Komatsu Hydraulic Excavator PC308USLC-3 Repair Service Manual & Operation Maintenance Manual & Parts Book

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC308USLC-3, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Excavators PC308USLC-3 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,143 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SEBM033101 - Hydraulic Excavator PC308USLC-3 Shop Manual.pdf

NJPT007900 - Hydraulic Excavator PC308USLC-3 Operation & Maintenance Manual & Parts Book.pdf

TEN00114-00 - Hydraulic Excavator GALEO PC308USLC-3 Operation & Maintenance Manual.pdf

MAIN SECTIONS

NJPT007900 - Hydraulic Excavator PC308USLC-3 Operation & Maintenance Manual_Parts Book...2

SEBM033101 - Hydraulic Excavator PC308USLC-3 Shop Manual...268

COVER...268

CONTENTS...269

SAFETY ...274

SAFETY NOTICE...274

FOREWARD...276

GENERAL...276

HOW TO READ THE SHOP MANUAL...277

HOISTING INSTRUCTIONS...278

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER...279

COATING MATERIALS...281

STANDARD TIGHTENING TORQUE...283

ELECTRIC WIRE CODE...286

CONVERSION TABLE...287

UNITS...293

01 GENERAL...294

SPECIFICATION DIMENSION DRAWINGS...295

SPECIFICATIONS...297

WEIGHT TABLE...299

FUEL, COOLANT, AND LUBRICANTS...301

10 STRUCTURE, FUNCTION, AND MAINTENANCE STANDARD...302

ENGINE RELATED PARTS...303

RADIATOR * OIL COOLER * AFTERCOOLER...304

POWER TRAIN...305

FINAL DRIVE...307

SWING MACHINERY...309

SWING CIRCLE...311

TRACK FRAME * RECOIL SPRING...313

IDLER...315

CARRIER ROLLER...317

TRACK ROLLER...318

TRACK SHOE...319

HYDRAULIC TANK...323

HYDRAULIC PUMP...324

CONTROL VALVE...345

SELF PRESSURE REDUCING VALVE...361

CLSS...366

SWING MOTOR...367

REVERSE PREVENTION VALVE...372

CENTER SWIVEL JOINT...374

TRAVEL MOTOR...376

TRAVEL JUNCTION VALVE...386

TRAVEL PPC SHUTTLE VALVE...388

VALVE CONTROL...390

WORK EQUIPMENT * SWING PPC VALVE...391

TRAVEL PPC VALVE...395

SERVICE PPC VALVE...404

SOLENOID VALVE...407

PPC ACCUMULATOR...409

RETURN OIL FILTER...410

BOOM HYDRAULIC DRIFT PREVENTION VALVE...411

LIFT CHECK VALVE...414

ATTACHMENT CIRCUIT SELECTOR VALVE...415

HYDRAULIC CYLINDER...417

WORK EQUIPMENT...419

AIR CONDITIONER...425

ENGINE CONTROL...426

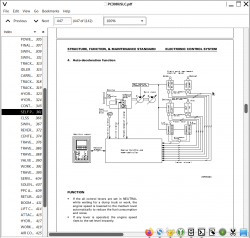

ELECTRONIC CONTROL SYSTEM...434

MONITORING SYSTEM...459

SENSOR...466

20 TESTING AND ADJUSTING...470

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS...471

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS...472

TESTING AND ADJUSTING...480

TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING...481

INSPECTION AND ADJUSTMENT OF ENGINE RPM...483

MEASUREMENT OF EXHAUST COLOR...485

ADJUSTMENT OF VALVE CLEARANCE...486

MEASUREMENT OF COMPRESSION PRESSURE...488

MEASUREMENT OF BLOW-BY PRESSURE...489

INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING...490

MEASUREMENT OF ENGINE OIL PRESSURE...492

ADJUSTMENT OF ENGINE SPEED SENSOR...493

INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION...493

EMERGENT ESCAPE FROM FAILURE IN ENGINE CONTROL SYSTEM...494

GOVERNOR MOTOR LEVER STROKE...495

HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT...496

PC VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE)...499

LS VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE) AND LS DIFFERENTIAL PRESSURE...501

CONTROL CIRCUIT OIL PRESSURE...504

MEASURING SOLENOID VALVE OUTPUT PRESSURE...505

MEASURING PPC VALVE OUTPUT PRESSURE...508

ADJUSTING WORK EQUIPMENT * SWING PPC VALVE...509

TESTING TRAVEL DEVIATION...510

TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT...511

MEASURING SWING, TRAVEL MOTOR OIL LEAKAGE...512

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT...513

TESTING CLEARANCE OF SWING CIRCLE BEARING...514

TESTING WEAR OF SPROCKET...515

TESTING AND ADJUSTING TRACK SHOE TENSION...516

BLEEDING AIR...517

INSPECTION PROCEDURES FOR DIODE...519

TROUBLESHOOTING...520

POINTS TO REMEMBER WHEN TROUBLESHOOTING...521

SEQUENCE OF EVENTS WHEN TROUBLESHOOTING...522

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE...523

CHECKS BEFORE TROUBLESHOOTING...531

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING...532

CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM...537

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...549

EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM...571

DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL...572

METHOD OF USING JUDGEMENT TABLE...587

METHOD OF USING TROUBLESHOOTING CHARTS...589

DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE...591

TROUBLESHOOTING OF COMMUNICATIONS ABNORMALITY (N MODE)...596

N-1 [E218] COMMUNICATIONS ABNORMALITY...597

TROUBLESHOOTING WHEN SERVICE CODE "ELECTRICAL SYSTEM" AND FAILURE CODE "MECHANICAL SYSTEM" ARE INDICATED...598

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE...601

SERVICE CODE IN ELECTRICAL SYSTEM [E101] (ABNORMAL DATA IN ERROR HISTORY)...603

SERVICE CODE IN ELECTRICAL SYSTEM [E112] (SHORT-CIRCUITING IN NORMAL ROTATION SYSTEM OF WINDSHIELD WIPER MOTOR DRIVE)...605

SERVICE CODE IN ELECTRICAL SYSTEM [E113] (SHORT CIRCUITING IN REVERSE ROTATION SYSTEM OF WINDSHIELD WIPER MOTOR DRIVE)...607

SERVICE CODE IN ELECTRICAL SYSTEM [E114] (SHORT CIRCUITING IN WINDOW WASHER DRIVE SYSTEM)...609

SERVICE CODE IN ELECTRICAL SYSTEM [E115] (ABNORMAL WINDSHIELD WIPER MOTION)...611

SERVICE CODE IN ELECTRICAL SYSTEM [E116] (ABNORMALITY IN RETRACTING WINDSHIELD WIPER)...613

SERVICE CODE IN ELECTRICAL SYSTEM [E201] (SHORT CIRCUITING IN TRAVEL INTERLOCKING SOLENOID)...615

SERVICE CODE IN ELECTRICAL SYSTEM [E203] (SHORT CIRCUITING IN SWING HOLDING BRAKE SOLENOID)...617

SERVICE CODE IN ELECTRICAL SYSTEM [E204] (SHORT CIRCUITING IN MERGE/DIVIDE SOLENOID)...619

SERVICE CODE IN ELECTRICAL SYSTEM [E205] (SHORT CIRCUITING IN 2 STAGE RELIEF SOLENOID)...621

SERVICE CODE IN ELECTRICAL SYSTEM [E206] (SHORT CIRCUITING IN TRAVEL SPEED SHIFTING SOLENOID)...623

SERVICE CODE IN ELECTRICAL SYSTEM [E211] (DISCONNECTION IN TRAVEL INTERLOCKING SOLENOID)...625

SERVICE CODE IN ELECTRICAL SYSTEM [E213] (DISCONNECTION IN SWING HOLDING BRAKE SOLENOID)...627

SERVICE CODE IN ELECTRICAL SYSTEM [E214] (DISCONNECTION OF MERGE/DIVIDE SOLENOID)...629

SERVICE CODE IN ELECTRICAL SYSTEM [E215] (DISCONNECTION IN 2 STAGE RELEIF SOLENOID)...631

SERVICE CODE IN ELECTRICAL SYSTEM [E216] (DISCONNECTION IN TRAVEL SPEED SHIFTING SOLENOID)...633

SERVICE CODE IN ELECTRICAL SYSTEM [E217] (ABNORMALITY IN INPUTTING MODEL CODE)...635

SERVICE CODE IN ELECTRICAL SYSTEM [E218] (DISCONNECTION OF S NET SIGNAL)...637

SERVICE CODE IN ELECTRICAL SYSTEM [E222] (SHORT CIRCUITING IN LS-EPC SOLENOID)...639

SERVICE CODE IN ELECTRICAL SYSTEM [E223] (DISCONNECTION IN LS-EPC SOLENOID SYSTEM)...640

SERVICE CODE IN ELECTRICAL SYSTEM [E224] (ABNORMALITY IN F PUMP PRESSURE SENSOR)...641

SERVICE CODE IN ELECTRICAL SYSTEM [E225] (ABNORMALITY IN R PUMP PRESSURE SENSOR)...643

SERVICE CODE IN ELECTRICAL SYSTEM [E226] (ABNORMALITY IN PRESSURE SENSOR POWER SOURCE)...645

SERVICE CODE IN ELECTRICAL SYSTEM [E227] (ABNORMALITY IN ENGINE ROTATION SENSOR)...647

SERVICE CODE IN ELECTRICAL SYSTEM [E228] (SHORT CIRCUITING IN ATTACHMENT RETURN SWITCHING RELAY)...648

SERVICE CODE IN ELECTRICAL SYSTEM [E232] (SHORT CIRCUITING IN PC-EPC SOLENOID)...649

SERVICE CODE IN ELECTRICAL SYSTEM [E233] (DISCONNECTION IN PC-EPC SOLENOID SYSTEM)...651

SERVICE CODE IN ELECTRICAL SYSTEM [E238] (DISCONNECTION IN ATTACHMENT RETURN SWITCHING RELAY)...653

SERVICE CODE IN ELECTRICAL SYSTEM [E256] (INCORRECT NONVOLATILE MEMORY DATA)...655

SERVICE CODE IN ELECTRICAL SYSTEM [E306] (ABNORMALITY IN GOVERNOR POTENTIOMETER)...657

SERVICE CODE IN ELECTRICAL SYSTEM [E308] (ABNORMALITY IN FUEL DIAL)...659

SERVICE CODE IN ELECTRICAL SYSTEM [E315] (SHORT CIRCUITING IN BATTERY RELAY)...661

SERVICE CODE IN ELECTRICAL SYSTEM [E316] (STEP OUT IN GOVERNOR MOTOR)...663

SERVICE CODE IN ELECTRICAL SYSTEM [E317] (DISCONNECTION IN GOVERNOR MOTOR PHASE A AND B)...665

SERVICE CODE IN ELECTRICAL SYSTEM [E318] (SHORT CIRCUITING IN GOVERNOR MOTOR PHASE A AND PHASE B)...667

SERVICE CODE IN ELECTRICAL SYSTEM [E501] ("MODEL SELECTION" FUNCTION NOT PROVIDED YET)...669

SERVICE CODE IN ELECTRICAL SYSTEM [E502] (MODEL SELECTING SIGNAL FAULT)...670

FAILURE CODE IN MECHANICAL SYSTEM [E104] (AIR CLEANER CLOGGING)...671

FAILURE CODE IN MECHANICAL SYSTEM [E108] (ENGINE COOLING WATER OVERHEATING)...672

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)...674

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE...675

E-1 ENGINE DOES NOT START (ENGINE DOES NOT ROTATE)...676

E-2 ENGINE STOPS WHILE IN OPERATION...679

E-3 ENGINE SPEED IS IRREGULAR, OR THERE IS HUNTING...681

E-4 ENGINE DOES NOT STOP...683

E-5 AUTO-DECELERATOR DOES NOT WORK...685

E-6 AUTO ENGINE WARM UP DEVICE DOES NOT WORK...686

E-7 PREHEATER DOES NOT WORK...687

E-8 ALL WORK EQUIPMENT, SWING AND TRAVEL DO NOT MOVE...689

E-9 ONE TOUCH POWER MAX SWITCH DOES NOT WORK...691

E-10 NO DISPLAY IN MONITOR PANEL AT ALL...692

E-11 PART OF DISPLAY ON MONITOR PANEL IS MISSING...693

E-12 MONITOR PANEL DISPLAYS CONTENTS IRRELEVANT TO THE MODEL...693

E-13 FUEL LEVEL MONITOR RED LAMP LIGHTS UP WHILE ENGINE IS RUNNING...694

E-14 ENGINE COOLING TEMPERATURE GAUGE DOES NOT INDICATE CORRECTLY...695

E-15 HYDRAULIC OIL TEMPERATURE GAUGE DOES NOT DISPLAY CORRECTLY...696

E-16 FUEL GAUGE DOES NOT DISPLAY CORRECTLY...697

E-17 SWING LOCK MONITOR DOES NOT DISPLAY CORRECTLY...699

E-18 WHEN THE MONITOR SWITCH IS OPERATED, NO DISPLAY APPEARS...701

E-19 WINDSHIELD WIPER DOES NOT WORK...703

E-20 ALARMING BUZZER CANNOT BE CANCELLED...705

E-21 "BOOM RAISE" IS NOT CORRECTLY DISPLAYED IN MONITOR FUNCTION...706

E-22 "BOOM LOWER" IS NOT CORRECTLY DISPLAYED IN MONITOR FUNCTION...707

E-23 "ARM DIGGING" IS NOT CORRECTLY DISPLAYED IN MONITOR FUNCTION...708

E-24 "ARM DUMPING" IS NOT CORRECTLY DISPLAYED IN MONITOR FUNCTION...709

E-25 "BUCKET DIGGING" IS NOT CORRECTLY DISPLAYED IN MONITOR FUNCTION...710

E-26 "BUCKET DUMPING" IS NOT CORRECTLY DISPLAYED IN MONITOR FUNCTION...711

E-27 "SWING" IS NOT CORRECTLY DISPLAYED IN MONITOR FUNCTION...713

E-28 "TRAVEL" IS NOT CORRECTLY DISPLAYED IN MONITOR FUNCTION...715

E-29 "TRAVEL DIFFERENTIAL PRESSURE" IS NOT CORRECTLY DISPLAYED IN MONITOR FUNCTION...717

E-30 "SERVICE" IS NOT CORRECTLY DISPLAYED IN MONITOR FUNCTION...719

E-31 AIR CONDITIONER DOES NOT WORK...721

E-32 TRAVEL ALARM DOES NOT SOUND...722

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)...724

SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS...725

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE...727

H-1 ALL WORK EQUIPMENT LACK POWER, OR TRAVEL AND SWING SPEEDS ARE SLOW...728

H-2 ENGINE SPEED SHARPLY DROPS OR ENGINE STALLS...729

H-3 NO WORK EQUIPMENT, TRAVEL OR SWING MOVE...730

H-4 ABNORMAL NOISE IS HEARD FROM AROUND HYDRAULIC PUMP...730

H-5 AUTO-DECELERATOR DOES NOT WORK...731

H-6 FINE CONTROL MODE DOES NOT FUNCTION...731

H-7 BOOM MOVES SLOWLY OR LACKS POWER...732

H-8 ARM MOVES SLOWLY OR LACKS POWER...733

H-9 BUCKET MOVES SLOWLY OR LACKS POWER...734

H-10 WORK EQUIPMENT DOES NOT MOVE IN ITS SINGLE OPERATION...734

H-11 WORK EQUIPMENT HAS A BIT TOO FAST HYDRAULIC DRIFT...735

H-12 WORK EQUIPMENT HAS A BIG TIME LAG...736

H-13 OTHER WORK EQUIPMENT MOVES WHEN RELIEVING SINGLE CIRCUIT...736

H-14 ONE TOUCH POWER MAX SWITCH DOES NOT OPERATE...736

H-15 IN COMOUND OPERATION, WORK EQUIPMENT WITH LARGER LOAD MOVES SLOWLY...737

H-16 IN SWING + BOOM RAISE OPERATION, BOOM MOVES SLOWLY...737

H-17 IN SWING + TRAVEL, TRAEL SPEED DROPS SHARPLY...737

H-18 MACHINE SWERVES IN TRAVEL...738

H-19 MACHINE TRAVELS SLOWLY...739

H-20 MACHINE CANNOT BE EASILY STEERED OR LACKS POWER...740

H-21 TRAVEL SPEED DOES NOT SHIFT, OR IT IS TOO SLOW OR FAST...741

H-22 TRACK SHOE DOES NOT TURN (ON ONE SIDE ONLY)...742

H-23 MACHINE DOES NOT SWING...743

H-24 SWING ACCELERATION IS POOR, OR SWING SPEED IS SLOW...744

H-25 EXCESSIVE OVERRUN WHEN STOPPING SWING...745

H-26 THERE IS A BIG SHOCK WHEN STOPPING SWING...746

H-27 THERE IS A BIG ABNORMAL NOISE CAUSED WHEN STOPPING SWING...746

TROUBLESHOOTING OF ENGINE (S MODE)...747

METHOD OF USING TROUBLESHOOTING CHARTS...748

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)...752

S-2 ENGINE DOES NOT START...754

(1) ENGINE DOES NOT TURN...754

(2) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)...755

(3) EXHAUST SMOKE COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)...756

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW UP IS POOR)...757

S-4 ENGINE STOPS DURING OPERATIONS...758

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)...759

S-6 ENGINE LACKS OUTPUT (OR LACKS POWER)...760

S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION)...761

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)...762

S-9 OIL BECOMES CONTAMINATED QUICKLY...763

S-10 FUEL CONSUMPTION IS EXCESSIVE...764

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN...765

S-12 OIL PRESSURE MONITOR LIGHTS UP (DROP IN OIL PRESSURE)...766

S-13 OIL LEVEL RISES (WATER, FUEL IN OIL)...767

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)...768

S-15 ABNORMAL NOISE IS MADE...769

S-16 VIBRATION IS EXCESSIVE...770

30 DISASSEMBLY AND ASSEMBLY...771

METHOD OF USING MANUAL...773

PRECAUTIONS WHEN CARRYING OUT OPERATION...775

SPECIAL TOOL LIST...778

REMOVAL OF ENGINE ASSEMBLY...781

INSTALLATION OF ENGINE ASSEMBLY...783

REMOVAL OF ENGINE FRONT SEAL...784

INSTALLATION OF ENGINE FRONT SEAL...785

REMOVAL OF ENGINE REAR SEAL...786

INSTALLATION OF ENGINE REAR SEAL...787

REMOVAL OF RADIATOR ASSEMBLY...788

INSTALLATION OF RADIATOR ASSEMBLY...789

REMOVAL OF HYDRAULIC OIL COOLER ASSEMBLY...790

INSTALLATION OF HYDRAULIC OIL COOLER ASSEMBLY...791

REMOVAL OF AFTERCOOLER ASSEMBLY...792

INSTALLATION OF AFTERCOOLER ASSEMBLY...792

REMOVAL OF FUEL TANK ASSEMBLY...793

INSTALLATION OF FUEL TANK ASSEMBLY...793

REMOVAL OF CENTER SWIVEL JOINT ASSEMBLY...794

DISASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY...795

ASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY...795

REMOVAL OF FINAL DRIVE ASSEMBLY...796

INSTALLATION OF FINAL DRIVE ASSEMBLY...796

DISASSEMBLY OF FINAL DRIVE ASSEMBLY...797

ASSEMBLY OF FINAL DRIVE ASSEMBLY...800

REMOVAL OF REVOLVING FRAME ASSEMBLY...806

INSTALLATION OF REVOLVING FRAME ASSEMBLY...806

REMOVAL OF SWING CIRCLE ASSEMBLY...807

INSTALLATION OF SWING CIRCLE ASSEMBLY...807

DISASSEMBLY OF RECOIL SPRING ASSEMBLY...808

ASSEMBLY OF RECOIL SPRING ASSEMBLY...809

REMOVAL OF SPROCKET...810

INSTALLATION OF SPROCKET...810

ASSEMBLY OF IDLER ASSEMBLY...811

ASSEMBLY OF TRACK ROLLER ASSEMBLY...813

EXPANSION OF TRACK SHOE ASSEMBLY...814

INSTALLATION OF TRACK SHOE ASSEMBLY...814

REMOVAL OF HYDRAULIC PUMP ASSEMBLY...815

INSTALLATION OF HYDRAULIC PUMP ASSEMBLY...816

REMOVAL OF OIL SEAL IN HYRAULIC PUMP INPUT SHAFT...817

INSTALLATION OF OIL SEAL IN HYRAULIC PUMP INPUT SHAFT...817

REMOVAL OF CONTROL VALVE ASSEMBLY...818

INSTALLATION OF CONTROL VALVE ASSEMBLY...820

DISASSEMBLY OF CONTROL VALVE ASSEMBLY...821

ASSEMBLY OF CONTROL VALVE ASSEMBLY...823

DISASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY...824

DISASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY...825

ASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY...825

REMOVAL OF WORK EQUIPMENT ASSEMBLY...826

INSTALLATION OF WORK EQUIPMENT ASSEMBLY...827

DISASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY...829

ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY...831

REMOVAL OF OPERATOR'S CAB ASSEMBLY...835

INSTALLATION OF OPERATOR'S CAB ASSEMBLY...836

REMOVAL OF FLOOR FRAME ASSEMBLY...837

INSTALLATION OF FLOOR FRAME ASSEMBLY...838

REMOVAL OF AIR CONDITIONER COMPRESSOR ASSEMBLY...839

INSTALLATION OF AIR CONDITIONER COMPRESSOR ASSEMBLY...839

REMOVAL OF AIR CONDITIONER CONDENSER ASSEMBLY...840

INSTALLATION OF AIR CONDITIONER CONDENSER ASSEMBLY...840

REMOVAL OF AIR CONDITIONER UNIT ASSEMBLY...841

INSTALLATION OF AIR CONDITIONER UNIT ASSEMBLY...842

REMOVAL, INSTALLATION OF COUNTERWEIGHT ASSEMBLY...843

REMOVAL OF MONITOR PANEL ASSEMBLY...844

INSTALLATION OF MONITOR PANEL ASSEMBLY...844

REMOVAL OF SWING MOTOR AND SWING MACHINERY ASSEMBLY...845

INSTALLATION OF SWING MOTOR AND SWING MACHINERY ASSEMBLY...845

DISASSEMBLY OF SWING MOTOR AND SWING MACHINERY ASSEMBLY...846

ASSEMBLY OF SWING MOTOR AND SWING MACHINERY ASSEMBLY...848

REMOVAL OF HYDRAULIC TANK ASSEMBLY...852

INSTALLATION OF HYDRAULIC TANK ASSEMBLY...853

90 OTHERS...855

HYDRAULIC CIRCUIT DIAGRAM...857

ELECTRICAL CIRCUIT DIAGRAM (1/4)...858

ELECTRICAL CIRCUIT DIAGRAM (2/4)...859

ELECTRICAL CIRCUIT DIAGRAM (3/4)...860

ELECTRICAL CIRCUIT DIAGRAM (4/4)...861

TEN00114-00 - Hydraulic Excavator GALEO PC308USLC-3 Operation & Maintenance Manual...862

COVER...862

FOREWORD...863

FOREWORD...864

SAFETY INFORMATION...867

INTRODUCTION...869

DIRECTIONS OF MACHINE...869

PRODUCT INFORMATION...870

PRODUCT IDENTIFICATION NUMBER (PIN), MACHINE SERIAL NO. PLATE...870

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION...870

SERVICE METER LOCATION...871

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR...871

CONTENTS...872

SAFETY...877

SAFETY INFORMATION...878

POSITION FOR ATTACHING SAFETY LABELS...880

POSITION FOR ATTACHING SAFETY LABELS...880

SAFETY LABELS...881

SAFETY INFORMATION...886

SAFETY RULES...886

IF ABNORMALITIES ARE FOUND...886

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS...886

FIRE EXTINGUISHER AND FIRST AID KIT...886

SAFETY EQUIPMENT...887

KEEP MACHINE CLEAN...887

KEEP OPERATOR'S COMPARTMENT CLEAN...887

LEAVING OPERATOR'S SEAT WITH LOCK...887

HANDRAILS AND STEPS...888

CRUSHING OR CUTTING PREVENTION...889

MOUNTING AND DISMOUNTING...889

NO PERSONS ON ATTACHMENTS...889

BURN PREVENTION...889

FIRE PREVENTION AND EXPLOSION PREVENTION...890

ACTION IF FIRE OCCURS...891

WINDSHIELD WASHER FLUID...891

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION...891

ATTACHMENT INSTALLATION...891

ATTACHMENT COMBINATIONS...892

CAB WIDOW GLASSES...892

UNAUTHORIZED MODIFICATIONS...892

SAFETY AT JOBSITE...892

WORKING ON LOOSE GROUND...893

DISTANCE TO HIGH VOLTAGE CABLES...893

ENSURE GOOD VISIBILITY...893

VENTILATION FOR ENCLOSED AREA...894

SIGNALMAN'S SIGNAL AND SIGNS...894

EMERGENCY EXIT FROM OPERATOR'S CAB...894

ASBESTOS DUST HAZARD PREVENTION...894

SAFETY MACHINE OPERATION...895

STARTING ENGINE...895

CHECKS BEFORE STARTING ENGINE...895

SAFETY RULES FOR STARTING ENGINE...896

STARTING ENGINE IN COLD WEATHER...896

OPERATION...897

CHECKS AFTER STARTING ENGINE...897

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS...897

SAFETY RULES FOR TRAVELING...898

TRAVELING ON SLOPES...899

OPERATIONS ON SLOPES...900

PROHIBITED OPERATIONS...900

OPERATIONS ON SNOW...902

PARKING MACHINE...902

TRANSPORTATION...903

LOADING AND UNLOADING...903

SHIPPING THE MACHINE...904

BATTERY...905

BATTERY HAZARD PREVENTION...905

STARTING ENGINE WITH BOOSTER CABLES...906

TOWING...907

SAFETY RULES FOR TOWING...907

LIFTING OBJECTS WITH BUCKET...908

SAFETY RULES FOR LIFTING OBJECTS...908

SAFETY MAINTENANCE INFORMATION...909

WARNING TAG...909

KEEP WORK PLACE CLEAN AND TIDY...909

APPOINT LEADER WHEN WORKING WITH OTHERS...909

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE...910

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING...911

PROPER TOOLS...911

ACCUMULATOR...912

PERSONNEL...912

ATTACHMENTS...912

WORK UNDER THE MACHINE...912

NOISE...913

WHEN USING HAMMER...913

WELDING WORKS...913

REMOVING BATTERY TERMINALS...913

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION...914

DO NOT DISASSEMBLE RECOIL SPRINGS...914

SAFETY RULES FOR HIGH-PRESSURE OIL...914

SAFETY HANDLING HIGH-PRESSURE HOSES...915

WASTE MATERIALS...915

AIR CONDITIONER MAINTENANCE...915

COMPRESSED AIR...915

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS...916

OPERATION...917

GENERAL VIEW...918

GENERAL VIEW OF MACHINE...918

GENERAL VIEW CONTROLS AND GAUGES...919

EXPLANATION OF COMPONENTS...920

MACHINE MONITOR...920

BASIC CHECK ITEMS...921

SWITCHES...933

CONTROL LEVERS, PEDALS...939

FRONT WINDOW...942

SLIDING DOOR...948

ASHTRAY...948

CONTROLLER (COMPUTER)...948

REAR UNDERVIEW MIRROR...949

HAMMER FOR EMERGENCY ESCAPE...949

CAP, COVER WITH LOCK...950

HOT AND COOL BOX...951

HANDLING AIR CONDITIONER...952

RADIO...958

FUSE...963

FUSIBLELINK...964

TOOL COMPARTMENT...964

GREASE GUN HOLDER...964

HANDLING ACCUMULATOR...965

MACHINE OPERATIONS AND CONTROLS...966

BEFORE STARTING ENGINE...966

STARTING ENGINE...980

AFTER STARTING ENGINE...984

IN COLD AREAS (AUTOMATIC WARMING-UP OPERATION)...987

STOPPING THE ENGINE...990

CHECK AFTER SHUT OFF ENGINE...990

MACHINE OPERATION...991

STEERING THE MACHINE...995

SWINGING...997

WORK EQUIPMENT CONTROLS AND OPERATIONS...998

OPERATING WORKING MODE...1000

PROHIBITED OPERATIONS...1001

GENERAL OPERATION INFORMATION...1003

TRAVELING ON SLOPES...1004

ESCAPE FROM MUD...1006

RECOMMENDED APPLICATIONS...1007

REPLACEMENT AND INVERSION OF BUCKET...1009

PARKING MACHINE...1012

CHECK AFTER FINISHING WORK...1013

LOCKING...1014

TRANSPORTATION...1015

TRANSPORTATION PROCEDURE...1015

LOADING AND UNLOADING WITH TRAILER...1016

LIFTING MACHINE...1025

COLD WEATHER OPERATION...1028

COLD WEATHER OPERATION INFORMATION...1028

AFTER DAILY WORK COMPLETION...1030

AFTER COLD WEATHER SEASON...1030

LONG TERM STORAGE...1031

BEFORE STORAGE...1031

DURING STORAGE...1031

AFTER STORAGE...1032

TROUBLESHOOTING...1033

AFTER RUNNING OUT OF FUEL...1033

PHENOMENA THAT ARE NOT FAILURES...1033

TOWING THE MACHINE...1034

LIGHTWEIGHT TOWING HOOK...1035

SEVERE JOB CONDITION...1035

DISCHARGED BATTERY...1036

OTHER TROUBLE...1040

MAINTENANCE...1047

MAINTENANCE INFORMATION...1048

LUBRICANTS, COOLANT AND FILTERS...1051

OUTLINE OF OIL, FUEL, COOLANT...1051

ELECTRIC SYSTEM MAINTENANCE...1053

HANDLING HYDRAULIC SYSTEM...1053

WEAR PARTS LIST...1055

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE...1056

PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS...1056

TIGHTENING TORQUE SPECIFICATIONS...1060

TIGHTENING TORQUE LIST...1060

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS...1061

SAFETY CRITICAL PARTS...1061

MAINTENANCE SCHEDULE...1062

MAINTENANCE SCHEDULE CHART...1062

MAINTENANCE PROCEDURE...1064

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)...1064

REPLACE FUEL FILTER CARTRIDGE...1090

CHECK ENGINE VALVE CLEARANCE, ADJUST...1104

WHEN REQUIRED...1065

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT...1065

CLEAN INSIDE OF COOLING SYSTEM...1068

CHECK AND TIGHTEN TRACK SHOE BOLTS...1071

CHECK AND ADJUST TRACK TENSION...1072

CHECK ELECTRICAL INTAKE AIR HEATER...1074

ADJUST BUCKET CLEARANCE...1075

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID...1076

CHECK AND ADJUST AIR CONDITIONER (ONLY MACHINES EQUIPPED WITH AIR CONDITIONER)...1077

WASHING WASHABLE FLOOR...1078

BLEEDING AIR FROM HYDRAULIC SYSTEM...1079

METHOD FOR RELEASING INTERNAL PRESSURE IN HYDRAULIC CIRCUIT...1081

CHECK BEFORE STARTING...1082

EVERY 100 HOURS MAINTENANCE...1083

LUBRICATING...1083

DRAIN WATER AND SEDIMENT FROM FUEL TANK...1084

EVERY 250 HOURS MAINTENANCE...1085

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL...1085

CHECK LEVEL OF BATTERY ELECTROLYTE...1086

CHECK, ADJUST TENSION OF AIR CONDITIONER COMPRESSOR BELT...1088

LUBRICATE SWING CIRCLE (2 PLACES)...1088

CHECK OIL LEVEL IN MACHINERY CASE, ADD OIL...1089

EVERY 500 HOURS MAINTENANCE...1090

REPLACE FUEL FILTER CARTRIDGE...1090

CHECK SWING PINION GREASE LEVEL, ADD GREASE...1091

LUBRICATING...1092

CLEAN AND INSPECT RADIATOR FINS, OIL COOLER FINS AND CONDENSER FINS...1094

CLEAN INTERNAL AND EXTERNAL AIR FILTERS OF AIR CONDITIONER SYSTEM...1096

REPLACE BREATHER ELEMENT IN HYDRAULIC TANK...1097

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE...1098

EVERY 1000 HOURS MAINTENANCE...1099

REPLACE HYDRAULIC FILTER ELEMENT...1099

CHANGE OIL IN SWING MACHINERY CASE...1101

CHECK OIL LEVEL IN DAMPER CASE, ADD OIL...1102

CHECK ALL TIGHTENING PARTS OF TURBOCHARGER...1102

CHECK PLAY OF TURBOCHARGER ROTOR...1102

CHECK FAN BELT TENSION AND REPLACE FAN BELT...1102

EVERY 2000 HOURS MAINTENANCE...1103

CHANGE OIL IN FINAL DRIVE CASE...1103

CLEAN HYDRAULIC TANK STRAINER...1104

CLEAN, CHECK TURBOCHARGER...1104

CHECK ALTERNATOR, STARTING MOTOR...1104

CHECK ENGINE VALVE CLEARANCE, ADJUST...1104

CHECK VIBRATION DAMPER...1105

EVERY 4000 HOURS MAINTENENCE...1106

CHECK WATER PUMP...1106

EVERY 5000 HOURS MAINTENANCE...1107

CHANGE OIL IN HYDRAULIC TANK...1107

SPECIFICATIONS...1109

SPECIFICATIONS...1110

ATTACHMENTS AND OPTIONS...1113

GENERAL PRECAUTIONS...1114

PRECAUTIONS RELATED TO SAFETY...1114

PRECAUTIONS WHEN INSTALLING ATTACHMENTS...1116

HANDLING BUCKET WITH HOOK...1117

CHECKING FOR DAMAGE TO BUCKET WITH HOOK...1117

PROHIBITED OPERATIONS...1117

MACHINES READY FOR ATTACHMENTS...1118

EXPLANATION OF COMPONENTS...1118

HYDRAULIC CIRCUIT...1122

ATTACHMENT MOUNTING/DISMOUNTING PROCEDURE...1127

OPERATION...1129

LONG-TERM STORAGE...1130

SPECIFICATIONS...1130

ATTACHMENT GUIDE...1131

SELECTION OF TRACK SHOES...1132

RECOMMENDED ATTACHMENT OPERATIONS...1133

HYDRAULIC BREAKER...1133

INDEX...1139