Komatsu Hydraulic Excavator PC80MR Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC80MR, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC80MR workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 302 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

WEBM008601 - Hydraulic Excavator PC80MR-3 Shop Manual.pdf

MAIN SECTIONS

CONTENTS...3

REVISED PAGES...5

k SAFETY...7

FOREWORD...9

HOW TO READ THE SHOP MANUAL...10

HOISTING INSTRUCTIONS...11

STANDARD TIGHTENING TORQUE...12

COATING MATERIALS...14

ELECTRIC...15

WEIGHT TABLE...16

TABLE OF OIL AND COOLANT QUANTITIES...17

CONVERSION TABLE...19

10 STRUCTURE AND FUNCTION...27

POWER TRAIN...28

SWING CIRCLE...29

SWING MACHINERY...31

TRACK FRAME AND IDLER CUSHION...34

IDLER...36

TRACK ROLLER...37

CARRIER ROLLER...38

SPROCKET...39

TRACK SHOE...40

SHOES...43

RUBBER SHOE...44

SWIVEL JOINT...45

TRAVEL MOTOR...46

WORK EQUIPMENT CYLINDER...48

SOLENOID VALVE GROUP...52

CONTROL VALVE...54

CLSS...65

SWING MOTOR...84

ATTACHMENT...93

TRAVEL PPC VALVE...98

BLADE, BOOM SWING, 2-PIECE BOOM PPC VALVES...102

EQUIPMENT...106

20 TESTING AND ADJUSTMENTS...109

NORMAL OR STANDARD TECHNICAL DATA...111

FOR THE ENGINE...111

FOR MACHINE...112

PUMP FEATURES...119

CHECK POSITIONS...120

SPECIAL TOOLS...125

MEASURING THE ENGINE SPEED...127

1. Measuring engine speed...127

2. Measuring engine speed to check compression pressure...128

CHECKING THE EXHAUST SMOKE COLOUR...129

1. Checking with tool G1...129

2. Checking with tool G2...129

REMOVAL OF VALVES COVER...131

ADJUSTING VALVE CLEARANCE...133

MEASURING COMPRESSION PRESSURE...136

TESTING AND ADJUSTING FUEL INJECTION TIMING...138

Test...138

Adjustment procedure...140

CHECKING ENGINE OIL PRESSURE...142

CHECKING AND REGULATING PRESSURE IN THE HYDRAULIC CIRCUITS...143

CHECKING AND CALIBRATING PRESSURE IN THE SECONDARY VALVES...145

1. Preparing the machine...145

2. Checking revolving frame rotational pressure...145

3. Adjusting general valve for revolving frame rotation and blade circuit...146

4. Checking boom, arm, bucket, boom swing and travel pressure...146

5. Adjusting secondary valve for boom, arm, bucket, boom swing and travel...147

6. Checking Unloading pressure...147

CHECKING AND ADJUSTING THE LS (Load Sensing) VALVE...148

1. Measuring DPLS differential pressure...148

2. With analog pressure gauge...149

3. Adjusting the valve...149

ADJUSTING PC VALVE...150

CHECKING SERVO-CONTROL CIRCUIT PRESSURE...151

1. Checking...151

2. Adjustment...151

CHECKING PPC VALVE DELIVERY PRESSURE...152

CHECKING SOLENOID VALVE OUTPUT PRESSURE...153

ADJUSTING BOOM SAFETY VALVE...154

SAFETY PRESSURE SWITCH CALIBRATION:...155

ADJUSTING PPC VALVE CLEARANCE...156

MEASURING TRAVEL DEVIATION...157

1. Measuring the deviation...157

CHECKING TRAVEL SPEED...158

ANALYSIS OF THE CAUSES OF HYDRAULIC DRIFTS...159

1. Boom test...159

2. Arm test...160

3. Testing the functionality of the boom safety valve...161

4. Bucket test...161

5. Boom swing test...162

8. Blade test...163

9. Swing motor test...164

10. Travel motors...164

METHODS FOR TESTING FOR LEAKAGES INSIDE THE SWIVEL JOINT...165

1. Functionality test...165

2. Identification of defective seal...165

ELIMINATING PRESSURES FROM CIRCUITS...166

MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS...167

TESTING AND ADJUSTING TRACK SHOE TENSION...168

1. Checking...168

2. Adjustment...168

AIR BLEEDING FROM HYDRAULIC CIRCUITS...169

Order for operations...169

1. Bleeding air from pump...169

2. Bleeding air from tank...170

3. Bleeding air from LS circuits...170

4. Bleeding air from hydraulic cylinders...170

5. Bleeding air from swing motors...171

6. Air bleeding from travel motors...171

7. Bleeding air from the revolving frame servocontrol circuit...171

TESTING THE AIR-CONDITIONING UNIT...172

1. Testing the working temperature...172

2. Checking the unit...173

EMPTYING THE AIR-CONDITIONING UNIT...174

30 REMOVAL AND INSTALLATION...175

HOW TO READ THE MANUAL...177

PRECAUTIONS TO BE TAKEN WHILE WORKING...178

SPECIAL TOOLS...179

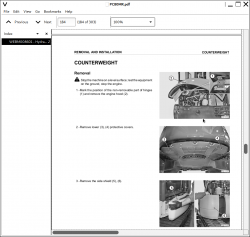

COUNTERWEIGHT...183

Removal...183

Installation...184

INJECTION PUMP...185

Removal...185

Installation...187

ENGINE HEAD...188

Removal...188

Installation...192

PUMP GROUP...193

Removal...193

Installation...195

GEAR-PUMP...196

Installation...196

ENGINE - PUMPS...197

Installation...201

COMPLETE RADIATOR AND AIR CONDITIONING CONDENSER...202

Removal...202

Installation...204

SWING MOTOR AND REDUCTION GEAR...205

Removal...205

Installation...206

SWING MOTOR...207

Removal...207

Installation...207

SWING REDUCTION GEAR...208

SWIVEL JOINT...221

Removal...221

Installation...222

CONTROL VALVE...224

Removal...224

Installation...226

LH PPC VALVE...227

Removal...227

Installation...228

R.H. PPC VALVE...229

Removal...229

Installation...229

EQUIPMENT PPC VALVES...230

TRAVEL PPC VALVE...231

Removal...231

Installation...232

ADDITIONAL EQUIPMENT AND BOOM SWING PPC VALVE...234

Removal...234

Installation...234

BLADE PPC VALVE...235

Removal...235

Installation...235

ACCELERATOR POTENTIOMETER...236

Removal...236

Installation...236

CONTROLLER...237

Removal...237

Installation...237

SAFETY MICROSWITCH...238

Removal...238

Installation...239

HYDRAULIC OIL TANK...240

Removal...240

Installation...241

FUEL TANK...242

Installation...244

CONTROL MODULES (MACHINE - ENGINE - KOMTRAX)...245

Removal...245

Installation...245

EVAPORATOR UNIT...246

Removal...246

Installation...250

CABIN...251

Removal...251

Installation...255

SWING CIRCLE...256

Removal...256

Installation...256

REVOLVING FRAME...257

Removal...257

Installation...259

EQUIPMENT (1-piece boom version)...260

Removal...260

Installation...262

BOOM CYLINDER (For 1-piece boom)...263

Removal...263

Installation...264

ARM CYLINDER...265

Removal...265

Installation...266

BUCKET CYLINDER...267

Removal...267

Installation...268

BOOM SWING CYLINDER...269

Removal...269

Installation...270

BLADE CYLINDER...271

Removal...271

Installation...271

CYLINDERS...272

SWING SUPPORT...277

Removal...277

Installation...279

STEEL SHOES...280

Removal...280

Installation...280

RUBBER SHOES...281

Removal...281

Installation...281

SPROCKET...282

Removal...282

Installation...282

COMPLETE TRAVEL ASSEMBLY...283

Removal...283

Installation...284

TRACK SHOE IDLER...285

BUMPER SPRING...288

LOWER IDLER ROLLERS...291

90 OTHER...295

HYDRAULIC CIRCUIT (STANDARD VERSION)...297

ELECTRICAL DIAGRAM...299