Komatsu Wheeled Excavator PW148 Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Wheeled Excavator PW148-8, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Wheeled Excavator PW148-8 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,158 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

VEBM720100 - Wheeled Excavator PW148-8 Shop Manual.pdf

MAIN SECTIONS

VEBM720100 PW148-8.....1

CONTENTS.....3

FOREWORD.....5

Safety.....5

Important safety notice.....5

General precautions.....5

Preparations for work.....5

Precautions during work.....6

General.....7

General.....7

Structure and function.....7

Testing, adjusting and troubleshooting.....7

Disassembly and assembly.....7

Maintenance standard.....7

How to read the shop manual.....8

Volumes.....8

Distribution and updating.....8

Filing method.....8

Revised edition mark.....8

Revisions.....8

Symbols.....8

Hoisting instructions.....9

Hoisting.....9

Wire Ropes.....9

Coating materials.....10

Standard tightening torque.....12

Standard tightening torque of bolts and nuts.....12

Tightening torque of hose nuts.....13

Tightening torque of split flange bolts.....13

Tightening torques for hoses (taper seal type and face seal type).....13

Tightening torque for 107 engine series (bolts and nuts).....14

Tightening torque for 107 engine series (eye joints).....14

Tightening torque for 107 engine series (tapered screws).....14

Electric wire code.....15

Classification by thickness.....15

Classification by color and code.....15

Conversion tables.....16

Method of using the conversion table.....16

Units.....22

GENERAL.....23

Specification dimension drawings.....24

Dimensions.....24

Working ranges.....26

Working range: 1 piece boom.....26

Working range: 2 piece boom.....27

Specifications.....29

Weight table.....31

1 piece boom.....32

2 piece boom.....33

Fuel, coolant and lubricants.....34

STRUCTURE AND FUNCTION.....35

KOMTRAX terminal system.....269

Service brake and suspension system.....264

Braking system.....264

Operation.....267

Steering system.....251

Operating principles.....251

Dynamic Steering.....251

2 - stage principle.....251

1. Condition 1.....252

2. Condition 2.....253

3. Condition 3.....254

4. Condition 4.....255

5. Condition 5.....256

6. Condition 6.....257

7. OLS priority valve.....258

8. Load sensing steering unit.....259

Travel system.....231

Travel circuit.....231

1. Travel motor.....232

2. Travel pedal.....241

3. Forward / Neutral / Reverse switch (F-N-R).....242

4. Forward / Reverse travel solenoid.....243

5. Travel / neutral solenoid.....244

6. Travel creep solenoid.....245

Operational and control features.....246

Operational and Control features (1).....246

Operational and Control features (2).....246

Operational and Control features (3).....247

7. 2-Stage relief solenoid.....248

8. Transmission clutch control valve.....250

1st attachment circuit hydraulic performance (main valve bypassed).....230

Sensor.....221

Coolant temperature sensor.....222

Oil pressure switch.....222

Rotation sensor.....223

Boost pressure and temperature sensor.....223

WIF (Water-In-Fuel detection) sensor.....224

Engine oil level sensor.....224

Coolant level sensor.....225

Coolant temperature sensor.....226

Hydraulic oil temperature sensor.....226

Fuel level sensor.....226

Air cleaner clogging sensor.....227

Overload Caution sensor.....227

Swing proximity sensor.....228

Travel PPC sensor.....228

PPC pressure sensor.....228

Park brake pressure sensor.....229

Brake accumulator low pressure sensor.....229

Brake stop light sensor.....229

Overload warning device.....220

Outline.....220

Function.....220

Structure.....220

Machine monitor system.....204

Monitor panel.....205

Outline.....205

Monitor control, display portion.....208

Monitor gauge displays.....212

Keypad layout.....217

Declaration of switch function on keypad.....218

Electrical control system.....181

Machine control system diagram.....182

1. Engine and pump control function.....183

Function.....184

Function.....188

Function.....190

Function.....192

Operation.....193

Function.....194

Function.....196

Function.....198

Function.....201

Specifications.....202

Function.....202

Function.....203

Operation.....203

Electrical system.....174

Engine control.....174

1. Operation of System.....174

2. Component.....175

Engine controller.....176

Pump controller.....178

Electrical wiring diagramm.....173

Air conditioner.....172

Air conditioner piping.....172

Work equipment.....166

Work equipment.....167

1. Dimension of arm.....168

2. Dimension of bucket.....170

Dozer cylinder.....164

Function.....165

Outrigger cylinder.....162

Function.....163

Hydraulic cylinder.....160

Boom cylinder.....160

Arm cylinder.....160

Bucket cylinder.....160

Adjust cylinder.....161

Boom safety valve.....158

Operation.....159

Solenoid valve block.....146

ON / OFF Solenoid valves (3 way valve).....148

Operation.....148

ON / OFF Solenoid valves (4 way valve).....150

Operation.....150

Hi/ Lo Solenoid valve (4 way valve).....152

Operation.....152

Attachment PPC valve.....154

Function.....155

Operation.....155

Work equipment - Swing PPC valve.....142

Operation.....144

Travel PPC pedal.....140

Centre swivel joint.....139

CLSS.....117

Outline of CLSS.....117

Features.....117

Structure.....117

Basic Principle.....118

Operation for each function and valve.....120

Hydraulic circuit diagram and name of valves.....120

1. Unload valve.....122

Function.....122

Operation.....122

Operation.....123

Operation.....124

2. Introduction of LS pressure.....125

Work equipment valve.....125

Function.....125

Operation.....125

3. LS bypass plug.....126

Outline.....126

Operation.....126

4. Pressure compensation valve.....128

Function.....128

Operation.....129

5. Area ratio of pressure compensation valve.....130

Function.....130

6. Boom regeneration circuit.....132

Function.....132

Operation.....132

Function.....133

Operation.....133

7. Arm regeneration circuit.....134

Function.....134

Operation.....134

Function.....135

Operation.....135

8. Swing bleeding valve.....136

Function.....136

Operation (In fine control operation).....136

9. Variable type pressure compensation valve (for service).....137

Function.....137

Simultaneous operation with work equipment under heavy load (boom RAISE, etc.).....137

10. LS select valve.....138

Function.....138

Operation.....138

Control valve.....106

Outline.....106

Pilot pressure control (PPC) system.....104

Function.....105

Operation.....105

Hydraulic pump.....81

Function.....83

Structure.....83

Operation.....84

LS valve.....86

PC valve.....87

Function.....88

Operation.....90

1. LS valve.....90

2. PC valve.....94

LS(PC)-EPC valve.....101

Function.....102

Operation.....102

Hydraulic tank.....79

Specifications.....80

Hydraulic circuit diagram.....78

Hydraulic equipment layout drawings.....76

Orbitrol valve.....75

Specifications.....75

Structure and function.....75

Steering column.....74

Steering system.....73

Structure and function.....73

Accumulator for brake valve.....72

Specifications.....72

Structure ans function.....72

Power brake valve.....70

Specifications.....71

Function.....71

Priority valve.....69

Specification.....69

Function.....69

Brake/steer pump.....68

Specifications.....68

Function.....68

Braking system.....66

Structure and function.....67

Suspension lock cylinder.....64

Specifications.....64

Structure and function.....64

Circuit.....65

Axle oscillation.....65

Axle.....60

Outline.....60

Clutch control circuit.....58

Function.....59

Travel motor.....54

Function.....55

Operation of travel motor.....56

ATT EPC valve assembly.....53

Shematic.....52

Quick coupler control valve.....51

Specification.....51

Operation.....51

Transmission.....48

Specifications.....48

Function.....49

Undercarriage.....46

Swing machinery & motor.....41

Specification.....42

Operation of swing lock.....43

Relief valve portion.....44

Operation.....44

Swing circle.....40

Specifications.....40

Power train.....38

Radiator, oil cooler, aftercooler and fuel cooler.....37

Engine related parts.....36

Outline.....36

TESTING AND ADJUSTING.....271

Standard value table for engine related parts.....272

Standard value table for chassis related parts.....273

Flow control characteristic of PC valve (STD).....286

Checking fuel circuit for leakage.....308

Checking and adjusting air conditioner compressor belt tension.....309

Checking.....309

Adjusting.....309

Replacing the fan belt.....310

Measurement of clearance in swing circle bearing.....311

Inspection and adjustment of hydraulic oil pressure in hydraulic circuit for work equipment, swing and travel.....312

Measurement.....312

Adjustment.....313

Inspection and adjustment of control circuit oil pressure.....315

Measurement.....315

Procedure for pressure reducing adjustment.....316

Inspection and adjustment of pump PC (valve inlet) control oil pressure.....317

Measurement.....317

Adjustment.....319

Inspection and adjustment of pump LS valve control oil pressure.....320

Measurement.....320

Adjustment.....323

Measurement of solenoid valve output pressure.....324

Measurement of PPC valve output pressure.....329

Checking Proportional Control PPC Circuit.....330

Adjustment of work equipment and swing PPC valve.....331

TESTING AND ADJUSTING (100).....287

Measuring and adjusting quick coupler control valve output pressure.....332

Measuring engine speed.....288

Measuring intake air pressure (boost pressure).....289

Checking exhaust gas colour.....290

Adjusting valve clearance.....292

Measurement of compression pressure.....294

Measuring blow-by pressure.....296

Measuring engine oil pressure.....297

Handling fuel system parts.....298

Releasing residual pressure from fuel system.....299

Measuring fuel pressure.....300

Measuring fuel return rate and leakage.....302

Bleeding air from fuel circuit.....306

Solenoid valve block.....326

Testing travel motor relief pressure.....333

Measuring travel motor relief pressure.....333

Adjusting travel motor relief pressure.....334

Testing propshaft speed.....335

Measuring rotating speed of propshaft.....335

Testing transmission clutch control circuit.....336

Description.....336

Inspection of locations of hydraulic drift of work equipment.....338

Release of remaining pressure in hydraulic circuit.....340

Measurement of oil leakage.....341

Air bleeding of various parts.....344

Inspection procedures for diode.....347

Special function of monitor panel.....348

TESTING AND ADJUSTING (220).....403

Troubleshooting.....403

Points to remember when troubleshooting.....404

Sequence of events in troubleshooting.....405

Points to remember when carrying out maintenance.....406

1. Points to remember when handling electric equipment.....406

2. Points to remember when troubleshooting electric circuits.....412

3. Points to remember when handling hydraulic equipment.....413

Checks before troubleshooting.....415

Classification and steps for troubleshooting.....416

Classification of troubleshooting.....416

Steps for troubleshooting.....416

Failure-looking phenomenon and troubleshooting no.....417

How to read electric wire code.....420

Connector location chart and electrical circuit diagram by system.....424

Connector table for revolving frame harness.....425

Connector table for operators cab wiring harness (Part 1/2).....428

Connector table for operators cab wiring harness (Part 2/2).....430

Connector table various wiring harness (Part 1/2).....432

Connector table various wiring harness (Part 2/2).....434

Connection table for connector pin numbers.....436

T-boxes and T-adapters table.....464

TESTING AND ADJUSTING (300).....469

Troubleshooting when failure code is indicated.....469

Before carrying out troubleshooting when failure code is displayed.....472

Information contained in troubleshooting table.....473

Relative electrical circuit diagram.....474

Failure code [6B2JMA] - Travel hydraulic abnormality.....475

Failure code [989L00] - Engine controller lock caution 1.....476

Failure code [989M00] - Engine controller lock caution 2.....477

Failure code [989N00] - Engine controller lock caution 3.....478

Failure code [AA10NX] - Air cleaner clogging.....479

Failure code [AB00KE] - Charge voltage low.....480

Failure code [B@BAZG] - Eng oil press. low.....481

Failure code [B@BAZK] - Eng oil level low.....482

Failure code [B@BCNS] - Eng water overheat.....483

Failure code [B@BCZK] - Eng water level low.....484

Failure code [B@HANS] - Hydr oil overheat.....485

Failure code [CA111] - EMC critical internal failure.....486

Failure code [CA115] - Engine neutral and backup speed sensor error.....487

Failure code [CA122] - Chg air press sensor high error.....488

Circuit diagram related to boost pressure/temperature sensor (combination sensor).....489

Failure code [CA123] - Chg air press sensor low error.....490

Circuit diagram related to boost pressure/temperature sensor (combination sensor).....491

Failure code [CA131] - Throttle sensor high error.....492

Circuit diagram related to fuel control dial.....493

Failure code [CA132] - Throttle sensor low error.....494

Circuit diagram related to fuel control dial.....495

Failure code [CA144] - Coolant temp sens high error.....496

Circuit diagram related to coolant temperature sensor.....497

Failure code [CA145] - Coolant temp sens low error.....498

Circuit diagram related to coolant temperature sensor.....499

Failure code [CA153] - Chg air temp sensor high error.....500

Circuit diagram related to boost pressure/temperature sensor (combination sensor).....501

Failure code [CA154] - Chg air temp sensor low error.....502

Circuit diagram related to boost pressure/temperature sensor (combination sensor).....503

Failure code [CA155] - Chg air temp high speed derate.....504

Failure code [CA187] - Sens supply 2 volt low error.....506

Circuit diagram related to sensor power supply 2.....507

Failure code [CA221] - Ambient press sens high error.....508

Circuit diagram related to ambient pressure sensor.....509

Failure code [CA222] - Ambient press sens low error.....510

Circuit diagram related to ambient pressure sensor.....511

Failure code [CA227] - Sens supply 2 volt high error.....512

Circuit diagram related to sensor power supply 2.....512

Failure code [CA234] - Eng overspeed.....513

Failure code [CA238] - Ne speed sens supply volt error.....514

Circuit diagram related to engine Ne speed sensor.....514

Failure code [CA271] - IMV/PCV1 short error.....515

Circuit diagram related to supply pump actuator (metering unit).....515

Failure code [CA272] - IMV/PCV1 open error.....516

Circuit diagram related to supply pump actuator (metering unit).....516

Failure code [CA322] - Inj #1 (L#1) open/short error.....518

Circuit diagram related to no. 1 injector.....519

Failure code [CA324] - Inj #3 (L#3) open/short error.....520

Failure code [CA331] - Inj #2 (L#2) open/short error.....522

Circuit diagram related to no. 2 injector.....523

Failure code [CA332] - Inj #4 (L#4) open/short error.....524

Circuit diagram related to no. 4 injector.....525

Failure code [CA342] - Calibration code incompatibility.....526

Failure code [CA351] - Injectors drive circuit error.....528

Circuit diagram related to engine controller.....529

Failure code [CA352] - Sens supply 1 volt low error.....530

Circuit diagram related to sensor power supply 1.....531

Failure code [CA386] - Sens supply 1 volt high error.....532

Circuit diagram related to sensor power supply 1.....532

Failure code [CA428] - Water in fuel sensor high error.....534

Circuit diagram related to water-in-fuel sensor.....535

Failure code [CA429] - Water in fuel sensor low error.....536

Circuit diagram related to water-in-fuel sensor.....537

Failure code [CA435] - Eng oil press sw error.....538

Circuit diagram related to engine oil pressure switch.....538

Failure code [CA441] - Battery voltage low error.....539

Circuit diagram related to engine controller power supply.....541

Failure code [CA442] - Battery voltage high error.....542

Circuit diagram related to engine controller power supply.....543

Failure code [CA449] - Rail press very high error.....544

Failure code [CA451] - Rail press sensor high error.....546

Circuit diagram related to common rail pressure sensor.....547

Failure code [CA452] - Rail press sensor low error.....548

Circuit diagram related to common rail pressure sensor.....549

Failure code [CA488] - Chg air temp high torque derate.....550

Failure code [CA553] - Rail press high error.....551

Failure code [CA559] - Rail press low error.....552

Failure code [CA689] - Eng Ne speed sensor error.....554

Circuit diagram related to engine Ne speed sensor.....555

Failure code [CA731] - Eng bkup speed sens phase error.....556

Failure code [CA757] - All continuous data lost error.....558

Circuit diagram related to engine controller power supply.....559

Failure code [CA778] - Eng bkup speed sensor error.....560

Circuit diagram related to engine G speed sensor.....561

Failure code [CA1633] - KOMNET datalink timeout error.....562

Circuit diagram related to CAN communication.....563

Failure code [CA2185] - Throttle sensor supply voltage high error.....564

Circuit diagram related to fuel control dial.....564

Failure code [CA2186] - Throttle sensor supply voltage low error.....565

Circuit diagram related to fuel control dial.....565

Failure code [CA2249] - Rail press very low error.....566

Failure code [CA2311] - IMV solenoid error.....568

Circuit diagram related to supply pump actuator (metering unit).....569

Failure code [CA2555] - Grid htr relay volt high error.....570

Circuit diagram related to engine preheater/starting motor/charging system.....571

Failure code [CA2556] - Grid heater relay volt low error.....572

Circuit diagram related to engine preheater/starting motor/charging system.....573

Failure code [D110KB] - Short-circuiting in battery relay.....574

Electrical circuit diagram for battery relay - Pump controller.....575

Failure code [D19JKZ] - Personal code relay abnormality.....576

Circuit diagram related to engine preheater/starting motor/charging system.....577

Failure code [D862KA] - GPS antenna disconnection.....578

Configuration diagram of KOMTRAX system.....578

Circuit diagram related to no. 3 injector.....521

Failure code [DA25KP] - 5V sensor 1 power abnormality.....580

Circuit diagram related to pressure sensor power supply of pump controller.....581

Failure code [DA2RMC] - CAN discon (pump con detected).....582

Circuit diagram related to CAN communication.....583

Failure code [DAFRMC] - GPS module error.....584

Failure code [DAFRMC] - CAN discon (monitor detected).....586

Circuit diagram related to CAN communication.....587

Failure code [DDP4KX] - Abnormality in travel PPC pressure switch.....588

Electrical circuit diagram for travel PPC pressure switch.....589

Failure code [DDWCKZ] - Abnormality in travel direction control switch.....590

Electrical circuit diagram for travel direction control switch.....591

Failure code [DFB1KZ] - 1st ATT service lever main potentio 1 abnormality.....592

Failure code [DFB2KZ] - 2nd ATT service lever main potentio 2 abnormality.....594

Failure code [DFB3L8] - 1st ATT service lever Potentio 1 error.....596

Failure code [DFB4L8] - 2nd ATT service lever potentio 2 error.....597

Failure code [DFB5KZ] - 1st ATT service lever main potentio 1 abnormality.....598

Failure code [DFB6KZ] - Service lever potentio 2 abnormality.....600

Failure code [DGH2KB] - Hydr oil sensor short.....602

Circuit diagram related to hydraulic oil temperature sensor.....603

Failure code [DH10KS] - Abnormality in 24V sensor power source.....604

Electrical circuit diagram for 24V sensor power source.....605

Failure code [DHPAMA] - F pump press sensor abnormality.....606

Circuit diagram related to pump pressure sensor of pump controller.....607

Failure code [DHS5KX] - Abnormality in travel PPC sensor.....608

Failure code [DHX1MA] - Abnormality in overload caution sensor.....610

Electrical Circuit Diagram for Overload Caution.....611

Failure code [DLT4KA] - Disconnection in transmission speed sensor in pump controller system.....612

Electrical circuit diagram for monitor panel power source.....613

Failure code [DW27KA] - Disconnection in transmission clutch solenoid.....614

Electrical circuit diagram for transmission clutch solenoid in pump controller.....615

Failure code [DW27KB] - Short-circuiting in transmission clutch solenoid.....616

Electrical circuit diagram for transmission clutch solenoid.....617

Failure code [DW4AKA] - Disconnection in suspension lock solenoid.....618

Electrical circuit diagram for suspension lock solenoid in pump controller.....619

Failure code [DW4AKB] - Short circuiting in suspension lock solenoid.....620

Electrical circuit diagram for suspension lock solenoid in pump controller.....621

Failure code [DW4CKA] - Disconnection in PPC lock solenoid.....622

Electrical circuit diagram for ppc lock solenoid in pump controller.....623

Failure code [DW4CKB] - PPC lock sol. S/C.....624

Circuit diagram related to swing holding brake solenoid of pump controller.....625

Failure code [DW4MKA] - Disconnection in creep solenoid.....626

Electrical circuit diagram for creep solenoid in pump controller.....627

Failure code [DW4MKB] - Short-circuiting in creep solenoid.....628

Electrical circuit diagram for creep solenoid in pump controller.....629

Failure code [DW44KA] - Disconnection of travel F/R solenoid.....630

Electrical circuit diagram for travel F/R solenoid.....631

Failure code [DW44KB] - Short-circuiting of travel F/R solenoid.....632

Electrical circuit for travel F/R solenoid in pump controller.....633

Failure code [DW45KA] - Disconnection in swing parking brake solenoid.....634

Electrical circuit diagram for swing and parking brake solenoid in pump controller.....635

Failure code [DW45KB] - Swing brake sol. S/C.....636

Circuit diagram related to swing holding brake solenoid of pump controller.....637

Failure code [DW91KA] - Disconnection in travel neutral solenoid.....638

Electrical circuit diagram for travel neutral solenoid.....639

Failure code [DW91KB] - Short-circuiting in travel neutral solenoid.....640

Electrical circuit diagram for travel neutral solenoid.....641

Failure code [DWK0KA] - Disconnection in 2-stage relief solenoid.....642

Electrical circuit diagram for 2-stage relief solenoid in pump controller.....643

Failure code [DWK0KB] - Short-circuiting in 2-stage relief solenoid.....644

Electric circuit diagram for 2-stage relief solenoid in pump controller.....645

Failure code [DWK2KA] - Disconnection in 2-stage back pressure solenoid.....646

Electrical circuit diagram for 2-stage back pressure solenoid in pump controller.....647

Failure code [DWK2KB] - Short circuiting in 2-stage back pressure solenoid.....648

Electrical circuit diagram for 2-stage back pressure solenoid in pump controller.....649

Failure code [DXA8KA] - Disconnection in PC-EPC (F) solenoid system.....650

Electrical circuit diagram for PC-EPC solenoid in pump controller.....651

Failure code [DXA8KB] - Short-circuiting in PC-EPC (F) solenoid.....652

Electrical circuit diagram for PC-EPC solenoid in pump controller.....653

Failure code [DXE0KA] - Disconnection in LS-EPC solenoid system.....654

Electrical circuit diagram for LS-EPC solenoid in pump controller.....654

Failure code [DXE0KB] - Short-circuiting in LS-EPC solenoid.....655

Electrical circuit diagram for LS-EPC solenoid in pump controller.....655

Failure code [DXE4KA] - 1st service current EPC discon (left hand).....656

Circuit diagram related to the 1st and 2 nd service EPC solenoids.....657

Failure code [DXE4KB] - 1st service current EPC short (left hand).....658

Circuit diagram related to the 1st and 2nd service EPC solenoids.....659

Failure code [DXE7KA] - 1st service current EPC discon (right hand).....660

Circuit diagram related to the 1st and 2nd service EPC solenoids.....661

Failure code [DXE7KB] - 1st service current EPC short (right hand).....662

Circuit diagram related to the 1st and 2nd service EPC solenoids.....663

Failure code [DXE8KA] - 2nd service current EPC discon (left hand).....664

Circuit diagram related to the 1st and 2nd service EPC solenoids.....665

Failure code [DXE8KB] - 2nd service current EPC short (left hand).....666

Circuit diagram related to the 1st and 2nd service EPC solenoids.....667

Failure code [DXE9KA] - 2nd service current EPC discon (right hand).....668

Circuit diagram related to the 1st and 2nd service EPC solenoids.....669

Failure code [DXE9KB] - 2nd service current EPC short (right hand).....670

Circuit diagram related to the 1st and 2nd service EPC solenoids.....671

Failure code [DY20KA] - Wiper working abnormality.....672

Circuit diagram related to wiper motor of machine monitor.....673

Failure code [DY20MA] - Wiper parking abnormality.....674

Circuit diagram related to wiper motor of machine monitor.....675

Failure code [DY2CKA] - Washer drive discon.....676

Circuit diagram related to wiper motor of machine monitor.....677

Failure code [DY2CKB] - Washer drive short.....678

Circuit diagram related to window washer motor of machine monitor.....679

Failure code [DY2DKB] - Wiper drive (for) short.....680

Circuit diagram related to wiper motor of machine monitor.....681

Failure code [DY2EKB] - Wiper drive (rev) short.....682

Circuit diagram related to wiper motor of machine monitor.....683

TESTING AND ADJUSTING (520).....685

Troubleshooting of electrical system (E-Mode).....685

Preparations for troubleshooting of electrical system.....686

Troubleshooting of electrical system (E-mode).....690

Before carrying out troubleshooting of electrical system.....690

Location of fusible links.....692

Location of fuse box and fuse numbers.....692

Information contained in troubleshooting table.....693

E-1 When starting switch turned ON, machine monitor displays nothing.....694

Circuit diagramm related to machine monitor power supply.....695

E-2 When starting switch turned ON (before starting engine), basic check item lights up.....696

Circuit diagram related to radiator coolant level switch.....697

Circuit diagram related to engine oil level switch.....698

E-3 Engine does not start (engine does not rotate).....699

Electrical circuit diagram for engine start, stop and battery charging.....701

E-4 Preheater does not operate.....702

Circuit diagram related to engine preheater.....703

E-5 Automatic warm-up system does not operate (in cold season).....704

E-6 All work equipment, swing and travel mechanism do not move or cannot be locked.....705

Electrical circuit diagram for PPC lock solenoid.....706

E-7 Precaution lights up while engine is running.....707

Circuit diagram related to engine preheater/starting motor/charging system.....708

Circuit diagram related to air cleaner clogging switch.....710

E-8 Emergency stop item lights up while engine is running.....712

Circuit diagram related to 2-stage relief solenoid.....713

E-9 Engine coolant temperature gauge does not indicate normally.....714

E-10 Hydraulic oil temperature gauge does not indicate normally.....715

E-11 Fuel level gauge does not indicate normally.....717

Circuit diagram related to fuel level sensor.....718

E-12 Contents of display by machine monitor are different from applicable machine.....720

E-13 Machine monitor does not display some items.....720

E-14 Function switch does not work.....720

E-15 Auto-decelerator does not operate normally.....721

E-16 Working mode does not change.....722

E-17 Travel speed does not change.....723

Circuit diagram related to travel speed shifting solenoid.....723

E-18 Alarm buzzer cannot be stopped.....724

Circuit diagram for Quick Coupler system.....725

E-19 Windshield wiper and window washer do not operate.....726

Circuit diagram related to windshield and window washer.....727

E-20 Power maximising function does not operate normally.....728

E-21 Swing holding brake does not operate normally.....729

Electrical circuit diagram for Swing Lock switch.....730

E-21 - "Boom/Stabiliser RAISE" is not correctly displayed in monitor function.....731

Electrical circuit diagram for boom RAISE PPC hydraulic switch.....731

E-22 Travel alarm does not sound or does not stop sounding.....732

Electrical circuit diagram for travel PPC hydraulic switch and travel alarm.....733

E-23 Air conditioner does not operate normally (including air conditioner abnormality record).....734

Circuit diagram related to air conditioner.....744

E-24 When starting switch is turned OFF, service meter is not displayed.....745

E-25 Machine monitor cannot be set in service mode.....745

E-26 Monitoring function does not display lever control signal normally.....746

Electrical circuit diagram for boom RAISE PPC hydraulic switch.....746

Electrical circuit diagram for boom LOWER PPC hydraulic switch.....747

Electrical circuit diagram for arm DIGGING PPC hydraulic switch.....748

Electrical circuit diagram for arm DUMPING PPC hydraulic switch.....749

Electrical circuit diagram for bucket DIGGING PPC hydraulic switch.....750

Electrical circuit diagram for bucket DUMPING PPC hydraulic switch.....751

Electrical circuit diagram for right and left swing PPC hydraulic switches.....753

Electrical circuit diagram for travel PPC hydraulic switch and travel alarm.....755

Electrical circuit diagram for 2 piece boom PPC hydraulic switch.....757

E-27 KOMTRAX system does not operate normally.....758

TESTING AND ADJUSTING (600).....759

Troubleshooting of electrical system (Error checking of items without monitor codes).....759

Swing lock proximity switch.....864

Brake and swing lock proximity switches.....865

Hazard warning lights contd (A).....861

Circuit diagram for indicators & hazard warning.....862

Hazard warning lights.....860

Indicators - Left hand.....858

Circuit diagram for indicators & hazard warning.....859

Indicators - Right hand.....856

Circuit diagram for indicators & hazard warning.....857

Driving lights - Position lights.....852

Driving lights - Position lights contd (1) and (2).....853

Circuit diagram for driving lights.....854

Driving lights - Main beam dipped.....850

Circuit diagram for driving lights.....851

Driving lights - Main beam flash.....848

Circuit diagram for driving lights.....849

Driving lights - Main beam.....846

Circuit diagram for driving lights.....847

Emergency travel control - Reverse.....844

Circuit diagram for travel direction control.....845

Emergency travel control - Neutral.....842

Circuit diagram for travel direction control.....843

Emergency travel control - Forward.....840

Circuit diagram for travel direction control.....841

Neutral start (engine) contd (C).....838

Circuit diagram for neutral start (engine).....839

Neutral start (engine) contd (B).....836

Circuit diagram for neutral start (engine).....837

Neutral start (engine) contd (A).....834

Circuit diagram for neutral start (engine).....835

Neutral start (engine).....832

Circuit diagram for neutral start (engine).....833

Swing lock - Emergency operation.....830

Circuit diagram for swing lock.....831

Swing lock - Normal operation.....828

Circuit diagram for swing lock.....829

Horns.....826

Circuit diagram for horn.....827

RH PPC Lever clamshell roller switch pushed to the RH or LH.....824

Circuit diagram for clamshell control.....825

RH PPC Lever clamshell roller switch pushed to the RH position.....822

Circuit diagram for clamshell control.....823

Park brake (displayed symbol).....820

Circuit diagram for park brake.....821

Park brake (not activating).....818

Circuit diagram for park brake.....819

Cigarette lighter.....816

Circuit diagram for cigarette lighter.....817

Operator cab interior light.....814

Circuit diagram for operator cab interior light.....815

Air seat compressor (option - air suspension seat).....812

Circuit diagram for air seat compressor (option - air suspension seat).....813

Flashing beacon (Fuel tank mount).....810

Circuit diagram for cab, counterweight & fuel tank beacon light.....811

Flashing beacon (Counterweight mount).....808

Circuit diagram for cab, counterweight & fuel tank beacon light.....809

Flashing beacon (Operators cabin mount).....806

Circuit diagram for cab, counterweight & fuel tank beacon light.....807

Worklights (Oil tank - side mount).....804

Circuit diagram for worklights - worklight switch (2).....805

Worklights (Counterweight - right hand).....802

Circuit diagram for worklights - worklight switch (2).....803

Worklights (Counterweight - left hand).....800

Circuit diagram for worklights - worklight switch (2).....801

Worklights (Revolving frame - right hand).....798

Circuit diagram for worklights - Worklight switch (1).....799

Worklights (Revolving frame - left hand).....796

Circuit diagram for worklights - Worklight switch (1).....797

Worklights (Boom - right hand).....794

Circuit diagram for worklights - Worklight switch (1).....795

Worklights (Boom - left hand).....792

Circuit diagram for worklights - Worklight switch (1).....793

Work lights (operator cab rear).....790

Circuit diagram for worklights - worklight switch (2).....791

Work lights (operator cab front right).....788

Circuit diagram for worklights - Worklight switch (1).....789

Work lights (operator cab front left).....786

Circuit diagram for worklights - Worklight switch (1).....787

Lower wiper does not work (optional fitment).....784

Circuit diagram for lower wiper.....785

Suspension lock.....782

Circuit diagram for suspension lock.....783

Heated seat does not warm up.....780

Circuit diagram for the heated seat.....781

Undercarriage attachments - Rear right outrigger.....778

Circuit diagram for undercarriage attachments - Mode selection.....779

Undercarriage attachments - Rear left outrigger.....776

Circuit diagram for undercarriage attachments - Mode selection.....777

Undercarriage attachments - Front right outrigger.....774

Circuit diagram for undercarriage attachments - Mode selection.....775

Undercarriage attachments - Front left outrigger.....772

Circuit diagram for undercarriage attachments - Mode selection.....773

Undercarriage attachments - Mode activation.....770

Circuit diagram for undercarriage attachments - Mode activation.....771

Undercarriage attachments - Mode selection.....768

Circuit diagram for undercarriage attachments - Mode selection.....769

Brake light circuit.....766

Circuit diagram for brake light circuit.....767

PPC lock circuit.....764

Circuit diagram for PPC lock circuit.....765

Radio cassette & telephone socket.....762

Electrical circuit diagram for radio cassette & telephone socket.....763

Information in troubleshooting table.....761

TESTING AND ADJUSTING (710).....867

Troubleshooting of engine (S-MODE).....894

S-1 - Starting performance is poor.....897

S-2 - Engine does not start.....898

S-3 - Engine does not pick up smoothly.....901

S-4 - Engine stops during operations.....902

S-5 - Engine does not rotate smoothly.....903

S-6 - Engine lacks output (or lacks power).....904

S-7 - Exhaust smoke is black (incomplete combustion).....905

S-8 - Oil consumption is excessive (or exhaust smoke is blue).....906

S-9 - Oil becomes contaminated quickly.....907

S-10 - Fuel consumption is excessive.....908

S-11 - Oil is in coolant (or coolant spurts back or coolant level goes down).....909

S-12 - Oil pressure drops.....910

S-13 - Oil level rises (Entry of coolant/fuel).....911

S-14 - Coolant temperature becomes too high (overheating).....912

S-15 - Abnormal noise is made.....913

S-16 - Vibration is excessive.....914

Method of using troubleshooting chart.....894

Troubleshooting of hydraulic and mechanical system (H-MODE).....867

System chart for hydraulic and mechanical systems.....869

Information contained in troubleshooting table.....873

H-1 - All work equipment lacks power, or travel and swing speeds are slow.....874

H-2 - Engine speed sharply drops or engine stalls.....875

H-3 - No work equipment, travel or swing move.....876

H-4 - Abnormal noise is heard from around hydraulic pump.....876

H-5 - Auto-decelerator does not work.....877

H-6 - Fine control mode does not function.....877

H-7 - Boom moves slowly or lacks power.....878

H-8 - Arm moves slowly or lacks power.....879

H-9 - Bucket moves slowly or lacks power.....880

H-10 - Work equipment does not move in its single operation.....880

H-11 - Work equipment hydraulic drift is too fast.....881

H-12 - Work equipment has big time lag.....882

H-13 - Other work equipment moves when relieving single circuit.....882

H-14 - One-touch power max. switch does not operate.....883

H-15 - In compound operation, work equipment with larger load moves slowly.....883

H-16 - In swing + boom RAISE operation, boom moves slowly.....883

H-17 - In swing + travel, travel speed drops sharply.....884

H-18 - Travel speed does not switch.....885

H-19 - Travel speed does not shift, or it is too slow or fast.....886

H-20 - Machine does not swing.....887

H-21 - Swing acceleration is poor, or swing speed is slow.....888

H-22 - Excessive overrun when stopping swing.....889

H-23 - There is big shock when stopping swing.....890

H-24 - There is loud abnormal noise caused when stopping swing.....890

H-25 - Swing natural drift is too big.....891

H-26 - Swing speed is faster than specified swing speed.....891

Quick coupler.....892

DISASSEMBLY AND ASSEMBLY.....915

How to read this manual.....920

Removal and installation of assemblies.....920

Special tools.....920

Removal of parts.....920

Installation of parts.....920

Sketches of special tools.....920

Coating material lists.....921

Special tools list.....924

Sketches of special tools.....926

List of tools.....928

Precautions when performing operation.....929

Removal and installation of fuel supply pump assembly.....931

Removal.....931

Installation.....932

Removal and installation of fuel injector assembly.....934

Special tools.....934

Removal.....934

Installation.....936

Removal and installation of front oil seal.....939

Special tools.....939

Removal.....939

Installation.....939

Removal and installation of rear oil seal.....941

Special tools.....941

Removal.....941

Installation.....942

Removal and installation of cylinder head assembly.....944

Special tools.....944

Removal.....944

Installation.....949

Removal and installation of fuel cooler assembly.....954

Removal and installation of combination cooler assembly.....955

Removal.....955

Installation.....957

Removal and installation of engine and hydraulic pump assembly.....958

Special tools.....958

Removal.....958

Installation.....963

Removal and installation of engine hood assembly.....965

Removal.....965

Installation.....965

Removal and installation of travel motor.....967

Removal.....967

Installation.....968

Disassembly and assembly of travel motor assembly.....970

Disassembly.....970

Assembly.....972

Removal and installation of swing motor and swing machinery.....974

Removal.....974

Installation.....975

Removal of swing motor assembly.....976

Removal.....976

Installation.....977

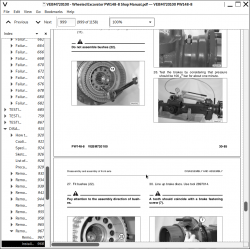

Disassembly and assembly of swing motor and swing machinery.....978

Disassembly.....978

Assembly.....980

Removal and installation of front axle assembly.....984

Removal.....984

Installation.....985

Disassembly and assembly of front axle.....986

Disassembly of steering cylinder.....986

Assembly of steering cylinder.....988

Disassembly of epicyclic reduction gear and brake.....992

Assembly of epicylic reduction gear and brake.....996

Disassembly of joint box.....1002

Assembly of joint box.....1006

Disassembly of beam trumpet and differential unit.....1011

Assembly of beam trumpet and differential unit.....1014

Disassembly of pinion group.....1020

Assembly of pinion group.....1022

Toe-in adjustment.....1028

Steering angle adjustment.....1029

Removal and installation of rear axle and transmission.....1030

Removal.....1030

Installation.....1031

Disassembly and assembly of rear axle assembly.....1032

Special tools.....1032

Removal of epicyclic reduction gear and brake.....1032

Installation of epicylic reduction gear and brake.....1036

Disassembly of beam trumpet and differential unit.....1043

Installation of beam trumpet and differential unit.....1047

Disassembly of pinion group.....1053

Installation of pinion group.....1056

Disassembly and assembly of transmission.....1062

Special tools.....1062

Removal of travel motor and flange.....1062

Installation of travel motor.....1063

Removal of transmission box.....1066

Installation of transmission box.....1074

Removal and installation of propshaft assembly.....1085

Removal.....1085

Installation.....1085

Removal and installation of wheel.....1086

Removal.....1086

Installation.....1086

Removal and installation of suspension lock cylinder assembly.....1087

Removal.....1087

Installation.....1087

Disassembly and assembly of suspension lock cylinders.....1088

Change Rod Seal.....1088

Removal and installation of outrigger assembly.....1089

Removal.....1089

Installation.....1089

Disassembly and assembly of outriggers.....1090

Disassembly.....1090

Assembly.....1090

Removal and installation of dozer blade assembly.....1091

Removal.....1091

Installation.....1091

Disassembly and assembly of dozer blade.....1092

Disassembly.....1092

Assembly.....1092

Removal and installation of swing circle assembly.....1093

Removal.....1093

Installation.....1093

Removal and installation of revolving frame assembly.....1094

Removal.....1094

Installation.....1096

Removal and installation of centre swivel joint.....1097

Removal.....1097

Installation.....1099

Disassembly and assembly of centre swivel joint assembly.....1100

Special tools.....1100

Disassembly.....1100

Assembly.....1101

Removal and installation of fuel tank assembly.....1102

Removal.....1102

Installation.....1103

Removal and installation of hydraulic tank assembly.....1104

Removal.....1104

Installation.....1106

Removal and installation of control valve assembly.....1107

Removal.....1107

Installation.....1109

Removal and installation of LS separation valve assembly.....1110

Removal.....1110

Installation.....1110

Removal and installation of pressure compensation valve assembly.....1111

Removal.....1111

Installation.....1111

Removal and installation of main relief valve assembly.....1112

Removal.....1112

Installation.....1112

Removal and installation of LS control EPC valve.....1113

Removal.....1113

Installation.....1113

Removal and installation of PC EPC valve assembly.....1114

Removal.....1114

Installation.....1114

Removal and installation of PPC valve block assembly.....1115

Removal.....1115

Installation.....1115

Removal and installation of oil seal in hydraulic pump input shaft.....1116

Special tools.....1116

Removal.....1116

Installation.....1116

Disassembly and assembly of work equipment PPC valve.....1117

Assembly.....1117

Disassembly and assembly of hydraulic cylinder.....1118

Special tools.....1118

Disassembly.....1118

Assembly.....1120

Removal and installation of monoboom work equipment.....1124

Special tools.....1124

Removal.....1124

Installation.....1125

Removal and installation of 2 piece boom work equipment.....1126

Special tools.....1126

Removal.....1126

Installation.....1127

Removal and installation of air conditioner unit.....1128

Special tools.....1128

Removal.....1128

Installation.....1131

Removal and installation of counterweight.....1132

Removal.....1132

Installation.....1133

Removal and installation of operator cab assembly.....1134

Removal.....1134

Installation.....1135

Removal and installation of monitor assembly.....1136

Removal.....1136

Installation.....1136

Removal and installation of pump controller assembly.....1137

Removal.....1137

Installation.....1137

Removal and installation of engine controller assembly.....1138

Removal.....1138

Installation.....1139

Removal and Installation of KOMTRAX terminal.....1140

Removal.....1140

Installation.....1140

OTHER.....1141

Hydraulic circuit diagram (1/3).....1143

Hydraulic circuit diagram (2/3).....1144

Hydraulic circuit diagram (3/3).....1145

Electrical circuit diagram (cabin 1/4).....1146

Electrical circuit diagram (cabin 2/4).....1147

Electrical circuit diagram (cabin 3/4).....1148

Electrical circuit diagram (cabin 4/4).....1149

Electrical circuit diagram (machine 1/4)).....1150

Electrical circuit diagram (machine 2/4)).....1151

Electrical circuit diagram (machine 3/4)).....1152

Electrical circuit diagram (machine 4/4)).....1153

Connector diagramm 1/5.....1154

Connector table for revolving frame harness.....1154

Connector diagram 2/5.....1155

Connector table for operators cab wiring harness (Part 1/2).....1155

Connector diagram 3/5.....1156

Connector table for operators cab wiring harness (Part 2/2).....1156

Connector diagram (4/5).....1157

Connector table various wiring harness (Part 1/2).....1157

Connector diagram (5/5).....1158

Connector table various wiring harness (Part 2/2).....1158