Komatsu Hydraulic Excavator PC200, PC200LC, PC210LC, PC220LC, PC250LC Repair Service Manual + Operation & Maintenance Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC200-6, PC200LC-6, PC210LC-6, PC220LC-6, PC250LC-6, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC200-6, PC200LC-6, PC210LC-6, PC220LC-6, PC250LC-6 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 2,913 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEBM000102 - Hydraulic Excavator PC200-6, PC200LC-6, PC210LC-6, PC220LC-6, PC250LC-6 Shop Manual.pdf

CEBM001001 - Hydraulic Excavator PC200LC-6, PC210LC-6, PC220LC-6, PC250LC-6 Shop Manual.pdf

CEBMX20601 - Hydraulic Excavator PC200-6, PC200LC-6, PC210LC-6, PC220LC-6, PC250LC-6 Shop Manual.pdf

CEAM000101 - Hydraulic Excavator PC200-6, PC200LC-6, PC210LC-6, PC220LC-6, PC250LC-6 Operation & Maintenance Manual.pdf

CEAM001200 - Hydraulic Excavator PC200-6, PC200LC-6, PC210LC-6, PC220LC-6, PC250LC-6 Operation & Maintenance Manual.pdf

CEAMX20601 - Hydraulic Excavator PC200-6, PC200LC-6, PC210LC-6, PC220LC-6, PC250LC-6 Operation & Maintenance Manual.pdf

MAIN SECTIONS

MAIN MENU...0

COVER...1

CONTENTS...2

01 GENERAL...25

GENERAL ASSEMBLY DRAWING (PC200-6, PC2OOLC-6, PC210LC-6)...26

GENERAL ASSEMBLY DRAWING (PC220LC-6, PC250LC-6)...28

SPECIFICATIONS (PC200-6, PC200LC-6)...31

SPECIFICATIONS (PC210LC-6)...33

SPECIFICATIONS (PC220LC-6)...35

SPECIFICATIONS (PC250LC-6)...37

WEIGHT TABLE (PC200-6, PC200LC-6)...39

WEIGHT TABLE (PC210LC-6)...41

WEIGHT TABLE (PC220LC-6, PC250LC-6)...43

FUEL, COOLANTS AND LUBRICANTS...45

10 STRUCTURE AND FUNCTION...48

ENGINE RELATED PARTS...49

RADIATOR, OIL COOLER, AFTERCOOLER...50

POWER TRAIN...51

FINAL DRIVE...52

SWING CIRCLE...54

SWING MACHINERY...55

TRACK FRAME, RECOIL SPRING...56

TRACK SHOE...57

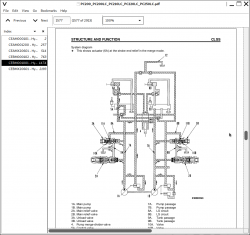

HYDRAULIC PIPING DRAWING...59

HYDRAULIC CIRCUIT DIAGRAM...60

HYDRAULIC TANK...62

HYDRAULIC PUMP...63

CONTROL VALVE...85

CLSS...94

SWING MOTOR...138

CENTER SWIVEL JOINT...141

TRAVEL MOTOR...142

VALVE CONTROL...153

WORK EQUIPMENT, SWING PPC VALVE...154

TRAVEL PPC VALVE...158

SERVICE PPC VALVE...162

SAFETY LOCK VALVE...165

PPC ACCUMULATOR...165

PPC SHUTTLE, TRAVEL JUNCTION VALVE...166

EPC, SOLENOID VALVE...173

HYDRAULIC CYLINDER...181

ADDITIONAL FILTER FOR BREAKER...182

OVERLOAD WARNING DEVICE...183

HOSE BURST PROTECTION VALVE (BOOM)...187

WORK EQUIPMENT...190

20 TESTING AND ADJUSTING...232

TABLE OF JUDGEMENT STANDARD VALUE...233

STANDARD VALUE TABLE FOR ELECTRICAL PARTS...245

TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTNG...254

MEASURING ENGINE SPEED...255

MEASURING INTAKE MANIFOLD PRESSURE...256

MEASURING INTAKE AIR RESTRICTION...257

MEASURING LUBRICATING OIL PRESSURE...258

MEASURING FUEL (FILTER) INLET RESTRICTION...259

MEASURING BLOWBY PRESSURE...260

MEASURING ENGINE BACK PRESSURE...261

MEASURING EXHAUST COLOR...262

MEASURING COOLANT TEMPERATURE...263

MEASURING VALVE CLEARANCE...264

CHECKING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR...265

ADJUSTING ENGINE SPEED SENSOR...266

TESTING AND ADJUSTING GOVERNOR MOTOR LEVER STROKE...267

TESTING CLEARANCE OF SWING CIRCLE BEARING...268

TESTING AND ADJUSTING TRACK SHOE TENSION...269

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT...270

TESTING AND ADJUSTING TVC VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE)...273

TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE) AND LS DIFFERENTIAL PRESSURE...275

TESTING AND ADJUSTING CONTROL PUMP CIRCUIT OIL PRESSURE...278

TESTING EPC VALVE, SOLENOID VALVE OUTPUT PRESSURE...280

MEASURING PPC VALVE OUTPUT PRESSURE AND TESTING PPC SHUTTLE VALVE...282

ADJUSTING WORK EQUIPMENT, SWING PPC VALVE...284

ADJUSTING TRAVEL LEVER...285

TESTING TRAVEL DEVIATION...286

TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT...287

MEASURING OIL LEAKAGE...289

RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT...290

TROUBLESHOOTING...293

POINTS TO REMEMBER WHEN TROUBLESHOOTING...294

SEQUENCE OF EVENTS IN TROUBLESHOOTING...295

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE...296

CHECKS BEFORE TROUBLESHOOTING...303

CONNECTOR TYPES AND MOUNTING LOCATIONS...304

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...308

EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM...321

DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL...322

METHOD OF USING JUDGEMENT TABLE...331

DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE...335

TROUBLESHOOTING OF ENGINE THROTTLE CONTROLLER SYSTEM (E MODE)...340

POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING OF ENGINE THROTTLE CONTROLLER SYSTEM...341

ENGINE THROTTLE CONTROLLER SYSTEM CIRCUIT DIAGRAM...342

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE...344

JUDGEMENT TABLE FOR ENGINE THROTTLE CONTROLLER AND ENGINE RELATED PARTS...345

E-1 Abnormality in engine throttle controller power source system (engine speed stays at low idling)...346

E-2 [E3:08] Abnormality in fuel control dial input value is displayed...347

E-3 [E3:17] Abnormality (disconnection) in governor motor drive system is displayed...348

E-4 [E3:18] Abnormality (short circuit) in governor motor drive system is displayed...349

E-5 [E3:01] Abnormality in network reception system is displayed...350

E-6 [E3:05] Abnormality in model code is displayed...352

E-7 [E3:06] Abnormality in governor potentiometer system is displayed...353

E-8 [E3:07] Abnormality in pump controller throttle system is displayed...354

E-9 [E3:15] Abnormality (short circuit) in battery relay output system is displayed...354

E-10 [E3:16] Abnormality (step-out) in governor motor system is displayed...355

E-11 Engine does not start...356

E-12 Engine speed is irregular...358

a) Idling speed is irregular...358

b) There is hunting...360

E-13 Lack of output (engine high idling speed is too low)...362

E-14 Engine does not stop...364

E-15 Defective operation of battery relay system (engine does not stop)...366

TROUBLESHOOTING OF ENGINE (S MODE)...367

METHOD OF USING TROUBLESHOOTING CHART...368

S-1 Starting performance is poor (Starting always takes time)...372

S-2 Engine does not start...373

1) Engine does not turn...373

2) Engine turns but no exhaust gas comes out (Fuel is not being injected)...374

3) Exhaust gas comes out but engine does not start (Fuel is being injected)...375

S-3 Engine does not pick up smoothly (Follow-up is poor)...376

S-4 Engine stops during operations...377

S-5 Engine does not rotate smoothly...378

S-6 Engine lacks output (no power)...379

S-7 Exhaust gas is black (incomplete combustion)...380

S-8 Oil consumption is excessive (or exhaust gas is blue)...381

S-9 Oil becomes contaminated quickly...382

S-10 Fuel consumption is excessive...383

S-11 Oil is in cooling water, or water spurts back, or water level goes down...384

S-12 Oil pressure lamp lights up (drop in oil pressure)...385

S-13 Oil level rises...386

S-14 Water temperature becomes too high (overheating)...387

S-15 Abnormal noise is made...388

S-16 Vibration is excessive...389

TROUBLESHOOTING OF PUMP CONTROLLER SYSTEM (C MODE)...390

POINTS TO REMEMNBER WHEN TROUBLESHOOTING PUMP CONTROLLER SYSTEM...391

ACTION TAKEN BY CONTROLLER WHEN ABNORMALITY OCCURS AND PROBLEMS ON MACHINE...392

JUDGEMENT TABLE FOR PUMP CONTROLLER AND HYDRAULIC RELATED PARTS...396

PUMP CONTROLLER SYSTEM CIRCUIT DIAGRAM...397

C-1 Abnormality in pump controller power source system (swing brake is not canceled, ect.)...398

C-2 [E2:32] Short circuit in front pump TVC solenoid system is displayed...399

[E2:36] Short circuit in rear pump TVC solenoid system is displayed...399

C-3 [E2:33] Disconnection in front pump TVC solenoid system is displayed...401

[E2:37] Disconnection in rear pump TVC solenoid system is displayed...401

C-4 [E2:03] Short circuit in swing brake solenoid system is displayed...403

C-5 [E2:13] Disconnection in swing brake solenoid system is displayed...405

C-6 [E2:02] Short circuit in LS select solenoid system is displayed...407

[E2:04] Short circuit in pump merge-divider solenoid system is displayed...407

[E2:05] Short circuit in 2-stage relief solenoid system is displayed...407

[E2:06] Short circuit in travel speed solenoid system is displayed...407

C-7 [E2:12] Disconnection in LS select solenoid system is displayed...409

[E2:14] Disconnection in pump merge-divider solenoid system is displayed...409

[E2:15] Disconnection in 2-stage relief solenoid system is displayed...409

[E2:16] Disconnection in travel speed solenoid system is displayed...409

C-8 [E2:17] Model selection input error is displayed...411

C-9 [E2:18] Network response overtime error is displayed...412

C-10 [E2:22] Short circuit in LS control EPC solenoid system is displayed...414

C-11 [E2:23] Disconnection in LS control EPC solenoid system is displayed...415

C-12 [E2:24] Abnormality in front pump pressure sensor system is displayed...416

[E2:25] Abnormality in rear pump pressure sensor system is displayed...416

C-13 [E2:26] Abnormality in pump pressure sensor power source system is displayed...418

C-14 [E2:27] Abnormality in engine speed sensor system is displayed...419

C-15 [E2:28] Abnormality in auto-deceleration output system is displayed...420

TROUBLESHOOTING OF PUMP CONTROLLER INPUT SIGNAL SYSTEM (F MODE)...421

F-1 Bit pattern 20-(1) Swing oil pressure switch does not light up...422

F-2 Bit pattern 20-(2) Travel oil pressure switch does not light up...423

F-3 Bit pattern 20-(3) Boom LOWER oil pressure switch does not light up...424

F-4 Bit pattern 20-(4) Boom RAISE oil pressure switch does not light up...425

F-5 Bit pattern 20-(5) Arm IN oil pressure switch does not light up...426

F-6 Bit pattern 20-(6) Arm OUT oil pressure switch does not light up...427

F-7 Bit pattern 21-(1) Bucket CURL oil pressure switch does not light up...428

F-8 Bit pattern 21-(2) Bucket DUMP oil pressure switch does not light up...429

F-9 Bit pattern 21-(3) Swing lock switch does not light up...430

F-10 Engine speed is not displayed in monitoring code 10 (abnormality in engine speed sensor system)...431

F-12 Bit pattern 22-(6) L.H. knob switch does not light up...432

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)...433

TABLE OF FAILURE MODES AND CAUSES FOR HYDRAULIC AND MECHANICAL SYSTEM...434

PUMP MERGE-DIVIDER LOGIC...436

All work equipment, travel, swing...437

H-1 Speeds of all work equipment, swing, travel are slow or lack power...437

H-2 There is excessive drop in engine speed, or engine stalls...439

H-3 No work equipment, travel, swing move...440

H-4 Abnormal noise generated...440