Komatsu Hydraulic Excavator PC600-8E0, PC600LC-8E0, PC650-8E0, PC650LC-8E0, PC700LC-8E0 Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC600-8E0, PC600LC-8E0, PC650-8E0, PC650LC-8E0, PC700LC-8E0, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC600-8E0, PC600LC-8E0, PC650-8E0, PC650LC-8E0, PC700LC-8E0 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,993 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

TEN00405-03 - Hydraulic Excavator PC600-8E0, PC600LC-8E0, PC650-8E0, PC650LC-8E0, PC700LC-8E0 Operation & Maintenance Manual.pdf

SEN05377-03 - Hydraulic Excavator PC600-8E0, PC600LC-8E0, PC650-8E0, PC650LC-8E0, PC700LC-8E0 Shop Manual.pdf

GEN00101-02 - Hydraulic Excavator PC600-8E0, PC600LC-8E0, PC650-8E0, PC650LC-8E0, PC700LC-8E0 Field Assembly Instruction.pdf

MAIN SECTIONS

GEN00101-02 - Hydraulic Excavator PC600-8E0, PC600LC-8E0, PC650-8E0, PC650LC-8E0, PC700LC-8E0 Field Assembly Instruction....2

COVER....2

FOREWORD....3

CONTENTS....4

SPECIFICATIONS....7

PRECAUTIONS FOR FIELD ASSEMBLY....9

DISPOSAL OF REMOVED PARTS....10

ASSEMBLING PROCEDURES, APPLICABLE EQUIPMENT AND SCHEDULE....11

KIT LAYOUT DIAGRAM....12

TRANSPORTATION....13

LIST OF TOOLS FOR FIELD ASSEMBLING....18

TIGHTENING TORQUE....19

COATING MATERIALS....24

SELECTION OF WIRE ROPES USED FOR ASSEMBLY....26

A. ASSEMBLY OF CHASSIS....27

A- 1. Installation of Left and Right Track Frames....28

A- 2. Installation of Travel Pipe....33

A- 3. Installation of Operator Cabs Left Handrail....38

A- 4. Installation of Operator Cabs Door Stopper and Striker....39

A- 5. Installation of Rearview Mirror....41

A- 6. Installation of Handrail....46

A- 7-1 Installation of Step....49

A- 7-2 Installation of Step....50

A- 8. Installation of Left Side Step....51

A- 9. Sticking Sheet to Counterweight....52

A-10. Installation of Rear View Camera....53

A-11. Installation of Counterweight....58

A-12. Installation of Step Light....60

A-13. Bleeding of Air from Travel Motor....62

A-14-1 Installation of Travel Piping Cover....63

A-14-2 Installation of Travel Piping Cover....67

A-15. Installation of Travel Motor Guard....70

A-16. Testing Track Shoe Tension....71

A-17. Check Fuel, Coolant and Oil Levels....74

B. ASSEMBLING OF WORK EQUIPMENT....77

B- 1. Assembly of Arm Cylinder....78

B- 2. Connection of Arm Cylinder Hoses....79

B- 3. Installation of Boom Cylinder....80

B- 4. Installation of Boom Cylinder Hoses....81

B- 5. Installation of Boom Foot Dust Seal....82

B- 6. Assembly of Boom Assembly....83

B- 7. Installation of Hoses from Chassis Along Top of Boom....84

B- 8. Connection of Boom Cylinder Head....86

B- 9. Installation of Arm Assembly....87

B-10. Installation of Bucket Cylinder Hoses between Boom and Bucket Cylinder....89

B-11. Installation of Bucket....90

B-12. Connection of Work Equipment Grease Piping....93

B-13. Connection of Work Equipment Wiring....94

B-14. Greasing after Assembling Work Equipment....96

B-15. Bleeding Air from Work Equipment Circuit....97

B-16. Parts to be Touched up After Field Assembly....98

C. Assembling of Work Equipment of Loading Shovel....99

C- 1. Releasing residual pressure in hydraulic circuit....100

C- 2. Pulling out boom foot pin and boom cylinder foot pin....101

C- 3. Installation of boom cylinder foot....102

C- 4. Installation of boom and arm assembly....103

C- 5. Installation of boom cylinder hoses....104

C- 6. Installation of boom cylinder rod pin....105

C- 7. Installation of boom cylinder....106

C- 8. Installation of arm cylinder hoses....107

C- 9. Installation of bucket cylinder....108

C-10. Installation of bucket cylinder hoses....109

C-11. Installation of connecting hoses between chassis and boom top....110

C-12. Installation of bottom dump cylinder hoses....111

C-13. Installation of bucket assembly....112

C-14. Installation of working lamps....114

C-15. Installation of work equipment grease piping....116

C-16. Greasing after assembling of work equipment....117

C-17. Bleeding air from work equipment circuit....118

C-18. Checking oil level in hydraulic tank and adding oil....119

D. ASSEMBLING OF COUNTERWEIGHT REMOVER....121

D- 1. Sticking Sheet to Counterweight....122

D- 2. Adjustment of Shims for Counterweight....123

D- 3. Greasing....128

D- 4. Installation of Counterweight Remover....129

D- 5. Installation of Covers....130

D- 6. Installation of Clamps....131

D- 7. Installation of Hoses....134

D- 8. Bleeding Air from Counterweight Remover Circuit....135

D- 9. Installation of Counterweight....136

D-10. Installation of Accessories....138

D-11. Check of Operation....139

M. PROCEDURE FOR INSPECTION AND MAINTENANCE AFTER COMPLETION OF ASSEMBLY....141

M- 1. Inspection of Oil Level in Hydraulic Tank and Refill....142

M- 2. Replacement of Return Filter (Standard Filter to Flushing Filter)....144

M- 3. Flushing of Hydraulic Circuit....147

M- 4. Failure code....149

M- 5. Operating Method of ....154

Field Assembly Inspection Report (Backhoe)....161

Field Assembly Inspection Report (Loading Shovel)....187

SEN05377-03 - Hydraulic Excavator PC600-8E0, PC600LC-8E0, PC650-8E0, PC650LC-8E0, PC700LC-8E0 Shop Manual....213

COVER....213

00 Index and foreword....223

Table of Contents....224

Table of Contents....224

Foreword and general information....234

Safety notice....234

How to read the shop manual....239

Explanation of terms for maintenance standard....241

Handling of hydraulic components....243

Method of disconnecting and connecting push-pull type coupler....245

Handling of electric equipment....248

How to read electric wire code....258

Precautions when performing work....261

Standard tightening torque table....264

List of abbreviation....268

Conversion table....272

01 Specification....277

Specifications....280

Specifications drawing....280

Working range drawings....282

Specifications....284

Table of weight....294

Table of fuel, coolant and lubricants....302

10 Structure and function....305

Engine and cooling system....307

Engine related parts....307

PTO....308

Cooling system....309

Power train system....310

Power train....310

Swing circle....312

Swing machinery....314

Final drive....316

Undercarriage and frame....318

Track frame and idler cushion....318

Hydraulic system....320

Hydraulic component layout....320

Valve control....322

Hydraulic tank and filter....324

Hydraulic pump (piston pump)....326

Cooling fan pump....354

Cooling fan motor....362

Control valve....368

Swing motor....384

Travel motor....392

PPC valve....413

Solenoid valve....421

PPC shuttle valve....428

Boom drift prevention valve....429

Boom LOWER regeneration valve....433

Arm regeneration valve....436

Quick return valve....439

Line oil filter....442

Center swivel joint....443

Accumulator....444

Electrical system....445

Engine control....445

Electrical control system....455

Monitor system....485

KOMTRAX system....511

Sensors....513

20 Standard value table....517

Standard value table....519

Standard value table for engine....519

Standard value table for machine....520

30 Testing and adjusting....543

Tool for testing, adjusting and troubleshooting....545

Tools for testing, adjusting, and troubleshooting....545

Engine and cooling system....549

Testing engine speed....549

Testing intake air pressure (boost pressure)....551

Testing exhaust gas temperature....552

Testing exhaust gas color....553

Testing and adjusting valve clearance....554

Testing compression pressure....555

Testing blowby pressure....557

Testing engine oil pressure....558

Testing EGR valve and bypass valve drive pressure....559

Handling fuel system parts....560

Releasing remaining pressure from fuel system....561

Testing fuel pressure....562

Cylinder cut-out test mode....563

No-injection cranking....564

Testing fuel return rate and leakage....565

Bleeding air from fuel circuit....568

Testing fuel circuit for leakage....570

Testing and adjusting alternator belt tension....571

Testing and adjusting air conditioner compressor belt tension....572

Undercarriage and frame....573

Testing swing circle bearing clearance....573

Checking and adjusting track tension....574

Hydraulic system....575

Testing and adjusting oil pressure in work equipment, swing and travel circuits....575

Testing and adjusting control circuit oil pressure....580

Testing and adjusting control oil pressure of piston pump....582

Testing servo piston movement....588

Testing PPC valve output pressure....590

Testing output pressure of solenoid valve and PPC shuttle valve....594

Adjusting play of work equipment and swing PPC vavles....600

Isolating the parts causing hydraulic drift in work equipment....601

Testing and adjusting travel deviation....603

Testing fan speed....605

Testing fan circuit oil pressure....606

Releasing remaining pressure from hydraulic circuit....607

Testing oil leakage....608

Bleeding air from each part....612

Electrical system....615

Special functions of machine monitor....615

Handling of voltage circuit of engine controller....659

Preparatory work for troubleshooting of electrical system....660

Inspection procedure of diode....665

Pm clinic....666

Pm Clinic service....666

UNDERCARRIAGE INSPECTION REPORT....678

40 Troubleshooting....681

General information on troubleshooting....688

Points to remember when troubleshooting....688

Sequence of events in troubleshooting....689

Checks before troubleshooting....690

Classification and procedures for troubleshooting....714

Failure codes table....717

Symptom and troubleshooting numbers....721

Information in troubleshooting table....724

Troubleshooting method for open circuit in wiring harness of pressure sensor system....726

Connector list and layout....728

Connection table for connector pin numbers....738

T- branch box and T- branch adapter table....774

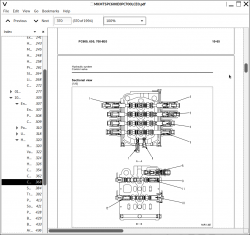

Fuse locations....777

Troubleshooting by failure code....780

Failure code [989L00] Engine Controller Lock Caution 1....780

Failure code [989M00] Engine Controller Lock Caution 2....781

Failure code [989N00] Engine Controller Lock Caution 3....782

Failure code [AA10NX] Air Cleaner Clogging....783

Failure code [AB00KE] Charge Voltage Low....784

Failure code [B@BAZG] Eng Oil Press Low....786

Failure code [B@BAZK] Eng Oil Level Low....787

Failure code [B@BCNS] Eng Water Overheat....788

Failure code [B@BCZK] Eng Water Level Low....790

Failure code [B@HANS] Hyd Oil Overheat....792

Failure code [CA111] ECM Critical Internal Failure....794

Failure code [CA115] Eng Ne and Bkup Speed Sens Error....796

Failure code [CA122] Chg Air Press Sensor High Error....798

Failure code [CA123] Chg Air Press Sensor Low Error....800

Failure code [CA131] Throttle Sensor High Error....802

Failure code [CA132] Throttle Sensor Low Error....804

Failure code [CA135] Eng Oil Press Sensor High Error....806

Failure code [CA141] Eng Oil Press Sensor Low Error....808

Failure code [CA144] Coolant Temp Sens High Error....810

Failure code [CA145] Coolant Temp Sens Low Error....812

Failure code [CA153] Chg Air Temp Sensor High Error....814

Failure code [CA154] Chg Air Temp Sensor Low Error....816

Failure code [CA187] Sens Supply 2 Volt Low Error....818

Failure code [CA221] Ambient Press Sens High Error....820

Failure code [CA222] Ambient Press Sens Low Error....822

Failure code [CA227] Sens Supply 2 Volt High Error....824

Failure code [CA234] Eng Overspeed....825

Failure code [CA238] Ne Speed Sens Supply Volt Error....826

Failure code [CA263] Fuel Temp Sensor High Error....828

Failure code [CA265] Fuel Temp Sensor Low Error....830

Failure code [CA271] IMV/PCV1 Short Error....832

Failure code [CA272] IMV/PCV1 Open Error....833

Failure code [CA273] PCV2 Short Error....834

Failure code [CA274] PCV2 Open Error....835

Failure code [CA322] Inj #1(L#1) Open/Short Error....836

Failure code [CA323] Inj #5 (L#5) Open/Short Error....838

Failure code [CA324] Inj #3(L#3) Open/Short Error....840

Failure code [CA325] Inj #6 (L#6) Open/Short Error....842

Failure code [CA331] Inj #2(L#2) Open/Short Error....844

Failure code [CA332] Inj #4 (L#4) Open/Short Error....846

Failure code [CA342] Calibration Code Incompatibility....848

Failure code [CA351] Injectors Drive Circuit Error....849

Failure code [CA352] Sens Supply 1 Volt Low Error....850

Failure code [CA386] Sens Supply 1 Volt High Error....852

Failure code [CA441] Battery Voltage Low Error....852

Failure code [CA442] Battery Voltage High Error....853

Failure code [CA449] Rail Press Very High Error....853

Failure code [CA451] Rail Press Sensor High Error....854

Failure code [CA452] Rail Press Sensor Low Error....856

Failure code [CA553] Rail Press High Error....858

Failure code [CA554] Rail Press Sensor In Range Error....858

Failure code [CA559] Supply Pump Press Low Error 1....859

Failure code [CA689] Eng Ne Speed Sensor Error....862

Failure code [CA731] Eng Bkup Speed Sens Phase Error....864

Failure code [CA757] All Continuous Data Lost Error....865

Failure code [CA778] Eng Bkup Speed Sensor Error....866

Failure code [CA1228] EGR Valve Servo Error 1....868

Failure code [CA1625] EGR Valve Servo Error 2....869

Failure code [CA1626] BP Valve Sol Current High Error....870

Failure code [CA1627] BP Valve Sol Current Low Error....872

Failure code [CA1628] Bypass Valve Servo Error 1....874

Failure code [CA1629] Bypass Valve Servo Error 2....875

Failure code [CA1631] BP Valve Pos Sens High Error....876

Failure code [CA1632] BP Valve Pos Sens Low Error....878

Failure code [CA1633] KOMNET Datalink Timeout Error....880

Failure code [CA2185] Throt Sens Sup Volt High Error....882

Failure code [CA2186] Throt Sens Sup Volt Low Error....884

Failure code [CA2249] Rail Press Very Low Error....885

Failure code [CA2271] EGR Valve Pos Sens High Error....886

Failure code [CA2272] EGR Valve Pos Sens Low Error....888

Failure code [CA2351] EGR Valve Sol Current High Error....890

Failure code [CA2352] EGR Valve Sol Current Low Error....892

Failure code [CA2555] Grid Htr Relay Open Circuit Error....894

Failure code [CA2556] Grid Htr Relay Short Circuit Error....896

Failure code [D110KB] Battery Relay Drive Short Circuit....898

Failure code [D163KB] Flash Light Relay Short Circuit....900

Failure code [D195KA] Step Light Relay Open Circuit....902

Failure code [D195KB] Step Light Relay Short Circuit....904

Failure code [D19JKZ] Personal code relay abnormality....906

Failure code [D862KA] GPS Antenna Open Circuit....908

Failure code [DA22KK] Pump Solenoid Power Low Error....910

Failure code [DA25KP] 5V Sensor1 Power Abnormality....912

Failure code [DA29KQ] Model Selection Abnormality....914

Failure code [DA2RMC] CAN Discon (Pump Con Detected)....916

Failure code [DA80MA] Auto. Lub. Abnormal....920

Failure code [DAF8KB] Camera Power Supply Short Circuit....922

Failure code [DAFGMC] GPS Module Error....924

Failure code [DAFRMC] CAN Discon (Monitor Detected)....925

Failure code [DGE5KB] Ambi. Temp Sensor Short Circuit....930

Failure code [DGH2KB] Hyd Oil Sensor Short....932

Failure code [DHPAMA] F Pump Press Sensor Abnormality....934

Failure code [DHPBMA] R Pump Press Sensor Abnormality....936

Failure code [DV20KB] Travel alarm short circuit....938

Failure code [DW43KA] Travel Speed Sol Open Circuit....940

Failure code [DW43KB] Travel Speed Sol Short Circuit....942

Failure code [DW45KA] Swing Brake Sol Open Circuit....944

Failure code [DW45KB] Swing Brake Sol Short Circuit....946

Failure code [DW48KA] CO Cancel Sol Open Circuit....948

Failure code [DW48KB] CO Cancel Sol Short Circuit....950

Failure code [DW4XKA] Bucket Curl Hi Cancel Sol Open Circuit....952

Failure code [DW4XKB] Bucket Curl Hi Cancel Sol Short Circuit....954

Failure code [DW7BKA] Fan Reverse Sol Open Circuit....956

Failure code [DW7BKB] Fan Reverse Sol Short Circuit....958

Failure code [DWK0KA] 2-stage Relief Sol Open Circuit....960

Failure code [DWK0KB] 2-stage Relief Sol Short Circuit....962

Failure code [DX16KA] Fan Pump EPC Sol Open Circuit....964

Failure code [DX16KB] Fan Pump EPC Sol Short Circuit....965

Failure code [DXA0KA] TVC Sol Open Circuit....966

Failure code [DXA0KB] TVC Sol Short Circuit....968

Failure code [DY20KA] Wiper Working Abnormality....970

Failure code [DY20MA] Wiper Parking Abnormality....974

Failure code [DY2CKA] Washer Drive Open Circuit....976

Failure code [DY2CKB] Washer Drive Short Circuit....978

Failure code [DY2DKB] Wiper Drive (Fwd) Short Circuit....980

Failure code [DY2EKB] Wiper Drive (Rev) Short Circuit....984

Failure code [DY2FMA] Upper Wiper Working Abnormality....988

Failure code [DY2GKM] Wiper Select Abnormality....990

Troubleshooting of electrical system (E-mode)....994

E-1 Engine does not start (Engine does not crank)....994

E-2 Preheater does not operate....999

E-3 When starting switch is turned to ON position, machine monitor displays nothing....1003

E-4 When starting switch is turned to ON position (before starting engine), basic check monitor lights up....1006

E-5 Precaution item lights up while engine is running....1008

E-6 Emergency stop item lights up while engine is running....1010

E-7 Engine coolant temperature gauge does not indicate properly....1011

E-8 Fuel gauge does not indicate properly....1012

E-9 Hydraulic oil temperature gauge does not indicate properly....1014

E-10 Content of display on machine monitor is different from that of actual machine....1016

E-11 Some areas of machine monitor screen are not displayed....1016

E-12 Function switch does not operate....1016

E-13 Automatic warm-up system does not operate (in cold season)....1017

E-14 Auto-decelerator does not operate properly....1018

E-15 Working mode does not change....1019

E-16 Travel speed does not change....1020

E-17 Alarm buzzer cannot be canceled....1021

E-18 When starting switch is turned OFF, service meter is not displayed....1021

E-19 Service mode cannot be selected....1021

E-20 Any of work equipment, swing and travel does not work or cannot be locked....1022

E-21 Machine push-up function does not work or cannot be canceled....1024

E-22 Boom shockless function does not operate normally....1026

E-23 Swing brake does not operate normally....1028

E-24 Windshield wiper and window washer do not operate....1030

E-25 Travel alarm does not sound or does not stop sounding....1033

E-26 BOOM RAISE indicator is not displayed properly with monitoring function....1034

E-27 BOOM LOWER indicator is not displayed properly with monitoring function....1036

E-28 ARM IN indicator is not displayed properly with monitoring function....1038

E-29 ARM DUMP indicator is not displayed properly with monitoring function....1040

E-30 BUCKET CURL indicator is not displayed properly with monitoring function....1042

E-31 BUCKET DUMP indicator is not displayed properly with monitoring function....1044

E-32 Swing indicator is not displayed properly with monitoring function....1046

E-33 Travel indicator is not displayed properly with monitoring function....1048

E-34 "Service" is not displayed normally by monitoring function....1050

E-35 Electric grease gun does not operate....1052

E-36 KOMTRAX system does not operate normally....1053

E-37 Bottom dump does not operate properly....1054

E-38 Horn does not sound or does not stop sounding....1057

E-39 Step light does not light up or go off....1060

Troubleshooting of hydraulic and mechanical system (H-mode)....1064

Before troubleshooting for hydraulic and mechanical systems....1064

Information in troubleshooting table (H-mode)....1069

H-1 All of work equipment, travel and swing work slow or lack power....1070

H-2 Engine speed lowers significantly or engine stalls....1072

H-3 Any of work equipment, swing and travel does not work....1074

H-4 Unusual noise is heard from around hydraulic pump....1076

H-5 Auto-decelerator is not canceled....1077

H-6 Speed or power of boom is low....1078

H-7 Speed or power of arm is low....1080

H-8 Speed or power of bucket is low....1081

H-9 Boom does not move....1082

H-10 Arm does not move....1082

H-11 Bucket does not move....1083

H-12 Bottom dump does not move....1083

H-13 Hydraulic drift of work equipment is large....1084

H-14 Time lag of work equipment is large....1085

H-15 One-touch power maximizing function does not work or is not canceled....1086

H-16 Machine push-up function does not work or is not canceled....1086

H-17 Boom/bucket speed is low at combined operation of arm and boom or bucket....1086

H-18 Speed of boom, arm, swing and travel is low at combined operation of bucket and boom, arm, swing and travel....1087

H-19 Swing speed is low at combined operation of arm and swing....1087

H-20 Machine deviates during travel....1088

H-21 Machine deviates significantly at start....1091

H-22 Machine deviates significantly during combined operation....1092

H-23 Travel speed or travel power is low....1093

H-24 One of tracks does not run (on one side alone)....1094

H-25 Travel speed does not change....1095

H-26 Upper structure does not swing....1096

H-27 Swing speed is low or acceleration is poor....1097

H-28 Upper structure overruns excessively when it stops swinging....1098

H-29 Shock is large when upper structure stops swinging....1099

H-30 Large unusual noise is heard when upper structure stops swinging40....1100

H-31 Hydraulic drift of swing is large....1101

Troubleshooting of engine (S-mode)....1102

Method of using troubleshooting chart....1102

S-1 Startability is poor....1106

S-2 Engine does not start....1108

S-3 Engine does not pick up smoothly....1112

S-4 Engine stops during operation....1113

S-5 Engine runs rough or is unstable....1114

S-6 Engine lacks power....1116

S-7 Exhaust smoke is black (incomplete combustion)....1118

S-8 Oil consumption is excessive (or exhaust smoke is blue)....1120

S-9 Oil becomes contaminated early....1121

S-10 Fuel consumption is excessive....1122

S-11 Oil is in coolant (or coolant spurts or coolant level goes down)....1123

S-12 Oil pressure drops....1124

S-13 Oil level rises (coolant or fuel in oil)....1126

S-14 Coolant temperature rises too high (overheating)....1128

S-15 Unusual noise is made....1129

S-16 Vibration is excessive....1130

50 Disassembly and assembly....1131

General information on disassembly and assembly....1134

How to read Disassembly and Assembly....1134

Coating materials list....1136

Special tools list....1139

Sketches of special tools....1146

Engine and cooling system....1154

Removal and installation of fuel supply pump assembly....1154

Removal and installation of fuel injector assembly....1160

Removal and installation of cylinder head assembly....1163

Removal and installation of radiator assembly....1180

Removal and installation of hydraulic oil cooler assembly....1182

Removal and installation of aftercooler assembly....1184

Removal and installation of engine front seal....1186

Removal and installation of engine rear seal....1190

Removal and installation of engine, PTO and hydraulic pump assembly....1195

Removal and installation of cooling fan motor assembly....1203

Removal and installation of fuel tank assembly....1207

Power train....1208

Removal and installation of PTO assembly....1208

Disassembly and assembly of PTO assembly....1210

Disassembly and assembly of final drive assembly....1213

Removal and installation of swing motor and swing machinery assembly50....1236

Disassembly and assembly of swing machinery assembly....1238

Removal and installation of swing circle assembly....1253

Undercarriage and frame....1254

Separation and connection of track shoe assembly....1254

Disassembly and assembly of one link in field....1258

Removal and installation of idler assembly....1262

Disassembly and assembly of idler assembly....1264

Removal and installation of idler cushion assembly....1271

Disassembly and assembly of idler cushion assembly....1274

Removal and installation of track roller assembly....1278

Disassembly and assembly of track roller assembly....1280

Removal and installation of carrier roller assembly....1286

Disassembly and assembly of carrier roller assembly....1288

Removal and installation of revolving frame assembly....1294

Removal and installation of counterweight assembly....1296

Removal and installation of counterweight remover assembly....1299

Hydraulic system....1301

Removal and installation of center swivel joint assembly....1301

Disassembly and assembly of center swivel joint assembly....1302

Removal and installation of hydraulic tank assembly....1304

Removal and installation of hydraulic pump assembly....1306

Removal and installation of control valve assembly....1309

Disassembly and assembly of control valve assembly....1311

Removal and installation of swing motor assembly....1313

Disassembly and assembly of work equipment PPC valve assembly....1314

Disassembly and assembly of travel PPC valve assembly....1316

Disassembly and assembly of grease gun assembly....1318

Work equipment....1319

Removal and installation of bucket cylinder assembly....1319

Removal and installation of arm cylinder assembly....1323

Removal and installation of boom cylinder assembly....1327

Removal and installation of bottom dump cylinder assembly....1331

Removal and installation of bucket assembly....1333

Removal and installation of arm assembly....1337

Removal and installation of boom assembly....1340

Removal and installation of work equipment assembly....1344

Disassembly and assembly of work equipment cylinder assembly....1348

Cab and its attachments....1354

Removal and installation of operator's cab assembly....1354

Removal and installation of operator's cab glass (adhered window glass)....1358

Removal and installation of front window assembly....1368

Removal and installation of air conditioner unit assembly....1375

Electrical system....1379

Removal and installation of air conditioner compressor assembly....1379

Removal and installation of air conditioner condenser assembly....1382

Removal and installation of engine controller assembly....1384

Removal and installation of pump controller assembly....1386

Removal and installation of KOMTRAX terminal assembly....1388

Removal and installation of machine monitor assembly....1389

60 Maintenance standard....1391

Engine and cooling system....1393

Engine mount....1393

PTO....1395

Cooling system....1396

Power train....1397

Swing circle....1397

Swing machinery....1398

Final drive....1400

Sprocket....1402

Undercarriage and frame....1406

Track frame and idler cushion....1406

Idler....1408

Track roller....1412

Carrier roller....1415

Track shoe....1418

Hydraulic system....1428

Hydraulic pump....1428

Control valve....1438

Swing motor....1444

Travel motor....1445

PPC valve....1448

Boom drift prevention valve....1455

Regeneration valve (boom, arm)....1456

Center swivel joint....1457

Work equipment....1458

Work equipment....1458

Work equipment dimension....1462

Work equipment cylinder....1468

80 Appendix....1473

Air conditioner....1475

Precautions for refrigerant....1475

Air conditioner component....1476

Configuration and function of refrigeration cycle....1478

Outline of refrigeration cycle....1479

Air conditioner unit....1482

Air conditioner controller....1487

Compressor....1488

Condenser....1489

Receiver drier....1490

Procedure for testing and troubleshooting....1492

Circuit diagram and arrangement of connector pins....1494

System diagram....1496

Detail of air conditioner unit....1498

Parts and connectors layout....1500

Testing air leakage (duct)....1503

Testing with self-diagnosis function....1504

Testing temperature control....1507

Testing vent (mode) changeover....1509

Testing FRESH/RECIRC air changeover....1512

Testing inner sensor....1514

Testing evaporator temperature sensor....1515

Testing sunlight sensor....1517

Testing (dual) pressure switch for refrigerant....1518

Testing relays....1519

Troubleshooting chart 1....1520

Troubleshooting chart 2....1522

Information in troubleshooting table....1524

Troubleshooting for power supply and CAN communication system (Air conditioner does not operate)....1526

Troubleshooting for compressor and refrigerant system (Air is not cooled)....1531

Troubleshooting for blower motor system (No air comes out or air flow is abnormal)....1535

Troubleshooting for temperature control....1539

Troubleshooting for vent (mode) changeover....1542

Troubleshooting for FRESH/RECIRC air changeover....1544

Troubleshooting for temperature sensor system....1546

Troubleshooting with gauge pressure....1547

Connection of service tool....1550

Precautions for disconnecting and connecting air conditioner piping....1552

Handling of compressor oil....1554

90 Diagrams and drawings....1557

Hydraulic circuit diagram....1559

Symbols used in hydraulic circuit diagrams....1559

Hydraulic circuit diagram....1563

Electrical circuit diagram....1567

Symbols used in electric circuit diagrams....1567

Electrical circuit diagram....1571

Air conditioner electrical circuit diagram....1583

TEN00405-03 - Hydraulic Excavator PC600-8E0, PC600LC-8E0, PC650-8E0, PC650LC-8E0, PC700LC-8E0 Operation & Maintenance Manual....1592

COVER....1592

FOREWORD....1593

BEFORE READING THIS MANUAL....1594

SAFETY INFORMATION....1595

INTRODUCTION....1596

USE OF MACHINE....1596

DIRECTIONS OF MACHINE....1596

VISIBILITY FROM OPERATOR'S SEAT....1597

PRODUCT INFORMATION....1599

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE....1599

EPA REGULATIONS, ENGINE NUMBER PLATE....1599

SERVICE METER LOCATION....1600

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR....1600

CONTENTS....1601

SAFETY....1605

SAFETY....1606

SAFETY LABELS....1609

LOCATION OF SAFETY LABELS....1610

SAFETY LABELS....1611

GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE....1617

PRECAUTIONS BEFORE STARTING OPERATION....1617

PREPARATIONS FOR SAFE OPERATION....1617

FIRE PREVENTION....1619

DO NOT GET CAUGHT IN WORK EQUIPMENT....1622

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES....1622

PROTECTION AGAINST FALLING, FLYING, INTRUDING OBJECTS....1623

UNAUTHORIZED MODIFICATION....1623

PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS....1624

PRECAUTIONS RELATED TO CAB GLASS....1624

PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING....1624

PRECAUTIONS FOR OPERATION....1625

PRECAUTIONS FOR JOBSITE....1625

STARTING ENGINE....1627

OPERATION....1629

TRANSPORTATION....1636

TOWING....1637

LIFTING OBJECTS WITH BUCKET....1638

PRECAUTIONS FOR MAINTENANCE....1639

PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE....1639

PRECAUTIONS FOR INSPECTION AND MAINTENANCE....1643

OPERATION....1649

MACHINE VIEW ILLUSTRATIONS....1650

OVERALL MACHINE VIEW....1650

CONTROLS AND GAUGES....1651

DETAILED CONTROLS AND GAUGES....1653

MONITORING SYSTEM....1653

SWITCHES....1721

CONTROL LEVERS AND PEDALS....1728

SUN ROOF....1731

WINDSHIELD....1732

EMERGENCY ESCAPE HAMMER....1738

DOOR LOCK....1738

CAP WITH LOCK....1739

HOT AND COOL BOX....1741

MAGAZINE BOX....1741

ASHTRAY....1741

AIR CONDITIONER CONTROLS....1742

RADIO....1755

FUSE....1760

CIRCUIT BREAKER....1761

CONTROLLER....1762

TOOL BOX....1762

GREASE PUMP....1763

FIRE EXTINGUISHER....1766

MACHINE OPERATIONS AND CONTROLS....1767

BEFORE STARTING ENGINE....1767

STARTING ENGINE....1787

AFTER STARTING ENGINE....1790

STOPPING THE ENGINE....1800

MACHINE OPERATION....1801

STEERING THE MACHINE....1805

SWINGING....1807

WORK EQUIPMENT CONTROLS AND OPERATIONS....1808

WORKING MODE....1810

PROHIBITED OPERATIONS....1813

GENERAL OPERATION INFORMATION....1818

TRAVELING ON SLOPES....1820

ESCAPE FROM MUD....1822

RECOMMENDED APPLICATIONS....1823

BUCKET REPLACEMENT....1824

PARKING MACHINE....1826

MACHINE INSPECTION AFTER DAILY WORK....1827

LOCKING....1828

TRANSPORTATION....1829

TRANSPORTATION PROCEDURE....1829

LIFTING MACHINE....1829

SHIPPING MACHINE INFORMATION....1830

TRANSPORTATION POSTURE....1831

PROCEDURE FOR INCREASING OR REDUCING TRACK FRAME GAUGE....1837

COLD WEATHER OPERATION....1839

COLD WEATHER OPERATION INFORMATION....1839

AFTER DAILY WORK COMPLETION....1841

AFTER COLD WEATHER SEASON....1841

LONG TERM STORAGE....1842

BEFORE STORAGE....1842

DURING STORAGE....1842

AFTER STORAGE....1843

STARTING MACHINE AFTER LONG-TERM STORAGE....1843

TROUBLES AND ACTIONS....1844

RUNNING OUT OF FUEL....1844

PHENOMENA THAT ARE NOT FAILURES....1845

TOWING THE MACHINE....1846

SEVERE JOB CONDITION....1847

DISCHARGED BATTERY....1847

OTHER TROUBLE....1851

MAINTENANCE....1857

MAINTENANCE INFORMATION....1858

OUTLINE OF SERVICE....1860

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC....1860

ELECTRIC SYSTEM MAINTENANCE....1863

WEAR PARTS....1864

WEAR PARTS LIST....1864

RECOMMENDED FUEL, COOLANT, AND LUBRICANT....1865

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL....1867

TIGHTENING TORQUE SPECIFICATIONS....1868

TIGHTENING TORQUE LIST....1868

SAFETY CRITICAL PARTS....1869

SAFETY CRITICAL PARTS LIST....1870

MAINTENANCE SCHEDULE....1871

MAINTENANCE SCHEDULE CHART....1871

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER....1873

MAINTENANCE PROCEDURE....1874

INITIAL 100 HOURS MAINTENANCE (ONLY AFTER THE FIRST 100 HOURS)....1874

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)....1874

WHEN REQUIRED....1875

CHECK BEFORE STARTING....1899

EVERY 10 HOURS MAINTENANCE....1900

EVERY 100 HOURS MAINTENANCE....1903

EVERY 250 HOURS MAINTENANCE....1904

EVERY 500 HOURS MAINTENANCE....1910

EVERY 1000 HOURS MAINTENANCE....1921

EVERY 2000 HOURS MAINTENANCE....1932

EVERY 4000 HOURS MAINTENANCE....1939

EVERY 5000 HOURS MAINTENANCE....1942

EVERY 8000 HOURS MAINTENANCE....1943

SPECIFICATIONS....1945

SPECIFICATIONS....1946

ATTACHMENTS AND OPTIONS....1951

GENERAL PRECAUTIONS FOR SAFETY....1952

PRECAUTIONS WHEN SELECTING....1952

READ THE INSTRUCTION MANUAL THOROUGHLY....1952

PRECAUTIONS WHEN REMOVING OR INSTALLING....1952

PRECAUTIONS WHEN USING....1952

ATTACHMENT GUIDE....1953

COMBINATIONS OF WORK EQUIPMENT....1954

TRACK SHOES SELECTION....1957

HANDLING COUNTERWEIGHT REMOVER....1958

HANDLING MACHINES EQUIPPED WITH KOMTRAX....1967

BASIC PRECAUTIONS....1967

LOADING SHOVEL....1969

EXPLANATION OF COMPONENTS....1970

SWITCHES....1970

FUSE....1973

OPERATIONS....1974

OPERATION OF WORK EQUIPMENT....1974

PRECAUTIONS DURING OPERATION....1976

PRECAUTIONS FOR OPERATION....1979

LOADING SHOVEL WORK....1981

TRANSPORTATION....1982

MACHINE CONFIGURATION FOR TRANSPORT....1982

WEAR PARTS....1983

WEAR PARTS LIST....1983

MAINTENANCE....1984

CHECK BEFORE STARTING....1984

EVERY 10 HOURS MAINTENANCE....1986

EVERY 5000 HOURS MAINTENANCE....1987

SPECIFICATION....1988

COMBINATION OF WORK EQUIPMENT....1989

COMBINATION OF WORK EQUIPMENT....1989

INDEX....1991