Komatsu Hydraulic Excavators PC300LC-7L, PC300HD-7L, PC300LL-7L Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC300LC-7L, PC300HD-7L, PC300LL-7L, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC300LC-7L, PC300HD-7L, PC300LL-7L workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

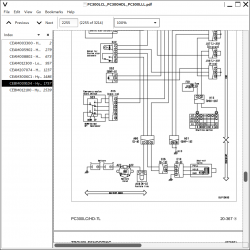

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 3,211 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEBM009104 - Hydraulic Excavator PC300LC-7L, PC300HD-7L Shop Manual.pdf

CEBM012100 - Hydraulic Excavator GALEO PC300LL-7L Shop Manual.pdf

CEAM3006C1 - Hydraulic Excavator PC300LC-6, PC300HD-6 Operation & Maintenance Manual.pdf

CEAM003300 - Hydraulic Excavator PC300LC-6, PC300HD-6 Operation & Maintenance Manual.pdf

CEAM005902 - Hydraulic Excavator PC300LC-6, PC300HD-6 Operation & Maintenance Manual.pdf

CEAM008802 - Hydraulic Excavator GALEO PC300LC-7L, PC300HD-7L Operation & Maintenance Manual.pdf

CEAM012300 - Logging Excavator GALEO PC300LL-7L Operation & Maintenance Manual.pdf

CEAM207074 - Hydraulic Excavator PC300-5 (Mighty), PC300LC-5 (Mighty), PC300LC-5K, PC300HD-5 Operation & Maintenance Manual.pdf

MAIN SECTIONS

MAIN MENU...0

COVER...1

CONTENTS...2

SAFETY...5

SAFETY NOTICE...5

FOREWARD...7

GENERAL...7

HOW TO READ THE SHOP MANUAL...8

HOISTING INSTRUCTIONS...9

COATING MATERIALS...10

STANDARD TIGHTENING TORQUE...12

ELECTRIC WIRE CODE...17

CONVERSION TABLES...18

UNITS...23

01 GENERAL...25

DIMENSION DRAWINGS...26

DIMENSIONS...26

WORKING RANGES...28

SPECIFICATIONS...30

WEIGHT TABLE...33

POWERED CAB RISER TILT UNIT TARGETS...35

FUEL COOLANT AND LUBRICANTS...36

PC300LL-7L...36

10 STRUCTURE AND FUNCTION...37

ENGINE RELATED PARTS...39

RADIATOR . OIL COOLER . AFTERCOOLER...40

FINAL DRIVE SYSTEM...42

PC300LL-7L...42

SWING MACHINERY...45

SWING CIRCLE...48

TRACK FRAME . RECOIL SPRING...50

PC300LL-7L...50

IDLER...51

TRACK ROLLER...53

TRACK SHOE...54

TRIPLE GROUSER SHOE...56

HYDRAULIC EQUIPMENT...57

HYDRAULIC TANK...59

HYDRAULIC PUMP...60

HPV125 + 125...60

LS VALVE...65

PC VALVE...65

LS(PC)-EPC VALVE...77

VARIABLE VOLUME VALVE...80

CONTROL VALVE...82

MAIN RELIEF VALVE...93

VARIABLE PRESSURE COMPENSATION VALVE...94

CLSS...95

SELF PRESSURE REDUCING VALVE...98

SWING MOTOR...101

SUCTION-SAFETY VALVE...104

SWING BRAKE...105

CENTER SWIVEL JOINT...106

PC300LL-7L...107

MOTOR OPERATION...109

PARKING BRAKE OPERATION...111

BRAKE VALVE OPERATION...112

TRAVEL JUNCTION VALVE...116

TRAVEL PPC SHUTTLE VALVE...118

VALVE CONTROL...122

WORK EQUIPMENT . SWING PPC VALVE...123

TRAVEL PPC VALVE...127

ATTACHMENT SOLENOID VALVE...136

PPC ACCUMULATOR...138

BOOM HYDRAULIC DRIFT PREVENTION VALVE...139

QUICK RETURN VALVE...145

LIFT CHECK VALVE...147

HYDRAULIC CYLINDER...148

BOOM CYLINDER...148

ARM CYLINDER...148

BUCKET CYLINDER...149

WORK EQUIPMENT...150

DIMENSION OF ARM...152

DIMENSION OF BUCKET...154

AIR CONDITIONER...156

PIPING...156

ENGINE CONTROL...157

FUEL CONTROL DIAL...159

GOVERNOR MOTOR...160

ENGINE THROTTLE AND PUMP CONTROLLER...161

INPUT AND OUTPUT SIGNALS...162

ELECTRONIC CONTROL SYSTEM...163

TOTAL SYSTEM DIAGRAM...164

MULTI MONITOR SYSTEM...187

MONITOR PANEL...188

MONITOR CONTROL, DISPLAY PORTION /MONITOR PORTION...190

MAINTENANCE FUNCTION...201

SENSORS...206

ENGINE OIL LEVEL SENSOR...206

ENGINE OIL PRESSURE SENSOR (FOR LOW PRESSURE)...206

COOLANT TEMPERATURE SENSOR...207

HYDRAULIC OIL TEMPERATURE SENSOR...207

FUEL LEVEL SENSOR...208

AIR CLEANER CLOGGING SENSOR...208

CAB RISER AND RELATED PARTS...209

POWER CONTROL...210

STRESS TARGETS FOR CAB RISER KIT...211

CAB RISER HYDRAULIC SYSTEM...212

20 TESTING, ADJUSTING AND TROUBLESHOOTING...213

STANDARD VALUE TABLES...215

ENGINE RELATED...215

CHASSIS RELATED...216

SERVICE TOOLS...224

ENGINE...224

AIR BOOST PRESSURE...224

AIR COMPRESSOR BELT TENSION...224

BLOW-BY PRESSURE...224

COMPRESSION PRESSURE...224

ENGINE OIL PRESSURE...224

ENGINE RPM...224

ENGINE SPEED SENSOR...225

EXHAUST GAS COLOR...225

FUEL INJECTION TIMING...225

VALVE CLEARANCE...225

EMERGENCY ESCAPE FROM ENGINE CONTROL FAILURE...226

SWING CIRCLE BEARINGS...226

TRACK SHOE TENSION...227

SPROCKET...228

OIL PRESSURE...228

WORK EQUIPMENT, SWING AND TRAVEL...228

CONTROL CIRCUIT...233

PUMP PC CONTROL CIRCUIT...234

PUMP LS CONTROL CIRCUIT...237

ATTACHMENT SOLENOID VALVE OUTPUT...241

ATTACHMENT PPC VALVE OUTPUT...244

WORK EQUIPMENT AND SWING PPC VALVE...245

WORK EQUIPMENT, HYDRAULIC DRIFT LOCATIONS...245

RELEASE OF REMAINING PRESSURE IN HYDRAULIC CIRCUIT...246

BOOM AND BUCKET CYLINDERS...246

BOOM LOCK VALVE...246

ARM CYLINDER...247

PPC VALVE...247

OIL LEAKAGE AMOUNT...249

BOOM CYLINDER...249

ARM CYLINDER...249

BUCKET CYLINDER...250

SWING MOTOR...250

TRAVEL MOTOR...250

AIR BLEEDING OF VARIOUS PARTS...251

DIODE INSPECTION PROCEDURES...253

MULTI-MONITOR PANEL...254

MONITOR PANEL FUNCTIONS...255

OPERATOR?S MENU AND DISPLAY (OUTLINE)...256

TABLE FOR SERVICE AND FAILURE CODE NOS...261

SERVICE MENU...263

WAY OF SWITCHING TO SERVICE MENU...263

TABLE FOR MONITORING ITEMS...266

ELECTRICAL SYSTEM TROUBLESHOOTING PREPARTIONS...278

PM TUNE SERVICE...279

TROUBLESHOOTING (GENERAL)...283

POINTS TO REMEMBER WHEN TROUBLESHOOTING...284

SEQUENCE OF EVENTS IN TROUBLESHOOTING...286

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE...287

PRECAUTIONS WHEN HANDLING ELECTRIC EQUIPMENT...287

HANDLING CONTROL BOX...292

POINTS TO REMEMBER WHEN TROUBLESHOOTING ELECTRIC CIRCUITS...293

POINTS TO REMEMBER WHEN HANDLING HYDRAULIC EQUIPMENT...294

CHECKS BEFORE TROUBLESHOOTING...296

CATEGORIES, PROCEDURE, AND METHOD OF USING TROUBLESHOOTING CHARTS...297

PHENOMENA CONSIDERED TO BE FAILURES AND TROUBLESHOOTING NO...298

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...301

T-ADAPTER TABLE...325

TROUBLESHOOTING ELECTRICAL SYSTEM (E MODE)...329

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM...331

ABNORMALITY RETURNS TO NORMAL BY ITSELF...331

USER CODE MEMORY RETENTION FUNCTION...331

INFORMATION CONTAINED IN TESTING PROCEDURES...332

(E101)...334

ABNORMAL DATA IN ERROR HISTORY...334

(E112)...336

SHORT IN WINDSHIELD WIPER MOTOR DRIVE FORWARD ROTATION...336

(E113)...338

SHORT IN WINDSHIELD WIPER MOTOR DRIVE REVERSE ROTATION...338

(E114)...340

SHORT OR OPEN IN WINDOW WASHER SYSTEM...340

(E115)...342

ABNORMAL WINDSHIELD WIPER MOTION...342

(E116)...344

ABNORMALITY IN PARKING WIPER ARM...344

(E201)...346

SHORT OR OPEN IN TRAVEL INTERLOCKING SOLENOID...346

(E203)...348

SHORT IN SWING AND PARKING SOLENOID GOVERNOR SYSTEM...348

(E204)...350

SHORT IN MERGE/DIVIDE SOLENOID...350

(E205)...352

SHORT IN 2 STAGE RELIEF SOLENOID...352

(E206)...354

SHORT IN TRAVEL SPEED SHIFT SOLENOID...354

(E211)...356

OPEN IN TRAVEL INTERLOCKING SOLENOID...356

(E213)...358

OPEN IN SWING PARKING BRAKE SOLENOID...358

(E214)...360

OPEN OF MERGE/DIVIDE SOLENOID...360

(E215)...362

OPEN IN 2 STAGE RELIEF SOLENOID...362

(E216)...364

OPEN IN TRAVEL SPEED SOLENOID...364

(E217)...366

ABNORMAL INPUT FOR MODEL CODE...366

(E218)...368

OPEN IN S-NET SIGNAL...368

(E222)...370

SHORT IN LS-EPC SOLENOID...370

(E223)...372

OPEN IN LS-EPC SOLENOID SYSTEM...372

(E224)...374

ABNORMAL F-PUMP PRESSURE SENSOR SIGNAL...374

(E225)...376

ABNORMAL R-PUMP PRESSURE SENSOR SIGNAL...376

(E226)...378

ABNORMAL PRESSURE SENSOR POWER SUPPLY...378

(E227)...380

ABNORMAL ENGINE RPM SIGNAL IN GOVERNOR PUMP CONTROLLER...380

(E228)...382

SHORT IN ATTACHMENT RETURN SWITCHING RELAY...382

(NO CODE)...384

SHORT OR OPEN IN ATTACHMENT SOLENOID SYSTEM...384

(NO CODE)...387

OPEN IN CAB TILT SYSTEM...387

(E232)...389

SHORT IN PC-EPC SOLENOID...389

(E233)...391

OPEN IN PC-EPC SOLENOID SYSTEM...391

(E238)...393

OPEN IN ATTACHMENT RETURN SWITCH RELAY...393

(E245)...395

SHORT IN ATTACHMENT OIL FLOW RATE EPC SYSTEM...395

(E246)...397

OPEN IN ATTACHMENT OIL FLOW RATE EPC SYSTEM...397

(E256)...399

INCORRECT NON-VOLATILE MEMORY DATA...399

(E304)...401

SHORT IN ENGINE STOP SOLENOID SYSTEM...401

(E314)...403

OPEN IN ENGINE STOP SOLENOID SYSTEM...403

(E306)...405

ABNORMAL GOVERNOR POTENTIOMETER SIGNALS...405

(E308)...407

ABNORMAL FUEL DIAL SIGNALS...407

(E315)...409

SHORT IN BATTERY RELAY SYSTEM...409

(E316)...411

STEP OUT IN GOVERNOR MOTOR...411

(E317)...413

OPEN IN GOVERNOR MOTOR PHASE ?A? AND ?B?...413

(E318)...415

SHORT IN GOVERNOR MOTOR PHASE ?A? AND ?B?...415

(E501)...417

MODEL SELECTION FUNCTION NOT PROVIDED...417

(E502)...418

MODEL SELECTING SIGNAL FAULT...418

(AA10NX)...419

AIR CLEANER CLOG INDICATOR FAILURE...419

(AB00KE)...420

LOW CHARGING VOLTAGE INDICATED...420

(B@BAZG)...422

ABNORMAL ENGINE OIL PRESSURE...422

(B@BAZK)...423

ABNORMAL ENGINE OIL LEVEL...423

(B@BCNS)...424

ENGINE COOLANT INDICATING OVERHEAT CONDITION...424

(B@BCZK)...425

ABNORMAL COOLANT LEVEL INDICATION...425

(B@HANS)...426

HYDRAULIC OIL OVERHEAT INDICATION...426

TROUBLESHOOTING MONITOR ELECTRICAL SYSTEM (E MODE)...427

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM...428

POINTS TO REMEMBER IF ABNORMALITY RETURNS TO NORMAL BY ITSELF...428

USER CODE MEMORY RETENTION FUNCTION...428

INFORMATION CONTAINED IN TESTING PROCEDURES...429

(E-1)...431

ENGINE WILL NOT CRANK...431

(E-2)...433

ENGINE STOPS WHILE IN OPERATION...433

(E-3)...435

ENGINE SPEED IRREGULAR, OR HUNTING...435

(E-4)...437

ENGINE DOES NOT SHUT DOWN...437

(E-5)...439

AUTO DECELERATOR DOES NOT WORK...439

(E-6)...440

AUTO ENGINE WARM UP DEVICE DOES NOT WORK...440

(E-7)...441