Komatsu Hydraulic Excavator PC800-8E0, PC800LC-8E0, PC800SE-8E0, PC850-8E0, PC850SE-8E0 Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC800-8E0, PC800LC-8E0, PC800SE-8E0, PC850-8E0, PC850SE-8E0, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavators PC800-8E0, PC800LC-8E0, PC800SE-8E0, PC850-8E0, PC850SE-8E0 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 3,253 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English / Spanish

GEN00102-02 - Hydraulic Excavator PC800-8E0, PC800LC-8E0, PC800SE-8E0, PC850-8E0, PC850SE-8E0 Field Assembly Instruction.pdf

TEN00379-04 - Hydraulic Excavator PC800-8E0, PC800LC-8E0, PC800SE-8E0, PC850-8E0, PC850SE-8E0 Operation & Maintenance Manual.pdf

SEN05276-03 - Hydraulic Excavator PC800-8E0, PC800LC-8E0, PC800SE-8E0, PC850-8E0, PC850SE-8E0 Shop Manual.pdf

GSN05276-03 - Excavadora Hidráulica PC800-8EO, PC800LC-8EO, PC800SE-8EO, PC850-8EO, PC850SE-8EO Manual de Taller.pdf

MAIN SECTIONS

GEN00102-02 - Hydraulic Excavator PC800-8E0, PC800LC-8E0, PC800SE-8E0, PC850-8E0, PC850SE-8E0 Field Assembly Instruction....2

COVER....2

FOREWORD....3

CONTENTS....4

SPECIFICATIONS....7

PRECAUTIONS FOR FIELD ASSEMBLY....8

DISPOSAL OF REMOVED PARTS....9

ASSEMBLING PROCEDURES, APPLICABLE EQUIPMENT AND SCHEDULE....10

5KIT LAYOUT DIAGRAM....11

TRANSPORTATION....12

LIST OF TOOLS FOR FIELD ASSEMBLING....17

TIGHTENING TORQUE....19

COATING MATERIALS LIST....23

SELECTION OF WIRE ROPES USED FOR ASSEMBLY....26

A. ASSEMBLY OF CHASSIS....27

A- 1. Installation of Left and Right Track Frames....28

A- 2. Installation of Travel Pipe....32

A- 3. Installation of Top Guard....35

A- 4. Installation of Radiator Cover....36

A- 5. Installation of Rearview Mirror....37

A- 6. Installation of Left Side Step....41

A- 7. Installation of Handrail....42

A- 8. Installation of Handrail....44

A- 9. Installation of Muffler Tail Tube....46

A-10. Sticking Sheet to Counterweight....47

A-11. Installation of Counterweight....48

A-12. Installation of KOMTRAX Antenna (if equipped)....51

A-13. Installation of Step Light....52

A-14. Air Bleeding of Travel Motor....54

A-15. Installation of Travel Piping Cover....55

A-16. Testing Track Shoe Tension....59

A-17. Check Fuel, Coolant and Oil Levels....62

A-18. Parts to be Touched up after Field Assembly....64

B. ASSEMBLING OF WORK EQUIPMENT OF BACKHOE....65

B- 1. Assembly of Arm Cylinder....66

B- 2. Connection of Arm Cylinder Hoses....68

B- 3. Installation of Boom Cylinder Foot....71

B- 4. Relieving Remaining Pressure from Hydraulic Circuit....72

B- 5. Installation of Boom Cylinder Hoses....73

B- 6. Installation of Boom Foot Dust Seal....74

B- 7. Assembly of Boom Assembly....75

B- 8. Hose Connection of Arm and Bucket Circuits....76

B- 9. Installation of Quick Return Hose....77

B-10. Installation of Boom Cylinder....78

B-11. Installation of Arm Assembly....79

B-12. Installation of Hose between Boom and Bucket Cylinder....81

B-13. Installation of Bucket Assembly....82

B-14. Lubrication Piping to Work Equipment....83

B-15. Wiring of Work Equipment....84

B-16. Greasing after Assembling Work Equipment....85

B-17. Air Bleeding from Hydraulic Cylinder....86

C. ASSEMBLING OF WORK EQUIPMENT OF LOADING SHOVEL....87

C- 1. Releasing residual pressure in hydraulic circuit....88

C- 2. Pulling out boom foot pin and boom cylinder foot pin....89

C- 3. Installation of boom and arm assembly....90

C- 4. Installation of piping between chassis and boom....91

C- 5. Installation of flushing piping for boom cylinder and arm cylinder....92

C- 6. Installation of flushing piping for bucket cylinder....93

C- 7. Installation of flushing piping for bottom dump cylinder....94

C- 8. Installation of boom cylinder....96

C- 9. Installation of boom cylinder foot....97

C-10. Installation of boom cylinder hoses....98

C-11. Installation of boom cylinder rod pin....99

C-12. Installation of arm cylinder hoses....100

C-13. Installation of bucket cylinder....101

C-14. Installation of bucket cylinder hose....102

C-15. Installation of connecting hoses between chassis and boom top....103

C-16. Installation of bottom dump cylinder hoses....104

C-17. Installation of bucket assembly....105

C-18. Installation of working lamps....107

C-19. Installation of work equipment grease piping....108

C-20. Greasing after assembling of work equipment....109

C-21. Bleeding air from work equipment circuit....110

D. ASSEMBLING OF COUNTERWEIGHT REMOVER....111

D- 1. Installation of Rubber Cushions....112

D- 2. Adjustment of Shims for Counterweight....113

D- 3. Greasing....118

D- 4. Installation of Counterweight Remover....119

D- 5. Installation of Covers....120

D- 6. Installation of Hoses....121

D- 7. Bleeding Air from Counterweight Remover Circuit....124

D- 8. Installation of Counterweight....125

D- 9. Installation of Accessories....127

D-10. Check of Operation....128

M. PROCEDURE FOR INSPECTION AND MAINTENANCE AFTER COMPLETION OF ASSEMBLY....129

M- 1. Inspection of Oil Level in Hydraulic Tank and Refill....130

M- 2. Replacement of Return Filter (Standard Filter to Flushing Filter)....132

M- 3. Flushing of Hydraulic Circuit....133

M- 4. Replacement of Return Filter (Flushing Filter to Standard Filter)....135

M- 5. Failure Code....137

Field Assembly Inspection Report (Backhoe)....141

Field Assembly Inspection Report (Loading Shovel)....167

GSN05276-03 - Excavadora Hidrulica PC800-8EO, PC800LC-8EO, PC800SE-8EO, PC850-8EO, PC850SE-8EO Manual de Taller....193

CUBIERTA....193

00 ndice y Prlogo....202

Tabla de contenido....203

Prefacio e informacin general....213

Avisos de seguridad....213

Cmo leer el manual de taller....218

Explicacin de trminos para normas de mantenimiento....220

Manipulacin de componentes hidrulicos....222

Mtodo para desconectar y conectar el tipo de acoplador de empuje-traccin....224

Manipulacin del equipo elctrico....227

Forma de leer el cdigo de alambres elctricos....237

Precauciones al realizar el trabajo....240

Tabla de torsin de apriete estndar....243

Lista de abreviacin....247

Tabla de conversin....251

Manual de Taller....257

01 Especificacin....257

Contenido....258

Especificaciones....260

Dibujo de especificaciones....260

Especificaciones....264

Tabla de peso....274

Tabla de combustible, lquido refrigerante y lubricantes....282

Manual de Taller....285

10 Estructura y funcionamiento....285

Contenido....286

Motor y sistema de enfriamiento....287

Acople....287

Sistema de lubricacin de acoplamiento....288

Sistema de enfriamiento....290

Sistema del tren de potencia....292

Tren de potencia....292

Crculo de giro....294

Maquinaria de giro....295

Mando final....297

Tren de rodaje y bastidor....298

Bastidor de oruga....298

Amortiguador de la rueda tensora....300

Sistema hidrulico....302

Diagrama de ubicacin....302

Tanque hidrulico y filtro....304

Bomba hidrulica....306

Sistema de control de la bomba....314

Servo-vlvula....316

Vlvula de auto-reduccin de presin....325

Bomba del ventilador de enfriamiento....328

Motor de ventilador de enfriamiento....337

Bomba de grasa elctrica....343

Vlvula de control....344

Vlvula de traslado en lnea recta....353

Motor de giro....356

Unin giratoria central....360

Motor de traslado....361

Vlvula PPC....371

Vlvula solenoide....379

Acumulador....387

Vlvula de retorno rpido....388

Filtro de Aceite de retorno....391

Filtro del aceite en la lnea....392

Filtro del aceite piloto....393

Drene el filtro de aceite....394

Sistema Elctrico....395

Control del motor....395

Control del sistema elctrico....405

Sistema monitor....444

Sensors....474

Sistema KOMTRAX....478

Manual de Taller....481

20 Tabla de valores estndar....481

Contenido....482

Tabla de valores estndar....483

Tabla de valores estndar para el motor....483

Tabla de valores estndar para la mquina....484

Manual de Taller....497

30 Pruebas y Ajustes....497

Contenido....498

Herramientas para comprobaciones, ajustes y localizacin de fallas....499

Herramientas para comprobaciones, ajustes y localizacin de fallas....499

Motor y sistema de enfriamiento....503

Comprobacin de la velocidad del motor....503

Forma de medir la presin del aire de admisin (presin de refuerzo)....504

Probando la temperatura del gas de escape....505

Comprobacin del color de los gases del escape....506

Ajustar la holgura de vlvulas....508

Prueba de presin de compresin....509

Prueba de la presin de gases de escape....511

Probando la presin de aceite del motor....512

Comprobacin de la presin de mando de la vlvula EGR y la vlvula de desvo....513

Manipulando partes del sistema de combustible....514

Purga de la presin restante del sistema de combustible....515

Comprobacin de las presiones de combustible....516

Comprobacin de la tasa de retorno y escapes del combustible....517

Purgar el aire del circuito de combustible....520

Probar el circuito de combustible para detectar fugas....522

Probando y ajustando la tensin de la correa del alternador....523

Prueba y ajuste de la tensin de la correa del compresor del acondicionador de aire....524

Tren de rodaje y bastidor....525

Comprobacin del espacio libre del rodamiento del crculo de giro....525

Comprobacin y ajuste de la tensin de la oruga....526

Sistema hidrulico....527

Comprobacin y ajuste de la presin de aceite en los circuitos del equipo de trabajo, giro y traslado....527

Comprobacin y ajuste de circuito de control de presin de aceite (presin de salida de la vlvula de auto-reductora de presin)....533

Comprobacin y ajuste de la seal de control de la bomba principal....535

Comprobar la presin de salida de la vlvula PPC....542

Medicin de la presin de salida de la vlvula de solenoide, vlvula de lanzadera oscilante PPC, y la vlvula de oscilacin prioridad selector....546

Ajuste el juego de la vlvula PPC de giro del equipo de trabajo....551

Comprobacin y ajuste del traslado....552

Inspeccionando los lugares con escape hidrulico interno en el equipo de trabajo....554

Medicin de la velocidad del ventilador....555

Medicin de la presin de aceite del circuito del ventilador....556

Corriente EPC bomba del ventilador....557

Mida la presin de salida del solenoide EPC de la bomba del ventilador....558

Medicin de la fuga de aceite....559

Liberar la presin restante del circuito hidrulico....563

Purgando el aire de varias partes....564

Procedimientos de inspeccin para los diodos....567

Ajuste del espejo....568

Sistema Elctrico....569

Funcin Especial del Monitor de la Mquina....569

Manejando el circuito de voltaje del controlador del motor....613

Trabajos de preparacin para la localizacin de fallas en el sistema elctrico....614

Pm Clinic....618

Pm Servicio Clnico....618

REPORTE DE INSPECCIN DEL TREN DE RODAJE....625

Manual de Taller....627

40 Localizacin de fallas....627

Contenido....628

Informacin general sobre localizacin de fallas....633

Aspectos a recordar durante la localizacin de fallas....633

Secuencia de eventos en la localizacin de fallas....634

Comprobaciones antes de localizar de fallas....635

Clasificacin y procedimientos de localizacin de fallas....661

Tabla de cdigos de falla....664

Nmeros de localizacin de fallas y sntomas....669

Informacin en la tabla de localizacin de fallas....672

Mtodo para la localizacin de fallas de un circuito abierto, en el cableado elctrico del sistema del sensor de presin....674

Lista de conector y diseo....676

Tabla de conexiones por nmero de espigas de los conectores....687

Caja del ramal "T" y tabla del adaptador ramal "T"....723

Localizacin del fusible....726

Localizacin de fallas por el cdigo de falla....729

Cdigo de falla [989L00] Cierre de Precaucin 1, controlador del motor....729

Cdigo de falla [989M00] Cierre del controlador del motor, Precaucin 2....730

Cdigo de falla [989N00] Cierre del controlador del motor, Precaucin 3....730

Cdigo de falla [AA10NX] Obstruccin del filtro de aire....731

Cdigo de falla [AB00KE] Bajo el Voltaje de Carga....732

Cdigo de falla [B@BAZG] Presin del aceite del motor baja....734

Cdigo de falla [B@BAZK] Nivel del aceite del motor baja....735

Cdigo de falla [B@BCNS] Agua del motor sobrecalentado....736

Cdigo de falla [B@BCZK] Bajo el nivel de agua del motor....738

Cdigo de falla [B@HANS] sobrecalentamiento del aceite hidrulico....740

Cdigo de falla [CA111] Falla Crtica Interna de la Vlvula Moduladora de Control Electrnico o ECMV....742

Cdigo de falla [CA115] error en el sensor de velocidad Ne del Motor y en el sensor de velocidad de reversa....744

Cdigo de falla [CA122] Error en sensor por alta presin de carga de aire....746

Cdigo de falla [CA123] Error en sensor por baja presin de aire de carga....748

Cdigo de falla [CA131] Error en Sensor por alta aceleracin....750

Cdigo de falla [CA132] Error en sensor por baja aceleracin....752

Cdigo de falla [CA135] Error en sensor de presin alta de aceite del motor....754

Cdigo de falla [CA141] Error. En sensor de baja presin de aceite del motor....756

Cdigo de falla [CA144] Error en sensor por alta temperatura del refrigerante....758

Cdigo de falla [CA145] Error en sensor por baja temperatura del refrigerante....760

Cdigo de falla [CA153] Error Alta temperatura del sensor del aire de carga....762

Cdigo de falla [CA154] Error en sensor por baja temperatura de aire de carga....764

Cdigo de falla [CA187] Error. Bajo suministro al sensor de 2 voltios....766

Cdigo de falla [CA221] Error. Sensor de alta presin ambiental....768

Cdigo de falla [CA222] Error. Sensor de presin ambiental, baja....770

Cdigo de falla [CA227] Error. Suministro 2 Alto voltaje al sensor....772

Cdigo de falla [CA234] Exceso de velocidad del motor....773

Cdigo de falla [CA238] Error. Suministro energtico al sensor de velocidad Ne....774

Cdigo de falla [CA263] Error en Sensor por Alta Temperatura del Combustible....776

Cdigo de falla [CA265] Error en Sensor por Baja Temperatura del Combustible....778

Cdigo de falla [CA271] IMV/PCV1 Error. Corto circuito....780

Cdigo de falla [CA272] IMV/PCV1 Error Abierto....781

Cdigo de falla [CA273] PCV2 Error. Corto circuito....782

Cdigo de falla [CA274] PCV2 Abierto. Error....783

Cdigo de falla [CA322] Inyector No. 1 (L No. 1) Abierto/Corto circuito Error....784

Cdigo de falla [CA323] Inyector No. 5 (L No. 5) Abierto/Corto circuito Error....786

Cdigo de falla [CA324] Inyector No. 3 (L No. 3) Abierto/Corto circuito Error....788

Cdigo de falla [CA325] Inyector No. 6 (L No. 6) Abierto/Corto circuito Error....790

Cdigo de falla [ CA331] Inyector No. 2 (L No. 2) Abierto/Corto circuito Error....792

Cdigo de falla [ CA332] Inyector No. 4 (L No. 4) Abierto/Corto circuito Error....794

Cdigo de falla [CA342] Incompatibilidad con el Cdigo de Calibracin....796

Cdigo de falla [CA351] Error en el circuito de mando de los inyectores....797

Cdigo de falla [CA352] Error. Bajo voltaje en el suministro energtico 1 del sensor....798

Cdigo de falla [CA386] Error. Alto el suministro 1 de voltaje al sensor....800

Cdigo de falla [CA441] Error. Bajo voltaje de batera....800

Cdigo de falla [CA442] Error. Alto voltaje de batera....801

Cdigo de falla [CA449] Error. Muy alta la presin en el mltiple de combustible....801

Cdigo de falla [CA451] Error. Alto. Sensor de presin en el mltiple de combustible....802

Cdigo de falla [CA452] Error. Bajo. Sensor de presin en el mltiple de combustible....804

Cdigo de falla [CA553] Error. Alto Presin del mltiple comn....806

Cdigo de falla [CA554] Sensor de Presin del Mltiple en Area de Error....807

Cdigo de falla [CA559] Baja Presin de la Bomba de Suministro Error 1....808

Cdigo de falla [CA689] Error en Sensor de velocidad Ne del Motor....812

Cdigo de falla [CA731] Error de fase en el sensor de velocidad de respaldo del Motor....814

Cdigo de falla [CA757] Error. Perdidos todos los datos de continuidad....815

Cdigo de falla [CA778] Error en el sensor de velocidad de reversa del motor....816

Cdigo de falla [CA1228] Error 1, Servo vlvula EGR....818

Cdigo de falla [CA1625] Error 2, Servo Vlvula EGR....819

Cdigo de falla [CA1626] Error. Corriente alta del solenoide de la vlvula BP....820

Cdigo de falla [CA1627] Error. Corriente baja del solenoide de la vlvula BP....822

Cdigo de falla [CA 1628] Error 1. Servo vlvula de desvo....824

Cdigo de falla [CA1629] Error 2. Servo vlvula de desvo....825

Cdigo de falla [CA 1631] Error. Alta seal de voltaje en el sensor de posicin de la vlvula BP....826

Cdigo de falla [CA 1632] Vlvula BP Pos Sens Bajo Error....828

Cdigo de falla [CA1633] Error de Tiempo Muerto del Enlace de Datos KOMNET....830

Cdigo de falla [CA2185] Error de Alto Voltaje Suministrado al Sensor de Aceleracin....832

Cdigo de falla [CA2186] Error por Bajo Voltaje Suministrado al Sensor de Aceleracin....834

Cdigo de falla [CA2249] Error. Muy baja la presin en el mltiple de combustible....835

Cdigo de falla [CA2271] Error. Alta seal de voltaje del sensor de posicin de vlvula EGR....836

Cdigo de falla [CA2272] Error. Bajo voltaje en el sensor de posicin de la vlvula EGR....838

Cdigo de falla [CA2351] Error. Alta corriente en el solenoide de la vlvula EGR....840

Cdigo de falla [CA2352] Error. Baja corriente en el solenoide de la vlvula EGR....842

Cdigo de falla [CA2555] Error del Circuito Abierto Rel de la Parrilla del Calentador....844

Cdigo de falla [CA2556] Error del Circuito Corto Rel de la Parrilla del Calentador....846

Cdigo de falla [D110KB] Corto Circuito en el Mando del Rel de la Batera....848

Cdigo de falla [D163KB] Corto Circuito del Rel de la Luz Intermitente....850

Cdigo de falla [D195KA] Circuito Abierto del Rel de la Luz del Peldao....852

Cdigo de falla [D195KB] Circuito Corto del Rel de la Luz del Peldao....854

Cdigo de falla [D19JKZ] Anormalidad en el rel de cdigo personal....856

Cdigo de falla [D862KA] GPS circuito abierto de antena....858

Cdigo de falla [DA22KK] Error de Baja Energa en la Bomba 1 del Solenoide....860

Cdigo de falla [DA25KP] Anormalidad energtica de 5V en Sensor 1....862

Cdigo de falla [DA29KQ] Anormalidad en seleccin de modelo....864

Cdigo de falla [DA2RMC] CAN Discon (Detectado Con de Bomba)....866

Cdigo de Error [DA80MA] Anormal la Auto Lubricacin....870

Codigo de error [DAF8KB] Corto Circuito en la Camara de Suministro de Energa....872

Cdigo de falla [DAFGMC] Error. Mdulo GPS....874

Cdigo de falla [DAFRMC] Desconexin CAN (Monitor detectado)....875

Cdigo de falla [DGE5KB] Ambi. Cortocircuito en sensor de temperatura....880

Cdigo de falla [DGH2KB] Corto del sensor del aceite hidrulico....882

Cdigo de falla [DH25KA] Circuito Abierto del Sensor del Chorro Izquierdo....884

Cdigo de falla [DH25KB] Circuito Corto del Sensor del Chorro Izquierdo....886

Cdigo de falla [DH26KA] Circuito Abierto del Sensor del Chorro Derecho....888

Cdigo de falla [DH26KB] Circuito Corto del Sensor del Chorro Derecho....890

Cdigo de Falla [DHPEKA] Circuito Abierto del Sensor de Presin del Ventilador de la Bomba de Adelante....892

Cdigo de Falla [DHPEKB] Circuito Corto del Sensor de Presin del Ventilador de la Bomba de Adelante....894

Cdigo de Falla [DHPFKA] Circuito Abierto del Sensor de Presin del Ventilador de la Bomba Trasera....896

Cdigo de Falla [DHPFKB] Circuito Corta del Sensor de Presin del Ventilador de la Bomba Trasera....898

Cdigo de falla [DV20KB] Circuito corto en la alarma de traslado....900

Cdigo de falla [DW41KA] Circuito Abierto del Solenoide de Prioridad del Giro....902

Cdigo de falla [DW41KB] Corto Circuito en el Solenoide de la Prioridad del Giro....904

Cdigo de falla [DW43KA] Circuito Abierto del Solenoide de Velocidad de Traslado....906

Cdigo de falla [DW43KB] Corto Circuito en el Solenoide de la Velocidad de Traslado....908

Cdigo de falla [DW45KA] Circuito Abierto del Solenoide del Freno de Giro....910

Cdigo de falla [DW45KB] Corto Circuito en el Solenoide del Freno del Giro....912

Cdigo de Falla [DW7BKA] Circuito Abierto del Solenoide del Ventilador en Reversa....914

Cdigo de Falla [DW7BKB] Circuito Corto del Solenoide del Ventilador en Reversa....916

Cdigo de falla [DW7JKA] Circuito Abierto del Solenoide de Prioridad del Fondo de Descarga....918

Cdigo de falla [DW7JKB] Circuito Corto del Solenoide de Prioridad del Fondo de Descarga....920

Cdigo de falla [DW91KA] Circuito Abierto del Solenoide de la Unin de Traslado....922

Cdigo de falla [DW91KB] Corto Circuito en el Solenoide de Unin de Traslado....924

Cdigo de falla [DWK0KA] Circuito Abierto del Solenoide de Alivio de 2 Etapas....926

Cdigo de falla [DWK0KB] Corto circuito en el Solenoide de Alivio de 2 Etapas....928

Cdigo de falla [DX16KA] Circuito Abierto del Solenoide de la Bomba EPC del Ventilador....930

Cdigo de falla [DX16KB] Circuito Corto del Solenoide de la Bomba EPC del Ventilador....932

Cdigo de falla [DXAAKA] Circuito Abierto del Solenoide de la Bomba EPC del Ventilador....934

Cdigo de falla [DXAAKB] Circuito Corto del Solenoide de la Bomba EPC del Ventilador....936

Cdigo de falla [DXABKA] Circuito Abierto del Solenoide de la Bomba EPC Trasera....938

Cdigo de falla [DXABKB] Corto del Solenoide de la Bomba EPC Trasera....940

Cdigo de falla (DY20KA) Anormalidad en el Trabajo del Limpiaparabrisas....942

Cdigo de falla [DY20MA] Anormalidad en la Parada del Limpiaparabrisas....946

Cdigo de falla [DY2CKA] Circuito Abierto del Mando del Lavaparabrisas....948

Cdigo de falla [DY2CKB] Corto Circuito en el Mando del Lavaparabrisas....950

Cdigo de falla [DY2DKB] Corto circuito (Avance) en el Mando del limpiaparabrisas....952

Cdigo de falla [DY2EKB] Corto Circuito (Retroceso) en el Mando del Limpiaparabrisas....956

Cdigo de falla [DY2FMA] Anormalidad en el Funcionamiento del Limpiaparabrisas Superior....960

Cdigo de falla [DY2GKM] Anormalidad del Selector del Limpiaparabrisas....962

Localizacin de fallas del sistema elctrico (Modo E)....965

E-1 El motor no arranca (El motor no da vueltas)....965

E-2 El precalentador no trabaja....970

E-3 Cuando el interruptor de arranque est en posicin de ENDENDIDO (ON), el monitor de la mquina no muestra nada....974

E-4 Cuando el interruptor de arranque es colocado en la posicin "ON" (antes de arrancar el motor), se iluminan los tems de revisin bsica....977

E-5 La luz del tem de precaucin se enciende mientras el motor est funcionando....978

E-6 El tem de paro por emergencia se enciende mientras el motor est funcionando....980

E-7 El indicador de temperatura del refrigerante del motor no indica normalmente....981

E-8 El medidor del nivel de combustible no funciona normalmente....982

E-9 El indicador de temperatura del aceite hidrulico no indica normalmente....984

E-10 Las pantallas de monitor de la mquina son diferentes de los de la mquina real....986

E-11 Algunas reas del monitor de la mquina no se muestran....986

E-12 El interruptor de funcin no trabaja....986

E-13 El sistema de precalentamiento automtico no funciona (en temporada fra)....987

E-14 El auto desacelerador no funciona....988

E-15 El modo de trabajo no cambia....989

E-16 La velocidad de traslado no cambia....990

E-17 No se puede cancelar la alarma zumbadora....991

E-18 Cuando el interruptor de arranque es colocado en posicin "OFF", el hormetro de servicio no es exhibido....991

E-19 El modo de servicio no puede ser seleccionado....991

E-20 Cualquiera de los equipos de trabajo, giro, y el traslado no funciona o no se puede cerrar....992

E-21 Funcin de izamiento de la mquina no funciona o no se puede cancelar....994

E-22 La funcin de anti-impactos no opera apropiadamente....996

E-23 Freno de giro no funciona correctamente....998

E-24 El limpiaparabrisas y el lavaparabrisas no funcionan....1000

E-25 La alarma de traslado no suena o no para de sonar....1004

E-26 El indicador de SUBIR el Aguiln no se visualiza correctamente con la funcin de supervisin....1006

E-27 El indicador de BAJAR el Aguiln no se visualiza correctamente con la funcin de supervisin....1008

E-28 El indicador del Brazo ADENTRO no se visualiza correctamente con la funcin de supervisin....1010

E-29 El indicador del Brazo AFUERA no se visualiza correctamente con la funcin de supervisin....1012

E-30 REPLIEGUE del cucharn indicador no se visualiza correctamente con la funcin de supervisin....1014

E-31 DESCARGA del cucharn indicador no se visualiza correctamente con la funcin de supervisin....1016

E-32 Indicador de girono se visualiza correctamente con la funcin de supervisin....1018

E-33 "Traslado de la mano izquierda" no se visualiza correctamente con la funcin de supervisin....1020

E-34 "Traslado de la MANO DERECHA" no se visualiza correctamente con la funcin de supervisin....1022

E-35 Aditamento indicador no se visualiza correctamente con la funcin de supervisin....1024

E-36 La pistola elctrica de engrase no funciona....1026

E-37 El sistema KOMTRAX no funciona apropiadamente....1028

E-38 La bocina no suena o no se detiene....1029

E-39 La luz del peldao ni se enciende ni se apaga....1032

Localizacin de fallas de los sistemas hidrulico y mecnico (Modo H)....1036

Antes de la Localizacin de fallas en los sistemas hidrulico y mecnico....1036

Informacin en la tabla de localizacin de fallas (H-modo)....1040

H-1 Todo el equipo de trabajo, el giro y trabajo de traslado o falta de energa....1042

H-2 La velocidad del motor disminuye significativamente o el motor se cala....1044

H-3 Cualquier del equipo de trabajo, del traslado y el giro no funcionan....1046

H-4 Se escucha ruido anormal alrededor de la bomba hidrulica....1048

H-5 La operacin del aguiln carece de velocidad o de potencia....1049

H-6 La operacin del brazo carece de velocidad o de potencia....1051

H-7 La operacin del cucharn carece de velocidad o de potencia....1052

H-8 El aguiln no se mueve....1053

H-9 El brazo no se mueve....1053

H-10 El cucharn no se mueve....1053

H-11 El deslizamiento hidrulico del equipo de trabajo es grande....1054

H-12 El lapso de tiempo en el equipo de trabajo es grande....1056

H-13 La funcin de levantamiento pesado no funciona o no esta restaurada....1057

H-14 La Funcin de elevacin de la mquina no funciona o no se libera....1057

H-15 La funcin anti-impactos del aguiln no funciona o no se cancela....1057

H-16 Mquina se desva en una direccin contra la intencin del operador cuando se traslada....1058

H-17 La mquina se desva en gran parte al arrancar....1061

H-18 La mquina se desva grandemente durante las operaciones combinadas....1062

H-19El traslado es lento, o le falta potencia....1063

H-20 Una de las pistas no se ejecuta....1064

H-21 La velocidad de traslado no cambia....1065

H-22 La estructura superior no gira....1066

H-23 La velocidad de giro es baja o de aceleracin es pobre....1067

H-24 En el funcionamiento combinado de los equipos de trabajo, la aceleracin de oscilacin es bajo o la velocidad de giro es pobre....1068

H-25 La estructura superior sigue movindose cuando se detiene el giro....1070

H-26 Se producen sacudidas grandes cuando la estructura superior termina su giro....1071

H-27 Ruido inusual grande se oye cuando la estructura superior deja de balanceo....1072

H-28 Desplazamiento del giro en una pendiente es grande....1073

H-29 La revolucin del ventilador es anormal (El sonido o vibracin es anormalmente grande, o el motor se recalienta)....1074

Localizacin de fallas en el motor (Modo-S)....1076

Mtodo para el uso de la tabla de localizacin de fallas....1076

S-1 El arranque es pobre....1080

S-2 El motor no arranca....1082

S-3 El motor no acelera suavemente....1086

S-4 El motor se para durante la operacin....1087

S-5 El motor funciona de forma irregular o est inestable....1088

S-6 El motor le falta potencia....1090

S-7 El gas de escape es negro (combustin incompleta)....1092

S-8 Excesivo consumo de aceite (o el humo de escape es color azul)....1094

S-9 El aceite se contamina rpidamente....1095

S-10 El consumo de combustible es excesivo....1096

S-11 Hay presencia de aceite en el enfriador (o el enfriador se escapa en borboteos o el nivel del enfriador desciende)....1097

S-12 Cae la presin del aceite....1098

S-13 Aumenta el nivel de aceite (refrigerante o combustible en el aceite)....1100

S-14 La temperatura del refrigerante se eleva demasiado (sobrecalentamiento)....1102

S-15 Un ruido anormal es producido....1103

S-16 La vibracin es excesiva....1104

Manual de Taller....1105

50 Desarme y Ensamblaje....1105

Contenido....1106

Informacin general sobre desensamble y ensamble....1108

Como leer Desarme y Ensamblaje....1108

Lista de materiales de recubrimiento....1110

Lista de herramientas especiales....1113

Dibujos de las herramientas especiales....1120

Motor y sistema de enfriamiento....1125

Desmontaje e instalacin del motor, PTO y conjunto de la bomba hidrulica....1125

Desmontaje e instalacin del conjunto del enfriador....1133

Remocin e instalacin del conjunto del posenfriador....1139

Desmontaje e instalacin del enfriador de combustible y el conjunto del condensador de aire....1141

Remocin e instalacin del conjunto del motor del ventilador....1143

Desmontaje e instalacin del conjunto del tanque de combustible....1148

Motor....1150

Desmontaje e instalacin del conjunto de la bomba de suministro de combustible....1150

Desmontaje e instalacin del conjunto del cabezal del cilindro....1155

Remocin e instalacin del conjunto del inyector de combustible....1171

Extraccin e instalacin del sello delantero del motor....1174

Extraccin e instalacin del sello trasero del motor....1176

Tren de potencia....1181

Remocin e instalacin de los conjuntos PTO....1181

Desensamblaje y ensamblaje del conjunto de la toma de fuerza (TDF)....1188

Remocin e instalacin del motor de giro y el conjunto de la maquinaria de giro....1190

Desarme y ensamblaje del conjunto de la maquinaria de giro....1193

Remocin e instalacin del conjunto del crculo de giro....1200

Desensamble y ensamble del conjunto del mando final....1201

Tren de rodaje y bastidor....1213

Separacin y conexin instalacin del conjunto de la zapata de la oruga....1213

Desensamble y ensamble de un eslabn en el campo....1215

Remocin e instalacin del conjunto de la rueda tensora....1219

Desensamble y ensamble de conjuntos de la rueda tensora....1220

Desensamble y ensamble de conjuntos de la rueda tensora del cilindro de ajuste....1223

Remocin e instalacin del conjunto del resorte tensor....1224

Desarme y ensamblaje del conjunto del resorte amortiguador....1226

Desmontaje e instalacin del conjunto del rodillo superior....1228

Desarme y ensamblaje del conjunto del rodillo superior....1229

Desmontaje e instalacin del conjunto de los rodillos....1232

Desarme y ensamblaje del conjunto del rodillo inferior....1233

Desmontaje y instalacin del conjunto de la estructura del piso....1236

Remocin e instalacin del conjunto del contrapeso....1238

Remocin e instalacin del conjunto de removedor del contrapeso....1239

Sistema hidrulico....1243

Desmontaje e instalacin del conjunto del tanque hidrulico....1243

Desmontaje e instalacin del conjunto de la bomba principal....1245

Desmontaje e instalacin del sello de aceite....1252

Desmontaje e instalacin del conjunto de la bomba del ventilador de enfriamiento....1253

Remocin e instalacin del conjunto de la vlvula de control....1256

Ensamblaje del conjunto de la vlvula reguladora....1259

Remocin e instalacin del conjunto del motor de giro....1265

Remocin e instalacin de conjunto de la unin giratoria central....1266

Desmontaje y montaje del conjunto de la junta central de montaje giratorio....1268

Remocin e instalacin del conjunto del motor de traslado....1270

Remocin e instalacin del conjunto de la vlvula de solenoide....1271

Remocin e instalacin del conjunto de la vlvula de amortiguacin del aguiln....1273

Desensamble y ensamble del conjunto de la vlvula PPC del equipo de trabajo....1274

Desensamble y ensamble del conjunto de la vlvula PPC de traslado....1276

Desarme y ensamble del conjunto del cilindro hidrulico....1279

Desmontaje y montaje del conjunto de pistola de grasa....1286

Equipo de trabajo....1287

Retiro e instalacin del conjunto del cilindro del cucharn....1287

Retiro e instalacin del conjunto del cilindro del brazo....1291

Retiro e instalacin del conjunto del cilindro del aguiln....1295

Retiro e instalacin del conjunto del cilindro del fondo de descarga....1299

Remocin e instalacin de los conjuntos del cucharn....1301

Remocin e instalacin del conjunto del brazo....1304

Remocin e instalacin del conjunto del aguiln....1308

Remocin e instalacin del conjunto del equipo de trabajo....1312

Cabina y sus aditamentos....1316

Remocin e instalacin del conjunto de la cabina del operador....1316

Remocin e instalacin del cristal de la cabina del operador (cristal adherido de las ventanas)....1319

Remocin e instalacin del conjunto de la ventana delantera....1328

Sistema Elctrico....1335

Extraccin e instalacin del conjunto de la unidad acondicionador de aire....1335

Remocin e instalacin del conjunto del controlador del motor....1338

Retiro e instalacin del conjunto del monitor....1340

Extraccin e instalacin del conjunto del controlador de la bomba....1342

Remocin e instalacin del conjunto del terminal KOMTRAX....1344

Manual de Taller....1345

60 Estndar de mantenimiento....1345

Contenido....1346

Motor y sistema de enfriamiento....1347

Acople....1347

Tren de potencia....1348

Crculo de giro....1348

Maquinaria de giro....1349

Mando final....1352

Rueda motriz....1354

Tren de rodaje y bastidor....1356

Bastidor de la oruga y gua de la rueda tensora....1356

Rueda tensora....1358

Rodillo superior....1360

Rodillo inferior....1362

Zapata de la oruga....1364

Sistema hidrulico....1368

Motor de ventilador de enfriamiento....1368

Vlvula de control....1370

Motor de giro....1376

Unin giratoria central....1378

Vlvula PPC....1379

Equipo de trabajo....1382

Equipo de trabajo....1382

Dimensin del equipo de trabajo....1388

Cilindro hidrulico....1392

Manual de Taller....1399

80 Apndice....1399

Tabla de contenido....1400

Acondicionador de aire....1401

Advertencias para refrigerante....1401

Componente del acondicionador de aire....1402

Configuracin y funcin del ciclo de refrigeracin....1404

Descripcin del ciclo de refrigeracin....1405

Unidad acondicionadora de aire....1408

Controlador del acondicionador de aire....1413

Compresor....1414

Condensador....1415

Recibidor-secador....1416

Procedimiento para realizar las pruebas y la localizacin de fallas....1418

Esquema elctrico y disposicin de las clavijas del conector....1420

Diagrama del sistema....1422

Detalle de la unidad acondicionador de aire....1424

Esquema de piezas y conectores....1426

Prueba de escapes de aire (conducto)....1429

Probando con la funcin de auto diagnstico....1430

Comprobacin del control de temperatura....1433

Comprobacin (modo) intercambio de ventilacin....1435

Comprobacin del amortiguador de cambio de aire FRESH/RECIRC (LIMPIO/DE RECIRCULACIN)....1438

Verificacin del sensor interior....1440

Verificacin del sensor de temperatura del evaporador....1441

Verificacin del sensor de la luz solar....1443

Comprobacin del (doble) interruptor de presin para el refrigerante....1444

Pruebas de rels....1445

Tablas de localizacin de fallas 1....1446

Tablas de localizacin de fallas 2....1448

Informacin en la tabla de localizacin de fallas....1450

Localizacin de fallas de problemas de alimentacin y sistema de comunicacin CAN (acondicionador de aire no funciona)....1452

Localizacin de fallas para el compresor y el sistema del refrigerante (Aire no esta fro)....1457

Localizacin de fallas para el sistema del soplador del motor (No sale aire o el fluyo de aire es anormal)....1461

Localizacin de fallas en el control de temperatura....1465

Comprobacin para el (modo) intercambio de ventilacin....1468

Localizacin de fallas para el intercambio de FRESH/RECIRC....1470

Localizacin de falla para el sistema de sensor de temperatura....1472

Localizacin de fallas con el medidor de la presin....1474

Conexin para herramienta de servicio....1476

Precauciones para desconectar la tuberia del acondicionador de aire....1478

Manipulacin del aceite del compresor....1480

Manual de Taller....1483

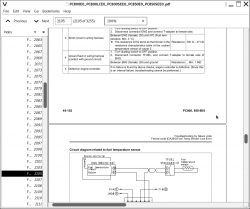

90 Diagramas y dibujos....1483

Contenido....1484

Diagrama del circuito hidrulico....1485

Smbolos usados en los diagramas del circuito hidrulico....1485

Diagrama del circuito elctrico....1491

Smbolos usados en los diagramas del circuito elctricos....1491

A....1512

B....1512

C....1512

D....1513

E....1513

F....1514

H....1514

I....1514

L....1514

M....1514

N....1515

P....1515

R....1515

S....1515

T....1515

U....1516

V....1516

ndice....1512

SEN05276-03 - Hydraulic Excavator PC800-8E0, PC800LC-8E0, PC800SE-8E0, PC850-8E0, PC850SE-8E0 Shop Manual....1520

COVER....1520

00 Index and foreword....1530

Table of contents....1531

Table of contents....1531

Foreword and general information....1541

Safety notice....1541

How to read the shop manual....1546

Explanation of terms for maintenance standard....1548

Handling of hydraulic components....1550

Method of disconnecting and connecting push-pull type coupler....1552

Handling of electric equipment....1555

How to read electric wire code....1565

Precautions when performing work....1568

Standard tightening torque table....1571

List of abbreviation....1575

Conversion table....1579

01 Specification....1584

Specifications....1587

Specifications drawing....1587

Specifications....1591

Table of weight....1601

Table of fuel, coolant and lubricants....1609

10 Structure and function....1612

Engine and cooling system....1614

Coupling....1614

Coupling lubrication system....1615

Cooling system....1617

Power train system....1619

Power train....1619

Swing circle....1621

Swing machinery....1622

Final drive....1624

Undercarriage and frame....1625

Track frame....1625

Idler cushion....1627

Hydraulic system....1629

Hydraulic component layout....1629

Hydraulic tank and filter....1631

Hydraulic pump....1633

Pump control system....1641

Servo valve....1643

Self-pressure reducing valve....1652

Cooling fan pump....1655

Cooling fan motor....1664

Electrical grease pump....1670

Control valve....1671

Straight-travel valve....1680

Swing motor....1683

Center swivel joint....1687

Travel motor....1688

PPC valve....1698

Solenoid valve....1706

Accumulator....1714

Quick return valve....1715

Return oil filter....1718

Line oil filter....1719

Pilot oil filter....1720

Drain oil filter....1721

Electrical system....1722

Engine control....1722

Electric control system....1732

Monitor system....1771

Sensors....1801

KOMTRAX system....1805

20 Standard value table....1808

Standard value table....1810

Standard value table for engine....1810

Standard value table for machine....1811

30 Testing and adjusting....1824

Tool for testing, adjusting and troubleshooting....1826

Tools for testing, adjusting, and troubleshooting....1826

Engine and cooling system....1830

Testing engine speed....1830

Testing intake air pressure (boost pressure)....1831

Testing exhaust gas temperature....1832

Testing exhaust gas color....1833

Adjusting valve clearance....1835

Testing compression pressure....1836

Testing blowby pressure....1838

Testing engine oil pressure....1839

Testing EGR valve and bypass valve drive pressure....1840

Handling fuel system parts....1841

Releasing remaining pressure from fuel system....1842

Testing fuel pressure....1843

Testing fuel return rate and leakage....1844

Bleeding air from fuel circuit....1847

Testing fuel circuit for leakage....1849

Testing and adjusting alternator belt tension....1850

Testing and adjusting air conditioner compressor belt tension....1851

Undercarriage and frame....1852

Testing swing circle bearing clearance....1852

Checking and adjusting track tension....1853

Hydraulic system....1854

Testing and adjusting oil pressure in work equipment, swing, and travel circuits....1854

Testing and adjusting control circuit oil pressure (output pressure of self-pressure reducing valve)....1860

Testing and adjusting control signal of main pump....1862

Testing PPC valve output pressure....1869

Measuring outlet pressure of solenoid valve, swing PPC shuttle valve, and swing priority selector valve....1873

Adjusting play of work equipment and swing PPC vavles....1878

Testing and adjusting travel deviation....1879

Inspecting locations of hydraulic drift in work equipment....1881

Measuring fan speed....1882

Measuring fan circuit oil pressure....1883

Measuring fan pump EPC current....1884

Measuring fan pump EPC solenoid valve outlet pressure....1885

Measuring oil leakage....1886

Releasing remaining pressure from hydraulic circuit....1890

Bleeding air from various parts....1891

Inspection procedures for diode....1894

Adjusting mirrors....1895

Electrical system....1896

Special functions of machine monitor....1896

Handling voltage circuit of engine controller....1940

Preparatory work for troubleshooting of electrical system....1941

Pm Clinic....1945

Pm clinic service....1945

UNDERCARRIAGE INSPECTION REPORT....1952

40 Troubleshooting....1954

General information on troubleshooting....1960

Points to remember when troubleshooting....1960

Sequence of events in troubleshooting....1961

Checks before troubleshooting....1962

Classification and procedures for troubleshooting....1988

Failure codes table....1991

Symptom and troubleshooting numbers....1996

Information in troubleshooting table....1999

Troubleshooting method for open circuit in wiring harness of pressure sensor system....2001

Connector list and layout....2003

Connection table for connector pin numbers....2014

T- branch box and T- branch adapter table....2050

Fuse locations....2053

Troubleshooting by failure code....2056

Failure code [989L00] Engine Controller Lock Caution 1....2056

Failure code [989M00] Engine Controller Lock Caution 2....2057

Failure code [989N00] Engine Controller Lock Caution 3....2057

Failure code [AA10NX] Air Cleaner Clogging....2058

Failure code [AB00KE] Charge Voltage Low....2059

Failure code [B@BAZG] Eng Oil Press Low....2061

Failure code [B@BAZK] Eng Oil Level Low....2062

Failure code [B@BCNS] Eng Water Overheat....2063

Failure code [B@BCZK] Eng Water Level Low....2065

Failure code [B@HANS] Hyd Oil Overheat....2067

Failure code [CA111] ECM Critical Internal Failure....2069

Failure code [CA115] Eng Ne and Bkup Speed Sens Error....2071

Failure code [CA122] Chg Air Press Sensor High Error....2073

Failure code [CA123] Chg Air Press Sensor Low Error....2075

Failure code [CA131] Throttle Sensor High Error....2077

Failure code [CA132] Throttle Sensor Low Error....2079

Failure code [CA135] Eng Oil Press Sensor High Error....2081

Failure code [CA141] Eng Oil Press Sensor Low Error....2083

Failure code [CA144] Coolant Temp Sens High Error....2085

Failure code [CA145] Coolant Temp Sens Low Error....2087

Failure code [CA153] Chg Air Temp Sensor High Error....2089

Failure code [CA154] Chg Air Temp Sensor Low Error....2091

Failure code [CA187] Sens Supply 2 Volt Low Error....2093

Failure code [CA221] Ambient Press Sens High Error....2095

Failure code [CA222] Ambient Press Sens Low Error....2097

Failure code [CA227] Sens Supply 2 Volt High Error....2099

Failure code [CA234] Eng Overspeed....2100

Failure code [CA238] Ne Speed Sens Supply Volt Error....2101

Failure code [CA263] Fuel Temp Sensor High Error....2103

Failure code [CA265] Fuel Temp Sensor Low Error....2105

Failure code [CA271] IMV/PCV1 Short Error....2107

Failure code [CA272] IMV/PCV1 Open Error....2108

Failure code [CA273] PCV2 Short Error....2109

Failure code [CA274] PCV2 Open Error....2110

Failure code [CA322] Inj #1(L#1) Open/Short Error....2111

Failure code [CA323] Inj #5 (L#5) Open/Short Error....2113

Failure code [CA324] Inj #3(L#3) Open/Short Error....2115

Failure code [CA325] Inj #6 (L#6) Open/Short Error....2117

Failure code [CA331] Inj #2(L#2) Open/Short Error....2119

Failure code [CA332] Inj #4 (L#4) Open/Short Error....2121

Failure code [CA342] Calibration Code Incompatibility....2123

Failure code [CA351] Injectors Drive Circuit Error....2124

Failure code [CA352] Sens Supply 1 Volt Low Error....2125

Failure code [CA386] Sens Supply 1 Volt High Error....2127

Failure code [CA441] Battery Voltage Low Error....2127

Failure code [CA442] Battery Voltage High Error....2128

Failure code [CA449] Rail Press Very High Error....2128

Failure code [CA451] Rail Press Sensor High Error....2129

Failure code [CA452] Rail Press Sensor Low Error....2131

Failure code [CA553] Rail Press High Error....2133

Failure code [CA554] Rail Press Sensor In Range Error....2134

Failure code [CA559] Supply Pump Press Low Error 1....2135

Failure code [CA689] Eng Ne Speed Sensor Error....2139

Failure code [CA731] Eng Bkup Speed Sens Phase Error....2141

Failure code [CA757] All Continuous Data Lost Error....2142

Failure code [CA778] Eng Bkup Speed Sensor Error....2143

Failure code [CA1228] EGR Valve Servo Error 1....2145

Failure code [CA1625] EGR Valve Servo Error 2....2146

Failure code [CA1626] BP Valve Sol Current High Error....2147

Failure code [CA1627] BP Valve Sol Current Low Error....2149

Failure code [CA1628] Bypass Valve Servo Error 1....2151

Failure code [CA1629] Bypass Valve Servo Error 2....2152

Failure code [CA1631] BP Valve Pos Sens High Error....2153

Failure code [CA1632] BP Valve Pos Sens Low Error....2155

Failure code [CA1633] KOMNET Datalink Timeout Error....2157

Failure code [CA2185] Throt Sens Sup Volt High Error....2159

Failure code [CA2186] Throt Sens Sup Volt Low Error....2161

Failure code [CA2249] Rail Press Very Low Error....2162

Failure code [CA2271] EGR Valve Pos Sens High Error....2163

Failure code [CA2272] EGR Valve Pos Sens Low Error....2165

Failure code [CA2351] EGR Valve Sol Current High Error....2167

Failure code [CA2352] EGR Valve Sol Current Low Error....2169

Failure code [CA2555] Grid Htr Relay Open Circuit Error....2171

Failure code [CA2556] Grid Htr Relay Short Circuit Error....2173

Failure code [D110KB] Battery Relay Drive Short Circuit....2175

Failure code [D163KB] Flash Light Relay Short Circuit....2177

Failure code [D195KA] Step Light Relay Open Circuit....2179

Failure code [D195KB] Step Light Relay Short Circuit....2181

Failure code [D19JKZ] Personal Code Relay Abnormality....2183

Failure code [D862KA] GPS Antenna Open Circuit....2185

Failure code [DA22KK] Pump Solenoid Power Low Error....2187

Failure code [DA25KP] 5V Sensor1 Power Abnormality....2189

Failure code [DA29KQ] Model Selection Abnormality....2191

Failure code [DA2RMC] CAN Discon (Pump Con Detected)....2193

Failure code [DA80MA] Auto. Lub. Abnormal....2197

Failure code [DAF8KB] Camera Power Supply Short Circuit....2199

Failure code [DAFGMC] GPS Module Error....2201

Failure code [DAFRMC] CAN Discon (Monitor Detected)....2202

Failure code [DGE5KB] Ambi. Temp Sensor Short Circuit....2207

Failure code [DGH2KB] Hyd Oil Sensor Short....2209

Failure code [DH25KA] L Jet Sensor Open Circuit....2211

Failure code [DH25KB] L Jet Sensor Short Circuit....2213

Failure code [DH26KA] R Jet Sensor Open Circuit....2215

Failure code [DH26KB] R Jet Sensor Short Circuit....2217

Failure code [DHPEKA] F Pump P. Sensor Open Circuit....2219

Failure code [DHPEKB] F Pump P. Sensor Short Circuit....2221

Failure code [DHPFKA] R Pump P. Sensor Open Circuit....2223

Failure code [DHPFKB] R Pump P. Sensor Short Circuit....2225

Failure code [DV20KB] Travel alarm short circuit....2227

Failure code [DW41KA] Swing Priority Sol Open Circuit....2229

Failure code [DW41KB] Swing Priority Sol Short Circuit....2231

Failure code [DW43KA] Travel Speed Sol Open Circuit....2233

Failure code [DW43KB] Travel Speed Sol Short Circuit....2235

Failure code [DW45KA] Swing Brake Sol Open Circuit....2237

Failure code [DW45KB] Swing Brake Sol Short Circuit....2239

Failure code [DW7BKA] Fan Reverse Sol Open Circuit....2241

Failure code [DW7BKB] Fan Reverse Sol Short Circuit....2243

Failure code [DW7JKA] Bottom Dump Priority Sol Open Circuit....2245

Failure code [DW7JKB] Bottom Dump Priority Sol Short Circuit....2247

Failure code [DW91KA] Travel Junction Sol Open Circuit....2249

Failure code [DW91KB] Travel Junction Sol Short Circuit....2251

Failure code [DWK0KA] 2-stage Relief Sol Open Circuit....2253

Failure code [DWK0KB] 2-stage Relief Sol Short Circuit....2255

Failure code [DX16KA] Fan Pump EPC Sol Open Circuit....2257

Failure code [DX16KB] Fan Pump EPC Sol Short Circuit....2259

Failure code [DXAAKA] F Pump EPC Sol Open Circuit....2261

Failure code [DXAAKB] F Pump EPC Sol Short Circuit....2263

Failure code [DXABKA] R Pump EPC Sol Open Circuit....2265

Failure code [DXABKB] R Pump EPC Sol Short Circuit....2267

Failure code [DY20KA] Wiper Working Abnormality....2269

Failure code [DY20MA] Wiper Parking Abnormality....2273

Failure code [DY2CKA] Washer Drive Open Circuit....2275

Failure code [DY2CKB] Washer Drive Short Circuit....2277

Failure code [DY2DKB] Wiper Drive (Fwd) Short Circuit....2279

Failure code [DY2EKB] Wiper Drive (Rev) Short Circuit....2283

Failure code [DY2FMA] Upper Wiper Working Abnormality....2287

Failure code [DY2GKM] Wiper Select Abnormality....2289

Troubleshooting of electrical system (E-mode)....2292

E-1 Engine does not start (Engine does not crank)....2292

E-2 Preheater does not operate....2297

E-3 When starting switch is turned to ON position, machine monitor displays nothing....2301

E-4 When starting switch is turned to ON position (before starting engine), basic check monitor lights up....2304

E-5 Precaution item lights up while engine is running....2305

E-6 Emergency stop item lights up while engine is running....2307

E-7 Engine coolant temperature gauge does not indicate properly....2308

E-8 Fuel gauge does not indicate properly....2309

E-9 Hydraulic oil temperature gauge does not indicate properly....2311

E-10 Displays on machine monitor are different from those for actual machine....2313

E-11 Some areas of machine monitor screen are not displayed....2313

E-12 Function switch does not operate....2313

E-13 Automatic warm-up system does not operate (in cold season)....2314

E-14 Auto-decelerator does not operate properly....2315

E-15 Working mode does not change....2316

E-16 Travel speed does not change....2317

E-17 Alarm buzzer cannot be canceled....2318

E-18 When starting switch is turned OFF, service meter is not displayed40....2318

E-19 Service mode cannot be selected....2318

E-20 Any of work equipment, swing and travel do not operate or cannot be locked....2319

E-21 Machine push-up function does not operate or cannot be canceled40....2321

E-22 Boom shockless function does not operate properly....2323

E-23 Swing brake does not operate properly....2325

E-24 Windshield wiper and window washer do not operate....2327

E-25 Travel alarm does not sound or does not stop sounding....2331

E-26 Boom RAISE indicator is not displayed properly with monitoring function....2333

E-27 Boom LOWER indicator is not displayed properly with monitoring function....2335

E-28 Arm IN indicator is not displayed properly with monitoring function40....2337

E-29 Arm OUT indicator is not displayed properly with monitoring function....2339

E-30 Bucket CURL indicator is not displayed properly with monitoring function....2341

E-31 Bucket DUMP indicator is not displayed properly with monitoring function....2343

E-32 Swing indicator is not displayed properly with monitoring function40....2345

E-33 "L.H. travel" is not displayed properly with monitoring function....2347

E-34 "R.H. travel" is not displayed properly with monitoring function....2349

E-35 "Attachment" is not displayed properly with monitoring function....2351

E-36 Electric grease gun does not operate....2353

E-37 KOMTRAX system does not operate properly....2355

E-38 Horn does not sound or does not stop sounding....2356

E-39 Step light does not light up or go off....2359

Troubleshooting of hydraulic and mechanical system (H-mode)....2363

Before starting troubleshooting for hydraulic and mechanical systems....2363

Information in troubleshooting table (H-mode)....2367

H-1 All of work equipment, swing and travel work slow or lack power....2369

H-2 Engine speed lowers significantly or engine stalls....2371

H-3 Any of work equipment, swing and travel does not work....2373

H-4 Unusual noise is heard from around hydraulic pump....2375

H-5 Boom operation lacks speed or power....2376

H-6 Arm operation lacks speed or power....2378

H-7 Bucket operation lacks speed or power....2379

H-8 Boom does not move....2380

H-9 Arm does not move....2380

H-10 Bucket does not move....2380

H-11 Hydraulic drift of work equipment is large....2381

H-12 Time lag of work equipment is large....2383

H-13 Heavy lift function does not work or is not released....2384

H-14 Machine push-up function does not work or is not released....2384

H-15 Boom shockless function does not work or is not canceled....2384

H-16 Machine deviates in one direction against operator's intention when travelling....2385

H-17 Machine deviates significantly at start....2388

H-18 Machine deviates significantly during combined operation....2389

H-19 Travel works slow or lack power....2390

H-20 One of tracks does not run....2391

H-21 Travel speed does not change....2392

H-22 Upper structure does not swing....2393

H-23 Swing speed is low or swing acceleration is poor....2394

H-24 In combined operation with work equipment, swing speed is low or swing acceleration is poor....2395

H-25 Upper structure overruns excessively when it stops swinging....2397

H-26 Shock is large when upper structure stops swinging....2398

H-27 Large unusual noise is heard when upper structure stops swinging40....2399

H-28 Swing drift on a slope is large....2400

H-29 Fan revolution is abnormal (Fan sound/vibration is abnormally large or engine overheats)....2401

Troubleshooting of engine (S-mode)....2403

Method of using troubleshooting chart....2403

S-1 Startability is poor....2407

S-2 Engine does not start....2409

S-3 Engine does not pick up smoothly....2413

S-4 Engine stops during operation....2414

S-5 Engine runs rough or is unstable....2415

S-6 Engine lacks power....2417

S-7 Exhaust smoke is black (incomplete combustion)....2419

S-8 Oil consumption is excessive (or exhaust smoke is blue)....2421

S-9 Oil becomes contaminated early....2422

S-10 Fuel consumption is excessive....2423

S-11 Oil is in coolant (or coolant spurts or coolant level goes down)....2424

S-12 Oil pressure drops....2425

S-13 Oil level rises (coolant or fuel in oil)....2427

S-14 Coolant temperature rises too high (overheating)....2429

S-15 Unusual noise is made....2430

S-16 Vibration is excessive....2431

50 Disassembly and assembly....2432

General information on disassembly and assembly....2435

How to read Disassembly and Assembly....2435

Coating materials list....2437

Special tools list....2440

Sketches of special tools....2447

Engine and cooling system....2452

Removal and installation of engine, PTO and hydraulic pump assembly50....2452

Removal and installation of cooling assembly....2460

Removal and installation of aftercooler assembly....2466

Removal and installation of fuel cooler and air condenser assembly....2468

Removal and installation of fan motor assembly....2470

Removal and installation of fuel tank assembly....2475

Engine....2477

Removal and installation of fuel supply pump assembly....2477

Removal and installation of cylinder head assembly....2482

Removal and installation of fuel injector assembly....2498

Removal and installation of engine front seal....2501

Removal and installation of engine rear seal....2503

Power train....2508

Removal and installation of PTO assembly....2508

Disassembly and assembly of PTO assembly....2515

Removal and installation of swing motor and swing machinery assembly50....2517

Disassembly and assembly of swing machinery assembly....2520

Removal and installation of swing circle assembly....2527

Disassembly and assembly of final drive assembly....2528

Undercarriage and frame....2540

Separation and connection of track shoe assembly....2540

Disassembly and assembly of one link in field....2542

Removal and installation of idler assembly....2546

Disassembly and assembly of idler assembly....2547

Disassembly and assembly of idler adjustment cylinder assembly....2550

Removal and installation of recoil spring assembly....2551

Disassembly and assembly of recoil spring assembly....2553

Removal and installation of carrier roller assembly....2555

Disassembly and assembly of carrier roller assembly....2556

Removal and installation of track roller assembly....2559

Disassembly and assembly of track roller assembly....2560

Removal and installation of revolving frame assembly....2563

Removal and installation of counterweight assembly....2565

Removal and installation of counterweight remover assembly....2566

Hydraulic system....2570

Removal and installation of hydraulic tank assembly....2570

Removal and installation of main pump assembly....2572

Removal and installation of main pump input shaft oil seal....2579

Removal and installation of cooling fan pump assembly....2580

Removal and installation of control valve assembly....2583

Assembly of control valve assembly....2586

Removal and installation of swing motor assembly....2592

Removal and installation of center swivel joint assembly....2593

Disassembly and assembly of center swivel joint assembly....2595

Removal and installation of travel motor assembly....2597

Removal and installation of solenoid valve assembly....2598

Removal and installation of boom damping valve assembly....2600

Disassembly and assembly of work equipment PPC valve assembly....2601

Disassembly and assembly of travel PPC valve assembly....2603

Disassembly and assembly of hydraulic cylinder assembly....2606

Disassembly and assembly of grease gun assembly....2613

Work equipment....2614

Removal and installation of bucket cylinder assembly....2614

Removal and installation of arm cylinder assembly....2618

Removal and installation of boom cylinder assembly....2622

Removal and installation of bottom dump cylinder assembly....2626

Removal and installation of bucket assembly....2628

Removal and installation of arm assembly....2631

Removal and installation of boom assembly....2635

Removal and installation of work equipment assembly....2639

Cab and its attachments....2643

Removal and installation of operator's cab assembly....2643

Removal and installation of operator's cab glass (adhered window glass)....2646

Removal and installation of front window assembly....2655

Electrical system....2662

Removal and installation of air conditioner unit assembly....2662

Removal and installation of engine controller assembly....2665

Removal and installation of monitor assembly....2667

Removal and installation of pump controller assembly....2669

Removal and installation of KOMTRAX terminal assembly....2671

60 Maintenance standard....2672

Engine and cooling system....2674

Coupling....2674

Power train....2675

Swing circle....2675

Swing machinery....2676

Final drive....2679

Sprocket....2681

Undercarriage and frame....2683

Track frame and idler cushion....2683

Idler....2685

Carrier roller....2687

Track roller....2689

Track shoe....2691

Hydraulic system....2695

Cooling fan motor....2695

Control valve....2697

Swing motor....2703

Center swivel joint....2705

PPC valve....2706

Work equipment....2709

Work equipment....2709

Work equipment dimension....2715

Hydraulic cylinder....2719

80 Appendix....2726

Air conditioner....2728

Precautions for refrigerant....2728

Air conditioner component....2729

Configuration and function of refrigeration cycle....2731

Outline of refrigeration cycle....2732

Air conditioner unit....2735

Air conditioner controller....2740

Compressor....2741

Condenser....2742

Receiver drier....2743

Procedure for testing and troubleshooting....2745

Circuit diagram and arrangement of connector pins....2747

System diagram....2749

Detail of air conditioner unit....2751

Parts and connectors layout....2753

Testing air leakage (duct)....2756

Testing with self-diagnosis function....2757

Testing temperature control....2760

Testing vent (mode) changeover....2762

Testing FRESH/RECIRC air changeover....2765

Testing inner sensor....2767

Testing evaporator temperature sensor....2768

Testing sunlight sensor....2770

Testing (dual) pressure switch for refrigerant....2771

Testing relays....2772

Troubleshooting chart 1....2773

Troubleshooting chart 2....2775

Information in troubleshooting table....2777

Troubleshooting for power supply and CAN communication system (Air conditioner does not operate)....2779

Troubleshooting for compressor and refrigerant system (Air is not cooled)....2784

Troubleshooting for blower motor system (No air comes out or air flow is abnormal)....2788

Troubleshooting for temperature control....2792

Troubleshooting for vent (mode) changeover....2795

Troubleshooting for FRESH/RECIRC air changeover....2797

Troubleshooting for temperature sensor system....2799

Troubleshooting with gauge pressure....2801

Connection of service tool....2803

Precautions for disconnecting and connecting air conditioner piping....2805

Handling of compressor oil....2807

90 Diagrams and drawings....2810

Hydraulic circuit diagram....2812

Symbols used in hydraulic circuit diagrams....2812

Hydraulic circuit diagram....2816

Electrical circuit diagram....2818

Symbols used in electric circuit diagrams....2818

Electrical circuit diagram....2822

Index....2839

TEN00379-04 - Hydraulic Excavator PC800-8E0, PC800LC-8E0, PC800SE-8E0, PC850-8E0, PC850SE-8E0 Operation & Maintenance Manual....2847

COVER....2847

FOREWORD....2848

BEFORE READING THIS MANUAL....2849

SAFETY INFORMATION....2850

INTRODUCTION....2851

USE OF MACHINE....2851

DIRECTIONS OF MACHINE....2851

VISIBILITY FROM OPERATOR'S SEAT....2852

PRODUCT INFORMATION....2854

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE....2854

EPA REGULATIONS, ENGINE NUMBER PLATE....2854

SERVICE METER LOCATION....2855

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR....2855

CONTENTS....2856

SAFETY....2860

SAFETY....2861

SAFETY LABELS....2864

LOCATION OF SAFETY LABELS....2865

SAFETY LABELS....2866

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE....2873

PRECAUTIONS BEFORE STARTING OPERATION....2873

PREPARATIONS FOR SAFE OPERATION....2873

FIRE PREVENTION....2875

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE....2876

DO NOT GET CAUGHT IN WORK EQUIPMENT....2878

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES....2878

PROTECTION AGAINST FALLING, FLYING, INTRUDING OBJECTS....2879

UNAUTHORIZED MODIFICATION....2879

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS....2880

PRECAUTIONS RELATED TO CAB GLASS....2880

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING....2880

PRECAUTIONS FOR OPERATION....2881

PRECAUTIONS FOR JOBSITE....2881

STARTING ENGINE....2883

OPERATION....2885

TOWING....2893

LIFTING OBJECTS WITH BUCKET....2894

PRECAUTIONS FOR MAINTENANCE....2895

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE....2895

PRECAUTIONS FOR INSPECTION AND MAINTENANCE....2899

OPERATION....2906

MACHINE VIEW ILLUSTRATIONS....2907

OVERALL MACHINE VIEW....2907

CONTROLS AND GAUGES....2908

DETAILED CONTROLS AND GAUGES....2910

MONITORING SYSTEM....2910

SWITCHES....2978

CONTROL LEVERS AND PEDALS....2985

SUN ROOF....2988

WINDSHIELD....2989

EMERGENCY ESCAPE HAMMER....2995

DOOR LOCK....2995

CAP WITH LOCK....2996

HOT AND COOL BOX....2998

MAGAZINE BOX....2998

ASHTRAY....2998

AIR CONDITIONER CONTROLS....2999

RADIO....3012

AUXILIARY ELECTRIC POWER....3017

FUSE....3018

CIRCUIT BREAKER....3019

CONTROLLER....3020

TOOL BOX....3020

GREASE PUMP....3021

FIRE EXTINGUISHER....3024

MACHINE OPERATIONS AND CONTROLS....3025

BEFORE STARTING ENGINE....3025

STARTING ENGINE....3046

AFTER STARTING ENGINE....3049

STOPPING THE ENGINE....3059

MACHINE OPERATION....3060

STEERING THE MACHINE....3064

SWINGING....3066

WORK EQUIPMENT CONTROLS AND OPERATIONS....3067

WORKING MODE....3069

PROHIBITED OPERATIONS....3072

GENERAL OPERATION INFORMATION....3077

TRAVELING ON SLOPES....3079

ESCAPE FROM MUD....3081

RECOMMENDED APPLICATIONS....3082

BUCKET REPLACEMENT....3083

PARKING MACHINE....3085

MACHINE INSPECTION AFTER DAILY WORK....3086

LOCKING....3087

TRANSPORTATION....3088

TRANSPORTATION PROCEDURE....3088

LIFTING MACHINE....3088

SHIPPING MACHINE INFORMATION....3090

TRANSPORTATION POSTURE....3091

PROCEDURE FOR INCREASING OR REDUCING TRACK FRAME GAUGE....3097

COLD WEATHER OPERATION....3099

COLD WEATHER OPERATION INFORMATION....3099

AFTER DAILY WORK COMPLETION....3101

AFTER COLD WEATHER SEASON....3101

LONG TERM STORAGE....3102

BEFORE STORAGE....3102

DURING STORAGE....3102

AFTER STORAGE....3102

STARTING MACHINE AFTER LONG-TERM STORAGE....3103

TROUBLES AND ACTIONS....3104

RUNNING OUT OF FUEL....3104

PHENOMENA THAT ARE NOT FAILURES....3105

TOWING THE MACHINE....3106

SEVERE JOB CONDITION....3106

DISCHARGED BATTERY....3107

OTHER TROUBLE....3111

MAINTENANCE....3118

MAINTENANCE INFORMATION....3119

OUTLINE OF SERVICE....3121

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC....3121

ELECTRIC SYSTEM MAINTENANCE....3124

WEAR PARTS....3125

WEAR PARTS LIST....3125

RECOMMENDED FUEL, COOLANT, AND LUBRICANT....3126

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL....3128

TIGHTENING TORQUE SPECIFICATIONS....3129

TIGHTENING TORQUE LIST....3129

SAFETY CRITICAL PARTS....3130

SAFETY CRITICAL PARTS LIST....3131

MAINTENANCE SCHEDULE....3132

MAINTENANCE SCHEDULE CHART....3132

MAINTENANCE PROCEDURE....3134

INITIAL 100 HOURS MAINTENANCE (ONLY AFTER THE FIRST 100 HOURS)....3134

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)....3134

WHEN REQUIRED....3135

CHECK BEFORE STARTING....3157

EVERY 10 HOURS MAINTENANCE....3158

EVERY 100 HOURS MAINTENANCE....3160

EVERY 250 HOURS MAINTENANCE....3161

EVERY 500 HOURS MAINTENANCE....3167

EVERY 1000 HOURS MAINTENANCE....3176

EVERY 2000 HOURS MAINTENANCE....3189

EVERY 4000 HOURS MAINTENANCE....3195

EVERY 5000 HOURS MAINTENANCE....3198

EVERY 8000 HOURS MAINTENANCE....3202

SPECIFICATIONS....3204

SPECIFICATIONS....3205

ATTACHMENTS AND OPTIONS....3208

GENERAL PRECAUTIONS FOR SAFETY....3209

PRECAUTIONS WHEN SELECTING....3209

READ THE INSTRUCTION MANUAL THOROUGHLY....3209

PRECAUTIONS WHEN REMOVING OR INSTALLING....3209

PRECAUTIONS WHEN USING....3209

ATTACHMENT GUIDE....3210

COMBINATIONS OF WORK EQUIPMENT....3211

TRACK SHOES SELECTION....3213

HANDLING COUNTERWEIGHT REMOVER....3214

HANDLING MACHINES EQUIPPED WITH KOMTRAX....3226

BASIC PRECAUTIONS....3226

LOADING SHOVEL....3228

EXPLANATION OF COMPONENTS....3229

SWITCHES....3229

FUSE....3232

OPERATIONS....3233

OPERATION OF WORK EQUIPMENT....3233

PRECAUTIONS DURING OPERATION....3235

PRECAUTIONS FOR OPERATION....3238

LOADING SHOVEL WORK....3240

TRANSPORTATION....3241

MACHINE CONFIGURATION FOR TRANSPORT....3241

WEAR PARTS....3242

WEAR PARTS LIST....3242

MAINTENANCE....3243

CHECK BEFORE STARTING....3243

EVERY 10 HOURS MAINTENANCE....3245

EVERY 5000 HOURS MAINTENANCE....3246

SPECIFICATION....3248

COMBINATION OF WORK EQUIPMENT....3249

COMBINATION OF WORK EQUIPMENT....3249

INDEX....3252