLINE OF OIL, FUEL, COOLANT.....239

OIL.....239

FUEL.....239

COOLANT.....240

GREASE.....240

CARRYING OUT KOWA (Komatsu Oil Wear Analysis).....240

STORING OIL AND FUEL.....241

FILTERS.....242

OUTLINE OF ELECTRIC SYSTEM.....242

OUTLINE OF HYDRAULIC SYSTEM.....243

WEAR PARTS LIST.....244

USE FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE.....245

PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS.....245

USE FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE CONT.....247

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS.....249

INTRODUCTION OF NECESSARY TOOLS.....249

TIGHTENING TORQUE SPECIFICATIONS.....250

TIGHTENING TORQUE LIST.....250

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS.....252

SAFETY CRITICAL PARTS.....253

MAINTENANCE SCHEDULE CHART.....254

KEY TO LUBRICATION POINTS.....258

SERVICE PROCEDURE.....260

INITIAL 250 HOURS SERVICE.....260

WHEN REQUIRED.....261

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT.....261

CLEAN INSIDE OF COOLING SYSTEM.....266

CLEAN INSIDE OF COOLING SYSTEM.....267

CHECKING COOLANT LEVEL.....269

DRAINING THE SYSTEM.....269

CLEANING THE SYSTEM.....270

FILLING THE SYSTEM.....270

REFILLING AN OVERHEATED SYSTEM.....270

CLEANING THE RADIATOR.....271

THERMOSTAT.....271

FAN.....271

CHECK AND TIGHTEN WHEEL NUTS.....272

CHECK ELECTRICAL INTAKE AIR HEATER.....272

CHECK ALTERNATOR.....272

CHECK START MOTOR.....273

REPLACE BUCKET SIDE CUTTERS.....273

REPLACE BUCKET TEETH.....274

REPLACE BUCKET TEETH (VERTICAL PIN TYPE).....274

REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE).....277

ADJUST BUCKET CLEARANCE.....278

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID.....279

CHECK AND ADJUST AIR CONDITIONER.....280

CHECK LEVEL OF REFRIGERANT (GAS).....280

DRAIN ENGINE BREATHER OIL CATCHER.....281

CHECK BEFORE STARTING.....282

CHECK COOLANT LEVEL, ADD WATER.....282

CHECK OIL LEVEL IN ENGINE OIL PAN, ADD OIL.....282

CHECK FUEL LEVEL, ADD FUEL.....283

CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL.....284

CHECK AIR CLEANER FOR CLOGGING.....284

CHECK ELECTRIC WIRING.....285

CHECK FOR WATER AND SEDIMENT IN SEDIMENTOR. DRAIN WATER AND SEDIMENT.....285

CHECK FOR WATER IN PRIMARY FUEL FILTER, DRAIN WATER.....286

EVERY 50 HOURS.....286

DRAIN WATER AND SEDIMENT FROM FUEL TANK.....286

EVERY 100 HOURS SERVICE.....286

LUBRICATING.....286

CLEANING FRESH AIR FILTER.....291

EVERY 250 HOURS MAINTENANCE.....292

CHECK OIL LEVEL IN MACHINERY CASE, ADD OIL.....292

CHECK OIL LEVEL IN WHEEL HUBS, ADD OIL (Front Axle).....292

CHECK OIL LEVEL IN WHEEL HUBS, ADD OIL (Rear Axle).....293

CHECK OIL LEVEL IN AXLES, ADD OIL.....293

CHECK OIL LEVEL IN TRANSMISSION, ADD OIL.....294

CHECK LEVEL OF BATTERY ELECTROLYTE.....294

BELTS, GENERAL.....295

CHECK FAN BELT TENSION, ADJUST TENSION.....295

CHECK, ADJUST TENSION OF AIR CONDITIONER COMPRESSOR BELT.....296

EVERY 500 HOURS SERVICE.....297

LUBRICATE SWING CIRCLE (2 POINTS).....297

REPLACE FUEL FILTER CARTRIDGE.....298

CHECK SWING PINION GREASE LEVEL, ADD GREASE.....299

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE.....300

CLEAN AND INSPECT RADIATOR FINS, OIL COOLER FINS AND CONDENSER FINS.....301

CLEAN INTERNAL AND EXTERNAL AIR FILTERS OF AIR CONDITIONER SYSTEM.....302

CLEANING RECIRCULATED AIR FILTER.....303

REPLACE HYDRAULIC TANK BREATHER ELEMENT.....304

EVERY 1000 HOURS SERVICE.....305

REPLACE HYDRAULIC FILTER ELEMENT.....305

CHANGE OIL IN SWING MACHINERY CASE.....306

CHECK ALL TIGHTENING PARTS OF TURBOCHARGER.....306

CHECK PLAY OF TURBOCHARGER ROTOR.....307

CHECK & ADJUST VALVE CLEARANCE.....307

CHECK FAN BELT TENSIONER BEARING BELT AND FAN HUB.....307

CHECK FAN BELT TENSION.....307

CHANGE OIL IN AXLES.....307

CHANGE OIL IN HUBS.....308

CHANGE OIL IN TRANSMISSION ASSEMBLY.....310

EVERY 2000 HOURS SERVICE.....311

CLEAN HYDRAULIC TANK STRAINER.....311

CLEAN, CHECK TURBOCHARGER.....311

CHECK ALTERNATOR, STARTING MOTOR.....311

CHECK VIBRATION DAMPER.....311

CHANGE ANTIFREEZE.....311

CHECK AND ADJUST VALVE CLEARANCE.....312

EVERY 4000 HOURS SERVICE.....312

CHECK WATER PUMP.....312

EVERY 5000 HOURS SERVICE.....313

CHANGE OIL IN HYDRAULIC TANK.....313

SPECIFICATIONS.....316

SPECIFICATIONS.....317

1 - PIECE BOOM.....318

2 - PIECE BOOM.....320

WORKING RANGE: ONE PIECE BOOM.....322

WORKING RANGE: TWO PIECE BOOM.....323

OPTIONS, ATTACHMENTS.....324

GENERAL PRECAUTIONS.....325

PRECAUTIONS RELATED TO SAFETY.....325

PRECAUTIONS WHEN INSTALLING ATTACHMENTS.....326

HANDLING BUCKET WITH HOOK.....328

CHECKING FOR DAMAGE TO BUCKET WITH HOOK.....328

PROHIBITED OPERATIONS.....328

PRECAUTIONS DURING OPERATIONS.....328

MACHINES READY FOR ATTACHMENTS.....329

GENERAL LOCATIONS.....329

HANDLING THE CLAMSHELL BUCKET.....331

How to install clamshell bucket.....331

HOW TO OPERATE.....332

OPERATION.....332

WHEN USING BREAKER.....333

METHOD FOR RELEASING PRESSURE IN CONTROL CIRCUIT OF MACHINES EQUIPPED WITH ACCUMULATOR.....334

LONG-TERM STORAGE.....334

SPECIFICATIONS.....334

INTRODUCTION OF ATTACHMENTS AND EXTENDING MACHINE SERVICE LIFE.....335

HYDRAULIC BREAKER.....335

POWER RIPPER.....338

FORK GRAB.....339

GRAPPLE BUCKET.....340

SCRAP GRAPPLE.....341

CRUSHER & SMASHER.....343

HYDRAULIC PILE DRIVER.....344

HYDRAULIC EXCAVATOR WITH MULTIPURPOSE CRANE.....345

GENERAL VIEW OF CONTROLS.....347

LEFT CONTROL LEVER (with auto-deceleration device).....348

RIGHT CONTROL LEVER (with auto-deceleration device).....348

UPPER BOOM CONTROL PEDAL.....349

EXCAVATORS WORK.....349

REPLACEMENT OF BUCKET.....351

HANDLING THE TRAPEZOIDAL BUCKET (If equipped).....352

UEAM003700 - Wheeled Excavator PW200-7K, PW220-7K Operation & Maintenance Manual.....358

FOREWORD.....360

SAFETY INFORMATION.....361

SAFETY MESSAGES.....361

NOISE.....362

VIBRATION.....362

EMERGENCY STEERING.....363

INTRODUCTION.....364

INTENDED USE.....364

FEATURES.....364

BREAKING IN YOUR NEW MACHINE.....365

LOCATIONS OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR.....366

MACHINE SERIAL NO. PLATE POSITION.....366

ENGINE SERIAL NO. PLATE POSITION.....366

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR.....366

MACHINE SERIAL PLATES.....367

STANDARD SERIAL PLATE.....367

GERMANY SERIAL PLATE.....367

ITALIAN SERIAL PLATE.....368

SAFETY.....376

GENERAL PRECAUTIONS.....377

PRECAUTION DURING OPERATION.....383

BEFORE STARTING ENGINE.....383

OPERATING MACHINE.....384

TRANSPORTATION.....390

BATTERY.....391

TOWING.....392

BUCKET WITH HOOK OR BUCKET LINK WITH LIFTING EYE.....393

GENERAL PRECAUTIONS.....393

PRECAUTIONS FOR LIFTING OPERATION.....394

PRECAUTIONS FOR MAINTENANCE.....396

BEFORE CARRYING OUT MAINTENANCE.....396

DURING MAINTENANCE.....399

POSITION FOR ATTACHING SAFETY LABELS.....402

POSITION FOR ATTACHING SAFETY LABELS.....402

LIFTING CAPACITY CHART PW200-7K.....410

ONE PIECE BOOM Lift capacity tables for 2.5 metre undercarriage.....410

ONE PIECE BOOM Lift capacity tables for 2.75 metre undercarriage.....417

TWO PIECE BOOM Lift capacity tables for 2.5 metre undercarriage.....424

TWO PIECE BOOM Lift capacity tables for 2.75 metre undercarriage.....431

LIFTING CAPACITY CHART PW220-7K.....438

ONE PIECE BOOM Lift capacity tables for 2.75 metre undercarriage and heavy duty counterweight.....438

ONE PIECE BOOM Lift capacity tables for 2.75 metre undercarriage.....445

TWO PIECE BOOM Lift capacity tables for 2.75 metre undercarriage and heavy duty counterweight.....452

TWO PIECE BOOM Lift capacity tables for 2.75 metre undercarriage.....459

OPERATION.....468

GENERAL VIEW.....469

GENERAL VIEW OF MACHINE.....469

GENERAL VIEW OF CONTROLS AND GAUGES.....470

EXPLANATION OF COMPONENTS.....471

1. MACHINE MONITOR.....471

BASIC OPERATION OF MACHINE MONITOR.....472

BASIC CHECK ITEMS.....474

CAUTION ITEMS.....476

EMERGENCY STOP ITEMS.....480

METER DISPLAY PORTION.....483

METERS.....485

MONITOR SWITCHES.....488

SWITCHES.....503

CONTROL LEVERS, PEDALS.....511

FRONT WINDOW.....516

EMERGENCY EXIT FROM OPERATOR'S CAB.....520

DOOR LOCK.....521

CAP, COVER WITH LOCK.....522

METHOD OF OPENING AND CLOSING CAP WITH LOCK (For the fuel tank filler port).....522

METHOD OF OPENING AND CLOSING COVER WITH LOCK (cover with lock).....522

FUSE.....523

LUGGAGE TRAY.....524

ASHTRAY.....524

CUP HOLDER.....524

HOT AND COOL BOX.....524

CAB RADIO.....525

PRECAUTION OF USE.....525

POWER PICK-UP PORT.....525

HANDLING AIR CONDITIONER.....526

GENERAL LOCATIONS OF CONTROL PANEL.....526

METHOD OF OPERATION.....530

PRECAUTIONS WHEN USING AIR CONDITIONER.....537

CHECK, MAINTAIN MACHINE EQUIPPED WITH AIR CONDITIONER.....538

OTHER FUNCTIONS.....538

FUSIBLE LINK.....539

CONTROLLER.....539

TOOL BOX.....540

REFUELLING PUMP.....540

SAFETY.....540

PROCEDURE.....540

MAINTENANCE.....541

WARNING LAMPS.....542

HANDLING ACCUMULATORS.....543

OPERATION.....544

CHECK BEFORE STARTING ENGINE.....544

WALK-AROUND CHECK.....544

CHECK BEFORE STARTING.....546

ADJUSTMENT BEFORE OPERATION OPERATORS SEAT (AIR SUSPENSION SEAT).....551

SEAT BELT.....553

ADJUSTMENT BEFORE OPERATION OPERATORS SEAT (MECHANICAL SEAT).....554

SEAT BELT.....555

OPERATIONS AND CHECKS BEFORE STARTING ENGINE.....556

STARTING ENGINE.....558

NORMAL STARTING.....558

STARTING IN COLD WEATHER.....559

OPERATIONS AND CHECKS AFTER STARTING ENGINE.....561

WARMING UP OPERATION.....561

IN COLD AREAS (AUTOMATIC WARMING-UP OPERATION).....564

MOVING MACHINE OFF.....567

MOVING MACHINE FORWARD.....567

STEERING.....570

TRAVELLING ON PUBLIC HIGHWAY.....571

STOPPING & PARKING.....572

STOPPING MACHINE (EMERGENCY).....573

SWINGING (Slewing the upper carriage).....574

OPERATION OF WORK EQUIPMENT.....575

WORKING MODE SELECTION.....578

PROHIBITIONS FOR OPERATION.....579

PRECAUTIONS FOR OPERATION.....580

PRECAUTIONS WHEN TRAVELLING UP OR DOWN HILLS.....582

HOW TO ESCAPE FROM MUD.....583

WHEN ONE SIDE IS STUCK.....583

WHEN BOTH SIDES ARE STUCK.....583

WORK POSSIBLE USING HYDRAULIC EXCAVATOR.....583

BACKHOE WORK.....583

SHOVEL WORK.....584

DITCHING WORK.....584

LOADING WORK.....584

LEVELLING WORK.....584

REPLACEMENT AND INVERSION OF BUCKET.....585

REPLACEMENT.....585

INVERSION.....585

STOPPING ENGINE.....587

CHECK AFTER FINISHING WORK.....587

CHECK AFTER STOPPING ENGINE.....588

LOCKING.....588

OVERLOAD WARNING DEVICE.....588

HANDLING THE WHEELS.....588

TRANSPORTATION.....592

LOADING, UNLOADING WORK.....592

PRECAUTIONS FOR LOADING.....594

HOW TO LIFT THE MACHINE.....595

PRECAUTIONS FOR TRANSPORTATION.....596

TRAVELLING POSTURE.....597

COLD WEATHER OPERATION.....598

PRECAUTIONS FOR LOW TEMPERATURE.....598

FUEL AND LUBRICANTS.....598

BATTERY.....599

PRECAUTIONS AFTER COMPLETION OF WORK.....600

AFTER COLD WEATHER.....600

LONG-TERM STORAGE.....601

BEFORE STORAGE.....601

DURING STORAGE.....601

AFTER STORAGE.....602

STARTING MACHINE AFTER LONG-TERM STORAGE.....602

TROUBLESHOOTING.....603

PHENOMENA THAT ARE NOT FAILURES.....603

METHOD OF TOWING MACHINE.....604

PRECAUTIONS ON PARTICULAR JOBSITES.....604

DISCHARGED BATTERY.....605

REMOVAL AND INSTALLATION OF BATTERY.....605

BATTERY CHARGES.....606

STARTING ENGINE WITH BOOSTER CABLES.....607

OTHER TROUBLE.....609

ELECTRICAL SYSTEM.....609

CHASSIS.....610

ENGINE.....611

ELECTRONIC CONTROL SYSTEM.....613

MAINTENANCE.....614

GUIDES TO MAINTENANCE.....615

OUTLINE OF SERVICE.....618

USE OF BIO-DEGRADEABLE OIL.....618

Filter changes.....618

Oil changes.....618

If an abnormality is found in the characteristics of the oil, change the oil immediately.....618

OUTLINE OF OIL, FUEL, COOLANT.....619

OIL.....619

FUEL.....619

COOLANT.....620

GREASE.....620

CARRYING OUT KOWA (Komatsu Oil Wear Analysis).....620

STORING OIL AND FUEL.....621

FILTERS.....622

OUTLINE OF ELECTRIC SYSTEM.....623

OUTLINE OF HYDRAULIC SYSTEM.....623

WEAR PARTS LIST.....625

USE FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE.....626

PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS.....626

USE FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE CONT.....628

STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS.....630

INTRODUCTION OF NECESSARY TOOLS.....630

TIGHTENING TORQUE SPECIFICATIONS.....631

TIGHTENING TORQUE LIST.....631

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS.....632

SAFETY CRITICAL PARTS.....633

MAINTENANCE SCHEDULE CHART.....634

KEY TO LUBRICATION POINTS.....638

SERVICE PROCEDURE.....640

INITIAL 250 HOURS SERVICE.....640

WHEN REQUIRED.....641

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT.....641

CLEAN INSIDE OF COOLING SYSTEM.....646

CLEAN INSIDE OF COOLING SYSTEM.....647

CHECKING COOLANT LEVEL.....649

DRAINING THE SYSTEM.....649

CLEANING THE SYSTEM.....650

FILLING THE SYSTEM.....650

REFILLING AN OVERHEATED SYSTEM.....650

CLEANING THE RADIATOR.....651

THERMOSTAT.....651

FAN.....651

CHECK AND TIGHTEN WHEEL NUTS.....652

CHECK ELECTRICAL INTAKE AIR HEATER.....652

CHECK ALTERNATOR.....652

CHECK START MOTOR.....653

REPLACE BUCKET SIDE CUTTERS.....653

REPLACE BUCKET TEETH.....654

REPLACE BUCKET TEETH (VERTICAL PIN TYPE).....654

REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE).....657

ADJUST BUCKET CLEARANCE.....658

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID.....659

CHECK AND ADJUST AIR CONDITIONER.....660

CHECK LEVEL OF REFRIGERANT (GAS).....660

DRAIN ENGINE BREATHER OIL CATCHER.....661

CHECK BEFORE STARTING.....662

CHECK COOLANT LEVEL, ADD WATER.....662

CHECK OIL LEVEL IN ENGINE OIL PAN, ADD OIL.....662

CHECK FUEL LEVEL, ADD FUEL.....663

CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL.....664

CHECK AIR CLEANER FOR CLOGGING.....664

CHECK ELECTRIC WIRING.....665

CHECK FOR WATER AND SEDIMENT IN SEDIMENTOR. DRAIN WATER AND SEDIMENT.....665

CHECK FOR WATER IN PRIMARY FUEL FILTER, DRAIN WATER.....666

EVERY 50 HOURS.....666

DRAIN WATER AND SEDIMENT FROM FUEL TANK.....666

EVERY 100 HOURS SERVICE.....666

LUBRICATING.....666

CLEANING FRESH AIR FILTER.....671

EVERY 250 HOURS MAINTENANCE.....672

CHECK OIL LEVEL IN MACHINERY CASE, ADD OIL.....672

CHECK OIL LEVEL IN WHEEL HUBS, ADD OIL (Front Axle).....672

CHECK OIL LEVEL IN WHEEL HUBS, ADD OIL (Rear Axle).....673

CHECK OIL LEVEL IN AXLES, ADD OIL.....673

CHECK OIL LEVEL IN TRANSMISSION, ADD OIL.....674

CHECK LEVEL OF BATTERY ELECTROLYTE.....674

BELTS, GENERAL.....675

CHECK FAN BELT TENSION, ADJUST TENSION.....675

CHECK, ADJUST TENSION OF AIR CONDITIONER COMPRESSOR BELT.....676

EVERY 500 HOURS SERVICE.....677

LUBRICATE SWING CIRCLE (2 POINTS).....677

REPLACE FUEL FILTER CARTRIDGE.....678

CHECK SWING PINION GREASE LEVEL, ADD GREASE.....679

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE.....680

CLEAN AND INSPECT RADIATOR FINS, OIL COOLER FINS AND CONDENSER FINS.....681

CLEAN INTERNAL AND EXTERNAL AIR FILTERS OF AIR CONDITIONER SYSTEM.....682

CLEANING RECIRCULATED AIR FILTER.....683

REPLACE HYDRAULIC TANK BREATHER ELEMENT.....684

EVERY 1000 HOURS SERVICE.....685

REPLACE HYDRAULIC FILTER ELEMENT.....685

CHANGE OIL IN SWING MACHINERY CASE.....686

CHECK ALL TIGHTENING PARTS OF TURBOCHARGER.....686

CHECK PLAY OF TURBOCHARGER ROTOR.....687

CHECK & ADJUST VALVE CLEARANCE.....687

CHECK FAN BELT TENSIONER BEARING BELT AND FAN HUB.....687

CHECK FAN BELT TENSION.....687

CHANGE OIL IN AXLES.....687

CHANGE OIL IN HUBS.....688

CHANGE OIL IN TRANSMISSION ASSEMBLY.....690

EVERY 2000 HOURS SERVICE.....691

CLEAN HYDRAULIC TANK STRAINER.....691

CLEAN, CHECK TURBOCHARGER.....691

CHECK ALTERNATOR, STARTING MOTOR.....691

CHECK VIBRATION DAMPER.....691

CHANGE ANTIFREEZE.....691

CHECK AND ADJUST VALVE CLEARANCE.....692

EVERY 4000 HOURS SERVICE.....692

CHECK WATER PUMP.....692

EVERY 5000 HOURS SERVICE.....693

CHANGE OIL IN HYDRAULIC TANK.....693

SPECIFICATIONS.....696

SPECIFICATIONS.....697

1 - PIECE BOOM.....698

2 - PIECE BOOM.....700

WORKING RANGE: ONE PIECE BOOM.....702

WORKING RANGE: TWO PIECE BOOM.....703

OPTIONS, ATTACHMENTS.....704

GENERAL PRECAUTIONS.....705

PRECAUTIONS RELATED TO SAFETY.....705

PRECAUTIONS WHEN INSTALLING ATTACHMENTS.....706

HANDLING BUCKET WITH HOOK.....708

CHECKING FOR DAMAGE TO BUCKET WITH HOOK.....708

PROHIBITED OPERATIONS.....708

PRECAUTIONS DURING OPERATIONS.....708

MACHINES READY FOR ATTACHMENTS.....709

GENERAL LOCATIONS.....709

HANDLING THE CLAMSHELL BUCKET.....711

How to install clamshell bucket.....711

HOW TO OPERATE.....712

OPERATION.....712

WHEN USING BREAKER.....713

METHOD FOR RELEASING PRESSURE IN CONTROL CIRCUIT OF MACHINES EQUIPPED WITH ACCUMULATOR.....714

LONG-TERM STORAGE.....714

SPECIFICATIONS.....714

INTRODUCTION OF ATTACHMENTS AND EXTENDING MACHINE SERVICE LIFE.....715

HYDRAULIC BREAKER.....715

POWER RIPPER.....718

FORK GRAB.....719

GRAPPLE BUCKET.....720

SCRAP GRAPPLE.....721

CRUSHER & SMASHER.....723

HYDRAULIC PILE DRIVER.....724

HYDRAULIC EXCAVATOR WITH MULTIPURPOSE CRANE.....725

GENERAL VIEW OF CONTROLS.....727

LEFT CONTROL LEVER (with auto-deceleration device).....728

RIGHT CONTROL LEVER (with auto-deceleration device).....728

UPPER BOOM CONTROL PEDAL.....729

EXCAVATORS WORK.....729

REPLACEMENT OF BUCKET.....731

HANDLING THE TRAPEZOIDAL BUCKET (If equipped).....732

UEBM001901 - Wheeled Excavator PW200-7K, PW220-7K Shop Manual.....738

PW200-7K.....738

PW220-7K.....738

K40001 AND UP.....738

K40001 AND UP.....738

01.pdf.....0

DIMENSIONS.....749

2 PIECE BOOM.....749

WORKING RANGES.....751

1 PIECE BOOM.....751

2 PIECE BOOM.....752

SPECIFICATION DIMENSION DRAWINGS.....747

DIMENSIONS.....747

1 pIECE BOOM.....747

SPECIFICATIONS.....753

PW200-7, PW220-7.....753

WEIGHT TABLE.....755

pW200-7, pW220-7.....755

1 piece boom.....756

2 piece boom.....757

FUEL, COOLANT AND LUBRICANTS.....758

10.pdf.....0

ENGINE RELATED PARTS.....761

RADIATOR OIL COOLER charge air cooler.....762

POWER TRAIN.....763

SWING CIRCLE.....765

SWING MACHINERY & motor.....767

SWING MOTOR.....771

Operation of swing lock.....774

RELIEF VALVE PORTION.....775

Operation.....775

UNDERCARRIAGE.....777

TRANSMISSION.....779

TRAVEL MOTOR.....782

oPERATION OF TRAVEL MOTOR.....784

CLUTCH CONTROL CIRCUIT.....786

AXLE.....788

sUSPENSION LOCK CYLINDER.....792

Braking System.....794

brake/steer pump.....796

PRIORITY VALVE.....797

Power brake valve.....798

ACCUMULATOR for brake system.....799

STEERING TRAIN.....800

STEERING COLUMN.....801

ORBITROL VALVE.....802

hydraulic equipment layout drawingS.....804

hydraulic CIRCUIT dIAgRAM.....806

HYDRAULIC TANK.....807

HYDRAULIC PUMP.....808

HPV95 + 95 (PW200-7K).....808

LS VALVE.....813

PC VALVE.....813

LS valve.....815

PC Valve.....819

PILOT PRESSURE CONTROL (PPC) SYSTEM.....825

CONTROL VALVE.....826

PW200 -220-7K.....826

CLSS.....839

OUTLINE OF CLSS.....839

CENTre SWIVEL JOINT.....840

travel ppc pedal.....841

WORK EQUIPMENT SWING PPC VALVE.....844

SERVICE PPC VALVE.....849

SOLENOID VALVE.....853

Travel-boom-stabiliser solenoid valve.....855

LS(pc)-EPC VALVE.....856

attachment epc valve.....860

Boom safety valve.....863

HYDRAULIC CYLINDER.....865

pw200-7, pw220-7.....865

BOOM CYLINDER.....865

ARM CYLINDER.....865

BUCKET CYLINDER.....865

ADJUST CYLINDER.....866

Outrigger CYLINDER.....867

dozer CYLINDER.....869

work equipment.....871

Pw200/220-7.....872

Work Equipment.....872

1. DIMENSION OF ARM.....873

2. Dimension of bucket.....875

air conditioner.....877

air conditioner piping.....877

electrical wiring diagram.....878

engine control system.....879

Governor motor.....882

Engine throttle and pump controller.....884

ELECTRONIC CONTROL SYSTEM.....886

machine control system diagram.....887

This page left intentionally blank.....910

machine MONITOR SYSTEM.....911

Monitor panel.....912

Overload warning device.....932

OUTLINE.....932

SENSOR.....933

1st attachment circuit hydraulic performance (main valve bypassed).....937

1st attachment circuit hydraulic performance (VIA main valve).....939

travel system.....941

TRAVEL CIRCUIT.....941

oPERATIONAL AND CONTROL FEATURES.....942

SteeRING system.....961

Operating principles.....961

SERVICE BRAKE AND SUSPENSION SYSTEM.....971

bRAKING SYSTEM.....971

operation.....975

20_101.pdf.....0

INSPECTION AND ADJUSTMENT OF ENGINE RPM.....995

MEASUREMENT OF EXHAUST GAS COLOR.....997

ADJUSTMENT OF VALVE CLEARANCE.....999

3MEASUREMENT OF COMPRESSION PRESSURE.....1001

MEASUREMENT OF BLOW-BY PRESSURE.....1002

INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING.....1003

MEASUREMENT OF ENGINE OIL PRESSURE.....1005

EMERGENcy sEtting iF FAILURE occurs IN ENGINE CONTROL SYSTEM.....1007

MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS.....1008

INSPECTION AND ADJUSTMENT OF HYDRAULIC OIL PRESSURE IN HYDRAULIC CIRCUIT FOR WORK EQUIPMENT, SWIN......1009

INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE.....1013

INSPECTION AND ADJUSTMENT OF PUMP PC (Valve INLET) CONTROL OIL PRESSURE(PW200/220).....1015

INSPECTION AND ADJUSTMENT OF PUMP LS valve CONTROL OIL PRESSURE(pW200/220).....1018

MEASUREMENT OF SOLENOID VALVE OUTPUT PRESSURE.....1022

7 - Stage solenoid block.....1024

4 - Stage solenoid block.....1026

2 - Stage solenoid block.....1027

MEASUREMENT OF PPC VALVE OUTPUT PRESSURE.....1028

ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE.....1030

testing travel motor relief pressure.....1031

adjusting travel motor relief pressure.....1032

Testing propshaft speed.....1033

tESTING TRANSMISSION CLUTCH CONTROL CIRCUIT.....1034

INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT.....1036

MEASUREMENT OF OIL LEAKAGE AMOUNT.....1038

AIR BLEEDING OF VARIOUS PARTS.....1040

INSPECTION PROCEDURES FOR DIODE.....1042

SPECIAL FUNCTION OF MONITOR PANEL.....1043

Operation of Operator's Menu and Display (Outline).....1045

Table for Service and Failure Code Nos.....1051

Operation and Display of Service Menu.....1054

Way of switching to Service Menu.....1054

PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM.....1069

20_201.pdf.....0

TROUBLESHOOTING.....1070

POINTS TO REMEMBER WHEN TROUBLESHOOTING.....1071

SEQUENCE OF EVENTS IN TROUBLESHOOTING.....1072

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE.....1073

CHECKS BEFORE TROUBLESHOOTING.....1081

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING.....1082

Classification of troubleshooting.....1082

Steps for troubleshooting.....1082

Failure-looking Phenomenon and Troubleshooting No.....1083

CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM.....1087

CONNECTOR LOCATION STEREOGRAM.....1093

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS.....1101

20_301.pdf.....0

TROUBLESHOOTING WHEN SERVICE CODE "ELECTRICAL SYSTEM" AND FAILURE CODE "MECHANICAL SYSTEM" ARE IN......1130

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE.....1122

Service Code in Electrical System (Abnormal data in Error History).....1118

Service Code in Electrical System (Disconnection of S-NET signal).....1137

Service Code in Electrical System (Short-circuiting in Travel Neutral Solenoid).....1139

Service Code in Electrical System (Short-circuiting of Travel F/R solenoid).....1141

Service Code in Electrical System (Short-circuiting in Merge/Divide solenoid).....1143

Service Code in Electrical System (Short-circuiting in 2-Stage Relief solenoid).....1145

Service Code in Electrical System (Short-circuiting in Transmission Clutch solenoid).....1147

Service Code in Electrical System (Short-circuiting in Creep solenoid).....1149

Service Code in Electrical System (Disconnection in Creep solenoid).....1151

Service Code in Electrical System (Disconnection in Travel Neutral solenoid).....1153

Service Code in Electrical System (Disconnection of Travel F/R solenoid).....1155

Service Code in Electrical System (Disconnection in Swing Parking Brake solenoid).....1157

Service Code in Electrical System (Disconnection of Merge/Divide solenoid).....1159

Service Code in Electrical System (Disconnection in 2-stage Relief solenoid).....1161

Service Code in Electrical System (Disconnection in Transmission Clutch solenoid).....1163

Service Code in Electrical System (Abnormality in inputting model code).....1115

Service Code in Electrical System (Abnormality in inputting model code).....1167

Service Code in Electrical System Disconnection of S-NET signal).....1067

Service Code in Electrical System (Short-circuiting in LS-EPC solenoid).....1171

Service Code in Electrical System (Disconnection in LS-EPC solenoid system).....1172

Service Code in Electrical System (Abnormality in F pump pressure sensor).....1173

Service Code in Electrical System (Abnormality in R pump pressure sensor).....1175

Service Code in Electrical System (Abnormality in Pressure sensor power source).....1177

Service Code in Electrical System (Abnormality in engine rotation sensor in governor pump contr......1179

Service Code in Electrical System (Short-circuiting in PC-EPC solenoid).....1181

Service Code in Electrical System (Disconnection in PC-EPC solenoid system).....1183

Service Code in Electrical System (Short circuiting in 2-stage back pressure solenoid).....1185

Service Code in Electrical System (Disconnection in 2-stage Back Pressure solenoid).....1187

Service Code in Electrical Equipment (Short-circuiting in attachment oil flow rate adjusting EPC).....1189

Service Code in Electrical System (Disconnection in attachment oil flow rate adjusting EPC).....1190

Service Code in Electrical System (Abnormality in travel PPC switch).....1191

Service Code In Electrical System (Abnormality in overload caution sensor).....1193

Service Code in Electrical System (Abnormality in travel PPC sensor).....1195

Service Code in Electrical System (Disconnection in engine rotation sensor in governor pump con......1197

Service Code in Electrical System (Incorrect nonvolatile memory data).....1199

Service Code in Electrical System (Abnormality in governor potentiometer).....1201

Service Code in Electrical System (Abnormality in fuel dial).....1203

Service Code in Electrical System (Short-circuiting in battery relay).....1205

Service Code in Electrical System (Step-out in governor motor).....1207

Service Code in Electrical System (Disconnection in governor motor Phase A and B).....1209

Service Code in Electrical System (Short-circuiting in governor motor Phase A and Phase B).....1092

Service Code in Electrical System ("Model Selection" function not provided yet).....1213

Service Mode in Electrical System (Model selecting signal fault).....1214

Failure Code in Mechanical System (Out-of-rate engine rotation at high idling).....1215

Failure Code in Mechanical System A000N2 (Out-of-rate engine rotation at low idling).....1215

Failure Code in Mechanical System (Air cleaner clogging).....1216

Failure Code in Mechanical System (Abnormally lowered charging voltage).....1217

Failure Code in Mechanical System (Abnormally lowered engine oil pressure).....1219

Failure Code in Mechanical System (Abnormally lowered engine oil level).....1220

Failure Code in Mechanical System (Engine cooling water overheating).....1221

Failure Code in Mechanical System (Abnormally lowered radiator water level).....1222

Failure Code in Mechanical System (Hydraulic oil overheating).....1223

20_701.pdf.....0

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H-MODE).....1130

SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS.....1361

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE.....1365

H-1 All work equipment lacks power, or travel and swing speeds are slow.....1366

H-2 Engine speed sharply drops or engine stalls.....1367

H-3 No work equipment, travel or swing move.....1368

H-4 Abnormal noise is heard from around hydraulic pump.....1368

H-5 Auto-decelerator does not work.....1369

H-6 Fine control mode does not function.....1369

H-7 Boom moves slowly or lacks power.....1370

H-8 Arm moves slowly or lacks power.....1371

H-9 Bucket moves slowly or lacks power.....1372

H-10 Work equipment does not move in its single operation.....1372

H-11 Work equipment hydraulic drift is too fast.....1373

H-12 Work equipment has big time lag.....1374

H-13 Other work equipment moves when relieving single circuit.....1374

H-14 One-touch power max. switch does not operate.....1374

H-15 In compound operation, work equipment with larger load moves slowly.....1375

H-16 In swing + boom RAISE operation, boom moves slowly.....1375

H-17 In swing + travel, travel speed drops sharply.....1375

H-18 Travel speed does not switch.....1376

H-19 Travel speed does not shift, or it is too slow or fast.....1377

H-20 Machine does not swing.....1378

H-21 Swing acceleration is poor, or swing speed is slow.....1379

H-22 Excessive overrun when stopping swing.....1380

H-23 There is big shock when stopping swing.....1381

H-24 There is loud abnormal noise caused when stopping swing.....1381

H-25 Swing natural drift is too big.....1382

H-26 Swing speed is faster than specified swing speed.....1111

Sec 30.pdf.....0

HOW TO READ THIS MANUAL.....1386

REMOVAL AND INSTALLATION OF ASSEMBLIES.....1386

DisassemblY and assemblY OF assemblIES.....1387

SPECIAL TOOLS.....1388

SKETCHES.....1388

LIST OF TOOLS.....1389

PRECAUTIONS WHEN PERFORMING OPERATION.....1390

GOVERNOR MOTOR ASSEMBLY.....1392

REMOVAL.....1392

INSTALLATION OF GOVERNOR MOTOR ASSEMBLY.....1392

STARTING MOTOR ASSEMBLY.....1393

REMOVAL.....1393

INSTALLATION.....1393

FUEL INJECTION PUMP ASSEMBLY.....1394

ENGINE FRONT SEAL.....1398

ENGINE REAR SEAL.....1400

CYLINDER HEAD ASSEMBLY.....1402

COMBINATION COOLER.....1408

ENGINE AND HYDRAULIC PUMP ASSEMBLIES.....1411

TRANSMISSION AND TRAVEL MOTOR ASSEMBLY.....1416

TRANSMISSION ASSEMBLY.....1418

TRAVEL MOTOR ASSEMBLY.....1432

SWING MOTOR AND SWING MACHINERY ASSEMBLY.....1436

SWING MOTOR AND SWING MACHINERY ASSEMBLY.....1437

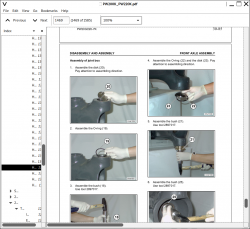

FRONT AXLE ASSEMBLY.....1444

FRONT AXLE ASSEMBLY.....1446

REAR AXLE ASSEMBLY.....1492

REAR AXLE ASSEMBLY.....1494

PROPSHAFT ASSEMBLY.....1516

WHEEL ASSEMBLY.....1517

SUSPENSION LOCK CYLINDER ASSEMBLY.....1518

SUSPENSION LOCK ASSEMBLY.....1519

OUTRIGGER ASSEMBLY.....1520

OUTRIGGER ASSEMBLY.....1521

DOZER BLADE ASSEMBLY.....1522

DOZER BLADE ASSEMBLY.....1523

SWING CIRCLE.....1524

ASSEMBLY.....1524

REVOLVING FRAME ASSEMBLY.....1525

CENTRE SWIVEL JOINT ASSEMBLY.....1528

CENTRE SWIVEL JOINT ASSEMBLY.....1531

HYDRAULIC TANK ASSEMBLY.....1533

FUEL TANK ASSEMBLY.....1536

CONTROL VALVE ASSEMBLY.....1538

LS SELECT VALVE ASSEMBLY.....1541

LS SHUTTLE VALVE ASSEMBLY.....1542

PRESSURE COMPENSATION VALVE ASSEMBLY.....1543

MAIN RELIEF VALVE ASSEMBLY.....1544

LS CONTROL EPC VALVE ASSEMBLY.....1545

L PC SOLENOID VALVE ASSEMBLY.....1546

PPC VALVE BLOCK ASSEMBLY.....1547

MANIFOLD BLOCK ASSEMBLY.....1548

OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT.....1549

WORK EQUIPMENT PPC VALVE ASSEMBLY.....1550

TRAVEL PEDAL VALVE ASSEMBLY.....1551

HYDRAULIC CYLINDER ASSEMBLY.....1552

MONOBOOM WORK EQUIPMENT ASSEMBLY.....1558

2 PIECE BOOM WORK EQUIPMENT ASSEMBLY.....1561

AIR CONDITIONER UNIT ASSEMBLY.....1564

COUNTERWEIGHT ASSEMBLY.....1567

OPERATOR CAB ASSEMBLY.....1569

MONITOR ASSEMBLY.....1572

GOVERNOR PUMP CONTROLLER ASSEMBLY.....1573

20-001.pdf.....0

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS.....979

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS.....980

Flow control characteristic of PC valve (STD).....993

20_501.pdf.....0

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E-MODE).....1224

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE.....1225

E-1 Engine does not start (Engine does not rotate).....1226

E-2 Engine stops while in operation.....1229

E-3 Engine speed is irregular, or there is hunting.....1231

E-4 Engine does not stop.....1233

E-5 Auto-decelerator does not work.....1235

E-6 Auto engine warm-up device does not work.....1379

E-7 Pre heater does not work.....1237

E-8 All work equipment, swing and travel do not move.....1239

E-9 One-touch Power Max Switch does not work.....1241

E-10 No display in monitor panel at all.....1242

E-11 Part of display on monitor panel is missing.....1243

E-12 Monitor panel displays contents irrelevant to the model.....1171

E-13 Fuel level monitor red lamp lights up while engine is running.....1244

E-14 Engine cooling water temperature gauge does not indicate correctly.....1245

E-15 Hydraulic oil temperature gauge does not display correctly.....1246

E-16 Fuel gauge does not display correctly.....1247

E-17 Swing lock monitor does not display correctly.....1249

E-18 When the monitor switch is operated, no display appears.....1251

E-19 Windshield wiper does not work.....1222

E-20 Alarming buzzer cannot be cancelled.....1255

E-21 "Boom RAISE" is not correctly displayed in monitor function.....1256

E-22 "Boom LOWER" is not correctly displayed in monitor function.....1257

E-23 "Arm DIGGING" is not correctly displayed in monitor function.....1258

E-24 "Arm DUMPING" is not correctly displayed in monitor function.....1259

E-25 "Bucket DIGGING" is not correctly displayed in monitor function.....1260

E-26 "Bucket DUMPING" is not correctly displayed in monitor function.....1261

E-27 "SWING" is not correctly displayed in monitor function.....1263

E-28 "TRAVEL" is not correctly displayed in monitor function.....1265

E-29 "Service" is not correctly displayed in monitor function.....1267

E-30 Air Conditioner does not work.....1269

E-31 Travel alarm does not sound.....1270

20-601.pdf.....0

TROUBLESHOOTING OF ELECTRICAL SYSTEM.....1272

(Error checking of items without Monitor codes).....1272

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE.....1274

Radio Cassette & Telephone Socket.....1275

PPC Circuit & Brake Light Interlock.....1574

Undercarriage Attachments - Mode Selection.....1279

Undercarriage Attachments - Front Left Outrigger.....1281

Undercarriage Attacments - Front Right Outrigger.....1283

Undercariage Attachments - Rear Left Outrigger.....1285

Undercarriage Attachments - Rear Right Outrigger.....1287

Heated Seat Does Not Warm Up.....1289

Suspension Lock.....1291

Lower Wiper Does Not Work (Optional Fitment).....1293

Work Lights (Operator Cab).....1295

Worklights (Boom & Counterweight).....1297

Beacon Light.....1299

Air Seat Compressor (Option - Air Suspension Seat).....1301

Operator Cab Interior Light.....1303

Quick Coupler.....1305

Cigar Lighter.....1307

Park Brake (Not Activating).....1309

Park Brake (Displayed Symbol).....1311

Clamshell Control - Rotate Right (1st Service).....1313

Clamshell Control - Rotate Left (1st Service).....1315

Horns.....1317

Swing Lock - Normal Operation.....1319

Swing Lock - Emergency Operation.....1321

Neutral Start (Engine).....1323

Emergency Travel Control - Forward.....1327

Emergency Travel Control - Neutral.....1329

Emergency Travel Control - Reverse.....1331

Driving Lights - Main Beam.....1335

Driving Lights - Main Beam Flash.....1338

Driving Lights - Main Beam Dipped.....1340

Driving Lights - Position Lights.....1342

Driving Lights - Parking Lights.....1346

Indicators - Right Hand.....1350

Indicators - Left Hand.....1352

Hazard Warning Lights.....1354

UEBM001900_A1_ A2.pdf.....0

hydraulic circuit diagram (1/2).....1576

PW200-7K, PW220-7K.....1576

This page left intentionally blank.....1273

hydraulic circuit diagram (2/2).....1578

PW200-7K, PW220-7K.....1578

This page left intentionally blank.....1579

electrical circuit diagram (1/3).....1580

PW200-7K, PW220-7K.....1580

This page left intentionally blank.....1581

electrical circuit diagram (2/3).....1582

This page left intentionally blank.....1583

electrical circuit diagram (3/3).....1584

This page left intentionally blank.....1585