Komatsu Hydraulic Mining Shovel PC3000 Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Mining Shovel PC3000-1, PC3000-6, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Mining Shovel PC3000-1, PC3000-6 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 11,070 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SMPC30006171 - Hydraulic Mining Shovel PC3000-1 Shop Manual.pdf

SMPC30006174 - Hydraulic Mining Shovel PC3000-1 Shop Manual.pdf

SMPC30006182 - Hydraulic Mining Shovel PC3000-1 Shop Manual.pdf

SMPC30006194 - Hydraulic Mining Shovel PC3000-1 Shop Manual.pdf

SMPC30006199 - Hydraulic Mining Shovel PC3000-1 Shop Manual.pdf

SMPC30006202 - Hydraulic Mining Shovel PC3000-1 Shop Manual.pdf

SMPC30006208 - Hydraulic Mining Shovel PC3000-6 Service Manual.pdf

SMPC30006219 - Hydraulic Mining Shovel PC3000-6 Shop Manual.pdf

SMPC30006224 - Hydraulic Mining Shovel PC3000-6 Shop Manual.pdf

SMPC30006225 - Hydraulic Mining Shovel PC3000-1 Shop Manual.pdf

FAMPC3000-07 - Hydraulic Mining Shovel PC3000-6 General Assembly Procedure.pdf

GZEAM06253 - Hydraulic Mining Shovel PC3000-6 Operation & Maintenance Manual.pdf

Hydraulic Mining Shovel PC3000-6 Operation & Maintenance Manual (SN06208 &up).pdf

Hydraulic Mining Shovel PC3000-6 Operation & Maintenance Manual (SN06208 &up, SN46151&up).pdf

Hydraulic Mining Shovel PC3000-6 Operation & Maintenance Manual (SN46172 &up).pdf

OMPC30006171 - Hydraulic Mining Shovel PC3000-1 Operation & Maintenance Manual.pdf

OMPC30006174 - Hydraulic Mining Shovel PC3000-1 Operation & Maintenance Manual.pdf

OMPC30006182 - Hydraulic Mining Shovel PC3000-1 Operation & Maintenance Manual.pdf

OMPC30006193 - Hydraulic Mining Shovel PC3000-1 Operation & Maintenance Manual.pdf

OMPC30006194 - Hydraulic Mining Shovel PC3000-1 Operation & Maintenance Manual.pdf

OMPC30006199 - Hydraulic Mining Shovel PC3000-1 Operation & Maintenance Manual.pdf

OMPC30006202 - Hydraulic Mining Shovel PC3000-1 Operation & Maintenance Manual.pdf

OMPC30006219 - Hydraulic Mining Shovel PC3000-6 Operation & Maintenance Manual.pdf

OMPC30006224 - Hydraulic Mining Shovel PC3000-6 Operation & Maintenance Manual.pdf

OMPC30006225 - Hydraulic Mining Shovel PC3000-1 Operation & Maintenance Manual.pdf

MAIN SECTIONS

FAMPC3000-07 - Hydraulic Mining Shovel PC3000-6 General Assembly Procedure......3

Cover......3

Contents......5

1. General ......7

1.1 Delivery of the Excavator ......7

1.2 Assembling of the Excavator ......7

1.3 Transportation and Lifting ......9

1.4 Manpower / Assembly Time* ......11

1.5 Assembly Site Requirements ......13

1.6 Space and Placing Requirements ......17

1.7 Preparation for Assembly ......17

1.8 Basic Measurements (Z24015) ......19

1.9 Transport Dimensions and Weights (as example) ......19

1.10 Illust. Configuration of Components on Erection Site ......21

2.0 Assembly sequence ......21

2.1. Assembly of Undercarriage (Z 24016; Z 24017; Z 20418) ......23

2.1.1 Assembly ......23

2.1.2 Determination of the tightening torque ......27

2.1.3 Final works ......31

2.2 Assembly of Superstructure onto the Undercarriage (Z 9031a) ......33

2.3. Mounting of Boom and Boom cylinders(Z 9032; Z 20949)......37

2.4. Mounting of Fuel Tank (Z 21924) ......39

2.5 Mounting of Hydraulic access Ladder (Z 24022) ......41

2.5. Mounting of Cab Base (Z 24023) ......43

2.6. Mounting of Counterweight (Z 24024) ......45

2.7. Mounting of Handrails, Steps and Gratings (Z 24025) ......47

2.8. Mounting of Cab (Z 24029) ......49

2.9 Pre-checks prior Initial Start up ......51

2.10 Mounting of Stick ......55

2.10.1 Backhoe Attachment (Z 24030) ......55

2.10.2 Bullclam Bucket Attachment (Z 20950; Z 20951; 20952) ......57

2.11 Assembly of the bucket to the stick ......63

2.11.1 Assembly of the backhoe to the stick (Z 23005) ......63

2.11.2 Assembly of the bullclam bucket to the stick (Z 20953) ......65

2.12 Mounting of the Pin Seals ......69

2.12.1 Backhoe (Z 23006) ......69

2.12.2 Bullclam bucket (Z 21963) ......71

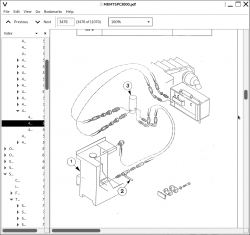

2.13 Putting the Central Lubrication System into operation (Z 24031) ......73

2.14 Standard Application Torque Chart ......75

2.14.1 Metric standard thread ......75

2.14.2 Metric fine thread ......77

2.14.3 Torque Chart for Flange Joints ......78

GZEAM06253 - Hydraulic Mining Shovel PC3000-6 Operation & Maintenance Manual......79

COVER......79

1. INTRODUCTION......81

1.1 CONTENTS OF THE BINDER......82

1.2 DIVISION OF THE BINDER......83

1.3 DESIGNATED USE OF THE SHOVEL......84

1.4 DELIVERY OF THE SHOVEL......85

1.5 EXPLANATION OF ABBREVIATIONS......86

1.6 TABLE OF CONTENTS......87

2. SAFETY......93

2.1 SAFETY INSTRUCTIONS......94

2.1.1 WARNINGS AND SYMBOLS......94

2.1.2 BASIC OPERATION AND DESIGNATED USE OF THE HYDRAULIC SHOVEL......94

2.1.3 ORGANIZATIONAL MEASURES......95

2.1.4 SELECTION AND QUALIFICATION OF PERSONNEL - BASIC RESPONSIBILITIES......97

2.1.5 SAFETY INSTRUCTIONS GOVERNING SPECIFIC OPERATIONAL PHASES......98

2.1.6 WARNING OF SPECIAL DANGERS......101

2.1.7 TRANSPORTING AND TOWING -RECOMMISSIONING......103

2.1.8 SPECIAL SAFETY EQUIPMENT......103

2.1.9 SAFETY HARNESS IN CONFORMITY WITH EN 361 (EUROPEAN STANDARD)......107

3. OPERATION......115

3.1 FOREWORD......116

3.2 CONSTRUCTION OF THE SHOVEL......117

3.2.1 OVERALL VIEW......117

3.2.2 UNDERCARRIAGE AND SUPERSTRUCTURE......118

3.2.3 HYDRAULICALLY OPERATED ACCESS LADDER......124

3.2.4 EMERGENCY ESCAPE LADDER......128

3.2.5 EMERGENCY ESCAPE LADDER AND ESCAPE HATCH IN THE MACHINERY HOUSE (SPECIAL EQUIPMENT)......130

3.2.6 EMERGENCY ENGINE SHUTDOWN FROM GROUND MAN OR OPERATOR WARNING SYSTEM......132

3.2.7 OPERATORS CAB WITH INTEGRATED FALLING OBJECT PROTECTIVE STRUCTURE (FOPS)......134

3.2.8 ENGINE OIL MANAGEMENT SYSTEM......142

3.3 OPERATORS CAB - CONTROLS......150

3.3.1 CONTROLS WITH BACKHOE ATTACHMENT......150

3.3.2 CONTROLS WITH BOTTOM DUMP BUCKET......154

3.3.3 OPERATORS CONSOLE......159

3.4 ELECTRONIC TEXT MONITORING SYSTEM ETM......166

3.4.1 INTRODUCTION......167

3.4.2 SYSTEM COMPONENTS......171

3.4.3 FUNCTIONS OF THE ETM SYSTEM......173

3.4.4 DISPLAY THE CONTENTS OF THE RECORD (PROTOCOL) MEMORY......177

3.4.5 SEVERAL MESSAGE CONDITIONS OCCUR AT THE SAME TIME......189

3.4.6 SETTINGS OF THE TEXT DISPLAY UNIT......191

3.5 OPERATING THE HEATER, VENTILATION AND AIR CONDITIONING......206

3.5.1 CONTROL MODULE FOR AUXILIARY CAB HEATER (IF SO EQUIPPED)......211

3.5.2 AUXILIARY HEATER FOR OPERATORS CAB (IF SO EQUIPPED)......213

3.5.3 AUXILLIARY HEATER FOR OPERATORS CAB (IF SO EQUIPPED)......215

3.5.4 FUEL PUMP ARRANGEMENT......217

3.6 MACHINERY HOUSE......218

3.6.1 EMERGENCY ENGINE SHUTDOWN SWITCHES......219

3.7 ELECTRICAL EQUIPMENT IN CAB BASE......220

3.7.1 SWITCH BOX (X2) IN CAB BASE......225

3.7.2 COMPONENTS OF ELECTRICAL PREHEATING SYSTEM IN CAB BASE......229

3.8 PREHEATING SYSTEMS......234

3.8.1 FOR OIL, COOLANT AND BATTERIES......234

3.8.2 HEATERS FOR MACHINERY HOUSE (SPECIAL EQUIPMENT)......240

3.9 CHECKS BEFORE STARTING THE ENGINE......242

3.10 STARTING THE ENGINE......248

3.10.1 STARTING PROCEDURE......249

3.10.2 STARTING PROCEDURE AT AMBIENT TEMPERATURE UP TO -25......251

3.11 MOVING THE SHOVEL......260

3.11.1 TRAVEL CONTROL WITH FOOT PEDALS......260

3.11.2 TRAVELLING INSTRUCTIONS......263

3.12 SLEWING AND BRAKING THE SUPERSTRUCTURE......264

3.12.1 SLEWING THE SUPERSTRUCTURE......264

3.13 WORKING WITH THE ATTACHMENT......267

3.13.1 MACHINES EQUIPPED WITHEURO CONTROL SYSTEM......267

3.13.2 MACHINES EQUIPPED WITHKMG CONTROL SYSTEM......268

3.13.3 BOTTOM DUMP BUCKET......269

3.13.4 DROP BALL OPERATION......270

3.13.5 COMBINED OPERATION CYCLES......273

3.14 WORKING INSTRUCTIONS......275

3.14.1 STABILITY OF THE SHOVEL......275

3.14.2 SHOVEL OPERATION......275

3.15 PARKING THE SHOVEL......278

3.16 STOPPING THE ENGINE......280

3.16.1 RELIEVE PRESSURE IN THE HYDRAULIC SYSTEM......283

3.17 AUTOMATIC LUBRICATION SYSTEMS......284

3.17.1 OPERATION OF THE AUTOMATIC LUBRICATION SYSTEMS......285

3.18 FIRE DETECTION AND SUPPRESSION SYSTEM......288

3.18.1 HIGH LEVEL ALARM FIRE......291

3.18.2 ENGINE SHUT-DOWN THROUGH FUEL SHUT-OFF SOLENOID VALVE......291

3.18.3 ACTUATION MODES OF THE FIRE SUPPRESSION SYSTEM......291

3.18.4 INDICATION OF OPERATIONAL MODES AT CONTROL MODULE, AFTER AUTOMATIC ACTUATION OF THE FIRE S.......293

3.18.5 LOCATION OF THE EXTINGUISHING AGENT TANK ASSEMBLIES AND EXPELLANT GAS CARTRIDGES ON POWER.......295

3.19 CENTRAL REFILLING SYSTEM......296

3.19.1 SYSTEMS CONNECTED TO THE REFILLING SYSTEM......297

3.19.2 OPERATING THE HYDRAULIC SERVICE ARM......299

3.19.3 RECEIVER PANEL WITH MONITOR BOX......301

3.19.4 REFILLABLE GREASE CONTAINERS OF THE AUTOMATIC LUBRICATION SYSTEMS......305

3.20 TRANSFER PUMP FOR HYDRAULIC OIL......306

3.20.1 OPERATING THE TRANSFER PUMP......307

3.20.2 FUNCTIONS OF THE TRANSFER PUMP......307

3.21 WORK ON THE LOADER ATTACHMENT......310

3.22 TRANSPORTATION AND LIFTING OF THE SHOVEL......311

3.22.1 DISASSEMBLING OF THE SHOVEL......311

3.22.2 TRANSPORTATION AND LIFTING......311

3.23 RETRIEVAL PROCEDURE......312

3.24 SHOVEL STORAGE......313

3.24.1 PREPARING FOR STORAGE......313

3.24.2 ONE MONTH REPETITIVE SERVICE PERIOD......314

3.24.3 SIX MONTH REPETITIVE SERVICE PERIOD......314

3.24.4 PREPARING FOR OPERATION......315

3.25 TROUBLE SHOOTING......316

3.25.1 ENGINE......316

3.25.2 HYDRAULIC SYSTEM......317

3.25.3 FINAL DRIVES AND SWING GEAR......318

3.25.4 CRAWLER TRACKS......318

4. MAINTENANCE......319

4.1 FOREWORD......320

4.2 PRECAUTIONS FOR MAINTENANCE......321

4.3 FLUIDS AND LUBRICANTS......323

4.3.1 LUBRICANTS FOR OPERATION IN COLD AND ARCTIC CLIMATES......323

4.3.2 FLUIDS AND LUBRICANTS FOR MODERATE AND HOT CLIMATES......324

4.4 FILLING CAPACITIES......326

4.5 STANDARD TORQUE LIST......327

4.6 LUBRICATION AND MAINTENANCE SCHEDULE......328

4.6.1 INITIAL SERVICING......328

4.6.2 PERIODIC SERVICING INTERVALS......328

4.6.3 PERIODIC SERVICING SCHEDULE......329

4.6.4 PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS......335

4.6.5 EXTENDED SERVICE INTERVALS FOR ENGINES WITH ENGINE OIL MANAGEMENT SYSTEM......339

4.6.6 RESETTING THE ENGINE OIL BURNING SYSTEM CENTINEL......341

4.6.7 MAINTENANCE OF THE ENGINE......345