Komatsu Hydraulic Excavator PC270LC-6LE, PC270LC-7L, PC270LL-7L Repair Service Manual + Operation Maintenance Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC270LC-6LE, PC270LC-7L, PC270LL-7L, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC270LC-6LE, PC270LC-7L, PC270LL-7L workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

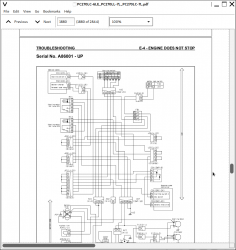

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 2,884 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEBD003001 - Hydraulic Excavator PC270LC-6LE Shop Manual.pdf

CEBM005905 - Hydraulic Excavator PC270LC-7L Shop Manual.pdf

CEBM014600 - Logging Excavator GALEO PC270LL-7L Shop Manual.pdf

CEAM008702 - Hydraulic Excavator PC270LC-7L Operation & Maintenance Manual.pdf

CEAM014700 - Hydraulic Excavator GALEO PC270LC-7L Operation & Maintenance Manual.pdf

MAIN SECTIONS

MAIN MENU...0

COVER...1

CONTENTS...2

FOREWORD...2

SAFETY...5

SAFETY NOTICE...5

IMPORTANT SAFETY NOTICE...5

GENERAL PRECAUTIONS...5

PREPARATIONS FOR WORK...5

PRECAUTIONS DURING WORK...5

GENERAL...7

HOW TO READ THE SHOP MANUAL...8

VOLUMES...8

DISTRIBUTION AND UPDATING...8

FILING METHOD...8

REVISED EDITION MARK...8

REVISIONS...8

SYMBOLS...8

HOISTING INSTRUCTIONS...9

HOISTING...9

WIRE ROPES...9

COATING MATERIALS...10

STANDARD TIGHTENING TORQUE...12

STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS...12

TIGHTENING TORQUE OF HOSE NUTS...13

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS...13

TIGHTENING TORQUE FOR FLARED NUTS...13

ELECTRIC WIRE CODE...14

CLASSIFICATION BY THICKNESS...14

CLASSIFICATION BY COLOR AND CODE...14

CONVERSION TABLES...15

METHOD OF USING THE CONVERSION TABLE...15

01 GENERAL...21

SPECIFICATION DIMENSION DRAWINGS...22

PC270LL-7L...22

DIMENSIONS...22

WORKING RANGES...24

WEIGHT TABLE...27

FUEL, COOLANT AND LUBRICANTS...29

PC270LL-7L...29

10 STRUCTURE AND FUNCTION...31

ENGINE RELATED PARTS...33

RADIATOR . OIL COOLER . AFTERCOOLER...34

POWER TRAIN...35

FINAL DRIVE...37

SWING CIRCLE...41

TRACK FRAME . RECOIL SPRING...43

IDLER...45

TRACK ROLLER...47

TRACK SHOE...48

TRIPLE GROUSER SHOE...50

HYDRAULIC EQUIPMENT...51

HYDRAULIC TANK...53

HYDRAULIC PUMP...55

HPV95 + 95...55

LS VALVE...60

PC VALVE...60

LS(PC)-EPC VALVE...73

CONTROL VALVE...77

SELF PRESSURE REDUCING VALVE...93

MAIN RELIEF VALVE...96

VARIABLE PRESSURE COMPENSATION VALVE...97

CLSS...99

SWING MOTOR...100

RELIEF VALVE PORTION...103

SWING LOCK...104

REVERSE PREVENTION VALVE...105

CENTER SWIVEL JOINT...108

TRAVEL MOTOR...110

PARKING BRAKE...115

TRAVEL JUNCTION VALVE...121

VALVE CONTROL...123

CONNECTIONS...123

LEVER POSITIONS...124

WORK EQUIPMENT . SWING PPC VALVE...125

TRAVEL PPC VALVE...130

SERVICE VALVE...139

SOLENOID VALVE...142

ATTACHMENT SOLENOID VALVE...143

PPC ACCUMULATOR...145

BOOM HYDRAULIC DRIFT PREVENTION VALVE...146

LIFT CHECK VALVE...149

HYDRAULIC CYLINDERS...150

BOOM CYLINDER...150

ARM CYLINDER...150

BUCKET CYLINDER...150

WORK EQUIPMENT...152

100 HOURS...153

500 HOURS...153

DIMENSION OF ARM...154

DIMENSION OF BUCKET...156

AIR CONDITIONER...158

PIPING...158

ENGINE CONTROL...159

FUEL CONTROL DIAL...161

GOVERNOR MOTOR...162

ENGINE THROTTLE AND PUMP CONTROLLER...164

INPUT AND OUTPUT SIGNALS...165

ELECTRONIC CONTROL SYSTEM...167

MACHINE CONTROL SYSTEM DIAGRAM...168

ENGINE AND PUMP CONTROL FUNCTION...170

SWING CONTROL FUNCTION WITH SOFT SWING...185

MULTI MONITOR SYSTEM...193

MONITOR PANEL...194

MONITOR CONTROL, DISPLAY PORTION MONITOR PORTION...196

MONITOR ITEMS AND DISPLAY...197

MAINTENANCE FUNCTION...206

SENSORS...211

ENGINE OIL LEVEL SENSOR...212

ENGINE OIL PRESSURE SENSOR (FOR LOW PRESSURE)...212

COOLANT TEMPERATURE SENSOR...212

HYDRAULIC OIL TEMPERATURE SENSOR...212

FUEL LEVEL SENSOR...213

AIR CLEANER CLOGGING SENSOR...213

CAB RISER AND RELATED PARTS...214

POWER CONTROL...215

CAB RISER HYDRAULIC SYSTEM...216

20 TESTING, ADJUSTING AND TROUBLESHOOTING...231

STANDARD VALUE TABLES...219

ENGINE...219

CHASSIS...220

TESTING AND ADJUSTING...231

SERVICE TOOLS...233

ENGINE...234

COMPRESSION PRESSURE...234

BLOW-BY PRESSURE...234

OIL PRESSURE...234

RPM...234

SPEED SENSOR...234

EXHAUST GAS COLOR...234

FUEL INJECTION TIMING...234

VALVE CLEARANCE...234

BELT TENSION - AIR COMPRESSOR...235

EMERGENCY ESCAPE FROM ENGINE CONTROL FAILURE...236

SWING CIRCLE BEARINGS...237

TRACK SHOE TENSION...238

SPROCKET...238

OIL PRESSURE...239

WORK EQUIPMENT, SWING AND TRAVEL...239

CONTROL CIRCUIT...243

PUMP PC CONTROL CIRCUIT...244

PUMP LS CONTROL CIRCUIT...247

SOLENOID VALVE OUTPUT PRESSURE...252

TABLE FOR FUNCTIONING CONDITIONS...253

PPC LOCK SOLENOID VALVE...253

SWING AND PARKING BRAKE SOLENOID...253

TRAVEL INTERCONNECTION SOLENOID VALVE...253

ATTACHMENT SOLENOID VALVE OUTPUT...256

PPC VALVE OUTPUT PRESSURE...257

ATTACHMENT PPC VALVE OUTPUT...258

WORK EQUIPMENT AND SWING PPC VALVE...259

WORK EQUIPMENT - HYDRAULIC DRIFT...260

RELEASING PRESSURE IN HYDRAULIC CIRCUIT...262

OIL LEAKAGE...263

AIR BLEEDING OF VARIOUS PARTS...266

SOFT SWING ADJUSTMENTS...268

DIODE INSPECTION PROCEDURES...269

CAB DOOR STOP ADJUSTMENT...271

MULTI-MONITOR PANEL...272

TABLE FOR SERVICE AND FAILURE CODE NUMBERS...279

SERVICE MENU...281

WAY OF SWITCHING TO SERVICE MENU...281

ELECTRICAL SYSTEM TROUBLESHOOTING...297

PM TUNE UP SERVICE...298

TROUBLESHOOTING...303

TROUBLESHOOTING GENERAL...303

POINTS TO REMEMBER WHEN TROUBLESHOOTING...305

SEQUENCE OF EVENTS IN TROUBLESHOOTING...307

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE...308

CHECKS BEFORE TROUBLESHOOTING...316

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING...317

CLASSIFICATION OF TROUBLESHOOTING...317

STEPS FOR TROUBLESHOOTING...317

FAILURE-LOOKING PHENOMENON AND TROUBLESHOOTING NO...318

CONNECTOR LOCATION CHART...321

CONNECTOR TABLE...321

CONNECTOR LOCATION DIAGRAM...328

ELECTRICAL CIRCUIT DIAGRAMS...333

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...334

CONNECTOR REPAIR PROCEDURES...357

CONTACT TERMINAL REMOVAL (HD30 TYPE)...357

STRIPPING INSULATION...358

CRIMPING CONTACT TERMINAL (HD30 TYPE)...359

INSERTION OF CONTACT TERMINAL (HD30 TYPE)...360

CONTACT TERMINAL REMOVAL (DT TYPE)...361

STRIPPING INSULATION...362

CRIMPING CONTACT TERMINAL (DT TYPE)...363

INSERTION OF CONTACT TERMINAL (DT TYPE)...364

TROUBLESHOOTING ELECTRICAL SYSTEM (E-MODE)...365

POINTS TO REMEMBER WHEN TROUBLESHOOTING SYSTEM...369

POINTS TO REMEMBER IF ABNORMALITY RETURNS TO NORMAL BY ITSELF...369

USER CODE MEMORY RETENTION FUNCTION...369

INFORMATION CONTAINED IN TESTING PROCEDURES...370

(E101)...372

ABNORMAL DATA IN ERROR HISTORY...372

(E112)...374

SHORT IN WINDSHIELD WIPER MOTOR DRIVE FORWARD ROTATION...374

SHORT IN GUARD WIPER MOTOR DRIVE FORWARD ROTATION...375

(E113)...377

SHORT IN WINDSHIELD WIPER MOTOR DRIVE REVERSE ROTATION...377

SHORT IN GUARD WIPER MOTOR DRIVE REVERSE ROTATION...378

(E114)...380

SHORT OR OPEN IN WINDOW WASHER SYSTEM...380

SHORT OR OPEN IN GUARD WASHER SYSTEM...381

(E115)...383

ABNORMAL WINDSHIELD WIPER MOTION...383

ABNORMAL GUARD WIPER MOTION...384

(E116)...386

ABNORMALITY IN PARKING WIPER ARM...386

ABNORMALITY IN PARKING WIPER ARM (GUARD)...387

(E201)...390

SHORT OR OPEN IN TRAVEL INTERLOCKING SOLENOID...390

(E203)...392

SHORT IN SWING AND PARKING SOLENOID GOVERNOR SYSTEM...392

SHORT IN SWING AND PARKING SOLENOID CONTROLLER SYSTEM (WITH SOFT SWING)...394

(E204)...396

SHORT IN MERGE/DIVIDE SOLENOID...396

(E205)...398

SHORT IN 2 STAGE RELIEF SOLENOID...398

(E206)...400

SHORT IN TRAVEL SPEED SHIFT SOLENOID...400

(E211)...402

OPEN IN TRAVEL INTERLOCKING SOLENOID...402

(E213)...404

OPEN IN SWING PARKING BRAKE SOLENOID...404

OPEN IN SWING PARKING BRAKE SOLENOID (WITH SOFT SWING)...406

NO CODE...408

SHORT OR OPEN IN SOFT SWING SOLENOID SYSTEM...408

(E214)...412

OPEN OF MERGE/DIVIDE SOLENOID...412

(E215)...414

OPEN IN 2 STAGE RELIEF SOLENOID...414

(E216)...416

OPEN IN TRAVEL SPEED SOLENOID...416

(E217)...418

ABNORMAL INPUT FOR MODEL CODE...418

(E218)...420

OPEN IN S-NET SIGNAL...420

(E222)...422

SHORT IN LS-EPC SOLENOID...422

(E223)...424

OPEN IN LS-EPC SOLENOID SYSTEM...424

(E224)...426

ABNORMAL F-PUMP PRESSURE SENSOR SIGNAL...426

(E225)...428

ABNORMAL R-PUMP PRESSURE SENSOR SIGNAL...428

(E226)...430

ABNORMAL PRESSURE SENSOR POWER SUPPLY...430

(E227)...432

ABNORMAL ENGINE RPM SIGNAL IN GOVERNOR PUMP CONTROLLER...432

(E228)...434

SHORT IN ATTACHMENT RETURN SWITCHING RELAY...434

NO CODE...436

SHORT OR OPEN IN ATTACHMENT SOLENOID SYSTEM...436

NO CODE...440

OPEN IN CAB TILT SYSTEM...440

(E232)...442

SHORT IN PC-EPC SOLENOID...442

(E233)...444

OPEN IN PC-EPC SOLENOID SYSTEM...444

(E238)...446

OPEN IN ATTACHMENT RETURN SWITCH RELAY...446

(E245)...448

SHORT IN ATTACHMENT OIL FLOW RATE EPC SYSTEM...448

(E246)...450

OPEN IN ATTACHMENT OIL FLOW RATE EPC SYSTEM...450

(E256)...452

INCORRECT NON-VOLATILE MEMORY DATA...452

(E306)...454

ABNORMAL GOVERNOR POTENTIOMETER SIGNALS...454

(E308)...456

ABNORMAL FUEL DIAL SIGNALS...456

(E315)...458

SHORT IN BATTERY RELAY SYSTEM...458

(E316)...460

STEP OUT IN GOVERNOR MOTOR...460

(E317)...462

OPEN IN GOVERNOR MOTOR PHASE "A" AND "B"...462

(E318)...464