Komatsu PC300LC, PC300HD Hydraulic Excavators & Logging Excavator PC300LL Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu PC300LC-6, PC300HD-6 Hydraulic Excavator, Logging Excavator PC300LL-6 avance, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu PC300LC-6, PC300HD-6 Hydraulic Excavator, Logging Excavator PC300LL-6 avance workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 3,445 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEBM002901 - Hydraulic Excavator PC300LC-6, PC300HD-6 Shop Manual.pdf

CEBM3006C2 - Hydraulic Excavator PC300LC-6, PC300HD-6 Shop Manual.pdf

CEBM009500 - Logging Excavator PC300LL-6 avance Shop Manual.pdf

CEBM018703 - Hydraulic Excavator PC300LC-8, PC300HD-8 Shop Manual.pdf

CEAM008500 - Logging Excavator PC300LL-6 avance Operation & Maintenance Manual.pdf

CEAM207040 - Hydraulic Excavator PC300LC-5 with KDC 614TA Engine Operation & Maintenance Manual.pdf

SEAM02070501 - Hydraulic Excavator PC300-5, PC300LC-5 Operation & Maintenance Manual.pdf

MAIN SECTIONS

CEBM018703 - PC300LC/HD-8...1

CONTENTS...2

REVISED PAGES...3

SAFETY...13

Safety Notice...13

IMPORTANT SAFETY NOTICE...13

General Precautions...13

Preparations For Work...13

Precautions During Work...13

GENERAL...15

HOW TO READ THE SHOP MANUAL...16

Volumes...16

Distribution and Updating...16

Filing Method...16

Revised Edition Mark...16

Revisions...16

Symbols...16

HOISTING INSTRUCTIONS...17

Hoisting...17

Wire Ropes...17

PUSH PULL COUPLER...18

Type 1...18

Disconnection...18

Connection...18

Type 2...19

Disconnection...19

Connection...19

Type 3...20

Disconnection...20

Connection...20

COATING MATERIALS...21

STANDARD TIGHTENING TORQUE...23

Standard Tightening Torque of Bolts And Nuts...23

Tightening Torque of Hose Nuts...24

Tightening Torque of Split Flange Bolts...24

Tightening Torque for Flared Nuts...24

Table of Tightening Torques for O-ring Boss Piping Joints...25

Table of Tightening Torques for O-ring Boss Plugs...25

Tightening Torque Table for Hoses (Taper Seal Type and Face Seal Type)...25

ELECTRIC WIRE CODE...26

Classification by Thickness...26

Classification by Color and Code...26

CONVERSION TABLES...27

Method of Using the Conversion Table...27

01 GENERAL...33

SPECIFICATION DIMENSION DRAWINGS...34

Dimensions...34

Working Ranges...35

SPECIFICATIONS...36

WEIGHT TABLE...39

FUEL, COOLANT, AND LUBRICANTS...41

10 STRUCTURE, FUNCTION ANDMAINTENANCE STANDARD...43

ENGINE AND COOLING SYSTEM...46

Engine Related Parts...46

Radiator, Oil Cooler and Aftercooler...47

POWER TRAIN...48

Power Train...48

Final Drive...50

PC300LC-8...50

PC300HD-8...52

Sprocket...54

PC300LC-8...54

PC300HD-8...56

Swing Machinery...58

Swing Circle...60

UNDERCARRIAGE AND FRAME...62

Track Frame and Recoil Spring...62

PC300LC-8...62

PC300HD-8...64

Idler...66

PC300LC-8...66

PC300HD-8...68

Carrier Roller...70

PC300LC-8...70

PC300HD-8...71

Track Roller...72

PC300LC-8...72

PC300HD-8...74

Track Shoe...76

PC300LC-8...76

PC300HD-8...78

Triple Grouser Shoe...80

PC300LC-8...80

PC300HD-8...81

HYDRAULIC SYSTEM...82

Hydraulic Equipment Layout Drawing...82

Hydraulic Tank and Filter...84

Hydraulic Pump...86

Type: HPV125+125...86

LS Valve...92

PC Valve...97

LS(PC)-EPC Valve...104

Variable Volume Valve...107

Control Valve...108

CLSS (Closed Center Load Sensing System)...120

Valve Functions and Operation...124

Hydraulic Circuit Diagram and the Name of Valves...124

Unloader Valve...126

LS Pressure...128

Pressure Compensation Valve...130

Pressure Compensation Valve Inner Shuttle...133

Boom Regeneration Circuit...135

Arm Regeneration Circuit...137

Merge-divider Valve...139

LS Select Valve...141

Self Pressure Reducing Valve...142

Travel Junction Valve...145

Travel PPC Shuttle Valve...147

Boom Drift Prevention Valve...149

Arm Drift Prevention Valve...152

Quick Return Valve...156

Lift Check Valve...158

Main Relief Valve...159

2-Stage Safety-suction Valve...160

Variable Pressure Compensation Valve...162

Attachment Circuit Selector Valve...164

Drift Prevention Valve...166

Valve Control...171

PPC Valve...172

Travel PPC Valve...177

Pressure Reducing Valve...180

Service PPC Valve (with EPC Valve)...186

Service PPC Valve...192

Solenoid Valve...194

PPC Accumulator...196

Return Oil Filter...197

Center Swivel Joint...198

Travel Motor - Type: HMV160ADT-2 - PC300LC-8...200

Parking Brake - PC300LC-8...206

Travel Motor - Type: KMV200ADT-2 - PC300HD-8...214

Parking Brake - PC300HD-8...220

Safety Valve...224

Swing Motor...228

Reverse Prevention Valve...234

Hydraulic Cylinder...238

Boom Cylinder...238

Arm Cylinder...238

Bucket Cylinder...238

WORK EQUIPMENT...240

Work Equipment...240

Dimension Of Arm...242

Dimension Of Bucket...244

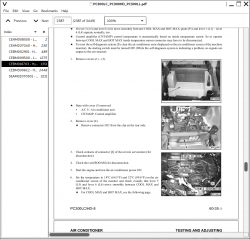

AIR CONDITIONER PIPING...246

ELECTRICAL SYSTEM...247

Engine Control...247

Fuel Control Dial...249

Engine Controller...250

Sensors...254

Coolant Temperature Sensor...254

Oil Pressure Switch...254

Engine Speed Sensor...255

Boost Pressure And Temperature Sensor...255

WIF (Water-in-fuel Detection) Sensor...256

Engine Oil Level Sensor...256

ELECTRONIC CONTROL SYSTEM...257

Control Function...257

System Diagram...258

Engine and Pump Control...260

Pump and Valve Control...266

LS Control Function...267

Cut-off Function...267

2-Stage Relief Function...267

Power Maximizing and Machine Push-up...268

Auto-deceleration...270

Auto-warm-up and Overheat Prevention...272

Swing Control...274

Travel Control...276

Attachment Flow Control and Circuit Selector...278

System Component Parts...279

PPC Oil Pressure Switch...279

Oil Pressure Sensor...280

Pump Pressure Sensor (High Pressure)...281

Pump Controller...282

MONITOR SYSTEM...285

Machine Monitor...286

Monitor Control, Display Portion...290

Monitor Items And Display...292

Switches...296

Sensors...313

KOMTRAX Terminal System...315

KOMTRAX Communication Modem - TH300...316

20 STANDARD VALUE TABLES...317

STANDARD VALUE TABLES...318

Engine Related...318

Chassis Related...319

30 TESTING AND ADJUSTING...327

CHASSIS SERVICE TOOLS...329

Sketches of special tools...333

ENGINE...334

Engine Speed...334

Air Boost Pressure...335

Exhaust Gas Color...336

Valve Clearance...338

Compression Pressure...340

Blow-by Pressure...345

Engine Oil Pressure...346

Fuel Pressure...347

Handling During Cylinder Cut-out Operation...352

Handling During No Injection Cranking Operation...352

Fuel Return Rate And Leakage...353

Bleeding Air From Fuel Circuit...356

Fuel Circuit For Leakage...357

AIR COMPRESSOR BELT TENSION...358

FAN BELT...359

ALTERNATOR BELT...360

SWING CIRCLE BEARINGS...361

TRACK SHOE TENSION...362

OIL PRESSURE IN WORK EQUIPMENT...363

OIL PRESSURE IN SWING...363

OIL PRESSURE IN TRAVEL CIRCUIT...363

CONTROL CIRCUIT OIL PRESSURE...368

PUMP PC OIL PRESSURE...369

PUMP LS OIL PRESSURE...372

SOLENOID VALVE OUTPUT PRESSURE...377

PPC VALVE OUTPUT PRESSURE...380

WORK EQUIPMENT VALVE ADJUSTMENT...381

SWING PPC VALVE ADJUSTMENT...381

HYDRAULIC DRIFT IN WORK EQUIPMENT...382

Boom and Bucket Cylinders...382

Arm Cylinder...382

Boom Lock Valve...383

PPC Valve...383

RELEASING HYDRAULIC PRESSURE...384

Oil Leakage Amount...384

BLEEDING AIR FROM VARIOUS SYSTEMS...387

DIODE INSPECTION PROCEDURES...390

MACHINE MONITOR - SPECIAL FUNCTIONS...392

Ordinary Functions and Special Functions of Machine Monitor...394

Operator Mode (Outline)...396

Display of Komatsu Logo...397

Display of Inputting Password...397

Display of Check of Breaker Mode...398

Display of Check Before Starting...398

Display of Warning After Check Before Starting...398

Display of Ending of Maintenance Interval...399

Display of Check of Working Mode and Travel Speed...399

Display of Ordinary Screen...399

Display of End Screen...400

Selection of Auto-deceleration...400

Selection of Working Mode...400

Selection of Travel Speed...401

Operation to Stop Alarm Buzzer...401

Operation of Windshield Wiper...402

Operation of Window Washer...402

Operation of Air Conditioner/heater...402

Operation to Display Camera Mode (if CameraiIs Installed)...403

Operation to Display Clock and Service Meter...403

Check of Maintenance Information...404

Setting and Display of User Mode...404

KOMTRAX Message...405

Display of Energy-saving Guidance...405

Display of Caution Monitor...405

Display of Automatic Judgment of Breaker...406

Display of User Code and Failure Code...406

Function of Checking Display of LCD (Liquid Crystal Display)...408

Function of Checking Service Meter...408

Function of Changing Attachment/Maintenance Password...409

Service Mode...411

Monitoring...413

Abnormality Record (Mechanical Systems)...418

Abnormality Record (Electrical Systems)...419

Abnormality Record (Air-conditioning System/Heater System)...427

Maintenance Record...428

Maintenance Mode Change...429

Phone Number Entry...432

Default (Key-ON Mode)...433

Default (Unit)...434

Default (With/Without Attachment)...435

Default (Attachment/Maintenance Password)...436

Default (Camera)...437

Default (ECO Display)...438

Default (Breaker Detect)...440

Adjustment (Pump Absorption Torque)...441

Adjustment (Low Speed)...442

Adjustment (Attachment Flow Adjustment)...443

Cylinder Cut-Out...444

No Injection...445

Fuel Consumption...447