Komatsu Hydraulic Excavator PC1100, PC1100LC, PC1100SP Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC1100-6, PC1100LC-6, PC1100SP-6, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC1100-6, PC1100LC-6, PC1100SP-6 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,233 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SEAM018304T-00 - Hydraulic Excavator PC1100-6, PC1100LC-6, PC1100SP-6 avance Operation & Maintenance Manual.pdf

SEAW001100 - Hydraulic Excavator PC1100-6, PC1100LC-6, PC1100SP-6 Field Assembly Manual.pdf

SEBM014207 - Hydraulic Excavator PC1100-6, PC1100LC-6, PC1100SP-6 Shop Manual.pdf

MAIN SECTIONS

SEAM018304T-00 - Hydraulic Excavator PC1100-6, PC1100LC-6, PC1100SP-6 avance Operation & Maintenance Manual....2

COVER....2

1. FOREWORD....3

2. SAFETY INFORMATION....6

3. INTRODUCTION....7

4. LOCATION OF PLATES,TABLE TO ENTER SERIAL NUMBER AND DISTRIBUTOR....8

5. CONTENTS....9

SAFETY....13

6. GENERAL PRECAUTIONS....14

7. PRECAUTIONS DURING OPERATION....22

7.1 BEFORE STARTING ENGINE....22

7.2 AFTER STARTING ENGINE....23

7.3 TRANSPORTATION....29

7.4 BATTERY....30

7.5 TOWING....32

8. SAFETY MAINTENANCE INFORMATION....33

8.1 BEFORE CARRYING OUT MAINTENANCE....33

9. POSITION FOR ATTACHING SAFETY LABELS....39

9.1 POSITION FOR ATTACHING SAFETY LABELS....39

9.2 CONTENT AND USE OF WARNING PLATES....43

OPERATION....44

10. GENERAL VIEW....45

10.1 GENERAL VIEW OF MACHINE....45

10.2 GENERAL VIEW OF CONTROLS AND GAUGES....46

11. EXPLANATION OF COMPONENTS....47

11.1 MACHINE MONITOR....47

11.2 SWITCHES....59

11.3 CONTROL LEVERS,PEDALS....65

11.4 DOOR LOCK....67

11.5 CAP,COVER WITH LOCK....68

11.6 EMERGENCY EXIT FROM OPERATOR'S CAB....69

11.7 HOT AND COOL BOX....69

11.8 LUGGAGE BOX....69

11.9 ASHTRAY....69

11.10 POWER SUPPLY SOCKET....69

11.11 FUSE....70

11.12 FUSIBLE LINK....71

11.13 CONTROLLERS....71

11.14 TOOL HOLDER (CLOTH BAG)....71

11.15 HANDLING GREASE PUMP....71

11.16 HANDLING ACCUMULATOR....74

12. OPERATION....76

12.1 CHECK BEFORE STARTING ENGINE....76

12.2 STARTING ENGINE....89

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE....92

12.4 MOVING MACHINE OFF....99

12.5 STEERING MACHINE....102

12.6 STOPPING MACHINE....104

12.7 SWINGING....105

12.8 OPERATION OF WORK EQUIPMENT....106

12.9 HANDLING WORKING MODE....107

12.10 PROHIBITIONS FOR OPERATION....108

12.11 PRECAUTIONS FOR OPERATION....110

12.12 PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS....111

12.13 HOW TO ESCAPE FROM MUD....113

12.14 WORK POSSIBLE USING HYDRAULIC....114

12.15 REPLACEMENT OF BUCKET....115

12.16 PARKING MACHINE....117

12.17 CHECK AFTER FINISHING WORK....118

12.18 STOPPING ENGINE....119

12.19 CHECK AFTER STOPPING ENGINE....120

12.20 LOCKING....120

13. TRANSPORTATION....121

13.1 PRECAUTIONS FOR TRANSPORTATION....121

13.2 METHOD OF LIFTING MACHINE....121

13.3 PRECAUTIONS FOR LOADING....123

13.4 TRANSPORTATION....124

14. COLD WEATHER OPERATION....130

14.1 PRECAUTIONS FOR LOW TEMPERATURE....130

14.2 PRECAUTIONS AFTER COMPLETION OF WORK....132

14.3 AFTER COLD WEATHER....132

15. LONG-TERM STORAGE....133

15.1 BEFORE STORAGE....133

15.2 DURING STORAGE....134

15.3 AFTER STORAGE....134

15.4 STARTING MACHINE AFTER LONG-TERM STORAGE....134

16. TROUBLESHOOTING....135

16.1 WHEN MACHINE RUNS OUT OF FUEL....135

16.2 PHENOMENA THAT ARE NOT FAILURES ....135

16.3 METHOD OF TOWING MACHINE....135

16.4 PRECAUTIONS ON PARTICULAR JOBSITES....135

16.5 IF BATTERY IS DISCHARGED....136

16.6 OTHER TROUBLE....141

MAINTENANCE....147

17. GUIDES TO MAINTENANCE....148

18. OUTLINES OF SERVICE....150

18.1 OUTLINE OF OIL,FUEL,COOLANT....150

18.2 OUTLINE OF ELECTRIC SYSTEM....154

18.3 OUTLINE OF HYDRAULIC SYSTEM....155

19. WEAR PARTS LIST....156

20. USE OF FUEL,COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE....157

21. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS....161

21.1 INTRODUCTION OF NECESSARY TOOLS....161

21.2 TORQUE LIST....162

22. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS....163

23. MAINTENANCE SCHEDULE CHART....165

23.1 MAINTENANCE SCHEDULE CHART....165

24. SERVICE PROCEDURE....169

24.1 INITIAL 100 HOURS SERVICE....169

24.2 INITIAL 250 HOURS SERVICE....169

24.3 WHEN REQUIRED....170

24.4 CHECK BEFORE STARTING....191

24.5 EVERY 10 HOURS SERVICE....192

24.6 EVERY 100 HOURS SERVICE....194

24.7 EVERY 250 HOURS SERVICE....195

24.8 EVERY 500 HOURS SERVICE....206

24.9 EVERY 1000 HOURS SERVICE....214

24.10 EVERY 2000 HOURS SERVICE....221

24.11 EVERY 4000 HOURS SERVICE....225

SPECIFICATIONS....226

25. SPECIFICATIONS....227

OPTION PARTS,ATTACHMENTS....233

26. GENERAL PRECAUTIONS....234

26.1 PRECAUTIONS REPLATED TO SAFETY....234

26.2 PRECAUTIONS WHEN INSTALLING ATTACHMENTS....235

27. HANDLING BUCKET WITH HOOK....236

27.1 CHECKING FOR DAMAGE TO BUCKET WITH HOOK....236

27.2 PROHIBITED OPERATIONS....236

27.3 PRECAUTIONS DURING OPERATIONS....236

28. USING SEAT BELT....237

28.1 SEAT BELT....237

29. INTRODUCTION OF OPTIONAL PARTS,ATTACHMENTS....239

29.1 COMBINATIONS OF WORK EQUIPMENT....239

29.2 SELECTION OF TRACK SHOES....241

30. HANDLING AIR CONDITIONER....243

30.1 HANDLING AIR CONDITIONER....243

31. HANDLING CAR RADIO....246

31.1 HANDLING CAR RADIO....246

32. AUTO-GREASING SYSTEM....251

32.1 GENERAL LOCATIONS....251

32.2 EXPLANATION OF EQUIPMENT....252

32.3 GREASING POINTS FOR AUTO-GREASING SYSTEM....254

32.4 OPERATION....255

32.5 TROUBLESHOOTING....258

32.6 MAINTENANCE....259

LOADING SHOVEL....265

33. GENERAL LOCATIONS....266

34. INSTRUMENTS AND CONTROLS....267

34.1 SWITCH....267

35. OPERATIONS....269

35.1 OPERATION OF WORK EQUIPMENT....269

36. PRECAUTIONS FOR MACHINE OPERATION....271

36.1 PRECAUTIONS DURING OPERATION....271

37. PRECAUTIONS WHEN DISASSEMBLING MACHINE....274

38. MAINTENANCE....275

38.1 CHECK BEFORE STARTING....275

38.2 EVERY 10 HOURS SERVICE....276

38.3 EVERY 2000 HOURS SERVICE....279

39. EXCAVATOR WORK....281

40. TRANSPORTATION....282

40.1 TRANSPORTATION....282

41. CONSUMABLE PARTS LIST....284

42. SPECIFICATIONS....285

43. COMBINATIONS OF WORK EQUIPMENT....288

43.1 COMBINATIONS OF WORK EQUIPMENT....288

SEAW001100 - Hydraulic Excavator PC1100-6, PC1100LC-6, PC1100SP-6 Field Assembly Manual....290

COVER....290

CONTENTS ....291

Outline of work processes....292

Tool list....293

Transportation posture, dimensions and weights of main components ....294

Outline of size of work place ....299

Precautions during operation ....300

List of parts sent individually....304

Detailed procedure for parts assembly work....313

Procedure for flushing hydraulic circuit....350

Procedure for bleeding air from hydraulic circuit....354

Procedure for adjusting track link....358

Procedure for inspecting oil, water, fuel....361

APPENDIX....369

FIELD ASSEMBLY INSPECTION REPORT....369

SEBM014207 - Hydraulic Excavator PC1100-6, PC1100LC-6, PC1100SP-6 Shop Manual....395

COVER....395

CONTENTS....396

01 GENERAL....422

SPECIFICATION DRAWINGS....423

SPECIFICATIONS....426

WEIGHT TABLE....430

FUEL, COOLANT AND LUBRICANTS....434

10 STRUCTURE AND FUNCTION....436

PTO....437

PTO LUBRICATION SYSTEM....438

RADIATOR, OIL COOLER, AFTERCOOLER....439

POWER TRAIN....441

SWING MACHINERY....443

SWING CIRCLE....444

FINAL DRIVE....445

TRACK FRAME....446

TRACE SHOE....447

AIR PIPING DIAGRAM....448

AIR CIRCUIT DIAGRAM....449

AIR GOVERNOR....450

AIR TANK....450

SAFETY VALVE....451

HORN VALVE....451

GREASE PUMP....452

HYDRAULIC PIPING DRAWING....453

HYDRAULIC CIRCUIT DIAGRAM....458

HYDRAULIC TANK....459

HYDRAULIC PUMP....460

NO.1 PUMP....461

NO.2 PUMP....484

NO.3 PUMP....489

LINE OIL FILTER....498

PILOT OIL FILTER....499

RETURN OIL FILTER....500

DRAIN OIL FILTER ....501

L.H.5-SPOOL CONTROL VALVE....502

R.H.4-SPOOL CONTROL VALVE....504

SWING 4-SPOOL CONTROL VALVE....506

STRAIGHT-TRAVEL VALVE....508

BOOM LOWER REGENERATION VALVE....511

SWING MOTOR....514

CENTER SWIVEL JOINT....516

TRAVEL MOTOR....517

PPC CONTROL RELIEF VALVE....527

SAFETY LOCK VALVE....528

ACCUMULATOR....529

VALVE CONTROL....530

WORK EQUIMENT, SWING PPC VALVE....531

TRAVLE PPC VALVE....535

SOLENOID VALVES....539

WORK EQUIPMENT....541

AIR CONDITIONER....542

ACTUAL ELECTRIC WIRING DIAGRAM....543

ELECTRICAL CIRCUIT DIAGRAM....548

ENGINE CONTROL....549

MACHINE CONTROL SYSTEM....559

MACHINE MONITOR SYSTEM....588

20 TESTING AND ADJUSTING....595

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS....596

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS....597

STANDARD VALUE TABLE FOR ELECTRICAL PARTS....614

TESTING AND ADJUSTING....629

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING....630

MEASURING ENGINE SPEED....631

MEASURING AIR SUPPLY PRESSURE (BOOST PRESSURE)....632

MEASURING EXHAUST TEMPERATURE....633

MEASURING EXHAUST COLOR....634

ADJUSTING VALVE CLEARANCE....635

MEASURING COMPRESSION PRESSURE....636

MEASURING BLOW-BY PRESSURE....637

TESTING AND ADJUSTING FUEL INJECTION TIMING....638

MEASURING ENGINE OIL PRESSURE....639

TESTING AND ADJUSTING FAN BELT TENSION....640

TESTING AND ADJUSTING ALTERNATOR BELT TENSION....640

TESTING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR....641

ADJUSTING ENGINE SPEED SENSOR....641

TESTING CLEARANCE OF SWING CIRCLE BEARING....642

MEASURING WEAR OF SPROCKET....643

TESTING AND ADJUSTING TRACK SHOE TENSION ....644

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT....645

TESTING AND ADJUSTING CONTROL PUMP CIRCUIT OIL PRESSURE....650

TESTING AND ADJUSTING PISTON PUMP CONTROL PRESSURE....651

MEASURING SERVO PISTON STROKE....659

MEASURING PPC VALVE OUTPUT PRESSURE AND TESTING PPC SHUTTLE VALVE....660

TESTING SOLENOID VALVE OUTPUT PRESSURE....664

ADJUSTING WORK EQUIPMENT, SWING PPC VALVE....666

TESTING TRAVEL DEVIATION....667

TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT....668

MEASURING OIL LEAKAGE....669

BLEEDING AIR....673

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT....675

TROUBLESHOOTING....676

POINTS TO REMEMBER WHEN TROUBLESHOOTING....677

SEQUENCE OF EVENTS IN TROUBLESHOOTING....678

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE....679

CHECKS BEFORE TROUBLESHOOTING....687

CONNECTOR TYPES AND MOUNTING LOCATIONS....688

COONECTION TABLE FOR CONNECTIOR PIN NUMBERS....694

EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM....705

DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL....706

ORDER OF TROUBLESHOOTING WHEN CARRYING OUT TROUBLESHOOTING....721

METHOD OF USING JUDGEMENT TABLE....723

METHOD OF USING TROUBLESHOOTING CHARTS....725

TROUBLESHOOTING OF COMMUNICATION ABNORMALITY SYSTEM (N MODE)....727

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE....728

ELECTRICAL CIRCUIT DIAGRAM OF N MODE SYSTEM....730

N-1 [E117, E118 OCCUR AT SAME TIME] MONITOR PANEL COMMUNICATION ABNORMALITY....731

N-2 [E117, E218 OCCUR AT SAME TIME] ENGINE CONTROLLER COMMUNICATION ABNORMALITY....733

N-3 [E118, E507 OCCUR AT SAME TIME] PUMP CONTROLLER COMMUNICATION ABNORMALITY....735

TROUBLESHOOTING OF ENGINE CONTROLLER & APS CONTROLLER SYSTEM (E MODE)....737

JUDGEMENT TABLE FOR ENGINE CONTROLLER, APS CONTROLLER, AND ENGINE RELATED PARTS....738

POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM....741

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE....742

ELECTRICAL CIRCUIT DIAGRAM OF E MODE SYSTEM....750

E-1 [E501] ABNORMALITY IN ENGINE CONTROLLER POWER SOURCE SYSTEM IS DISPLAYED....754

E-2 [E502] ABNORMALITY IN ENGINE CONTROLLER IS DISPLAYED....755

E-3 [E521] DISCONNECTION IN GOVERNOR CONTROL SOLENOID SYSTEM IS DISPLAYED....756

E-4 [E522] SHORT CIRCUIT IN GOVERNOR CONTROL SOLENOID SYSTEM IS DISPLAYED....757

E-5 [E531] ABNORMALITY IN GOVERNOR SERVO IS DISPLAYED....758

E-6 [E537] ABNORMALITY IN CONTORLLER SOLENOID POWER SUPPLE SYSTEM IS DISPLAYED....759

E-7 [E508] ABNORMALITY IN RACK SENSOR POWER SOURCE SYSTEM IS DISPLAYED....760

E-8 [E511] ABNORMALITY IN RACK SENSOR SIGNAL SYSTEM IS DISPLAYED....761

E-9 [E515] DISCONNECTION IN PRESTROKE CONTROL SOLENOID SYSTEM IS DISPLAYED....762

E-10 [E516] SHORT CIRCUIT IN PRESTROKE CONCTOR SOLENOID SYSTEM IS DISPLAYED....763

E-11 [E513] ABNORMALITY IN ENGINE SPEED (1) SYSTEM IS DISPLAYED....764

E-12 [E514] ABNORMALITY IN ENGINE SPEED SENSOR (2) SYSTEM IS DISPLAYED....765

E-13 [E525] DISCONNECTION IN GOVERNOR CUT RELAY SYSTEM IS DISPLAYED....766

E-14 [E526] SHORT CIRCUIT IN GOVERNOR CUT RELAY SYSTEM IS DISPLAYED....767

E-15 [E505] ABNORMALITY IN FUEL CONTROL DIAL VOLTAGE IS DISPLAYED....768

E-16 [E503] MISTAKEN CONNECTION OF CONNECTOR IS DISPLAYED....769

E-17 [E504] ENGINE OVERRUN IS DISPLAYED....770

E-18 [E535] ABNORMALITY IN ENGINE CONTORLLER BACKUP POWER SUPPLE SYSTEM IS DISPLAYED....771

E-19 [E536] ABNORMALITY IN CONTROLLER POWER SUPPLE SYSTEM IS DISPLAYED....772

E-20 ENGINE DOES NOT START....773

E-21 ENGINE DOES NOT STOP....776

E-22 DEFECTIVE ACTUATION OF APS....777

E-23 [E534] ABNORMALITY IN MACHINE SELECTION INPUT TO ENGINE CONTROLLER IS DISPLAYED....784

TROUBLESHOOTING OF ENGINE SYSTEM (S MODE)....785

METHOD OF USING TROUBLESHOOTING CHARTS....786

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)....790

S-2 ENGINE DOES NOT START....791

S-3 ENGINE DOES NOT PICK UP SMOOTHLY(FOLLOW-UP IS POOR)....793

S-4 ENGINE STOPS DURING OPERATIONS....794

S-5 ENGINE DOES NOT ROTATE SMOOTHLY(HUNTING)....795

S-6 ENGINE LACKS OUTPUT(NO POWER)....796

S-7 EXHAUST SMOKE IS BLACK(INCOMPLETE COMBUSTION)....797

S-8 OIL CONSUMPTION IS EXCESSIVE(OR EXHAUST SMOKE IS BLUE)....798

S-9 OIL BECOMES CONTAMINATED QUICKLY....799

S-10 FUEL CONSUMPTION IS EXCESSIVE....800

S-11 OIL IS IN COOLING WATER,OR WATER SPURTS BACK,OR WATER LEVEL GOES DOWN ....801

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP(DROP IN OIL PRESSURE)....802

S-13 OIL LEVEL RISES....803

S-14 WATER TEMPERATURE BECOMES TOO HIGH(OVERHEATING)....804

S-15 ABNORMAL NOISE IS MADE....805

S-16 VIBRATION IS EXCESSIVE....806

TROUBLESHOOTING OF PUMP CONTROLLER SYSTEM(C MODE)....807

JUDGEMENT TABLE FOR PUMP CONTROLLER AND HYDRAULIC(MECHANICAL)RELATED PARTS....808

POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING OF PUMP CONTROLLER SYSTEM....811

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE....812

ELECTRICAL CIRCUIT DIAGRAM FOR C MODE SYSTEM....818

C-1 ABNORMALITY IN CONTROLLER POWER SOURCE SYSTEM(CONTROLLER LED IS OFF)....820

C-2 [E232] SHORT CIRCUIT IN TVC SOLENOID SYSTEM IS DISPLAYED....821

C-3 [E233] DISCONNECTION IN TVC SOLENOID SYSTEM IS DISPLAYED....823

C-4 [E203] SHORT CIRCUIT IN SWING HOLDING BRAKE SOLENOID RELAY SYSTEM IS DISPLAYED....825

C-5 [E213] DISCONNECTION IN SWING HOLDING BRAKE SOLENOID RELAY SYSTEM IS DISPLAYED....827

C-6 [E201] SHORT CIRCUIT IN CO CANCEL SOLENOID SYSTEM IS DISPLAYED....829

C-7 [E211] DISCONNECTION IN CO CANCEL SOLENOID SYSTEM IS DISPLAYED....830

C-8 [E202] SHORT CIRCUIT IN STRAIGHT-TRAVEL SOLENOID SYSTEM IS DISPLAYED....831

C-9 [E212] DISCONNECTION IN STRAIGHT-TRAVEL SOLENOID SYSTEM IS DISPLAYED....832

C-10 [E204] SHORT CIRCUIT IN 2-STAGE RELIEF SOLENOID SYSTEM IS DISPLAYED....833

C-11 [E214] DISCONNECTION IN 2-STAGE RELIEF SOLENOID SYSTEM IS DISPLAYED....834

C-12 [E205] SHORT CIRCUIT IN SWING PRIORITY SOLENOID SYSTEM IS DISPLAYED....835

C-13 [E215] DISCONNECTION IN SWING PRIORITY SOLENOID SYSTEM IS DISPLAYED....836

C-14 [E206] SHORT CIRCUIT IN TRAVEL SPEED SOLENOID SYSTEM IS DISPLAYED....837

C-15 [E216] DISCONNECTION IN TRAVELE SPEED SOLENOID SYSTEM IS DISPLAYED....838

C-16 [E217] MODEL SELECTION INPUT ERROR IS DISPLAYED....839

C-17 [E227] ABNORMALITY IN ENGINE SPEED SENSOR(2)SYSTEM IS DISPLAYED....841

C-18 [E228] ABNORMALITY IN AUTO-DECELERATION OUTPUT SYSTEM IS DISPLAYED....842

C-19 ABNORMALITY IN SWING HOLDING BRAKE SYSTEM(NO SERVICE CODE IS DISPLAYED)....843

C-20 ABNORMALITY IN MACHINE PUSH-UP SOLENOID SYSTEM(NO SERVICE CODE IS DISPLAYED)....845

C-21 ABNORMALITY IN BOOM SHOCKLESS SOLENOID SYSTEM(NO SERVICE CODE IS DISPLAYED)....847

TROUBLESHOOTING OF PUMP CONTROLLER INPUT SIGNAL SYSTE(F MODE)....850

ELECTRICAL CIRCUIT DIAGRAM OF F MODE....851

F-1 [BIT PATTERN 20-(1)] (SWING TO RIGHT OIL PRESSURE SWITCH)DOES NOT LIGHT UP....853

F-2 [BIT PATTERN 20-(2)] (R.H.TRAVEL OIL PRESSURE SWITCH)DOES NOT LIGHT UP....854

F-3 [BIT PATTERN 20-(3)] (BOOM LOWER OIL PRESSURE SWITCH)DOES NOT LIGHT UP....855

F-4 [BIT PATTERN 20-(4)] (BOOM RAISE OIL PRESSURE SWITCH)DOES NOT LIGHT UP....856

F-5 [BIT PATTERN 20-(5)] (ARM IN OIL PRESSURE SWITCH)DOES NOT LIGHT UP....857

F-6 [BIT PATTERN 20-(6)] (ARM OUT OIL PRESSURE SWITCH)DOES NOT LIGHT UP....858

F-7 [BIT PATTERN 21-(1)] (BUCKET CURL OIL PRESSURE SWITCH)DOES NOT LIGHT UP....859

F-8 [BIT PATTERN 21-(2)] (BUCKET DUMP OIL PRESSURE SWITCH)DOES NOT LIGHT UP....860

F-9 [BIT PATTERN 21-(5)] (L.H.TRAVEL OIL PRESSURE SWITCH)DOES NOT LIGHT UP....861

F-10 [BIT PATTERN 26-(5)] (SWING TO LEFT OIL PRESSURE SWITCH)DOES NOT LIGHT UP....862

F-11 [BIT PATTERN 21-(3)] (SWING LOCK SWITCH)DOES NOT LIGHT UP....863

TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM(H MODE)....864

TABLE OF FALIURE MODES AND CAUSES....865

BEFORE CARRYING OUT TROUBLESHOOTING OF HYDRAULIC SYSTEM(H MODE)....867

H-1 SPEEDS OF ALL WORK EQUIPMENT,SWING,TRAVEL ARE SLOW OR LACK POWER....872

H-2 THERE IS EXCESSIVE DROP IN ENGINE SPEED,OR ENGINE STALLS....874

H-3 NO WORK EQUIPMENT,TRAVEL,SEWING MOVE....876

H-4 ABNORMAL NOISE GENERATED(FORM AROUND PUMP)....877

H-5 BOOM IS SLOW OR LACKS POWER....878

H-6 ARM IS SLOW OR LACKS POWER....880

H-7 BUCKET IS SLOW OR LACKS POWER....880

H-8 BOOM DOES NOT MOVE....881

H-9 ARM DOES NOT MOVE ....881

H-10 BUCKET DOES NOT MOVE....881

H-11 EXCESSIVE HYDRAULIC DRIFT....882

H-12 EXCESSIVE TIME LAG....882

H-13 BOOM SHOCKLESS FUNCTION IS NOT ACTUATED OR CANNOT BE CANCELED....883

H-14 MACHINE DEVIATES NATURALLY TO ONE SIDE DURING TRAVEL OPERATIONS....884

H-15 DEVIATION IS EXCESSIVE WHEN STRARTING....886

H-16 TRAVEL DEVIATION IS EXCESSIVE DURING COMPOUND OPERATIONS....887

H-17 TRAVEL SPEED IS SLOW OR LACKS POWER....887

H-18 TRAVEL DOES NOT MOVE(ONE SIDE ONLY)....888

H-19 TRAVEL SPEED DOES NOT SWITCH....889

H-20 DOES NOT SWING ....890

H-21 SWING SPEED IS SLOW OR SWING ACCELERATION IS POOR....891

H-22 IN COMPOUND OPERATIONS WITH BUCKET,SWING SPEED IS SLOW OR SWING ACCELERATION IS POOR....892

H-23 IN COMPOUND OPERATIONS WITH BOON WHEN SWING PRIORITY IS ON,SWING SPEED IS SLOW OR SWING ACCELERATION IS POOR....892

H-24 EXCESSIVE OVERRUN WHEN STOPPING SWING....893

H-25 EXCESSIVE SHOCK WHEN STOPPING SWING....894

H-26 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING....895

H-27 EXCESSIVE HYDRAULIC DRIFT OF SWING....895

TROUBLESHOOTING OF MACHINE MONITOR SYSTEM(M MODE)....896

ACTION TAKEN BY MONITOR PANEL WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE....897

ELECTRICAL CIRCUIT DIAGRAM FOR M MODE SYSTEM....901

M-1 [E101] ABNORMALITY IN ERROR DATA IS DISPLAYED OR [E102]ABNORMALITY IN CLOCK DATA IS DISPLAYEED....903

M-2 [E103] SHOT CIRCUIT IN BUZZER OUTPUT SYSTEM IS DISPLAYED....904

M-3 [E104] AIR CLEANER CLOGGING DETECTED IS DISPLAYED....905

M-4 [E106] DROP IN ENGINE OIL HI PRESSURE DETECTED IS DISPLAYED....905

M-5 [E108] ENGINE WATER TEMPERATURE 105C DETECTED IS DISPLAYED....906

M-6 WHEN STARTING SWITCH IS TURNED ON,NONE OF LAMPS ON MONITOR PANEL LIGHT UP FOR 3 SECONDS....907

M-7 WHEN STARTING SWITCH IS TURNED ON, MONITOR PANEL LAMPS ALL STAY LIGHT UP AND DO NOT GO OUT....909

M-8 WHEN STARTING SWITCH IS TURNED ON,ITEMS LIGHTED UP ON MONITOR PANEL ARE DIFFERENT FROM MACHINE....909

M-9 WHEN STARTING SWITCH IS TURNED ON(ENGINE STOPPED),BASIC CHECK ITEMS FLASH....910

M-10 WHEN STARTING SWITCH IS TURNED ON(ENGINE STOPPED),(PREHEATING MONITOR)DISPLAY IS NOT NORMAL....913

M-11 WHEN ENGINE IS STARTED,BASIC CHECK ITEMS FLASH....914

M-12 WHEN STARTING SWITCH IS TURNED ON(ENGINE STOPPED),CAUTION ITEMS,EMERGENCY STOP ITEMS FLASH....916

M-13 WHEN ENGINE IS STARTED,CAUTION ITEMS,EMERGENCY STOP ITEMS FLASH(BUT THERE IS NO ABNORMALITY IN ANY ITEM)....918

M-14 WHEN STARTING SWITCH IS TURNED ON(ENGINE STOPPED),BUZZER DOES NOT SOUND FOR 1 SECOND CAUTION ITEM FLASHES BUT BUZZER DOES NOT SOUND....923

M-15 NO ABNORMALITY IS DISPLAYED NO MONITOR BUT BUZZER SOUNDS....923

M-16 NIGHT LIGHTING ON MONITOR PANEL DOES NOT LIGHT UP....924

M-17 ENGINE WATER TEMPERATURE GAUGE DOES NOT RISE....925

M-18 ENGINE WATER TEMPERATURE GAUGE DOES NOT GIVE ANY DISPLAY(GAUGE DOES NOT EVEN DISPLAY 1ST LEAVE)....925

M-19 FUEL LEVEL GAUGE ALWAYS DISPLAYS FULL....926

M-20 FUEL LEVEL GAUGE DOES NOT GIVE ANY DISPLAY(GAUGE DOSENOT EVEN DISPLAY 1ST LEVEN....926

M-21 SWING LOCK SWITCH IS TURNED ON,BUT (SWING LOCK MONITOR) DOES NOT LIGHT UP ....927

M-22 SWING PROLIX SWITCH IS TURNED ON (PROLIX),BUT (SWING LOCK MONITOR) DOES NOT FLASH....928

M-23 SERVICE METER DOES NOT ADVANCE WHILE ENGINE IS RUNNING....929

M-24 WHEN STARTING SWITCH IS AT OFF AND TIME SWITCH IS PRESSED,SERVICE METER DOES NOT GIVE DISPLAY....929

M-25 DEFECTIVE FUEL LEVEL SENSOR SYSTEM....930

M-26 DEFECTIVE ENGINE WATER TEMPERATURE SENSOR SYSTEM AND DEFECTIVE HYDRAULIC OIL TEMPERATURE SENSOR SYSTEM....931

M-27 DEFECTIVE ENGINE OIL LEVEL SENSOR SYSTEM AND DEFECTIVE HYDRAULIC OIL LEVEL SENSOR SYSTEM....932

M-28 DEFECTIVE RADIATOR WATER LEVEL SENSOR SYSTEM....933

M-29 DEFECTIVE OPERATION OF WIPER(INCLUDING CASES WHERE[E113]IS DISPLAYED]....934

M-30 DEFECTIVE OPERATION OF WINDOW WASHER(INCLUDING CASES WHERE SERVICE CODE[E114]IS DISPLAYED)....937

30 DISASSEMBLY AND ASSEMBLY....940

METHOD OF USING MANUAL....942

PRECAUTIONS WHEN CARRYING OUT OPERATION....944

SPECIAL TOOL LIST....946

SKETCHES OF SPECIAL TOOLS....953

STARTING MOTOR ASSEMBLY....960

REMOVAL AND INSTALLATION....960

ALTERNATOR ASSEMBLY....961

REMOVAL AND INSTALLATION....961

NOZZLE HOLDER ASSEMBLY....962

REMOVAL AND INSTALLATION....962

ENGINE OIL COOLER ASSEMBLY....963

REMOVAL AND INSTALLATION....963

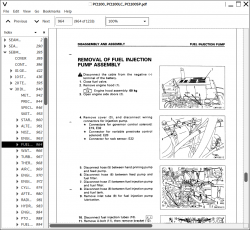

FUEL INJECTION PUMP ASSEMBLY....964

REMOVAL....964

INSTALLATION....965

WATER PUMP ASSEMBLY....966

REMOVAL AND INSTALLATION....966

TURBOCHARGER ASSEMBLY....967

REMOVAL AND INSTALLATION....967

THERMOSTAT ASSEMBLY....968

REMOVAL AND INSTALLATION....968

AIR COMPRESSOR ASSEMBLY....969

REMOVAL AND INSTALLATION....969

ENGINE FRONT SEAL ....970

REMOVAL AND INSTALLATION....970

ENGINE REAR SEAL ....972

REMOVAL AND INSTALLATION....972

CYLINDER HEAD ASSEMBLY....974

REMOVAL....974

INSTALLATION....978

AFTERCOOLER ASSEMBLY....980

REMOVAL AND INSTALLATION....980

RADIATOR,HYDRAULLIC COOLER ASSEMBLY....981

REMOVAL....981

INSTALLATION....982

HYDRAULIC COOLER ASSEMBLY....983

REMOVAL AND INSTALLATION....983

ENGINE,PTO,HYDRAULIC PUMP ASSEMBLY....984

REMOVAL....984

INSTALLATION....987

PTO ASSEMBLY....988

REMOVAL....988

INSTALLATION ....989

DISASSEMBLY....990

ASSEMBLY....992

FUEL TANK ASSEMBLY....994

REMOVAL AND INSTALLATION....994

FINAL DRIVE ASSEMBLY....995

REMOVAL AND INSTALLATION....995

DISASSEMBLY....996

ASSEMBLY....1000

REVOLVING FRAME ASSEMBLY....1008

REMOVAL AND INSTALLATION....1008

SWING MACHINERY ASSEMBLY....1009

REMOVAL AND INSTALLATION....1009

DISASSEMBLY....1010

ASSEMBLY....1014

SWING CIRCLE ASSEMBLY....1019

REMOVAL AND INSTALLATION....1019

TRACK SHOE ASSEMBLY....1020

REMOVAL....1020

INSTALLATION....1021

SPROCKET....1022

REMOVAL AND INSTALLATION....1022

IDLER ASSEMBLY....1023

REMOVAL AND INSTALLATION....1023

DISASSEMBLY....1024

ASSEMBLY....1026

IDLER ADJUSTMENT CYLINDER ASSEMBLY....1028

DISASSEMBLY AND ASSEMBLY....1028

RECOIL SPRING ASSEMBLY....1029

REMOVAL AND INSTALLATION....1029

DISASSEMBLY....1031

ASSEMBLY....1032

CARRIER ROLLER ASSEMBLY....1033

REMOVAL AND INSTALLATION....1033

DIAASSEMBLY....1034

ASSEMBLY....1035

TRACK ROLLER ASSEMBLY....1036

REMOVAL AND INSTALLATION....1036

DISASSEMBLY....1037

ASSEMBLY....1038

HYDRAULIC TANK ASSEMBLY....1040

REMOVAL....1040

INSTALLATION....1041

TVC VALVE ASSEMBLY....1042

REMOVAL AND INSTALLATION....1042

SERVO VALVE ASSEMBLY....1043

REMOVAL AND INSTALLATION....1043

HYDEAULIC PUMP ASSEMBLY....1044

REMOVAL AND INSTALLATION....1044

NO.1, 2 PUMP (HPV95+95)....1045

DISASSEMBLY ....1045

ASSEMBLY....1055

NO.3 PUMP (HPV160+160)....1071

DISASSEMBLY....1071

ASSEMBLY....1081

MAIN PUMP INPUT SHAFT OIL SEAL....1096

REMOVAL AND INSTALLATION....1096

MAIN RELIEF VALVE ASSEMBLY....1097

REMOVAL AND INSTALLATION....1097

DISASSEMBLY AND ASSEMBLY....1098

PILOT RELIEF VALVE ASSEMBLY....1099

REMOVAL AND INSTALLATION....1099

5-SPOOL CONTROL VALVE ASSEMBLY(NO.1)....1100

REMOVAL....1100

INSTALLATION....1101

4-SPOOL CONTROL VALVE ASSEMBLY(NO.2)....1102

REMOVAL....1102

INSTALLATION....1103

4-SPOOL CONTROL VALVE ASSEMBLY(NO.3)....1104

REMOVAL....1104

INSTALLATION ....1105

CONTROL VALVE ASSEMBLY(NO.1)....1106

DISASSEMBLY....1106

ASSEMBLY....1107

CONTROL VALVE ASSEMBLY(NO.2)....1109

DISASSEMBLY....1109

ASSEMBLY....1110

CONTROL VAVLE ASSEMBLY(NO.3)....1113

DISASSEMBLY....1113

ASSEMBLY....1114

SWING MOTOP ASSEMBLT....1117

REMOVAL AND INSTALLATION....1117

CENTER SWIVEL JOINT ASSEMBLY....1118

REMOVAL AND INSTALLATION....1118

DISASSEMBLY AND ASSEMBLY....1119

TRAVEL MOTOR ASSEMBLY....1120

REMOVAL AND INSTALLATION....1120

WORK EQUIPMENT PPC VALVE ASSEMBLY....1121

REMOVAL AND INSTALLATION....1121

DISASSEMBLY....1122

ASSEMBLY....1123

TRAVEL PPC VALVE ASSEMBLY....1124

REMOVAL AND INSTALLATION....1124

DISASSEMBLY....1125

ASSEMBLY ....1126

BUCKET CYLINDER ASSEMBLY....1127

BACKHOE....1127

REMOVAL....1127

INSTALLATION....1128

LOADING SHOVEL....1129

REMOVAL....1129

INSTALLATION....1130

ARM CYLINDER ASSEMBLY....1131

BACKHOE....1131

REMOVAL....1131

INSTALLATION....1132

LOADING....1133

REMOVAL....1133

INSTALLATION....1134

BOOM CYLINDER ASSEMBLY....1135

BACKHOE....1135

REMOVAL....1135

INSTALLATION....1136

LOADING....1137

REMOVAL....1137

INSTALLATION....1138

BOTTOM DUMP CYLINDER ASSEMBLY....1139

LOADING SHOVEL....1139

REMOVAL....1139

INSTALLATION....1140

BUCKET ASSEMBLY....1141

BACKHOE....1141

REMOVAL....1141

INSTALLATION....1142

LOADING SHOVEL....1143

REMOVAL....1143

INSTALLATION....1144

ARM ASSEMBLY....1145

BACKHOE....1145

REMOVAL....1145

INSTALLATION....1146

LOADING SHOVEL....1147

REMOVAL ....1147

INSTALLATION....1148

BOOM ASSEMBLY....1149

BACKHOE....1149

REMOVAL....1149

INSTALLATION....1150

LOADING SHOVEL....1151

REMOVAL....1151

INSTALLATION....1153

BUKET,ARM ASSEMBLY....1155

REMOVAL....1155

INSTALLATION ....1156

WORK EQUIPMENT ASSEMBLY....1157

BACKOE....1157

REMOVAL....1157

INSTALLATION....1158

LOADING SHOVEL....1159

REMOVAL ....1159

INSTALLATION....1160

CAB ASSEMBLY....1161

REMOVAL....1161

INSTALLATION....1162

COUNTERWEIGHT ASSEMBLY....1163

REMOVAL AND INSTALLATION....1163

RECEIVER TANK ASSEMBLY....1164

REMOVAL AND INSTALLATION....1164

AIR CONDITIONER CONDENSER ASSEMBLY....1165

REMOVAL AND INSTALLATION....1165

AIR CONDITIONER COMPRESSOR ASSEMBLY....1166

REMOVAL AND INSTALLATION....1166

AIR CONDITIONER UNIT ASSEMBLY....1167

REMOVAL ....1167

INSTALLATION ....1168

SOLENOID VAVLE ASSEMBLY....1169

REMOVAL AND INSTALLATION....1169

GOVERNOR CONTROLLER ASSEMBLY....1170

REMOVAL AND INSTALLATION....1170

MONITOR PANEL ASSEMBLY....1171

REMOVAL AND INSTALLATION....1171

PUMP CONTROLLER ASSEMBLY....1172

REMOVAL AND INSTALLATION....1172

BOOM ROCK PREVENTION VALVE ASSEMBLY....1173

REMOVAL AND INSTALLATION....1173

ACCUMULATOR ASSEMBLY....1174

REMOVAL AND INSTALLATION....1174

BOOM LOWER REGENERATION VALVE ASSEMBLY....1175

REMOVAL AND INSTALLATION....1175

40 MAINTENANCE STANDARD....1176

ENGINE MOUNT....1177

PTO....1178

SWING CIRCLE....1179

SWING MACHINERY....1180

FINAL DRIVE....1182

TRACK FRAME....1184

IDLER....1185

CARRIER ROLLER....1187

TRACK ROLLER....1188

TRACK SHOE....1189

HYDRAULIC PUMP....1193

CONTROL,PTO LUBRICATING,AFTERCOOLER FAN DRIVE PUMP....1195

L.H.5-SPOOL CONTROL VALVE....1196

R.H.4-SPOOL CONTROL VALVE....1198

SWING 4-SPOOL CONTROL VALVE....1200

STRAIGHT-TRAVEL VALVE....1203

BOOM LOWER REGENERATION VALVE....1204

SWING NOTOR....1205

TRAVEL MOTOR....1206

CENTER SWIVEL JOINT....1208

PPC CONTROL RELIEF VALVE....1209

WORK EQUIPMENTSWING PPC VALVE....1210

TRAVEL PPC VALVE....1211

HYDRAULIC CYLINDER ....1212

FOR BACKHOE....1212

FOR LOADING SHOVEL....1214

WORK EQUIPMENT....1215

FOR BACKHOE....1215

FOR LOADING SHOVEL....1217

DIMENSIONS OF WORK EQUIPMENT....1219

90 OTHERS....1223

HYDRAULIC CIRCUIT DIAGRAM....1224

FOR BACKHOE....1224

FOR LOADING SHOVEL....1225

ELECTRICAL CIRCUIT DIAGRAM....1226

FOR BACKHOE(1/4)....1226

FOR BACKHOE(2/4)....1227

FOR BACKHOE(3/4)....1228

FOR BACKHOE(4/4)....1229

FOR LOADING SHOVEL(1/4)....1230

FOR LOADING SHOVEL(2/4)....1231

FOR LOADING SHOVEL(3/4)....1232

FOR LOADING SHOVEL(4/4)....1233