Komatsu Hydraulic Excavator PC210, PC210LC, PC210NLC, PC230NHD, PC240LC, PC240NLC Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 3,330 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

UEN00084-07 - Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Shop Manual.pdf

UEN00084 - Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Shop Manual.pdf

SEAM02050307 - Hydraulic Excavator PC200-3, PC210-3, PC220-3, PC240-3, PC280-3 Operation & Maintenance Manual.pdf

UEAM004904 - Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Operation & Maintenance Manual.pdf

UEAM004912 - Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Operation & Maintenance Manual.pdf

MAIN SECTIONS

00 Index and foreword...3

Index...3

Organization list of the shop manual...4

Table of contents...6

00 Index and foreword...17

Foreword and general information...17

Foreword and general information...18

Safety notice...18

How to read the shop manual...22

Explanation of terms for maintenance standard...24

Handling electric equipment and hydraulic component...26

How to read electric wire code...34

Method of disassembling and connecting push-pull type coupler...37

Standard tightening torque table...40

Conversion table...44

01 Specification...51

Specification and technical data...51

Specification and technical data...52

Specification dimension drawings...52

Working range diagram...53

Specifications...54

Weight table...58

Table of fuel, coolant and lubricants...62

10 Structure, function and maintenance standard...65

Engine and cooling system...65

Engine and cooling system...66

Engine related parts...66

Radiator, oil cooler, aftercooler and fuel cooler...67

Diesel Particulate Filter...68

Diesel Particulate Filter - Component Parts...69

System Description...70

Regeneration...70

10 Structure, function and maintenance standard...73

Power train...73

Power train...74

Power train...74

Final drive...76

Swing machinery...78

Swing circle...82

10 Structure, function and maintenance standard...85

Undercarriage and frame...85

Undercarriage and frame...86

Track frame and recoil spring...86

Idler...88

Carrier roller...90

Track roller...91

Track shoe...92

10 Structure, function and maintenance standard...99

Hydraulic system, Part 1...99

Hydraulic system, Part 1...100

Hydraulic equipment layout drawing...100

Hydraulic tank and filter...102

Hydraulic pump...103

Hydraulic pump...104

Pilot oil filter...127

10 Structure, function and maintenance standard...129

Hydraulic system, Part 2...129

Hydraulic system, Part 2...130

Control valve...130

CLSS...143

Functions and operation by valve...148

Hydraulic drift prevention valve...174

10 Structure, function and maintenance standard...187

Hydraulic system, Part 3...187

Hydraulic system, Part 3...189

Swing motor...189

Centre swivel joint...198

Travel motor...201

PPC valve...212

Valve control...232

ATT EPC Valve Assembly...234

Solenoid valve...236

PPC Accumulator...238

Return oil filter...239

Attachment circuit selector valve...240

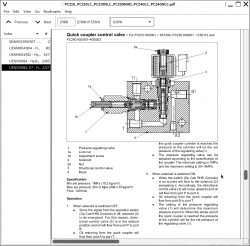

Quick coupler control valve - For PC210 K50001 ~ K51094, PC230 K50001 ~ K50113 and PC240 K50001~K50303...242

Quick coupler control valve - For PC210 K51095 - K53243, PC230 K50114 - K50286 and PC240 K50304 - K51093.)...244

Quick coupler control valve - For PC210 K53424 and up, PC230 K50287 and up and PC240 K51094 and up...246

Hydraulic cylinder...248

10 Structure, function and maintenance standard...253

Work equipment...253

Work equipment...254

Dimensions of components...254

10 Structure, function and maintenance standard...261

Cab and its attachments...261

Cab and its attachments...262

Air conditioner piping...262

10 Structure, function and maintenance standard...265

Electrical system...265

Electrical system...266

Engine control...266

Electrical control system...274

Monitor system...300

Sensor...331

PPC Levers...334

KOMTRAX terminal system...336

10 Structure, function and maintenance standard...339

Auto Grease system...339

Outline of Auto Grease System...340

20 Standard value table...355

Standard service value table...355

Standard service value table...356

Standard value table for engine related parts...356

Standard value table for chassis related parts...358

30 Testing and adjusting...377

Testing and adjusting, Part 1...377

Testing and adjusting, Part 1...379

Tools for testing, adjusting, and troubleshooting...379

Measuring engine speed...382

Measuring intake air pressure (boost pressure)...383

Checking exhaust gas colour...384

Adjusting valve clearance...385

Measuring compression pressure...387

Measuring blow-by pressure...389

Measuring engine oil pressure...390

Handling fuel system parts...391

Releasing residual pressure from fuel system...391

Measuring fuel pressure...392

Measuring fuel return rate and leakage...394

Bleeding air from fuel circuit...396

Checking fuel circuit for leakage...398

Checking and adjusting air conditioner compressor belt tension...399

Measuring swing circle bearing clearance...400

Checking and adjusting track shoe tension...401

Measuring and adjusting oil pressure in work equipment, swing, and travel circuits...403

Measuring control circuit basic pressure...407

Measuring and adjusting oil pressure in pump PC control circuit...408

Measuring and adjusting oil pressure in pump LS control circuit...412

Measuring solenoid valve output pressure...418

Measuring PPC valve output pressure...421

Adjusting play of work equipment and swing PPC valves...423

Measuring and adjusting quick coupler control valve output pressure - For PC210 K50001 - K53423, PC230 K50001 - K50286 and PC240 K50001 - K51093...424

Measuring and adjusting quick coupler control valve output pressure - For PC210 K53424 and up, PC230 K50287 and up and PC240 K51094 and up...425

Checking parts which cause hydraulic drift of work equipment...426

Releasing residual pressure from hydraulic circuit...428

Measuring oil leakage...429

Bleeding air from each part...432

Checking cab tipping stopper...435

Adjusting mirrors...436

Adjusting mirrors...438

30 Testing and adjusting...441

Testing and adjusting, Part 2...441

Testing and adjusting, Part 2...442

Special functions of machine monitor...442

30 Testing and adjusting...507

Testing and adjusting, Part 3...507

Testing and adjusting, Part 3...508

Handling high-voltage circuit of engine controller...508

Preparation work for troubleshooting of electrical system...509

Procedure for testing diodes...513

Pm Clinic service...515

Warning...517

Pm Clinic service...521

40 Troubleshooting...529

General information on troubleshooting...529

General information on troubleshooting...530

Points to remember when troubleshooting...530

Sequence of events in troubleshooting...531

Check before troubleshooting...532

Classification and procedures for troubleshooting...533

How to read electric wire code...537

Connection table for connector pin numbers...540

T-boxes and T-adapters table...571

40 Troubleshooting...577

Troubleshooting by failure code (Display of code), Part 1...577

Troubleshooting by failure code (Display of code), Part 1...579

Failure codes table...579

Before carrying out troubleshooting when failure code is displayed...584

Before carrying out troubleshooting when failure code is displayed...585

Information in troubleshooting table...590

Failure code [989L00] Engine Controller Lock Caution 1...592

Failure code [989M00] Engine Controller Lock Caution 2...592

Failure code [989N00] Engine Controller Lock Caution 3...593

Failure code [AA10NX] Air Cleaner Clogging...593

Failure code [AB00KE] Charge Voltage Low...594

Failure code [B@BAZG] Eng Oil Press. Low...596

Failure code [B@BAZK] Eng Oil Level Low...596

Failure code [B@BCNS] Eng Water Overheat...597

Failure code [B@BCZK] Eng Water Level Low...597

Failure code [B@HANS] Hydr Oil Overheat...598

Failure code [CA111] EMC Critical Internal Failure...598

Failure code [CA115] Eng Ne and Bkup Speed Sens Error...599

Failure code [CA122] Chg Air Press Sensor High Error...600

Failure code [CA123] Chg Air Press Sensor Low Error...602

Failure code [CA131] Throttle Sensor High Error...604

Failure code [CA132] Throttle Sensor Low Error...606

Failure code [CA144] Coolant Temp Sens High Error...608

Failure code [CA145] Coolant Temp Sens Low Error...610

Failure code [CA153] Chg Air Temp Sensor High Error...612

Failure code [CA154] Chg Air Temp Sensor Low Error...614

Failure code [CA155] Chg Air Temp High Speed Derate...616

Failure code [CA187] Sens Supply 2 Volt Low Error...618

Failure code [CA221] Ambient Press Sens High Error...620

Failure code [CA222] Ambient Press Sens Low Error...622

Failure code [CA227] Sens Supply 2 Volt High Error...624

Failure code [CA234] Eng Overspeed...625

Failure code [CA238] Ne Speed Sens Supply Volt Error...626

Failure code [CA271] IMV/PCV1 Short Error...627

Failure code [CA272] IMV/PCV1 Open Error...628

Failure code [CA322] Inj #1 (L#1) Open/Short Error...630