Komatsu Hydraulic Excavator PC130-6K, PC150LGP-6K Repair Service Manual + Operation & Maintenance Manual

Komatsu Hydraulic Excavator PC130-6K, PC150LGP-6K Repair Service Manual + Operation & Maintenance Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC130-6K, PC150LGP-6K, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC130-6K, PC150LGP-6K workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,449 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

EEBM001501 - Hydraulic Excavator PC130-6K, PC150LGP-6K Shop Manual.pdf

SEAM021K0303 - Hydraulic Excavator PC150-3, PC150LC-3, PC150HD-3, PC150NHD-3 Operation & Maintenance Manual.pdf

UEAM000602 - Hydraulic Excavator PC130-6K, PC150LGP-6K Operation & Maintenance Manual.pdf

UEAM003601 - Hydraulic Excavator PC130-7K Operation & Maintenance Manual.pdf

MAIN SECTIONS

01 General...25

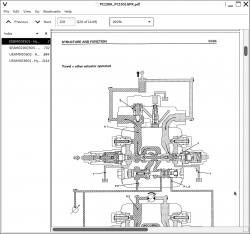

10 Structure and function ...42

20 Testing and adjusting...237

30 Dissasembly and Assembly...530

40 Maintenance Standard...681

90 Others...725

FOREWORD...3

FOREWORD...4

SAFETY INFORMATION...5

NOISE...7

VIBRATION...7

INTRODUCTION...8

DIRECTIONS OF MACHINE...8

BREAKING-IN THE NEW MACHINE...8

PRODUCT INFORMATION...9

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE...9

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION...9

SERVICE METER LOCATION...10

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR...10

MACHINE SERIAL NUMBER PLATE...11

FOREWORD...12

SAFETY...12

OPERATION...12

MAINTENANCE...15

SPECIFICATIONS...17

ATTACHMENTS AND OPTIONS...17

INDEX...18

COLOPHON...18

SAFETY...19

SAFETY INFORMATION...20

SAFETY LABELS...22

LOCATION OF SAFETY LABELS...22

SAFETY LABELS...23

SAFETY INFORMATION...30

SAFETY MACHINE OPERATION...39

STARTING ENGINE...39

OPERATION...41

TRANSPORTATION...48

BATTERY...49

TOWING...51

LIFTING OBJECTS WITH BUCKET...52

SAFETY MAINTENANCE INFORMATION...54

OPERATION...61

MACHINE VIEW ILLUSTRATIONS...62

OVERALL MACHINE VIEW...62

CONTROLS AND GAUGES...63

DETAILED CONTROLS AND GAUGES...64

MONITORING SYSTEM...64

Basic Check Monitors...65

Caution Monitors...67

Emergency Monitors...69

Meter Display Portion...71

Monitor Switches Portion...74

SWITCHES...77

CONTROL LEVERS AND PEDALS...83

SUN ROOF...86

WINDSHIELD...86

EMERGENCY EXIT FROM OPERATOR'S CAB...91

DOOR LOCK...91

CAP WITH LOCK...92

HOT AND COOL BOX...94

MAGAZINE BOX...94

ASHTRAY...94

AIR CONDITIONER CONTROLS...95

Air Conditioner Control Panel...95

Method of Operation...100

Use Air Conditioner with Care...106

Inspection and maintenance of Air Conditioner Equipped Machine...106

Other Functions...107

CAB RADIO CASSETTE...108

Controls of Radio cassette...108

Precautions when Using...108

AUXILIARY ELECTRIC POWER...109

24V power source...109

12V power source...109

FUSE...109

FUSIBLE LINK...110

CONTROLLERS...111

TOOL BOX...111

GREASE GUN HOLDER...111

HANDLING GREASE GUN...112

REFUELLING PUMP...113

ACCUMULATOR...115

Releasing Hydraulic Pressure with Accumulator...115

MACHINE OPERATIONS AND CONTROLS...116

BEFORE STARTING ENGINE...116

Walk-around Checks...116

Checks Before Starting...118

Adjustment...124

Seat Belt...127

Operations Before Starting Engine...128

STARTING ENGINE...130

Normal Starting...130

Starting Engine in Cold Weather...132

AFTER STARTING ENGINE...134

Warming-up Operation...134

In Cold Weather Areas...137

STOPPING THE ENGINE...141

MACHINE OPERATION...142

Preparations for Moving the Machine Off...142

Moving Machine Forward...143

Moving Machine Backward...144

Stopping Machine...145

STEERING THE MACHINE...146

Steering...146

SWINGING...148

WORK EQUIPMENT CONTROLS AND OPERATIONS...149

WORKING MODE...151

PROHIBITED OPERATIONS...152

GENERAL OPERATION INFORMATION...154

TRAVELING ON SLOPES...155

ESCAPE FROM MUD...157

Stuck One Side of Track...157

Stuck Both Sides of Tracks...157

RECOMMENDED APPLICATIONS...158

Backhoe Work...158

Shovel Work...158

Ditching Work...158

Loading Work...159

BUCKET REPLACEMENT AND INVERSION...160

Replacement...160

Inversion...161

PARKING MACHINE...162

CHECK AFTER SHUT OFF ENGINE...163

MACHINE INSPECTION AFTER DAILY WORK...164

LOCKING...164

OVERLOAD WARNING DEVICE...164

TRANSPORTATION...165

TRANSPORTATION PROCEDURE...165

LOADING AND UNLOADING WITH TRAILER...166

Loading...167

Securing Machine...169

Unloading...171

LIFTING MACHINE...173

COLD WEATHER OPERATION...174

COLD WEATHER OPERATION INFORMATION...174

Fuel and Lubricants...174

Cooling System Coolant...174

Battery...175

AFTER DAILY WORK COMPLETION...176

AFTER COLD WEATHER SEASON...176

LONG TERM STORAGE...177

BEFORE STORAGE...177

DURING STORAGE...177

AFTER STORAGE...178

STARTING MACHINE AFTER LONG-TERM STORAGE...178

TROUBLES AND ACTIONS...179

RUNNING OUT OF FUEL...179

PHENOMENA THAT ARE NOT FAILURES...179

TOWING THE MACHINE...180

LIGHTWEIGHT TOWING HOLE...180

SEVERE JOB CONDITION...181

DISCHARGED BATTERY...182

Battery Removal and Installation...182

Battery Charges...183

Starting Engine with Booster Cables...184

OTHER TROUBLE...186

Electrical System...186

Chassis...187

Engine...188

Electronic Control System...190

MAINTENANCE...191

MAINTENANCE INFORMATION...192

LUBRICANTS, COOLANT AND FILTERS...195

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC...195

Oil...195

Fuel...195

Cooling System Coolant...196

Grease...196

Carrying Out KOWA (Komatsu Oil Wear Analysis)...197

Oil and Fuel Storage...198

Filters...198

ELECTRIC SYSTEM MAINTENANCE...198

WEAR PARTS...199

WEAR PARTS LIST...199

LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS...200

PROPER SELECTION...200

TIGHTENING TORQUE SPECIFICATIONS...204

TIGHTENING TORQUE LIST...204

SAFETY CRITICAL PARTS...205

SAFETY CRITICAL PARTS LIST...205

MAINTENANCE SCHEDULE...206

MAINTENANCE SCHEDULE CHART...206

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER...208

MAINTENANCE PROCEDURE...209

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)...209

INITIAL 1000 HOURS MAINTENANCE (ONLY AFTER THE FIRST 1000 HOURS)...209

WHEN REQUIRED...210

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT...210

CLEAN INSIDE OF COOLING SYSTEM...215

CHECK AND TIGHTEN TRACK SHOE BOLTS...218

CHECK AND ADJUST TRACK TENSION...219

CHECK ELECTRICAL INTAKE AIR HEATER...221

REPLACE BUCKET TEETH (VERTICAL PIN TYPE)...222

REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE)...225

ADJUST BUCKET CLEARANCE...226

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID...227

CHECK AND ADJUST AIR CONDITIONER...228

WASH WASHABLE FLOOR...229

BLEEDING AIR FROM HYDRAULIC SYSTEM...233

METHOD FOR RELEASING INTERNAL PRESSURE IN HYDRAULIC CIRCUIT...236

CHECK NITROGEN GAS CHARGE PRESSURE IN ACCUMULATOR (control circuit)...236

CHECK BEFORE STARTING...237

EVERY 100 HOURS MAINTENANCE...238

LUBRICATING...238

CHECK SWING MACHINERY CASE OIL, ADD OIL...240

EVERY 250 HOURS MAINTENANCE...241

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL...241

CHECK LEVEL OF BATTERY ELECTROLYTE...242

EVERY 500 HOURS MAINTENANCE...245

REPLACE FUEL FILTER CARTRIDGE...245

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE...246

CHECK SWING PINION GREASE LEVEL, ADD GREASE...247

LUBRICATE SWING CIRCLE...247

Radiator Core and Fins - Check/Clean...248

CLEAN AIR CONDITIONER FRESH/RECIRC FILTERS...249

REPLACE HYDRAULIC OIL FILTER ELEMENT...251

REPLACE BREATHER ELEMENT IN HYDRAULIC TANK...252

CHECK AND ADJUST COOLING FAN BELT TENSION...253

CHECK, ADJUST AIR CONDITIONER COMPRESSOR BELT TENSION...254

EVERY 1000 HOURS MAINTENANCE...255

CHANGE OIL IN SWING MACHINERY CASE...255

CHANGE OIL IN FINAL DRIVE CASE...256

CHECK ALL TIGHTENING PARTS OF TURBOCHARGER...256

CHECK PLAY TURBOCHARGER ROTOR...256

CHECK NITROGEN GAS CHARGE PRESSURE IN ACCUMULATOR (for breaker)...256

EVERY 2000 HOURS MAINTENANCE...257

CHECK PTO GEAR CASE, ADD OIL...257

CLEAN HYDRAULIC TANK STRAINER...258

CLEAN, CHECK TURBOCHARGER...258

CHECK ALTERNATOR, STARTING MOTOR...258

CHECK ENGINE VALVE CLEARANCE, ADJUST...258

EVERY 4000 HOURS MAINTENENCE...259

CHECK WATER PUMP...259

EVERY 5000 HOURS MAINTENANCE...260

CHANGE OIL IN HYDRAULIC TANK...260

SPECIFICATIONS...261

SPECIFICATIONS...262

EXPLANATION OF LIFTING CAPACITY CHART (PC130-7K 1- PC BOOM)...264

EXPLANATION OF LIFTING CAPACITY CHART (PC130-7K 2-PC BOOM)...265

ATTACHMENTS AND OPTIONS...269

GENERAL PRECAUTIONS FOR SAFETY...270

PRECAUTIONS WHEN SELECTING...270

READ THE INSTRUCTION MANUAL THOROUGHLY...270

PRECAUTIONS WHEN REMOVING OR INSTALLING...270

PRECAUTIONS WHEN USING...271

BUCKET WITH HOOK...272

HOOK CONDITION...272

PROHIBITED OPERATIONS...272

MACHINE READY FOR ATTACHMENT...273

LOCATIONS...273

HYDRAULIC CIRCUIT...276

Hydraulic Circuit Connection...276

ATTACHMENT REMOVAL AND INSTALLATION...277

Attachment Removal...277

Attachment Installation...277

ATTACHMENT OPERATIONS...279

When Using Breaker...279

When Using General Attachment Such as Crusher...280

ACCUMULATOR...281

Hydraulic System - Pressure Release...281

LONG TERM STORAGE...282

SPECIFICATIONS...282

ATTACHMENT GUIDE...283

OTHER ATTACHMENTS...283

ATTACHMENT COMBINATIONS...284

TRACK SHOES SELECTION...285

BUCKET TEETH SELECTION...286

Teeth Selection...286

Selection Guide for Horizontal or Vertical Pin Type Tooth...286

HANDLING OF RUBBER PAD SHOE AND ROAD LINER...287

Working Environment...287

Working Conditions...287

Storage, Protection...288

Extent of Damage to Rubber...288

Check Road Liner...288

Replace Road Liner...288

RECOMMENDED ATTACHMENT OPERATIONS...289

HYDRAULIC BREAKER...289

2-PC BOOM...294

FEATURES OF 2-PIECE BOOM & ARM...294

OPERATION...295

BEFORE STORAGE POSTURE WHEN LEAVING MACHINE...296

TESTING AND ADJUSTING...297

PERODIC MAINTENANCE...297

TRANSPORTATION...298

INDEX...301

COLOPHON...305