Komatsu Hydraulic Excavator PC300-3, PC300LC-3, PC300-5 (Mighty), PC300LC-5(K) (Mighty), PC300HD-5, PC300LC-5, PC360LC-3, PC400-5 (Mighty), PC400LC-5 (Mighty), PC400HD-5 Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC300-3, PC300LC-3, PC300-5 (Mighty), PC300LC-5(K) (Mighty), PC300HD-5, PC300LC-5, PC360LC-3, PC400-5 (Mighty), PC400LC-5 (Mighty), PC400HD-5, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC300-3, PC300LC-3, PC300-5 (Mighty), PC300LC-5(K) (Mighty), PC300HD-5, PC300LC-5, PC360LC-3, PC400-5 (Mighty), PC400LC-5 (Mighty), PC400HD-5 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 2,194 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEBM207041 - Excavators PC300LC-5 with KDC 614TA & PC400LC-5 with Cummins LTA-10C Engine Shop Manual.pdf

CEBM207077 - Hydraulic Excavator PC300-5 (Mighty), PC300LC-5(K) (Mighty), PC300HD-5, PC300LC-5 & PC400-5 (Mighty), PC400LC-5 (Mighty), PC400HD-5 Shop Manual.pdf

SEBM02070308 - Hydraulic Excavator PC300-3, PC300LC-3, PC360LC-3 Shop Manual.pdf

MAIN SECTIONS

CEBM207041 - Excavators PC300LC-5 with KDC 614TA & PC400LC-5 with Cummins LTA-10C Engine Shop Manual.....2

CONTENTS.....10

01 GENERAL.....20

GENERAL VIEW - PC300LG5, PC400LG5.....22

MACHINE DIMENSIONS - PC300LG5.....23

WORKING RANGE DIMENSIONS - PC300LC-5.....24

MACHINE SPECIFICATIONS - PC300LG5.....25

MACHINE DIMENSIONS - PC400LC-5.....27

WORKING RANGE DIMENSIONS - PC400LC-5.....28

MACHINE SPECIFICATIONS - PC400LC-5.....29

WEIGHT TABLE.....31

REFILL SPECIFICATIONS AND CAPACITIES.....33

PC300LC-5.....33

PC400LC-5.....34

10 STRUCTURE AND FUNCTION.....42

ENGINE RELATED PARTS AND ENGINE MOUNT PC300LC .....45

ENGINE RELATED PARTS AND ENGINE MOUNT PC400LC .....46

RADIATOR AND OIL COOLER PC300LC .....47

RADIATOR AND OIL COOLER PC400LC .....48

FUEL TANK AND PIPING PC300LC .....49

FUEL TANK AND PIPING PC400LC .....50

POWER TRAIN .....51

FINAL DRIVE PC300LC .....52

FINAL DRIVE PC400LC .....53

SWING CIRCLE PC300LC .....54

SWING CIRCLE PC400LC .....55

SWING MACHINERY PC300LC .....56

SWING MACHINERY PC400LC .....57

TRACK FRAME AND RECOIL SPRING PC300LC .....58

TRACK FRAME AND RECOIL SPRING PC400LC .....59

IDLER PC300LC .....60

IDLER PC400LC .....61

TRACK ROLLER .....62

CARRIER ROLLER .....62

TRACK SHOE PC300LC .....63

TRACK SHOE PC400LC .....64

HYDRAULIC PIPING .....66

HYDRAULIC CIRCUIT DIAGRAM .....68

HYDRAULIC TANK PC300LC .....70

HYDRAULIC TANK PC400LC .....71

OLSS (Open Center Load Sensing System) .....72

HYDRAULIC PUMP .....74

LINE OIL FILTER .....93

CONTROL VALVE .....95

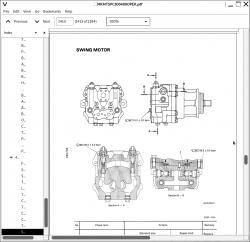

SWING MOTOR .....107

CENTER SWIVEL JOINT .....110

TRAVEL MOTOR PC300LC .....111

TRAVEL MOTOR PC400LC .....113

VALVE CONTROL .....120

PPC VALVE .....121

ACCUMULATOR .....127

SAFETY LOCK VALVE .....127

SOLENOID VALVE ASSEMBLY .....128

SHUTTLE VALVE .....132

BOOM HOLDING VALVE .....133

HYDRAULIC CYLINDER .....136

WORK EQUIPMENT .....139

ELECTRICAL WIRING DIAGRAM PC300LC .....141

ELECTRICAL WIRING DIAGRAM PC400LC .....143

ELECTRICAL CIRCUIT DIAGRAM PC300LC .....146

ELECTRICAL CIRCUIT DIAGRAM PC400LC .....150

ENGINE CONTROL SYSTEM PC300LC (S/N A30001 THRU A30110, A30112 AND A30114 THRU A30116).....154

ENGINE CONTROL SYSTEM PC300LC (S/N A30111, A30113 AND A30117 AND UP).....155

ENGINE CONTROL SYSTEM PC400LC .....157

PEMC SYSTEM .....169

EMACC (ELECTRONIC MONITOR AND CONTROL CONSOLE) .....198

20 TESTING AND ADJUSTING .....208

TABLE OF JUDGEMENT STANDARD VALUE .....209

STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM .....234

TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING .....246

ADJUSTING TRAVEL OF GOVERNOR MOTOR LEVER .....247

ADJUSTING ENGINE SPEED SENSOR .....248

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING AND TRAVEL CIRCUIT .....249

TESTING AND ADJUSTING CHARGING PUMP PRESSURE .....252

TESTING AND ADJUSTING MAIN PUMP CONTROL PRESSURE .....254

TESTING AND ADJUSTING TRAVEL DEVIATION .....261

MEASURING STROKE OF SERVO PISTON .....264

MEASURING OUTPUT PRESSURE OF PPC VALVE .....265

ADJUSTING WORK EQUIPMENT AND SWING PPC VALVE .....266

TESTING PPC SHUTTLE VALVE .....267

MEASURING SOLENOID VALVE OUTLET PORT PRESSURE .....268

TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT .....269

BLEEDING AIR .....271

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT.....273

TROUBLESHOOTING .....274

POINTS TO REMEMBER WHEN TROUBLESHOOTING .....276

SEQUENCE OF EVENTS IN TROUBLESHOOTING .....277

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE .....278

HANDLING CONNECTORS - YAZAKI TYPE CONNECTOR.....283

HANDLING CONNECTORS - PACKARD COMPANY CONNECTOR.....284

CHECKS BEFORE TROUBLESHOOTING.....287

ELECTRICAL CIRCUIT DIAGRAM - ENGINE THROTTLE CONTROLLER SYSTEM (PC300LC).....288

ELECTRICAL CIRCUIT DIAGRAM - ENGINE THROTTLE CONTROLLER SYSTEM (PC400LC).....289

PUMP CONTROLLER SYSTEM - PC300LC.....290

PUMP CONTROLLER SYSTEM - PC400LC.....291

MONITOR SYSTEM - PC300LC.....292

MONITOR SYSTEM - PC400LC.....293

POSITION OF CONNECTORS FOR TROUBLESHOOTING TABLE - PC300LC .....294

POSITION OF CONNECTORS FOR TROUBLESHOOTING - PC300LC .....296

POSITION OF CONNECTORS FOR TROUBLESHOOTING TABLE - PC400LC .....298

POSITION OF CONNECTORS FOR TROUBLESHOOTING - PC400LC .....300

CONNECTION TABLE FOR CONNECTOR (N-SLC TYPE).....302

CONNECTION TABLE FOR CONNECTOR (M TYPE).....303

CONNECTION TABLE FOR CONNECTOR (S TYPE).....305

CONNECTION TABLE FOR CONNECTOR (AMP040 TYPE).....306

CONNECTION TABLE FOR CONNECTOR (SWP TYPE).....307

CONNECTION TABLE FOR CONNECTOR (MIC TYPE).....308

CONNECTION TABLE FOR CONNECTOR (X TYPE).....309

CONNECTION TABLE FOR CONNECTOR .....310

EXPLANATION OF THE FUNCTIONS OF THE CONTROL MECHANISM OF THE ELECTRICAL SYSTEM .....311

DISPLAY METHOD FOR MONITOR PANEL, PUMP CONTROLLER AND ENGINE THROTTLE CONTROLLER .....314

ACTION OF SELF-DIAGNOSTIC FUNCTION AND SYMPTONS ON MACHINE - ENGINE THROTTLE CONTROLLER SYSTEM.....318

ACTION OF SELF-DIAGNOSTIC FUNCTION AND SYMPTOMS ON MACHINE - PUMP CONTROLLER SYSTEM.....320

METHOD OF USING JUDGEMENT TABLE .....324

METHOD OF USING TROUBLESHOOTING CHARTS .....326

TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM (E-MODE).....328

ENGINE THROTTLE CONTROLLER OR IN ENGINE RELATED PARTS .....330

POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING ON ENGINE THROTTLE CONTROLLER SYSTEM .....332

E-1 [ABNORMALITY IN POWER SOURCE SYSTEM OR CONTROLLER] IS DISPLAYED (ALL LAMPS OFF) .....333

E-2 [SHORT CIRCUIT IN GOVERNOR MOTOR] IS DISPLAYED. .....335

E-3 [DISCONNECTION IN WIRING HARNESS OF GOVERNOR MOTOR] IS DISPLAYED.....336

E-4 [ABNORMALITY IN GOVERNOR POTENTIOMETER] IS DISPLAYED.....337

E-5 [ABNORMALITY IN FUEL CONTROL DIAL] IS DISPLAYED .....339

E-6 [ABNORMALITY IN NO.2 THROTTLE SIGNAL] IS DISPLAYED.....341

E-7 ENGINE DOES NOT START .....343

E-7 ENGINE DOES NOT START (PC300LC).....345

E-7 ENGINE DOES NOT START (PC400LC).....346

E-8 ENGINE ROTATION IS IRREGULAR .....347

E-9 LACK OF OUTPUT POWER (MAX. ENGINE SPEED IS TOO LOW) .....351

E-10 ENGINE DOES NOT STOP (PC300LC).....353

E-10 ENGINE DOES NOT STOP (PC400LC).....354

E-l 1 AUTOMATIC WARMING-UP OPERATION IS DEFECTIVE .....355

TROUBLESHOOTING OF PUMP SYSTEM (C MODE).....356

CHART FOR DISTINGUISHING IF FAILURE IS IN PUMP CONTROLLER OR IN HYDRAULIC RELATED PARTS .....358

C-1 [OFF] SELF-DIAGNOSTIC DISPLAY OF CONTROLLER DOES NOT LIGHT UP.....360

C-2 [SHORT CIRCUIT IN 2-STAGE RELIEF SOLENOID VALVE SYSTEM] IS DISPLAYED .....361

C-3 [SHORT CIRCUIT IN ARM HALF FLOW SOLENOID VALVE SYSTEM] IS DISPLAYED.....362

C-4 [SHORT CIRCUIT IN SWING BRAKE SOLENOID VALVE SYSTEM] IS DISPLAYED.....363

C-5 [SHORT CIRCUIT IN TRAVEL SPEED SOLENOID VALVE SYSTEM] IS DISPLAYED.....364

C-6 [SHORT CIRCUIT IN CO CANCEL SOLENOID VALVE SYSTEM] IS DISPLAYED.....365

C-7 [SHORT CIRCUIT IN TVC SOLENOID SYSTEM (1)] IS DISPLAYED .....366

C-8 [SHORT CIRCUIT IN TVC SOLENOID VALVE SYSTEM (2)] IS DISPLAYED.....367

C-9 [DISCONNECTION IN 2-STAGE RELIEF SOLENOID VALVE SYSTEM] IS DISPLAYED.....368

C-10 [DISCONNECTION IN ARM HALF FLOW SOLENOID VALVE SYSTEM] IS DISPLAYED.....369

C-11 [DISCONNECTION IN SWING BRAKE SOLENOID VALVE SYSTEM] IS DISPLAYED.....370

C-12 [DISCONNECTION IN TRAVEL SPEED SOLENOID VALVE SYSTEM] IS DISPLAYED.....371

C-13 [DISCONNECTION IN CO CANCEL SOLENOID VALVE SYSTEM] IS DISPLAYED.....372

C-14 [DISCONNECTION IN TVC SOLENOID VALVE SYSTEM] IS DISPLAYED .....373

C-15 [ABNORMALITY IN NO.2 THROTTLE SIGNAL SYSTEM] IS DISPLAYED .....374

C-16 [ ABNORMALITY IN THROTTLE SIGNAL SYSTEM] IS DISPLAYED .....375

C-17 [ABNORMALITY IN FRONT PUMP PRESSURE SENSOR SIGNAL SYSTEM] IS DISPLAYED.....377

C-18 [ABNORMALITY IN REAR PUMP PRESSURE SENSOR SIGNAL SYSTEM] IS DISPLAYED.....379

C-19 [ABNORMALITY IN PRESSURE SENSOR POWER SOURCE SYSTEM] IS DISPLAYED.....381

C-20 [ABNORMALITY IN ENGINE SPEED SENSOR SYSTEM] IS DISPLAYED .....383

C-21 [ABNORMALITY IN AUTO-DECELERATION SIGNAL OUTPUT SYSTEM] IS DISPLAYED.....384

C-22 [ABNORMALITY IN OVERHEAT SIGNAL SYSTEM] IS DISPLAYED .....385

C-23 [CONTROLLER ABNORMAL SYSTEM] IS DISPLAYED.....386

TROUBLESHOOTING OF PUMP CONTROLLER INPUT SIGNAL SYSTEM (F MODE).....388

F-1 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [WORK EQUIPMENT SWING OIL PRESSURE SWITCH].....389

F-2 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [TRAVEL OIL PRESSURE SWITCH].....390

F-3 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [SWING LOCK SWITCH].....391

F-4 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [TRAVEL SPEED SWITCH].....392

F-5 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [AUTO-DECELERATION SWITCH].....393

F-6 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [POWER MAXIMIZING SWITCH].....394

F-7 PUMP CONTROLLER MONITOR DOES NOT DISPLAY [DECIMAL POINT OF ENGINE SPEED SENSOR].....395

F-8 PUMP CONTROLLER WORKING MODE DISPLAY DOES NOT SWITCH.....396

F-9 PUMP CONTROLLER POWER SET DISPLAY DOES NOT SWITCH .....397

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H-MODE).....398

H-1 SPEEDS OF WORK EQUIPMENT, TRAVEL AND SWING ARE ALL SLOW .....399

H-2 THERE IS EXCESSIVE DROP IN ENGINE SPEED OR ENGINE STALLS .....401

H-3 WORK EQUIPMENT, TRAVEL AND SWING DO NOT MOVE OR SPEED IS EXTREMELY SLOW .....403

H-4 WORK EQUIPMENT, TRAVEL AND SWING LACK POWER .....405

H-5 POWER SET SELECTION SYSTEM DOES NOT SWITCH.....405

H-6 ABNORMAL NOISE GENERATED (FROM AROUND PUMP) .....406

H-7 AUTO-DECELERATION DOES NOT WORK .....406

H-8 BOOM AND ARM SPEED IS EXTREMELY SLOW .....407

H-9 WORK EQUIPMENT (BOOM, ARM AND BUCKET) SPEED IS SLOW .....409

H-10 WHEN BOOM AND ARM IS OPERATED SIMULTANEOUSLY, BOOM IS SLOW.....411

H-11 WORK EQUIPMENT (BOOM, ARM AND BUCKET) LACKS POWER .....411

H-12 EXCESSIVE HYDRAULIC DRIFT .....411

H-13 EXCESSIVE TIME LAG .....413

H-14 DOES NOT ENTER F.O. MODE (HALF FLOW FUNCTION) .....413

H-15 WHEN ARM AND SWING ARE OPERATED SIMULTANEOUSLY, ARM IS SLOW .....413

H-16 WHEN MACHINE IS TRAVELING, IT DEVIATES NATURALLY TO ONE SIDE .....415

H-17 EXCESSIVE DEVIATION DURING COMPOUND OPERATIONS .....418

H-18 EXCESSIVE DEVIATION WHEN STARTING .....419

H-I9 TRAVEL LACKS POWER (OR SPEED IS SLOW) .....421

H-20 TRAVEL SPEED DOES NOT SWITCH .....421

H-21 MACHINE DOES NOT MOVE (ONE SIDE ONLY) .....422

H-22 DOES NOT SWING .....423

H-23 SWING SPEED IS SLOW OR ACCELERATION IS POOR .....425

H-24 EXCESSIVE OVERRUN WHEN STOPPING SWING .....426

H-25 EXCESSIVE SHOCK WHEN STOPPING SWING .....426

H-26 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING .....427

H-27 EXCESSIVE HYDRAULIC DRIFT OF SWING .....427

H-28 WHEN OPERATED SIMULTANEOUSLY WITH ARM, SWING SPEED IS SLOW .....427

TABLE OF FAILURE MODES AND CAUSES .....428

TROUBLESHOOTING OF MONITOR SYSTEM (P-MODE).....430

P-1 MONITOR PANEL LAMPS DO NOT LIGHT UP FOR 3 SECONDS WHEN STARTING SWITCH IS TURNED ON .....432

P-2 MONITOR PANEL LAMPS ALL LIGHT UP WHEN STARTING SWITCH IS TURNED ON BUT DO NOT GO OUT .....433

P-3 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), CHECK ITEMS FLASH (LEVELS FOR CHECK ITEMS ARE AS SPECIFIED) .....434

P-4 WHEN STARTING SWITCH IS TURNED ON AND ENGINE IS STARTED, CHECK ITEMS FLASH .....437

P-5 WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), CAUTION ITEMS FLASH .....438

P-6 WHEN STARTING SWITCH IS TURNED ON AND ENGINE IS STARTED, CAUTION ITEMS FLASH (WHEN THERE IS NO ABNORMALITY IN CHECK ITEMS OR ENGINE) .....439

P-7(a) WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED), BUZZER DOES NOT SOUND FOR 1 SECOND CAUTION ITEM IS FLASHING BUT BUZZER DOES NOT SOUND.....442

P-7(b) THERE IS NO ABNORMALITY DISPLAY ON THE MONITOR BUT THE BUZZER SOUNDS .....442

P-8 PANEL LIGHTING OF MONITOR PANEL DOES NOT LIGHT UP (LIQUID CRYSTAL DISPLAY IS NORMAL) .....443

P-9 COOLANT TEMPERATURE SHOWS ABNORMALITY LOW TEMPERATURE .....444

P-10 COOLANT TEMPERATURE GAUGE GIVES NO DISPLAY (DURING OPERATION, NO LEVEL OF GAUGE IS DISPLAYED).....444

P-11 FUEL GAUGE ALWAYS DISPLAYS FULL .....445

P-12 FUEL GAUGE GIVES NO DISPLAY .....445

P-13(a) LAMPS DO NOT LIGHT UP .....447

P-13(b) LAMPS LIGHT UP EVEN WHEN LAMP SWITCH IS NOT OPERATED .....447

P-14(a) WIPERS DO NOT WORK .....449

P-14(b) WIPERS WORK EVEN WHEN WIPER SWITCH IS NOT OPERATED .....449

P-15(a) FAN DOES NOT WORK .....451

P-15(b) FAN WORKS EVEN WHEN FAN SWITCH IS NOT OPERATED.....451

P-16 WORKING MODE DOES NOT SWITCH .....453

P-17 POWER SET DOES NOT SWITCH .....454

P-18 AUTO-DECELERATION DOES NOT SWITCH (DOES NOT ENTER AUTO-DECELERATION: AUTO-DECELERATION IS NOT CANCELED) .....455

P-19 TRAVEL SPEED DOES NOT SWITCH BETWEEN HI AND LO .....456

P-20 WARMING-UP OPERATION IS NOT CARRIED OUT BELOW 3OC, OR WARMING-UP OPERATION IS NOT CANCELED EVEN WHEN TEMPERATURE GOES ABOVE 30C .....457

P-21 EVEN WHEN SWING LOCK SWITCH IS TURNED ON (LOCK), SWING LOCK LAMP ON MONITOR PANEL DOES NOT LIGHT UP .....458

P-22 FUEL LEVEL SENSOR SYSTEM DEFECTIVE .....459

P-23 COOLANT TEMPERATURE SENSOR SYSTEM DEFECTIVE .....460

P-24 ENGINE OIL LEVEL SENSOR SYSTEM DEFECTIVE.....461

P-25 COOLANT LEVEL SENSOR SYSTEM DEFECTIVE .....462

P-26 HYDRAULIC OIL LEVEL SENSOR SYSTEM DEFECTIVE .....463

30 DISASSEMBLY AND ASSEMBLY.....464

METHOD OF USING MANUAL .....468

PRECAUTIONS WHEN CARRYING OUT OPERATION .....469

SPECIAL TOOL LIST PC300LC .....471

SPECIAL TOOL LIST PC400LC .....474

WEIGHT TABLE .....477

TIGHTENING TORQUES AND STANDARD VALUES TABLE .....478

LUBRICANT AND COOLANT TABLE .....484

REMOVAL OF GOVERNOR MOTOR ASSEMBLY .....485

REMOVAL OF HYDRAULIC COOLER ASSEMBLY.....487

INSTALLATION OF HYDRAULIC COOLER ASSEMBLY .....487

REMOVAL OF HYDRAULIC COOLER ASSEMBLY.....487

INSTALLATION OF HYDRAULIC COOLER ASSEMBLY .....487

REMOVAL OF RADIATOR, HYDRAULIC OIL COOLER .....489

INSTALLATION OF RADIATOR, HYDRAULIC OIL COOLER ASSEMBLY.....489

REMOVAL OF ENGINE, HYDRAULIC PUMP ASSEMBLY.....491

INSTALLATION OF ENGINE, HYDRAULIC PUMP ASSEMBLY.....491

REMOVAL OF ENGINE, HYDRAULIC PUMP ASSEMBLY .....493

INSTALLATION OF ENGINE, HYDRAULIC PUMP ASSEMBLY .....493

REMOVAL OF DAMPER ASSEMBLY .....495

INSTALLATION OF DAMPER ASSEMBLY .....495

REMOVAL OF CENTER SWIVEL JOINT ASSEMBLY.....497

INSTALLATION OF CENTER ASSEMBLY SWIVEL JOINT.....497

DISASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY.....497

ASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY .....497

REMOVAL OF FINAL DRIVE DRIVE ASSEMBLY .....499

INSTALLATION OF FINAL DRIVE ASSEMBLY.....499

DISASSEMBLY OF FINAL DRIVE ASSEMBLY .....499

ASSEMBLY OF FINAL DRIVE ASSEMBLY .....503

DISASSEMBLY OF TRAVEL MOTOR ASSEMBLY (HMV280ADT) (HMV355ADT) .....507

ASSEMBLY OF TRAVEL MOTOR ASSEMBLY (HMV280ADT) (HMV355ADT) .....512

REMOVAL OF SPROCKET.....521

INSTALLATION OF SPROCKET.....521

REMOVAL OF SWING MOTOR ASSEMBLY .....521

INSTALLATION OF SWING MOTOR ASSEMBLY .....521

DISASSEMBLY OF SWING MOTOR ASSEMBLY (KMF160) .....523

ASSEMBLY OF SWING MOTOR ASSEMBLY (KMFI 60) .....526

REMOVAL OF SWING MACHINERY ASSEMBLY.....531

INSTALLATION OF SWING MACHINERY ASSEMBLY.....531

REMOVAL OF SWING MACHINERY ASSEMBLY.....531

INSTALLATION OF SWING MACHINERY ASSEMBLY .....531

DISASSEMBLY OF SWING MACHINERY ASSEMBLY .....533

ASSEMBLY OF SWING MACHINERY ASSEMBLY .....535

REMOVAL OF REVOLVING FRAME ASSEMBLY .....541

INSTALLATION OF REVOLVING FRAME ASSEMBLY .....541

REMOVAL OF SWING CIRCLE ASSEMBLY .....543

INSTALLATION OF SWING CIRCLE ASSEMBLY.....543

REMOVAL OF IDLER, RECOIL SPRING ASSEMBLY.....543

INSTALLATION OF IDLER, RECOIL SPRING ASSEMBLY .....543

DISASSEMBLY OF RECOIL SPRING ASSEMBLY.....545

ASSEMBLY OF RECOIL SPRING ASSEMBLY.....545

REMOVAL OF TRACK ROLLER ASSEMBLY.....547

INSTALLATION OF TRACK ROLLER ASSEMBLY .....547

REMOVAL OF CARRIER ROLLER ASSEMBLY.....547

INSTALLATION OF CARRIER ROLLER ASSEMBLY.....547

REMOVAL OF TRACK SHOE ASSEMBLY.....549

INSTALLATION OF TRACK SHOE ASSEMBLY.....549

REMOVAL OF CHARGING PUMP ASSEMBLY.....549

INSTALLATION OF CHARGING PUMP ASSEMBLY .....549

REMOVAL OF HYDRAULIC PUMP ASSEMBLY .....551

INSTALLATION OF HYDRAULIC PUMP ASSEMBLY.....551

REMOVAL OF HYDRAULIC PUMP ASSEMBLY.....551

DISASSEMBLY OF HYDRAULIC PUMP ASSEMBLY (HPV160+160) .....553

ASSEMBLY OF HYDRAULIC PUMP ASSEMBLY (HPV160+160) .....560

CHECKING CONTACT BETWEEN CYLINDER BLOCKAND VALVE PLATE, AND ROCKER CAM AND CRADLE.....574

REMOVAL OF HYDRAULIC PUMP INPUT SHAFT OIL SEAL .....577

INSTALLATION OF HYDRAULIC PUMP INPUT SHAFT OIL SEAL .....577

REMOVAL OF CONTROL VALVE ASSEMBLY.....579

INSTALLATION OF CONTROL VALVE ASSEMBLY.....579

DISASSEMBLY OF CONTROL VALVE ASSEMBLY .....581

ASSEMBLY OF CONTROL VALVE ASSEMBLY .....583

REMOVAL OF MAIN RELIEF VALVE ASSEMBLY .....585

INSTALLATION OF MAIN RELIEF VALVE ASSEMBLY.....585

DISASSEMBLY OF MAIN RELIEF VALVE ASSEMBLY.....585

ASSEMBLY OF MAIN RELIEF VALVE ASSEMBLY .....585

REMOVAL OF TVC VALVE ASSEMBLY.....587

INSTALLATION OF TVC VALVE ASSEMBLY .....587

REMOVAL OF CONC VALVE ASSEMBLY .....587

INSTALLATION OF CONC VALVE ASSEMBLY .....587

REMOVAL OF SERVO VALVE ASSEMBLY.....587

INSTALLATION OF SERVO VALVE ASSEMBLY.....587

REMOVAL OF WORK EQUIPMENT PPC VALVE ASSEMBLY .....589

INSTALLATION OF WORK EQUIPMENT PPC VALVE ASSEMBLY .....589

DISASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY .....589

ASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY .....589

REMOVAL OF TRAVEL PPC VALVE ASSEMBLY.....591

INSTALLATION OF TRAVEL PPC VALVE ASSEMBLY.....591

DISASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY.....591

ASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY .....591

REMOVAL OF BOOM HOLDING VALVE ASSEMBLY.....593

INSTALLATION OF BOOM HOLDING VALVE ASSEMBLY.....593

DISASSEMBLY OF BOOM HOLDING VALVE ASSEMBLY.....593

ASSEMBLY OF BOOM HOLDING VALVE ASSEMBLY.....593

REMOVAL OF PPC SHUTTLE VALVE ASSEMBLY.....595

INSTALLATION OF PPC SHUTTLE VALVE ASSEMBLY.....595

REMOVAL OF BOOM CYLINDER ASSEMBLY .....597

INSTALLATION OF BOOM CYLINDER ASSEMBLY.....597

REMOVAL OF ARM CYLINDER ASSEMBLY.....599

INSTALLATION OF ARM CYLINDER ASSEMBLY.....599

REMOVAL OF BUCKET CYLINDER ASSEMBLY.....601

INSTALLATION OF BUCKET CYLINDER ASSEMBLY.....601

DISASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY.....603

ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY .....605

REMOVAL OF WORK EQUIPMENT ASSEMBLY.....607

INSTALLATION OF WORK EQUIPMENT ASSEMBLY.....607

REMOVAL OF BUCKET ASSEMBLY .....609

INSTALLATION OF BUCKET ASSEMBLY.....609

REMOVAL OF ARM ASSEMBLY.....609

INSTALLATION OF ARM ASSEMBLY .....609

REMOVAL OF ARM, BUCKET ASSEMBLY.....611

INSTALLATION OF ARM, BUCKET ASSEMBLY.....611

REMOVAL OF BOOM ASSEMBLY.....613

INSTALLATION OF BOOM ASSEMBLY.....613

REMOVAL OF OPERATORS CAB ASSEMBLY.....615

INSTALLATION OF OPERATORS CAB ASSEMBLY .....615

REMOVAL OF COUNTERWEIGHT .....615

INSTALLATION OF COUNTERWEIGHT .....615

REMOVAL OF ENGINE THROTTLE CONTROLLER.....617

INSTALLATION OF ENGINE THROTTLE CONTROLLER .....617

REMOVAL OF PUMP CONTROLLER ASSEMBLY .....617

INSTALLATION OF PUMP CONTROLLER ASSEMBLY .....617

REMOVAL OF MONITOR PANEL ASSEMBLY.....617

INSTALLATION OF MONITOR PANEL ASSEMBLY .....617

PROCEDURE FOR FLUSHING HYDRAULIC CIRCUIT .....619

PROCEDURE FOR FLUSHING HYDRAULIC CIRCUIT.....627

40 MAINTENANCE STANDARD.....636

FINAL DRIVE PC300LC.....639

FINAL DRIVE PC400LC.....641

SWING MACHINERY PC300LC.....643

SWING MACHINERY PC400LC.....645

SWING CIRCLE PC300LC.....647

SWING CIRCLE PC400LC.....648

TRACK FRAME AND RECOIL SPRING PC300LC.....649

TRACK FRAME AND RECOIL SPRING PC400LC.....650

IDLER PC300LC.....651

IDLER PC400LC.....653

TRACK ROLLER PC300LC.....655

TRACK ROLLER PC400LC.....656

CARRIER ROLLER .....657

TRACK SHOE PC300LC.....659

TRACK SHOE PC400LC.....661

CHARGING PUMP AND RELIEF VALVE .....663

CONTROL VALVE .....664

TRAVEL SHUTTLE VALVE .....671

SWING MOTOR .....672

TRAVEL MOTOR PC300LC.....673

TRAVEL MOTOR PC400LC.....674

PPC VALVE, FOR WORK EQUIPMENT AND SWING.....675

PPC VALVE, FOR TRAVEL.....676

PPC SHUTTLE VALVE .....677

BOOM HOLDING VALVE .....678

HYDRAULIC CYLINDER PC300LC.....679

HYDRAULIC CYLINDER PC400LC.....680

WORK EQUIPMENT PC300LC.....681

WORK EQUIPMENT PC400LC.....683

CEBM207077 - Hydraulic Excavator PC300-5 (Mighty), PC300LC-5(K) (Mighty), PC300HD-5, PC300LC-5 & PC400-5 (Mighty), PC400LC-5 (Mighty), PC400HD-5 Shop Manual.....685

SAFETY.....687

FOREWORD.....689

HOW TO READ THE SHOP MANUAL.....690

HOISTING INSTRUCTIONS.....691

STANDARD TIGHTENING TORQUE.....692

COATING MATERIALS.....693

ELECTRIC WIRE CODE.....694

CONVERSION TABLE.....695

WEIGHT TABLE.....702

LIST OF LUBRICANT AND WATER.....716

10 STRUCTURE AND FUNCTION.....719

POWER TRAIN.....720

FINAL DRIVE.....722

SWING CIRCLE.....724

SWING MACHINERY.....726

TRACK FRAME AND RECOIL SPRING.....728

IDLER.....734

TRACK ROLLER.....736

CARRIER ROLLER.....736

TRACK SHOE.....737

HYDRAULIC PIPING.....741

HYDRAULIC CIRCUIT DIAGRAM.....742

HYDRAULIC TANK.....747

OLSS (Open center Load Sensing System).....749

HYDRAULIC PUMP.....751

LINE OIL FILTER.....770

CONTROL VALVE.....772

SWING MOTOR.....790

CENTER SWIVEL JOINT.....793

TRAVEL MOTOR.....794

VALVE CONTROL.....803

PPC VALVE.....806

ACCUMULATOR.....812

SAFETY LOCK VALVE.....812

SOLENOID VALVE ASSEMBLY.....813

SHUTTLE VALVE.....817

BOOM HOLDING VALVE.....818

HYDRAULIC CYLINDER.....821

WORK EQUIPMENT.....824

ELECTRICAL WIRING DIAGRAM.....830

ELECTRICAL CIRCUIT DIAGRAM.....834

ENGINE CONTROL SYSTEM.....844

PEMC SYSTEM.....857

EMACC (ELECTRONIC MONITOR AND CONTROL CONSOLE).....886

20 TESTING AND ADJUSTING.....895

TABLE OF JUDGEMENT STANDARD VALUE.....896

STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM.....925

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING.....937

ADJUSTING VALVE CLEARANCE.....938

MEASURING COMPRESSION PRESSURE.....940

TESTING AND ADJUSTING FUEL INJECTION TIMING.....941

TESTING AND ADJUSTING TRAVEL OF GOVERNOR MOTOR LEVER.....943

ADJUSTING ENGINE SPEED SENSOR.....944

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT.....947

TESTING AND ADJUSTING CHARGING PUMP PRESSURE.....950

TESTING AND ADJUSTING MAIN PUMP CONTROL PRESSURE.....952

TESTING AND ADJUSTING TRAVEL DEVIATION.....960

MEASURING STROKE OF SERVO PISTON.....962

MEASURING OUTPUT PRESSURE OF PPC VALVE.....963

ADJUSTING WORK EQUIPMENT, SWING PPC VALVE.....964

TESTING PPC SHUTTLE VALVE.....965

MEASURING SOLENOID VALVE OUTLET PORT PRESSURE.....966

TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT.....967

BLEEDING AIR.....969

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT.....971

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT.....971

TROUBLESHOOTING.....973

POINTS TO REMEMBER WHEN TROUBLESHOOTING.....974

SEQUENCE OF EVENTS IN TROUBLESHOOTING.....975

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE.....976

CHECKS BEFORE TROUBLESHOOTING.....985

ELECTRICAL CIRCUIT DIAGRAM.....986

POSITION OF CONNECTORS FOR TROUBLESHOOTING.....990

CONNECTION TABLE FOR CONNECTOR.....994

EXPLANATION OF FUNCTIONS OF CONTROL MECHANISM OF ELECTRICAL SYSTEM.....1002

DISPLAY METHOD FOR MONITOR PANEL, PUMP CONTROLLER AND ENGINE THROTTLE CONTROLLER.....1005

ACTION OF SELF-DIAGNOSTIC FUNCTION AND SYMPTOMS ON MACHINE.....1009

METHOD OF USING JUDGEMENT TABLE.....1012

METHOD OF USING TROUBLESHOOTING CHARTS.....1014

TROUBLESHOOTING OF ENGINE THROTTLE CONTROLLER SYSTEM (E MODE).....1017

ENGINE THROTTLE CONTROLLER OR IN ENGINE RELATED PARTS.....1018

POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING ON ENGINE THROTTLE CONTROLLER SYSTEM.....1019

E-1 [Abnormality in power source system or controller] is displayed (All lamps OFF).....1020

E-2 [Short circuit in governor motor] is displayed.....1024

E-3 [Abnormality in battery relay] is displayed.....1025

E-4 [Disconnection in wiring harness of governor motor] is displayed.....1026

E-5 [Abnormality in governor potentiometer] is displayed.....1028

E-6 [Abnormality in fuel control dial] is displayed.....1030

E-7 [Abnormality in No. 2 throttle signal] is displayed.....1032

E-8 Engine does not start.....1034

E-9 Engine rotation is irregular.....1036

a) Idling rotation is irregular.....1036

b) There is hunting.....1038

E-10 Lack of output power (max. engine speed is too low).....1040

E-11 Engine does not stop.....1042

E-12 Automatic warming-up operation is defective.....1044

TROUBLESHOOTING OF PUMP CONTROLLER SYSTEM (C MODE).....1045

CHART FOR DISTINGUISHING IF FAILURE IS IN PUMP CONTROLLER OR IN HYDRAULIC RELATED PARTS.....1047

C-1[OFF] Self-diagnostic display of controller does not light up.....1048

C-2 [Short circuit in 2-stage relief solenoid valve system] is displayed.....1049

C-3 [Short circuit in arm half flow solenoid valve system] is displayed.....1050

C-4 [Short circuit in swing brake solenoid valve system] is displayed.....1051

C-5 [Short circuit in travel speed solenoid valve system] is displayed.....1052

C-6 [ Short circuit in CO cancel solenoid valve system] is displayed.....1053

C-7 [Short circuit in TVC solenoid sysem (1)] is displayed.....1054

C-8 [Short circuit in TVC solenoid valve system (2)] is displayed.....1055

C-9 [ Disconnection in 2-stage relief solenoid valve system] is displayed.....1056

C-10 [Disconnection in arm half flow solenoid valve system] is displayed.....1057

C-11 [Disconnection in swing brake solenoid valve system].....1058

C-12 [Disconnection in travel speed solenoid valve system] is displayed.....1059

C-13 [Disconnection in CO cancel solenoid valve system] is displayed.....1060

C-14 [Disconnection in TVC solenoid valve system] is displayed.....1061

C-15 [Abnormality in No. 2 throttle signal system] is displayed.....1062

C-16 [Abnormality in throttle signal system] is displayed.....1063

C-17 [ Abnormality in front pump pressure sensor signal system] is displayed.....1064

C-18 [Abnormality in rear pump pressure sensor signal system] is displayed.....1066

C-19 [Abnormality in pressure sensor power source system] is displayed.....1068

C-20 [Abnormality in engine speed sensor system] is displayed.....1070

C-21 Abnormality in auto-deceleration signal output system] is displayed.....1071

C-22 [Abnormality in overheat signal system] is displayed.....1072

C-23 [Controller abnormal system] is displayed.....1073

TROUBLESHOOTING OF PUMP CONTROLLER INPUT SIGNAL SYSTEM (F MODE).....1075

F-1 Pump controller monitor does not display [Work equipment - Swing oil pressure switch].....1076

F-2 Pump controller monitor does not display [Travel oil pressure switch].....1077

F-3 Pump Controller monitor does not display [Swing lock switch].....1078

F-4 Pump controller monitor does not display [Travel speed switch].....1079

F-5 Pump controller monitor does not display [Auto-deceleration switch].....1080

F-6 Pump controller monitor does not display [Power maximizing switch].....1081

F-7 Pump controller monitor does not display [decimal point of [Engine speed sensor].....1082

F-8 Pump controller working mode display does not switch.....1083

F-9 Pump controller power set display does not switch.....1084

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE).....1085

H-1 Speeds of work equipment, travel, swing are all slow.....1086

H-2 There is excessive drop in engine speed, or engine stalls.....1088

H-3 Work equipment, travel, swing do not move, or speed is extremely slow.....1090

H-4 Work equipment, travel, swing lack power.....1092

H-5 Power set selection system does not switch.....1092

H-6 Abnormal noise generated (from around pump).....1093

H-7 Auto-deceleration does not work.....1093

H-8 Boom, arm speed is extremely slow.....1094

H-9 Work equipment (boom, arm, bucket) speed is slow.....1096

H-10 When boom and arm are operated simultaneously, boom is slow.....1098

H-11 Work equipment (boom, arm, bucket) lacks power.....1098

H-12 Excessive hydraulic drift.....1098

H-13 Excessive time lag.....1100

H-14 Does not enter F.0 mode (Half flow functiuon).....1100

H-15 When arm and swing are operated simultaneously, arm is slow.....1100

H-16 When machine is traveling, it deviates naturally to one side.....1102

a) Deviates in same direction both in forward and reverse.....1102

b) Deviates in different direction in forward and reverse (See Fig. I).....1104

H-17 Excessive deviation during compound operations.....1105

H-18 Excessive deviation when starting.....1106

H-19 Travel lacks power (or speed is slow).....1108

H-20 Travel speed does not switch.....1108

H-21 Machine does not move (one side only).....1109

H-22 Does not swing.....1110

H-23 Swing speed is slow or acceleration is poor.....1112

H-24 Excessive overrun when stopping swing.....1113

H-25 Excessive shock when stopping swing.....1113

H-26 Excessive abnormal noise when stopping swing.....1114

H-27 Excessive hydraulic drift of swing.....1114

H-28 When operated simultaneously with arm, swing speed is slow.....1114

TABLE OF FAILURE MODES AND CAUSES.....1115

TROUBLESHOOTING OF MONITOR SYSTEM (P MODE).....1117

P-1 Monitor panel lamps do not light up for 3 seconds when starting switch is turned ON.....1118

a) No monitor panel lamps light up.....1118

b) Some monitor panel lamps do not light up.....1118

P-2 Monitor panel lamps all light up when starting switch is turned ON, but do not go out.....1119

P-3 When starting switch is turned ON (engine stopped), CHECK items flash (Levels for CHECK items are as specified).....1120

a) (Coolant level) flashes.....1120

b) Engine oil level) flashes.....1121

c) (Hydraulic oil level) flashes.....1122

P-4 Preheating is not being used, but preheating display lights up.....1123

P-5 When starting switch is turned ON and engine is started, CHECK items flash.....1125

a) Alternator system.....1125

b) Engine oil pressure system.....1125

P-6 When starting switch is turned ON (engine stopped), CAUTION items flash.....1126

P-7 When starting switch is turned ON and engine is started, CAUTION items flash (When there is no abnormality in CHECK items).....1127

a) (Engine oil pressure) flashes.....1127

b) (Coolant level) flashes.....1127

c) (Coolant temperature) flashes.....1128

d) (Charge) flashes.....1128

e) (Fuel level) flashes.....1129

P-8 (a) When starting switch is turned ON (engine buzzer does not sound for 1 second CAUTION item is flashing but no buzzer soun.....1130

P-8 (b) There is no abnormality display on the monitor, but the buzzer sounds.....1130

P-9 Panel lighting of monitor panel does not light up (liquid crystal display is normal).....1131

P-10 Coolant temperature shows abnormally low temperature.....1132

P-11 Coolant temperature gauge gives no display (during operation, no level of gauge is displayed).....1132

P-12 Fuel gauge always displays FULL.....1133

P-13 Fuel gauge gives no display.....1133

P-14 (a) Lamps do not light up.....1134

P-14 (b) Lamps light up even when lamp switch is not operated.....1134

P-15 (a) Wipers do not work.....1136

P-15 (b) Wipers work even when wiper switch is not operated.....1136

P-16 (a) Fan does not work.....1138

P-16 (b) Fan works even when fan switch is not operated.....1138

P-17 Working mode does not switch.....1140

P-18 Power set does not switch.....1141

P-19 Auto-deceleration does not switch (Does not enter auto-deceleration; auto-deceleration is not canceled).....1142

P-20 Travel speed does not switch between Hi and Lo.....1143

P-21 Warming-up operation is not carried out below 30C, or warming-up operation is not canceled even when temperature goes abov.....1144

P-22 Even when swing lock switch is turned ON (LOCK), swing lock lamp on monitor panel does not light up.....1145

30 DISASSEMBLY AND ASSEMBLY.....1151

METHOD OF USING MANUAL.....1153

PRECAUTIONS WHEN CARRYING OUT OPERATION.....1154

SPECIAL TOOL LIST.....1156

WEIGHT TABLE.....1163

TIGHTENING TORQUES AND STANDARD VALUES TABLE.....1168

STARTING MOTOR ASSEMBLY.....1174

ALTERNATOR ASSEMBLY.....1174

ENGINE OIL COOLER ASSEMBLY.....1176

FUEL INJECTION PUMP ASSEMBLY.....1178

WATER PUMP ASSEMBLY.....1180

NOZZLE HOLDER ASSEMBLY.....1182

TURBOCHARGER ASSEMBLY.....1184

THERMOSTAT ASSEMBLY.....1184

ENGINE FRONT OIL SEAL.....1186

ENGINE REAR OIL SEAL .....1188

GOVERNOR MOTOR ASSEMBLY .....1190

CYLINDER HEAD ASSEMBLY .....1192

AFTERCOOLER CORE ASSEMBLY .....1196

HYDRAULIC COOLER ASSEMBLY.....1198

RADIATOR, HYDRAULIC OIL COOLER ASSEMBLY.....1200

ENGINE, HYDRAULIC PUMP ASSEMBLY .....1202

DAMPER ASSEMBLY .....1206

CENTER SWIVEL JOINT ASSEMBLY.....1208

FINAL DRIVE ASSEMBLY.....1210

INSTALLATION OF FINAL DRIVE ASSEMBLY .....1210

ASSEMBLY OF FINAL DRIVE ASSEMBLY .....1214

TRAVEL MOTOR ASSEMBLY .....1220

SPROCKET ASSEMBLY .....1234

SWING MOTOR ASSEMBLY .....1234

SWING MACHINERY ASSEMBLY .....1244

REVOLVING FRAME ASSEMBLY .....1254

SWING CIRCLE ASSEMBLY.....1256

IDLER, RECOIL SPRING ASSEMBLY.....1256

CARRIER ROLLER ASSEMBLY .....1260

TRACK ROLLER ASSEMBLY.....1260

CHARGING PUMP ASSEMBLY.....1262

TRACK SHOE ASSEMBLY .....1262

HYDRAULIC PUMP ASSEMBLY.....1264

HYDRAULIC PUMP INPUT SHAFT OIL SEAL .....1290

CONTROL VALVE ASSEMBLY .....1292

MAIN RELIEF VALVE ASSEMBLY .....1298

TVC VALVE ASSEMBLY .....1300

SERVO ASSEMBLY.....1300

CO-NC VALVE ASSEMBLY.....1300

WORK EQUIPMENT PPC VALVE ASSEMBLY .....1302

TRAVEL PPC VALVE ASSEMBLY .....1304

BOOM HOLDING VALVE ASSEMBLY.....1306

PPC SHUTTLE VALVE ASSEMBLY.....1308

BOOM CYLINDER ASSEMBLY .....1310

ARM CYLINDER ASSEMBLY .....1314

BUCKET CYLINDER ASSEMBLY .....1318

BOTTOM DUMP CYLINDER ASSEMBLY.....1322

HYDRAULIC CYLINDER ASSEMBLY .....1324

WORK EQUIPMENT ASSEMBLY.....1330

BUCKET ASSEMBLY .....1332

ARM ASSEMBLY.....1336

ARM, BUCKET ASSEMBLY . .....1340

BOOM ASSEMBLY .....1342

OPERATORS CAB ASSEMBLY.....1346

COUNTERWEIGHT .....1346

THROTTLE CONTROLLER .....1348

PUMP CONTROLLER ASSEMBLY.....1348

MONITOR PANEL ASSEMBLY .....1348

PROCEDURE FOR FLUSHING HYDRAULIC CIRCUIT .....1358

40 MAINTENANCE STANDARD.....1367

FINAL DRIVE.....1368

SWING MACHINERY .....1372

SWING CIRCLE .....1376

TRACK FRAME AND RECOIL SPRING .....1378

IDLER .....1382

TRACK ROLLER .....1386

CARRIER ROLLER .....1388

TRACK SHOE .....1390

CHARGING PUMP AND RELIEF VALVE .....1396

CONTROL VALVE .....1397

TRAVEL SHUTTLE VALVE .....1412

SWING MOTOR .....1413

TRAVEL MOTOR .....1414

PPC VALVE .....1416

PPC SHUTTLE VALVE .....1418

BOOM HOLDING VALVE .....1419

HYDRAULIC CYLINDER .....1420

WORK EQUIPMENT.....1424

SEBM02070308 - Hydraulic Excavator PC300-3, PC300LC-3, PC360LC-3 Shop Manual.....1433