Komatsu Hydraulic Excavators PC1000, PC1000LC, PC1000SE, PC1000SP Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC1000-1, PC1000LC-1, PC1000SE-1, PC1000SP-1, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC1000-1, PC1000LC-1, PC1000SE-1, PC1000SP-1 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,734 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SEBM021N0107 - Hydraulic Excavator PC1000-1, PC1000LC-1, PC1000SE-1, PC1000SP-1 Shop Manual.pdf

SEAM007701 - Hydraulic Excavator PC1000-1, PC1000LC-1, PC1000SE-1 Operation & Maintenance Manual.pdf

SEAM008701 - Hydraulic Excavator PC1000-1, PC1000LC-1, PC1000SE-1 Operation & Maintenance Manual.pdf

SEAM018300 - Hydraulic Excavator PC1100-6, PC1100LC-6, PC1100SP-6 avance Operation & Maintenance Manual.pdf

SEAW0021N0103 - Hydraulic Excavator PC1000-1 Field Assembly Manual.pdf

MAIN SECTIONS

SEAM007701 - Hydraulic Excavator PC1000-1, PC1000LC-1, PC1000SE-1 Operation & Maintenance Manual....2

COVER....2

1. FOREWORD....7

2. SAFETY INFORMATION....8

3. INTRODUCTION....9

4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR....10

5. CONTENTS....11

SAFETY....15

6. GENERAL PRECAUTIONS....16

7. PRECAUTIONS DURING OPERATION....22

7.1 BEFORE STARTING ENGINE....22

7.2 OPERATING MACHINE....24

7.3 TRANSPORTATION....29

7.4 BATTERY....30

7.5 BUCKET WITH HOOK....31

8. PRECAUTIONS FOR MAINTENANCE....34

8.1 BEFORE CARRYING OUT MAINTENANCE....34

8.2 DURING MAINTENANCE....37

9. POSITION FOR ATTACHING SAFETY LABELS....41

OPERATION....45

10. GENERAL VIEW....46

10.1 GENERAL VIEW OF MACHINE....46

10.2 GENERAL VIEW OF CONTROLS AND GAUGES....47

11. EXPLANATION OF COMPONENTS....48

11.1 MACHINE MONITOR....48

11.2 LAMP....58

11.3 SWITCHES....59

11.4 CONTROL LEVERS, PEDALS....64

11.5 CEILING WINDOW....67

11.6 FRONT WINDOW....68

11.7 DOOR LOCK....70

11.8 DUST INDICATOR....70

11.9 AIR CONDITIONER....71

11.10 RADIO....74

11.11 FUSE....76

11.12 CONTROLLERS....77

11.13 TOOL BOX....77

11.14 GREASE PUMP....77

11.15 HANDLING GREASE PUMP....78

11.16 HANDLING ACCUMULATOR....80

12. OPERATION....81

12.1 CHECK BEFORE STARTING ENGINE....81

12.2 STARTING ENGINE....90

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE....94

12.4 MOVING MACHINE OFF....96

12.5 STEERING MACHINE....100

12.6 STOPPING MACHINE....102

12.7 SWINGING....104

12.8 OPERATION OF WORK EQUIPMENT....105

12.9 WORKING MODE SELECTION....106

12.10 PROHIBITIONS FOR OPERATION....107

12.11 PRECAUTIONS FOR OPERATION....110

12.12 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS....111

12.13 HOW TO ESCAPE FROM MUD....113

12.14 WORK POSSIBLE USING HYDRAULIC EXCAVATOR....114

12.15 PARKING MACHINE....115

12.16 CHECK AFTER FINISHING WORK....116

12.17 STOPPING ENGINE....117

12.18 CHECK AFTER STOPPING ENGINE....118

12.19 LOCKING....118

13. TRANSPORTATION....119

13.1 PRECAUTIONS FOR TRANSPORTATION....119

13.2 PARTS FOR TRANSPORT....120

13.3 PROCEDURE FOR INCREASING OR REDUCING TRACK FRAME GAUGE....123

14. COLD WEATHER OPERATION....125

14.1 PRECAUTIONS FOR LOW TEMPERATURE....125

14.2 PRECAUTIONS AFTER COMPLETION OF WORK....127

14.3 AFTER COLD WEATHER....127

15. LONG-TERM STORAGE....128

15.1 BEFORE STORAGE....128

15.2 DURING STORAGE....129

15.3 AFTER STORAGE....129

15.4 STARTING MACHINE AFTER LONG-TERM STORAGE....129

16. TROUBLESHOOTING....130

16.1 PHENOMENA THAT ARE NOT FAILURES....130

16.2 PRECAUTIONS ON PARTICULAR JOBSITES....130

16.3 IF BATTERY IS DISCHARGED....131

16.4 OTHER TROUBLE....135

MAINTENANCE....143

17. GUIDES TO MAINTENANCE....144

18. OUTLINES OF SERVICE....147

18.1 OUTLINE OF OIL, FUEL, COOLANT....147

18.2 OUTLINE OF ELECTRICAL SYSTEM....150

18.3 OUTLINE OF HYDRAULIC SYSTEM....151

18.4 RELEASING PRESSURE....152

18.5 BLEEDING AIR FROM CIRCUIT....154

18.6 OIL FILLER AND LEVEL GAUGE POSITIONS....159

19. CONSUMABLE PARTS LIST....160

20. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE....161

21. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS....165

21.1 INTRODUCTION OF NECESSARY TOOLS....165

21.2 TORQUE LIST....166

22. PERIODIC REPLACEMENT OF CRITICAL SAFETY PARTS....167

23. MAINTENANCE SCHEDULE CHART....170

23.1 MAINTENANCE SCHEDULE CHART....170

24. SERVICE PROCEDURE....174

24.1 INITIAL 100 HOURS SERVICE....174

CLEAN STRAINER OF PTO LUBRICATING OIL FILTER....174

24.2 INITIAL 250 HOURS SERVICE....174

REPLACE FUEL FILTER CARTRIDGE....174

CHANGE OIL OF SWING MACHINERY CASE....174

CHANGE OIL OF PTO CASE....174

CHANGE OIL OF FINAL DRIVE CASE....174

CHECK ENGINE VALVE CLEARANCE, ADJUST....174

24.3 WHEN REQUIRED....175

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT....175

CLEAN INSIDE OF COOLING SYSTEM....177

CHECK AND TIGHTEN TRACK SHOE BOLTS....181

CHECK AND ADJUST TRACK TENSION....182

CHECK ELECTRICAL INTAKE AIR HEATER....185

REPLACE BUCKET TEETH (VERTICAL PIN TYPE)....186

REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE)....189

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID....190

CHECK AND ADJUST AIR CONDITIONER....191

CLEAN LINE FILTER....192

REPLACEMENT OF FAN BELT AND ADJUSTMENT OF AUTO TENSIONER....193

CHECK APS (AUTOMATIC PRIMING SYSTEM)....194

24.4 CHECK BEFORE STARTING....195

CHECK COOLANT LEVEL, ADD WATER....195

CHECK OIL LEVEL IN ENGINE OIL PAN, ADD OIL....195

CHECK FUEL LEVEL, ADD FUEL....196

CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL....197

CHECK DUST INDICATOR....198

CHECK ELECTRIC WIRING....198

DRAIN WATER AND SEDIMENT FROM FUEL TANK....199

CHECK MONITOR SYSTEM....199

CHECK OIL LEVEL IN PTO CASE....199

CHECK OIL LEVEL IN SWING MACHINERY CASE....199

24.5 CHECK EVERY 10 HOURS SERVICE....200

LUBRICATING....200

BOOM CONCENTRATION LUBRICATING BLOCK....200

BOOM CYLINDER FOOT PIN (2 POINTS)....201

ARM CONCENTRATION LUBRICATING BLOCK (4 POINTS)....201

BUCKET CYLINDER ROD END PIN (2 POINTS)....201

BUCKET CYLINDER ROD END LINK COUPLING PIN (4 POINTS)....201

BUCKET CYLINDER FOOT PIN (2 POINTS)....201

BUCKET-LINK COUPLING PIN (2 POINTS)....201

ARM-BUCKET COUPLING PIN (2 POINTS)....201

ARM-LINK COUPLING PIN (2 POINTS)....201

BUCKET HINGE PIN (2 POINTS)....202

BOTTOM DUMP CYLINDER FOOT PIN (2 POINTS)....202

BOTTOM DUMP CYLINDER ROD END PIN (2 POINTS)....202

24.6 EVERY 100 HOURS SERVICE....203

CLEAN STRAINER OF PTO LUBRICATION FILTER....203

LUBRICATING SWING CIRCLE....203

DRAIN WATER AND SEDIMENT FROM FUEL TANK....203

24.7 EVERY 250 HOURS SERVICE....204

LUBRICATING....204

FAN PULLEY ASSEMBLY....204

TENSION PULLEY ASSEMBLY....204

CHANGE OIL AND FINAL DRIVE CASE....204

CHECK LEVEL OF BATTERY ELECTROLYTE....205

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE....206

REPLACE HYDRAULIC FILTER ELEMENT....207

CHECK ALTERNATOR DRIVE BELT TENSION, ADJUST....208

CHECK AIR CONDITIONER COMPRESSOR BELT TENSION, ADJUST....209

CHECK, CLEAN FUEL STRAINER....210

CHECK AND TIGHTEN TRACK SHOE BOLTS....210

CHECK AND TIGHTEN TRACK FRAME AND AXLE CONNECTING BOLTS....210

24.8 EVERY 500 HOURS SERVICE....211

CLEAN HYDRAULIC TANK STRAINER....211

CHECK AND CLEAN RADIATOR FINS....212

CLEAN PILOT FILTER STRAINER....212

CLEAN STRAINER OF PTO LUBRICATION OIL FILTER....212

CHANGE FUEL FILTER....213

CHECK FAN BELT....213

CHECK INSPECTION OF WELDINGS STRUCTURE (COLOR CHECK)....214

24.9 EVERY 100 HOURS SERVICE....218

CHANGE OIL IN SWING MACHINERY CASE....218

CHECK TURBOCHARGER CLAMPING JOINT....218

LUBRICATING OF TENSION PULLEY (2 POINTS)....218

CHANGE OIL IN PTO CASE....219

REPLACE CORROSION RESISTOR CARTRIDGE....219

REPLACE HYDRAULIC TANK BREATHER ELEMENT....220

24.10 EVERY 2000 HOURS SERVICE....221

CHANGE OIL IN FINAL DRIVE CASE....221

CHANGE OIL IN HYDRAULIC TANK, CLEAN STRAINER....222

CLEAN, CHECK TURBOCHARGER....222

CHECK TURBOCHARGER ROTOR PLAY....222

CHECK SWING PINION GREASE LEVEL, ADD GREASE....223

CLEAN ENGINE BREATHER....224

CHECK ALTERNATOR, STARTING MOTOR....224

CHECK ENGINE VALVE CLEARANCE, ADJUST....224

CHECK VIBRATION DAMPER....224

24.11 EVERY 4000 HOURS SERVICE....225

CHECK WATER PUMP....225

CHECK FAN PULLEY AND TENSION PULLEY....225

CHECK AIR COMPRESSOR, ADJUST....225

SPECIFICATIONS....227

25. SPECIFICATIONS....228

OPTIONS, ATTACHMENTS....231

26. GENERAL PRECAUTIONS....232

26.1 PRECAUTIONS RELATED TO SAFETY....232

26.2 PRECAUTIONS WHEN INSTALLING ATTACHMENTS....233

27. HANDLING BUCKET WITH HOOK....234

27.1 CHECKING FOR DAMAGE TO BUCKET WITH HOOK....234

27.2 PROHIBITED OPERATIONS....234

27.3 PRECAUTIONS DURING OPERATIONS....234

28. USING SEAT BELT....235

28.1 SEAT BELT....235

29. INTRODUCTION OF ATTACHMENTS....237

29.1 SPECIFICATION, USE....237

BACK HOE TYPE SHOVEL....239

30. GENERAL LOCATIONS....240

31. INSTRUMENTS AND CONTROLS....241

31.1 SWITCH....241

31.2 CONTROL LEVERS....242

31.3 CONTROL BOX....244

31.4 FUSE BOX....245

32. OPERATION....246

32.1 OPERATION OF WORK EQUIPMENT....246

32.2 CHECK BEFORE STARTING ENGINE....248

33. PRECAUTIONS FOR MACHINE OPERATION....251

33.1 PRECAUTIONS DURING OPERATION....251

34. PRECAUTIONS WHEN DISASSEMBLING MACHINE....253

35. MAINTENANCE....254

35.1 OIL FILLER AND LEVEL GAUGE POSITION....254

35.2 ADJUST BUCKET CLEARANCE....255

35.3 CHECK BEFORE STARTING....256

35.4 EVERY 10 HOURS SERVICE....257

36. EXCAVATOR WORK....260

37. TRANSPORTATION....261

38. INTRODUCTION OF ATTACHMENTS....264

38.1 ATTACHMENT INSTALLATION COMBINATION TABLE....264

38.2 SPECIFICATION, USE....265

39. SPECIFICATIONS....266

SEAM008701 - Hydraulic Excavator PC1000-1, PC1000LC-1, PC1000SE-1 Operation & Maintenance Manual....271

COVER....271

1. FOREWARD....272

2. SAFETY INFORMATION....273

3. INTRODUCTION....274

4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR....275

5. CONTENTS....276

SAFETY....280

6. GENERAL PRECAUTIONS....281

7. PRECAUTIONS DURING OPERATION....287

7.1 BEFORE STARTING ENGINE....287

7.2 OPERATING MACHINE....289

7.3 TRANSPORTATION....294

7.4 BATTERY....295

7.5 LIFTING OPERATION....296

8. PRECAUTIONS FOR MAINTENANCE....297

8.1 BEFORE CARRYING OUT MAINTENANCE....297

8.2 DURING MAINTENANCE....300

9. POSITION FOR ATTACHING SAFETY LABELS....304

OPERATION....308

10. GENERAL VIEW....309

10.1 GENERAL VIEW OF MACHINE....309

10.2 GENERAL VIEW OF CONTROLS AND GAUGES....310

11. EXPLANATION OF COMPONENTS....311

11.1 MACHINE MONITOR....311

11.2 LAMP....321

11.3 SWITCHES....322

11.4 CONTROL LEVERS, PEDALS....327

11.5 CEILING WINDOWS....330

11.6 FRONT WINDOW....331

11.7 DOOR LOCK....333

11.8 DUST INDICATOR....333

11.9 AIR CONDITIONER....334

11.10 RADIO....337

11.11 FUSE....339

11.12 CONTROLLERS....340

11.13 TOOL BOX....340

11.14 GREASE PUMP....340

11.15 HANDLING GREASE PUMP....341

11.16 HANDLING ACCUMULATOR....343

11.17 LUGGAGE BOX....345

11.18 METHOD OF RELEASING PRESSURE IN CONTROL CIRCUIT ON MACHINE EQUIPPED WITH ACCUMULATOR....345

11.19 LOCATION OF FIRE EXTINGUISHER....345

12. OPERATION....346

12.1 CHECK BEFORE STARTING ENGINE....346

12.2 STARTING ENGINE....356

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE ....360

12.4 MOVING MACHINE OFF....362

12.5 STEERING MACHINE....366

12.6 TOPPING MACHINE....368

12.7 SWINGING....370

12.8 OPERATION OF WORK EQUIPMENT....371

12.9 WORKING MODE SELECTION....372

12.10 PROHIBITIONS FOR OPERATION....373

12.11 PRECAUTIONS FOR OPERATION....376

12.12 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS....377

12.13 HOW TO ESCAPE FROM MUD....379

12.14 WORK POSSIBLE USING HYDRAULIC EXCAVATOR....380

12.15 PARKING MACHINE....381

12.16 CHECK AFTER FINISHING WORK....382

12.17 STOPPING ENGINE....383

12.18 CHECK AFTER STOPPING ENGINE....384

12.19 LOCKING....384

13. TRANSPORTATION....385

13.1 LOADING UNLOADING WORK....385

13.2 PRECAUTION FOR TRANSPORTATION....272

13.3 PARTS FOR TRANSPORT....386

13.4 PROCEDURE FOR RAISING CHASSIS....389

13.5 SECURING MACHINE....392

13.6 PROCEDURE FOR INCREASING OR REDUCING TRACK FRAME GAUGE....393

14. COLD WEATHER OPERATION....395

14.1 PRECAUTIONS FOR TRANSPORTATION....395

14.2 PRECAUTIONS AFTER COMPLETION OF WORK....397

14.3 AFTER COLD WEATHER....397

15. LONG-TERM STORAGE....398

15.1 BEFORE STORAGE....398

15.2 DURING STORAGE....399

15.3 AFTER STORAGE....399

15.4 STARTING MACHINE AFTER LONG-TERM STORAGE....399

16. TROUBLESHOOTING....400

16.1 PHENOMENA THAT ARE NOT FAILURES....400

16.2 METHOD OF TOWING MACHINE....400

16.3 PRECAUTIONS ON PARTICULAR JOBSITES....401

16.4 IF BATTERY IS DISCHARGED....402

16.5 OTHER TROUBLE....406

MAINTENANCE....414

17. GUIDES TO MAINTENANCE....415

18. OUTLINES OF SERVICE....418

18.1 OUTLINE OF OIL, FUEL, COOLANT....418

18.2 OUTLINE OF ELECTRICAL SYSTEM....421

18.3 OUTLINE OF HYDRAULIC SYSTEM....422

18.4 RELEASING PRESSURE....423

18.5 BLEEDING AIR FROM CIRCUIT....425

18.6 OIL FILTER AND LEVEL GAUGE POSITIONS....430

19. CONSUMABLE PARTS LIST....431

20. USE FUEL,COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERANCE....432

21. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS....436

21.1 INTROUCTION OF NECESSARY TOOLS....436

21.2 TORQUE LIST....437

22. PERIODIC REPLACEMENT OF CRITICAL SAFETY PARTS....438

23. MAINTENANCE SCHEDULE CHART....444

23.1 MAINTENANCE SCHEDULE CHART....444

24. SERVICE PROCEDURE....448

24.1 INTIAL 100 HOURS SERVICE....448

24.2 INTIAL 250 HOURS SERVICE....448

24.3 WHEN REQUIRED....449

24.4 CHECK BEFORE STARTING....469

24.5 EVERY 10 HOURS SERVICE....474

24.6 EVERY 100 HOURS SERVICE....477

24.7 EVERY 250 HOURS SERVICE....478

24.8 EVERY 500 HOURS SERVICE....485

24.9 EVERY 1000 HOURS SERVICE....492

24.10 EVERY 2000 HOURS SERVICE....495

24.11 EVERY 4000 HOURS SERVICE....499

SPECIFICATIONS....500

25. SPECIFICATIONS....501

OPTIONS, ATTACHMENTS....504

26. GENERAL PRECAUTIONS....505

26.1 PRECAUTIONS RELATED TO SAFETY....505

26.2 PRECAUTIONS WHEN INSTALLING ATTACHMENTS....506

27. USING SEAT BELT....507

27.1 SEAT BELT....507

28. INTRODUCTION OF ATTACHMENTS....509

28.1 SPECIFICATION, USE....509

BACK HOE TYPE SHOVEL....510

29. GENERAL LOCATIONS....511

30. INSTRUMENTS AND CONTROLS....512

30.1 SWITCH....512

30.2 CONTROL LEVERS....513

30.3 CONTROL BOX....515

30.4 FUSE BOX....516

31. OPERATION....517

31.1 OPERATION OF WORK EQUIPMENT....517

31.2 CHECK BEFORE STARTING ENGINE....519

32. PRECAUTIONS FOR MACHINE OPERATION....522

32.1 PRECAUTIONS DURING OPERATION....522

33. PRECAUTIONS WHEN DISASSEMBLING MACHINE....524

34. MAINTENANCE....525

34.1 OIL FILTER AND LEVEL GAUGE POSITION....525

34.2 ADJUST BUCKET CLEARANCE....526

34.3 CHECK BEFORE STARTING....527

34.4 EVERY 10 HOURS SERVICE....528

35. EXCAVATOR WORK....531

36. TRANSPORTATION....532

37. INTRODUCTION OF ATTACHMENT....536

37.1 ATTACHMENT INSTALLATION COMBINATION TABLE....536

37.2 SPECIFICATION, USE....537

38. SPECIFICATIONS....538

SEAM018300 - Hydraulic Excavator PC1100-6, PC1100LC-6, PC1100SP-6 avance Operation & Maintenance Manual....542

COVER....542

1. FOREWORD....543

2. SAFETY INFORMATION....544

3. INTRODUCTION....545

4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR....546

5. CONTENTS....547

SAFETY....551

6. GENERAL PRECAUTIONS....552

7. PRECAUTIONS DURING OPERATION....561

7.1 BEFORE STARTING ENGINE....561

7.2 AFTER STARTING ENGINE....563

7.3 TRANSPORTATION....571

7.4 BATTERY....572

7.5 TOWING....574

7.6 LIFTING OPERATIONS....574

7.7 BUCKET WITH HOOK....575

8. PRECAUTIONS FOR MAINTENANCE....576

8.1 BEFORE CARRYING OUT MAINTENANCE....576

8.2 DURING MAINTENANCE....581

9. POSITION FOR ATTACHING SAFETY LABELS....588

OPERATION....593

10. GENERAL VIEW....594

10.1 GENERAL VIEW OF MACHINE....594

10.2 GENERAL VIEW OF CONTROLS AND GAUGES....595

11. EXPLANATION OF COMPONENTS....596

11.1 MACHINE MONITOR....596

11.2 SWITCHES....607

11.3 CONTROL LEVERS, PEDALS....612

11.4 DOOR LOCK....614

11.5 CAP, COVER WITH LOCK....615

11.6 HOT AND COOL BOX....616

11.7 LUGGAGE BOX....616

11.8 ASHTRAY....616

11.9 POWER SUPPLY SOCKET....616

11.10 FUSE....617

11.11 FUSIBLE LINK....618

11.12 CONTROLLERS....618

11.13 TOOL HOLDER (CLOTH bAG)....618

11.14 HANDLING GREASE PUMP....618

11.15 HANDLING ACCUMULATOR....621

12. OPERATION....623

12.1 CHECK BEFORE STARTING ENGINE....623

12.2 STARTING ENGINE....636

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE....639

12.4 MOVING MACHINE OFF....646

12.5 STEERING MACHINE....649

12.6 STOPPING MACHINE....651

12.7 SWINGING....652

12.8 OPERATION OF WORK EQUIPMENT....653

12.9 HANDLING WORKING MODE....654

12.10 PROHIBITIONS FOR OPERATION....655

12.11 PRECAUTIONS FOR OPERATION....657

12.12 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS....658

12.13 HOW TO ESCAPE FROM MUD....660

12.14 WORK POSSIBLE USING HYDRAULIC EXCAVATOR....661

12.15 REPLACEMENT OF BUCKET....662

12.16 PARKING MACHINE....663

12.17 CHECK AFTER FINISHING WORK....664

12.18 STOPPING ENGINE....665

12.19 CHECK AFTER STOPING ENGINE....666

12.20 LOCKING....666

13. TRANSPORTATION....667

13.1 PRECAUTIONS FOR TRANSPORTATION....667

13.2 METHOD OF LIFTING MACHINE....667

13.3 PRECAUTIONS FOR LOADING....669

13.4 TRANSPORTATION POSTURE....670

14. COLD WEATHER OPERATION....676

14.1 PRECAUTIONS FOR LOW TEMPERATURE....676

14.2 PRECAUTIONS AFTER COMPLETION OF WORK....678

14.3 AFTER COLD WEATHER....678

15. LONG-TERM STORAGE....679

15.1 BEFORE STORAGE....679

15.2 DURING STORAGE....680

15.3 AFTER STORAGE....680

15.4 STARTING MACHINE AFTER LONG-TERM STORAGE....680

16. TROUBLESHOOTING....681

16.1 WHEN MACHINE RUNS OUT OF FUEL....681

16.2 PHENOMENA THAT ARE NOT FAILURES....681

16.3 METHOD OF TOWING MACHINE....681

16.4 PRECAUTIONS ON PARTICULAR JOBSITES....681

16.5 IF BATTERY IS DISCHARGED....682

16.6 OTHER TROUBLE....687

MAINTENANCE....693

17. GUIDES TO MAINTENANCE....694

18. OUTLINES OF SERVICE....697

18.1 OUTLINE OF OIL, FUEL, COOLANT....697

18.2 OUTLINE OF ELECTRIC SYSTEM....700

18.3 OUTLINE OF HYDRAULIC SYSTEM....701

19. WEAR PARTS LIST....702

20. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE....703

21. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS....707

21.1 INTRODUCTION OF NECESSARY TOOLS....707

21.2 TORQUE LIST....708

22. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS....709

23. MAINTENANCE SCHEDULE CHART....711

23.1 MAINTENANCE SCHEDULE CHART....711

24. SERVICE PRODEDURE....715

24.1 INITIAL 100 HOURS SERVICE....715

24.2 INITIAL 250 HOURS SERVICE....715

24.3 WHEN REQUIRED....716

24.4 CHECK BEFORE STARTING....732

24.5 EVERY 10 HOURS SERVICE....738

24.6 EVERY 100 HOURS SERVICE....740

24.7 EVERY 250 HOURS SERVICE....741

24.8 EVERY 500 HOURS SERVICE....751

24.9 EVERY 1000 HOURS SEVICE....759

24.10 EVERY 2000 HOURS SERVICE....767

24.11 EVERY 4000 HOURS SERVICE....775

SPECIFICATIONS....777

25. SPECIFICATIONS....778

OPTIONAL PARTS, ATTACHMENTS....785

26. GENERAL PRECAUTIONS....786

26.1 PRECAUTIONS RELATED TO SAFETY....786

26.2 PRECAUTIONS WHEN INSTALLING ATTACHMENTS....787

27. HANDLING BUCKET WITH HOOK....788

27.1 CHECKING FOR DAMAGE TO BUCKET WITH HOOK....788

27.2 PROHIBITED OPERATIONS....788

27.3 PRECAUTIONS DURING OPERATIONS....788

28. USING SEAT BELT....789

28.1 SEAT BELT....789

29. INTRODUCTION OF OPTIONAL PARTS, ATTACHMENTS....791

29.1 COMBINATIONS OF WORK EQUIPMENT....791

29.2 SELECTION OF TRACK SHOES....793

30. HANDLING AIR CONDITIONER....795

30.1 HANDLING AIR CONDITIONER....795

31. HANDLING CAR RADIO....798

31.1 HANDLING CAR RADIO....798

SEAW0021N0103 - Hydraulic Excavator PC1000-1 Field Assembly Manual....805

COVER PAGE....805

TABLE OF CONTENTS....806

A. GENERAL....809

A-1: BEFORE ASSEMBLY....809

A-2: LIST OF PARTS SENT INDIVIDUALLY....813

A-3: POINTS REGARDING LOCAL ASSEMBLY....834

A-4: PRECAUTIONS WHEN ASSEMBLING, TIGHTENING TORQUE OF BOLTS, SCREWS AND TAPER SEAL HOSES....835

A-5: TABLE OF TOOLS FOR LOCAL ASSEMBLY....838

A-6: PLACE TO SET (UNLOAD) EACH UNIT....839

B. ASSEMBLY OF MACHINE (PART I)....840

B-1: INSTALLATION OF LEFT, RIGHT TRACK FRAMES....841

B-2: INSTALLATION OF TRAVEL PIPING....843

B-3: EXCHAING RETURN FILTER (STANDARD PART - SPECIAL FLUSHING PART)....846

B-4: CHECK OF OIL AND WATER LEVELS....848

B-5: CHECK CENTRAL MONITOR....849

B-6: BLEEDING AIR FROM HYDRAULIC PUMP, SWING PUMP....850

B-7: FLUSHING TRAVEL CIRCUIT....851

B-8: INSTALLATION OF TRAVEL PIPING....852

C. ASSEMBLY OF MACHINE (PART II)....853

C-1: INSTALLATION OF LEFT SIDE STEP....854

C-2: INSTALLATION OF STEP....855

C-3: INSTALLATION OF HANDRAIL....856

C-4: INSTALLATION OF STEP (ONLY WHEN INSTALLING HIGH CAB)....857

C-5: INSTALLATION OF OPERATOR'S CAB ASSEMBLY....858

C-6: CONNECTION OF ELECTRICAL COMPONENTS IN OPERATOR'S CAB (ONLY WHEN INSTALLING HIGH CAB)....859

C-7: INSTALLATION OF AIR CONDITIONER (ONLY WHEN INSTALLING HIGH CAB)....860

C-8: INSTALLATION OF OPERATOR'S SEAT ASSEMBLY (ONLY WHEN INSTALLING HIGH CAB)....863

C-9: INSTALLATION OF ADDITIONAL REAR VIEW MIRROR (OPTION)....864

C-10: INSTALLATION OF FOPS (OPTION)....865

C-11: INSTALLATION OF MUFFLER TAIL PIPE....869

C-12: INSTALLATION OF COUNTERWEIGHT ASSEMBLY....871

C-13: EXCHANGING RETURN FILTER (STANDARD PART - SPECIAL FLUSHING PART)....872

C-14: CHECK OF OIL AND WATER LEVELS....873

C-15: CHECK CENTRAL MONITOR (CARRY OUT ONLY WHEN MACHINE IS DIVIDED INTO THREE PARTS FOR TRANSPORTATION)....873

C-16: BLEEDING AIR FROM TRAVEL MOTOR CIRCUIT....874

C-17: BLEEDING AIR FROM HYDRAULIC IDLER CUSHION CIRCUIT....875

C-18: ADJUSTMENT OF HYDRAULIC IDLER CUSHION CYLINDER....877

C-19: ADJUSTING TRACK TENSION....878

D. PROCEDURE FOR ASSEMBLY OF WORK EQUIPMENT (BACKHOE SPECIFICATION)....879

D-1: ASSEMBLY OF BOOM ASSEMBLY....880

D-2: RELEASING PRESSURE FROM HYDRAULIC CIRCUIT....881

D-3: WORK EQUIPMENT PIPING (BETWEEN CHASSIS AND BOOM) (BETWEEN CHASSIS AND BOOM CYLINDER)....882

D-4: FLUSHING WORK EQUIPMENT PIPING....885

D-5: INSTALLATION OF BOOM CYLINDER FOOT PIN....886

D-6: INSTALLING BOOM CYLINDER HOSES....887

D-7: INSTALLATION OF BOOM CYLINDER TOP PIN....888

D-8: INSTALLATION OF ARM CYLINDER FOOT PIN....889

D-9: WORK EQUIPMENT PIPING (ARM CYLINDER)....890

D-10: INSTALLATION OF ARM AND ARM CYLINDER TOP PIN....891

D-11: WORK EQUIPMENT PIPING (BOOM-BUCKET CYLINDER)....892

D-12: ASSEMBLY OF BUCKET ASSEMBLY....893

D-13: MAINTENANCE STANDARD....895

D-14: INSTALLATION OF WORK EQUIPMENT GREASE PIPING....897

D-15: INSTALLATION OF WORK EQUIPMENT WIRING AND WORK EQUIPMENT HOSE CLAMPS....899

D-16: BLEEDING AIR FROM CYLINDER....901

D-17: CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL....902

E. PROCEDURE FOR ASSEMBLY OF WORK EQUIPMENT (FRONT LOADING SHOVEL SPECIFICATION)....903

E-1: INSTALLATION OF ARM CYLINDER FOOT PIN....904

E-2: CONNECTION OF BOOM AND ARM....905

E-3: INSTALLATION OF ARM CYLINDER TOP PIN....906

E-4: INSTALLATION OF BUCKET CYLINDER FOOT PIN....907

E-5: CONNECTION OF LINK AND BUCKET CYLINDER TOP PIN....908

E-6: ASSEMBLY OF BOOM ASSEMBLY....910

E-7: RELEASING PRESSURE FROM HYDRAULIC CIRCUIT....912

E-8: WORK EQUIPMENT PIPING (BETWEEN CHASSIS AND BOOM)....913

E-9: WORK EQUIPMENT PIPING....914

E-10: FLUSHING WORK EQUIPMENT PIPING....919

E-11: INSTALLATION OF BOOM CYLINDER FOOT PIN....921

E-12: INSTALLATION OF BOOM CYLINDER HOSES....922

E-13: INSTALLATION OF BOOM CYLINDER TOP PIN....923

E-14: INSTALLATION OF ARM CYLINDER HOSES....924

E-15: INSTALLATION OF BUCKET CYLINDER PIPING....925

E-16: INSTALLATION OF BOTTOM DUMP CYLINDER PIPING....926

E-17: INSTALLATION OF BUCKET ASSEMBLY....927

E-18: MAINTENANCE STANDARD....929

E-19: INSTALLATION OF BOTTOM DUMP CYLINDER PIPING....931

E-20: INSTALLATION OF WORK EQUIPMENT PIPING CLAMPS....932

E-21: INSTALLATION OF WORKING LAMP....934

E:22: INSTALLATION OF WORK EQUIPMENT GREASE PIPING....935

E-23: BLEEDING AIR FROM WORK EQUIPMENT CIRCUIT....938

E-24: CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL....939

E-25: INSTALLATION OF BOOM FOOT POTENTIOMETER....940

E-26: INSTALLATION AND ADJUSTMENT OF BOOM TOP POTENTIOMETER (BOOM - ARM JOINT)....942

E-27: INSTALLATION OF CLAMPS AND COVER FOR BOOM FOOT POTENTIOMETER....943

E-28: INSTALLATION OF CLAMPS AND COVER FOR BOOM TOP POTENTIOMETER....944

E-29: ADJUSTMENT OF WORK EQUIPMENT CONTROLLER (FOR AUTOMATIC CONTROL OF LOADING SHOVEL)....945

F. ASSEMBLY OF MACHINE (PART III)....951

F-1: EXTENDING TRACK FRAME GAUGE WIDTH (ONLY WHEN DIVIDED INTO THREE PARTS FOR TRANSPORTATION)....952

F-2: INSTALLATION OF TRAVEL PIPING COVERS....954

G. CHECK OF ALL PARTS DURING AND AFTER ASSEMBLY....956

H. PCIOOO-1 55C AUSTRALIA SPECIFICATION....957

APPENDIX....973

FIELD ASSEMBLY INSPECTION REPORT....973

SEBM021N0107 - Hydraulic Excavator PC1000-1, PC1000LC-1, PC1000SE-1, PC1000SP-1 Shop Manual....985

CONTENTS....986

LIST OF REVISED PAGES....987

SAFETY NOTICE....992

FOREWORD....994

HOW TO READ THE SHOP MANUAL....995

HOISTING INSTRUCTIONS....996

WIRE ROPES....996

COATING MATERIALS....997

STANDARD TIGHTENING TORQUE....999

STANDARD TIGHTENING TORQUES OF BOLTS AND NUTS....999

TIGHTENING TORQUE OF HOSE NUTS....999

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS....999

TIGHTENING TORQUE OF O-RING BOSS CONNECTOR....1000

TIGHTENING TORQUE OF O-RING BOSS CONNECTOR....1000

TIGHTENING TORQUES OF FLARE NUT....1000

TIGHTENING TORQUE FOR 102 SERIES ENGINE (BOLT AND NUTS)....1001

TIGHTENING TORQUE FOR 102 SERIES ENGINE (EYE JOINTS)....1001

TIGHTENING TORQUE FOR 102 SERIES ENGINE (TAPERED SCREWS)....1001

ELECTRIC WIRE CODE....1002

CLASSIFICATION BY THICKNESS....1002

CLASSIFICATION BY COLOR AND CODE....1002

CONVERSION TABLE....1003

METHOD OF USING THE CONVERSION TABLE....1003

Millimeters to Inches....1004

Kilogram to Pound....1004

Liter to U.S. Gallon....1005

Liter to U.K. Gallon....1005

kgm to ft. lb....1006

kg/cm2 to lb/in2....1007

Temperature....1008

10 ENGINE....1012

11 STRUCTURE AND FUNCTION....1012

PTO (Power Take-Off)....1013

PTO LUBRICATION SYSTEM....1014

AUTO-DECELERATION SYSTEM....1015

OPERATION TABLE....1018

1. DECELERATOR CYLINDER....1019

2. SOLENOID VALVE....1020

OPERATION....1021

1. SOL A excited (engine running, control levers at NEUTRAL)....1021

2. SOL A, B deactivated (engine running, control levers at NEUTRAL)....1021

3. SOL B excited (engine running, control levers operated)....1021

3. OIL PRESSURE SWITCH....1022

4. AUTO-DECELERATOR SELECTOR SWITCH....1022

12 TESTING AND ADJUSTING....1023

STANDARD FOR TESTING AND ADJUSTING....1024

TESTING AND ADJUSTING TOOL LIST....1026

ADJUSTING VALVE CLEARANCE....1027

MEASURING COMPRESSION PRESSURE....1028

MEASURING BLOW-BY PRESSURE....1029

TESTING AND ADJUSTING FUEL INJECTION TIMING....1030

ADJUSTING FUEL CONTROL LEVER....1033

ADJUSTING AUTO-DECELERATION SYSTEM....1036

MEASURING EXHAUST GAS COLOR....1038

13 DISASSEMBLY AND ASSEMBLY....1039

STARTING MOTOR....1040

REMOVAL....1040

INSTALLATION....1040

ALTERNATOR....1040

REMOVAL....1040

INSTALLATION....1040

ENGINE OIL COOLER....1042

REMOVAL....1042

INSTALLATION....1042

WATER PUMP....1042

REMOVAL....1042

INSTALLATION....1042

FUEL INJECTION PUMP....1044

REMOVAL ....1044

INSTALLATION....1044

NOZZLE HOLDER....1046

REMOVAL....1046

INSTALLATION....1046

TURBOCHARGER....1048

REMOVAL....1048

INSTALLATION....1048

CYLINDER HEAD....1050

REMOVAL....1050

INSTALLATION Serial No.: 10001 - 10371....1061

INSTALLATION Serial No.: 10372 and up....1067

HYDRAULIC OIL COOLER....1073

REMOVAL....1073

INSTALLATION....1073

RADIATOR....1073

REMOVAL....1073

INSTALLATION....1073

ENGINE, PTO, HYDRAULIC PUMP....1075

REMOVAL....1075

INSTALLATION....1077

PTO....1083

REMOVAL....1083

INSTALLATION....1083

DISASSEMBLY....1085

ASSEMBLY....1085

AUTO-DECELERATION CYLINDER....1089

REMOVAL Serial No.: 10001 - 10371....1089

INSTALLATION Serial No.: 10001 - 10371....1089

REMOVAL Serial No.: 10372 and up....1089

INSTALLATION Serial No.: 10372 and up....1089

14 MAINTENANCE STANDARD....1091

PTO (Power Take-Off)....1092

20 POWER TRAIN....1093

21 STRUCTURE AND FUNCTION....1093

POWER TRAIN....1094

TRAVEL AND BRAKE SYSTEM....1095

1. TRAVEL CONTROL CIRCUIT SCHEMATICS....1095

2. TRAVEL CONTROL CIRCUIT....1096

3. STRAIGHT-TRAVEL SYSTEM....1097

4. CENTER SWIVEL JOINT....1102

5. TRAVEL MOTOR AND BRAKE VALVE....1103

6. FINAL DRIVE....1115

SWING SYSTEM....1117

1. SWING HYDRAULIC CIRCUIT SCHEMATICS....1117

2. SWING HYDRAULIC CIRCUIT....1118

3. SWING PUMP....1119

4. SWING CONTROL VALVE....1122

5. SWING MOTOR (WITH MECHANICAL BRAKE) AND SAFETY VALVE....1124

6. SWING BRAKE (AUTOMATIC) AND SWING PARKING BRAKE (MANUAL)....1128

7. FREE SWING SYSTEM....1132

8. SWING MACHINERY....1135

9. SWING CIRCLE....1137

23 DISASSEMBLY AND ASSEMBLY....1138

CENTER SWIVEL JOINT ASSEMBLY....1139

REMOVAL....1139

INSTALLATION....1139

DISASSEMBLY....1141

ASSEMBLY....1141

TRAVEL MOTOR, BRAKE VALVE....1143

REMOVAL....1143

INSTALLATION....1143

TRAVEL MOTOR....1145

DISASSEMBLY....1145

ASSEMBLY....1151

ASSEMBLY OF END COVER ASSEMBLY....1151

1. Servo piston assembly....1151

2. Valve plate....1151

ASSEMBLY OF BRAKE VALVE ASSEMBLY....1151

3. Suction valve....1151

4. Safety valve assembly....1151

5. Counterbalance valve....1153

ASSEMBLY OF MOTOR....1153

6. Bearing outer race....1153

7. Shaft assembly....1153

8. Disc, plate....1155

9. Piston, retainer....1155

10. Brake piston assembly....1157

11. Cylinder block....1157

12. Spring....1157

13. Motor case....1157

14. End cover assembly....1157

15. Block....1157

16. Measuring rotation torque....1157

17. Measuring brake torque....1159

FINAL DRIVE ASSEMBLY....1161

REMOVAL....1161

INSTALLATION....1161

DISASSEMBLY....1163

1. Case assembly....1163

2. Coupling, pinion gear....1163

3. Case, gear assembly....1163

4. Carrier assembly (small)....1163

5. Ring gear (small)....1165

8. Carrier assembly (large)....1165

7. Shaft....1165

8. Ring gear, housing assembly....1165

9. Case assembly....1165

ASSEMBLY....1167

1. Housing....1167

2. Case assembly....1167

3. Bearing....1167

4. Ring gear, housing assembly....1167

5. Preload adjustment, retainer....1167

6. Shaft....1169

7. Carrier assembly (large)....1169

8. Carrier assembly (small)....1171

9. Ring gear (small)....1171

10. Case and gear assembly....1171

11. Pinion gear....1173

12. Case assembly....1173

SPROCKET....1175

REMOVAL....1175

INSTALLATION....1175

SWING PUMP....1177

REMOVAL....1177

INSTALLATION....1177

DISASSEMBLY....1179

ASSEMBLY....1183

ASSEMBLY OF PUMP SUBASSEMBLY....1183

1. Cradle, piston assembly....1183

2. Cylinder block....1183

3. Shaft assembly....1185

4. Servo piston....1187

5. Pump subassembly....1189

6. Adjusting end play of bearing....1189

7. End cap....1189

8. Servo piston cap....1189

9. Impeller....1191

10. Servo and CO-NC valves....1193

11. Rear pump assembly....1193

CO-NC VALVE ASSEMBLY....1195

REMOVAL....1195

INSTALLATION....1195

SERVO VALVE....1195

REMOVAL....1195

INSTALLATION....1195

PPC VALVE....1197

REMOVAL....1197

INSTALLATION....1197

DISASSEMBLY....1197

ASSEMBLY....1197

SWING CONTROL VALVE....1199

REMOVAL....1199

INSTALLATION....1199

MAIN RELIEF VALVE....1199

REMOVAL....1199

INSTALLATION....1199

SWING CONTROL VALVE....1203

DISASSEMBLY....1201

ASSEMBLY....1203

FRONT SWING MOTOR....1205

REMOVAL....1205

INSTALLATION....1205

REAR SWING MOTOR....1205

REMOVAL....1205

INSTALLATION....1205

SWING MOTOR ASSEMBLY....1211

DISASSEMBLY....1207

ASSEMBLY....1211

1. Outer race....1211

2. Shaft assembly....1211

3. Belleville spring, spacer, bearing....1211

4. Spacer....1211

5. Cover....1211

6. Plate, disc....1211

7. Brake piston....1213

8. Piston, shaft....1213

9. Spring....1213

10. Cylinder block....1213

11. Valve plate....1213

12. Belleville spring....1213

13. Check valve....1213

14. Relief valve....1213

15. Valve case assembly ....1213

16. Inspection of rotating torque of drive shaft....1213

REVOLVING FRAME....1215

REMOVAL....1215

INSTALLATION....1215

SWING CIRCLE....1217

REMOVAL....1217

INSTALLATION....1217

FRONT SWING MACHINERY....1219

REMOVAL....1219

INSTALLATION....1219

REAR SWING MACHINERY....1221

REMOVAL....1221

INSTALLATION....1221

SWING MACHINERY....1223

DISASSEMBLY....1223

1. Cover....1223

2. Coupling....1223

3. Ring gear....1223

4. Thrust washer....1223

5. Sungear....1223

6. Carrier assembly....1223

7. Thrust washer....1223

8. Bolt, plate....1223

9. Gear assembly....1223

10. Shaft....1223

11. Spacer....1225

12. Snap ring, bearing....1225

13. Oil seal....1225

DISASSEMBLY OF CARRIER ASSEMBLY....1225

14. Shaft....1225

15. Gear assembly....1225

SWING MACHINERY ....1227

DISASSEMBLY Serial No. 10001-10077....1223

1. Cover....1223

2. Coupling....1223

3. Ring gear....1223

4. Thrust washer....1223

5. Sungear....1223

6. Carrier assembly....1223

7. Thrust washer....1223

8. Bolt, plate....1223

9. Gear assembly....1223

10. Shaft....1223

11. Spacer....1225

12. Snap ring, bearing....1225

13. Oil seal....1225

14. Shaft....1225

15. Gear assembly....1225

ASSEMBLY Serial No. 10001-10077....1227

1. Gear assembly....1227

2. Shaft....1227

3. Oil seal....1227

4. Bearing, snap ring....1227

6. Shaft....1227

6. Spacer....1227

7. Bearing....1229

8. Gear assembly....1229

9. Plate, bolt....1229

10. Thrust washer....1229

11. Carrier assembly, sun gear....1229

12. Thrust washer....1231

13. Ring gear....1231

14. Coupling....1231

15. Cover....1231

16. Refilling with oil....1231

DISASSEMBLY Serial No. 10078 and up....1233

1. Oil filler....1233

2. Cover....1233

3. No. 1 sun gear....1233

4. No. 1 carrier assembly....1233

5. Ring gear....1234

6. No. 2 carrier assembly....1235

7. Swing pinion....1236

8. Spacer....1237

9. Oil seal, bearing....1237

10. Bearing....1237

ASSEMBLY Serial No. 10078 and up....1238

1. Bearing, oil seal....1238

2. Swing pinion....1238

3. Retainer....1239

4. No. 2 carrier assembly....1239

5. Ring gear....1241

6. No. 1 carrier assembly....1241

7. No. 1 sun gear....1242

8. Cover....1243

9. Oil filler....1244

24 MAINTENANCE STANDARD....1245

TRAVEL MOTOR AND BRAKE VALVE....1246

TRAVEL RELIEF VALVE....1248

TRAVEL SHUTTLE VALVE....1249

STRAIGHT-TRAVEL VALVE....1250

FINAL DRIVE....1251

SWING CONTROL VALVE....1252

JET SENSOR....1253

CONNECTION VALVE....1254

SWING MOTOR....1255

SWING MACHINERY....1256

SWING CIRCLE....1258

30 UNDERCARRIAGE....1259

31 STRUCTURE AND FUNCTION....1259

TRACK FRAME....1260

IDLER CUSHION....1263

IDLER....1267

TRACK ROLLER....1268

CARRIER ROLLER....1268

TRACK SHOE....1269

33 DISASSEMBLY AND ASSEMBLY....1271

TRACK....1272

REMOVAL....1272

INSTALLATION....1272

IDLER....1274

REMOVAL....1274

INSTALLATION....1274

IDLER CUSHION....1274

REMOVAL....1274

INSTALLATION....1274

DISASSEMBLY....1276

ASSEMBLY....1276

IDLER ADJUSTMENT CYLINDER....1276

DISASSEMBLY....1276

ASSEMBLY....1276

TRACK ROLLER....1278

REMOVAL....1278

INSTALLATION....1278

CARRIER ROLLER....1278

REMOVAL....1278

INSTALLATION....1278

34 MAINTENANCE STANDARD....1280

TRACK FRAME....1281

TRACK ROLLER....1282

IDLER....1283

CARRIER ROLLER....1285

TRACK SHOE....1286

50 AIR SYSTEM....1288

51 STRUCTURE AND FUNCTION....1288

AIR PIPING....1289

AIR CIRCUIT DIAGRAM....1289

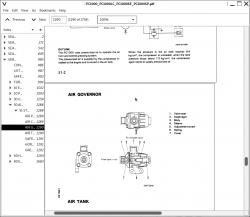

AIR GOVERNOR....1290

AIR TANK....1290

SAFETY VALVE....1291

HORN VALVE....1291

GREASE PUMP....1292

60 HYDRAULIC SYSTEM....1293

61 STRUCTURE AND FUNCTION....1293

HYDRAULIC SYSTEM LOCATION....1294

HYDRAULIC CIRCUIT DIAGRAM....1295

WORK EQUIPMENT CONTROL....1300

ELECTRONIC AUTOMATIC WORK EQUIPMENT CONTROL SYSTEM....1319

HYDRAULIC TANK....1328

MAIN PUMP....1329

CHARGING AND PTO LUBRICATING PUMP....1346

HYDRAULIC OIL FILTER....1347

2-STAGE AND 3-STAGE MODE SELECTOR OLSS (Open center Load Sensing System)....1349

HYDRAULIC CONTROL VALVE....1367

PPC VALVE....1374

PPC ACCUMULATOR....1380

PPC SHUTTLE VALVE....1381

PILOT RELIEF VALVE....1383

SAFETY LOCK VALVE....1385

HYDRAULIC CYLINDER....1386

WORK EQUIPMENT....1393

62 TESTING AND ADJUSTING....1394

TABLE OF JUDGEMENT STANDARD VALUE....1395

TABLE OF JUDGEMENT STANDARD VALVE (FOR MACHINES EQUIPPED WITH 3-STAGE MODE SELECTOR OLSS)....1406

TABLE OF ELECTRICAL JUDGEMENT STANDARD VALUE....1417

TESTING AND ADJUSTING TOOL LIST....1430

TESTING AND ADJUSTMENT OF RELIEF PRESSURE....1431

TESTING AND ADJUSTMENT OF CONTROL CIRCUIT PRESSURE....1433

BLEEDING AIR AND RELEASING PRESSURE....1436

CHARGING ACCUMULATOR WITH GAS....1440

CHECKING SWIVEL JOINT....1441

TESTING AND ADJUSTING OF TRAVEL CONTROL LEVER AND ROD....1443

ADJUSTMENT OF WORK EQUIPMENT POTENTIOMETER (LOADING SHOVEL)....1444

ADJUSTMENT OF WORK EQUIPMENT CONTROL BOX (LOADING SHOVEL)....1445

TROUBLESHOOTING....1450

ELECTRICAL CIRCUIT DIAGRAM....1451

3-STAGE MODE SELECTOR ELECTRONIC OLSS....1452

SWING PARKING BRAKE AND SWING BRAKE SYSTEM....1453

TRAVEL SPEED SELECTOR SYSTEM....1453

ELECTRONIC AUTOMATIC WORK EQUIPMENT CONTROL SYSTEM....1456

CNE9 (Engine potentiometer)....1457

CN5 (Intermediate connector)....1458

CN 13 (WC solenoid)....1459

CN23 (Intermediate connector)....1460

CN36 (Prolix circuit switch)....1461

CN46 (Auto-deceleration solenoid B)....1462

CN62 (Hydraulic pressure switch for ARM IN, BUCKET CURL and DUMP)....1463

OLSS control box....1464

POSITION OF CONNECTORS FOR TROUBLESHOOTING....1454

CONNECTION TABLE FOR CONNECTOR PINS....1465

TROUBLESHOOTING PROCEDURE....1469

CHECKS BEFORE TROUBLESHOOTING....1470

E. H MODE TROUBLESHOOTING....1473

ABNORMALITY JUDGEMENT CONDITIONS FOR SELF-TESTING DISPLAY....1474

TROUBLESHOOTING....1475

E-1 Machine deviates excessively (always deviates)....1479

a) Self-testing display shows abnormality....1480

b) If cause is removed when switching to prolix circuit (when self-testing display shows normal)....1482

E-2 Work equipment, swing, travel speeds extremely slow, or lack of power....1483

a) Self-testing display shows abnormality....1483

b) If cause is removed when switching to prolix circuit (when self-testing display shows normal)....1485

E-3 Engine stalls during operations, or engine speed drops....1488

a) Self-testing display shows abnormality....1488

b) If cause is removed when switching to prolix circuit (when self-testing display shows normal)....1490

E-4 No change in output when mode switch is operated....1491

a) Self-testing display shows abnormality....1492

b) If cause is removed when switching to prolix circuit (when self-testing display shows normal)....1492

E-5 Auto-deceleration does not work....1497

a) Self-testing display shows abnormality....1497

b) Self-testing display shows normality....1501

E-6 Swing does not work....1503

E-7 Excessive hydraulic drift of swing....1505

E-8 Travel speed does not switch....1506

a) Speed does not increase when placed in Hi (does not switch to Hi)....1506

b) Speed does not decrease when placed in Lo....1506

H-1 Machine deviates excessively (deviates more than standard when only travel system is used, travel lever at FULL position)....1512

H-2 Excessive deviation in travel during simultaneous operations....1514

H-3 Machine deviates excessively when starting....1516

H-4 Control levers are extremely heavy....1518

a) If travel lever is heavy....1518

b) If work equipment levers are heavy....1518

H-5 Work equipment, travel, and swing start suddenly during fine control operations....1519

H-6 Speeds for work equipment, swing, and travel are all extremely slow, or there is no power....1520

a) Machine hardly moves....1520

b) Abnormality in some part (abnormality on one side)....1522

c) Individual symptoms....1522

d) If work equipment speed on either side is slow....1523

e) For failures except for those in (a), (b), (c) and (d). (Auto-deceleration is normal.)....1524

H-7 Engine stalls or engine speed drops during operations....1526

H-8 No change in output when mode selector switch is operated....1527

H-9 Auto-deceleration does not come on, or does not not go off....1527

H-10 Abnormal noise comes from around pump....1528

H-11 Swing speed is slow, or overrun when stopping swing is excessive....1529

H-12 Upper structure does not swing....1531

H-13 Excessive hydraulic drift....1533

H-16 Excessive time lag for work equipment....1533

H-17 Troubleshooting Chart....1534

FAILURE MODE AND COMPONENTS....1535

W. L MODE TROUBLESHOOTING....1536

ABNORMALITY JUDGEMENT CONDITIONS FOR SELF-TESTING DISPLAY....1537

TROUBLESHOOTING....1538

W-1 In arc digging mode, work equipment carries out horizontal digging, or there is bucket angle....1540

W-2 In horizontal digging mode, work equipment does not carry out horizontal digging....1541

a) Self-testing display does not show abnormality....1541

b) Self-testing display shows abnormality....1543

W-3 In horizontal digging mode, there is bucket angle compensation....1549

W-4 In horizontal digging + bucket angle compensation mode, work equipment carries out horizontal digging, but there is no.....1550

a) Self-testing display does not show abnormality....1550

b) Self-testing display shows abnormality....1552

W-5 In horizontal digging + bucket angle compensation mode, there is bucket angle compensation, but work equipment does not.....1554

a) Self-testing display does not show abnormality....1554

b) Self-testing display shows abnormality....1554

W-6 In horizontal digging + bucket angle compensation mode, work equipment does not carry out horizontal digging, and there.....1556

a) Self-testing display does not show abnormality....1556

b) Self-testing display shows abnormality....1557

L-1 Work equipment does not carry out horizontal digging or bucket angle compensation....1563

63 DISASSEMBLY AND ASSEMBLY....1564

CHARGING PUMP....1565

REMOVAL....1565

INSTALLATION....1565

NO. 1 PUMP....1567

REMOVAL....1567

INSTALLATION....1569

NO. 2 PUMP....1571

REMOVAL....1571

INSTALLATION....1571

PISTON PUMP....1573

DISASSEMBLY (HPV160 + 160)....1573

DISASSEMBLY OF PUMP BODY....1573

DISASSEMBLY OF PUMP SUB-ASSEMBLY....1575

ASSEMBLY (HPV160 + 160)....1577

ASSEMBLY OF PUMP SUBASSEMBLY....1577

ASSEMBLY OF PUMP BODY....1579

CHECKING CONTACT BETWEEN CYLINDER BLOCK AND VALVE PLATE, AND ROCKER CAM AND CRADLE....1585

CONC VALVE ASSEMBLY (for No. 1 front pump)....1587

REMOVAL....1587

INSTALLATION....1587

CONC VALVE ASSEMBLY (for No. 1 rear pump with TVC valve)....1587

REMOVAL....1587

INSTALLATION....1587

TVC VALVE (for No. 1 rear pump)....1589

REMOVAL....1589

INSTALLATION....1589

SERVO VALVE (for No. 1 front pump)....1591

REMOVAL....1591

INSTALLATION....1591

SERVO VALVE (for No; 1 rear pump)....1591

REMOVAL....1591

INSTALLATION....1591

SERVO VALVE (for No. 2 front pump)....1591

REMOVAL....1591

INSTALLATION....1591

SERVO VALVE (for No. 2 rear pump)....1591

REMOVAL....1591

INSTALLATION....1591

L.H. 5-SPOOL CONTROL VALVE....1593

REMOVAL....1593

INSTALLATION....1595

R.H. 4-SPOOL CONTROL VALVE ASSEMBLY....1597

REMOVAL....1597

INSTALLATION....1599

CONTROL VALVE....1601

DISASSEMBLY....1601

ASSEMBLY....1601

MAIN RELIEF VALVE (for 4-, 5-SPOOL CONTROL VALVE)....1603

REMOVAL, DISASSEMBLY....1603

INSTALLATION, ASSEMBLY....1603

PILOT RELIEF VALVE....1605

REMOVAL, DISASSEMBLY....1605

ASSEMBLY, INSTALLATION....1605

PPC VALVE ASSEMBLY (for work equipment and swing)....1605

DISASSEMBLY, ASSEMBLY....1605

BOOM CYLINDER (BACKHOE)....1607

REMOVAL INSTALLATION....1607

ARM CYLINDER (BACKHOE)....1609

REMOVAL....1609

INSTALLATION....1609

BUCKET CYLINDER ASSEMBLY (BACKHOE)....1611

REMOVAL....1611

INSTALLATION....1611

BOOM CYLINDER ASSEMBLY (LOADING SHOVEL)....1613

REMOVAL....1613

INSTALLATION....1613

ARM CYLINDER ASSEMLBY (LOADING SHOVEL)....1615

REMOVAL....1615

INSTALLATION....1615

BUCKET CYLINDER ASSEMBLY (LOADING SHOVEL)....1617

REMOVAL....1617

INSTALLATION....1617

BOTTOM DUMP CYLINDER ASSEMBLY (LOADING SHOVEL)....1619

REMOVAL....1619

INSTALLATION....1619

HYDRAULIC CYLINDER....1621

DISASSEMBLY....1621

ASSEMBLY....1625

BUCKET ASSEMBLY (BACKHOE)....1629

REMOVAL....1629

INSTALLATION....1629

ARM (BACKHOE)....1631

REMOVAL....1631

INSTALLATION....1631

BOOM (BACKHOE)....1633

REMOVAL....1633

INSTALLATION....1633

BUCKET AND ARM (BACKHOE)....1635

REMOVAL....1635

INSTALLATION....1635

WORK EQUIPMENT (BACKHOE)....1637

REMOVAL....1637

INSTALLATION....1637

BUCKET (LOADING SHOVEL)....1639

REMOVAL....1639

INSTALLATION....1639

ARM (LOADING SHOVEL)....1641

REMOVAL....1641

INSTALLATION....1641

BOOM (LOADING SHOVEL)....1643

REMOVAL....1643

INSTALLATION....1645

WORK EQUIPMENT (LOADING SHOVEL)....1647

REMOVAL....1647

INSTALLATION....1647

POTENTIOMETER (LOADING SHOVEL)....1649

DISASSEMBLY....1649

ASSEMBLY....1649

COUNTERWEIGHT....1649

REMOVAL....1649

INSTALLATION....1649

64 MAINTENANCE STANDARD....1651

CHARGING AND PTO LUBRICATION PUMP....1652

PILOT RELIEF VALE....1653

L.H. 5-SPOOL CONTROL VALVE....1654

R.H. 4-SPOOL CONTROL VALVE....1656

PPC VALVE....1658

PPC SHUTTLE VALVE....1659

WORK EQUIPMENT SAFETY VALVE....1661

HYDRAULIC CYLINDER....1664

WORK EQUIPMENT....1666

80 ELECTRIC AND ELECTRONIC SYSTEM....1683

82 TESTING AND ADJUSTING....1683

ELECTRICAL CIRCUIT DIAGRAM....1684

POSITION OF CONNECTORS FOR TROUBLESHOOTING....1686

M MODE TROUBLESHOOTING....1696

M-1 When starting switch is turned ON, monitor panel display does not appear....1697

M-2 When starting switch is turned ON, monitor panel display does not go out....1697

M-3 When starting switch is turned ON (do not start engine), ....1698

a) (coolant level) flashes....1698

b) (engine oil level) flashes....1698

c) (hydraulic oil level) flashes....1699

M-4 APS switch is not being used, but APS monitor lights up....1701

M-5 When starting switch is turned ON, (engine started), CHECK BEFORE STARTING items flash....1702

a) Alternator system....1702

b) Engine oil pressure system....1702

M-6 When starting switch is turned ON, (do not start engine), CAUTION items flash....1704

M-7 When starting switch is ON (engine started), caution items flash....1705

a) (engine oil pressure) flashes....1705

b) (coolant level) flashes....1705

c) (coolant temperature gauge) flashes....1706

d) (charge level) flashes....1706

e) (hydraulic oil filter) flashes....1707

f) (hydraulic oil temperature) flashes....1707

M-8 When starting switch is turned ON (engine stopped) for 1 second, or when CAUTION items are flashing, warning buzzer does.....1710

M-9 No abnormal display on monitor but warning buzzer sounds....1710

M-10 Monitor panel lamps do not light up (Indication on monitor panel is correct)....1712

M-11 When engine is started, service meter does not move....1713

a) Service meter does not move, when engine is started....1713

b) Service meter does not stop moving, when engine is stopped....1713

M-12 Engine coolant temperature is high, but lowest level displayed....1715

M-13 Engine coolant temperature gauge gives no display....1715

M-14 Fuel tank is not full but display shows full tank....1717

M-15 No display is given for fuel level....1717

P MODE TROUBLESHOOTING....1719

P-1 APS fuse (4) is blown....1720

P-2 Even when APS switch is turned ON, monitor lamp does not start to flash....1723

P-3 When APS switch is turned ON, monitor lamp flashes, but time taken to change to ON is not 60 - 100 sec....1726

P-4 When APS switch is turned ON, flashing of monitor lamp changes to ON after approx. 80 sec. but engine does not start easily....1727

P-5 Engine can be started with APS, but when starting motor stops, engine immediately stalls....1730

P-6 Function of APS does not stop....1731

a) Function of APS is normal, but APS does not stop even when water temperature is more than 20C....1731

b) APS is actuated even when APS switch on panel is not turned ON....1731

FAILURE MODE AND COMPONENTS....1733