Komatsu Hydraulic Excavators PC88MR Repair Service Manual + Operation Maintenance Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavators PC88MR, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavators PC88MR workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

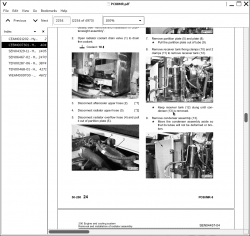

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 4,973 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

CEBM007301 - Hydraulic Excavator PC88MR-8 Shop Manual.pdf

SEN04329-11 - Hydraulic Excavator PC88MR-8 Shop Manual.pdf

SEN06467-02 - Hydraulic Excavator PC88MR-10 Shop Manual.pdf

TEN00287-06 - Hydraulic Excavator PC88MR-8 Operation & Maintenance Manual.pdf

TEN00468-01 - Hydraulic Excavator PC88MR-8 Operation & Maintenance Manual.pdf

WEAM009700 - Hydraulic Excavator PC80MR-3 Operation & Maintenance Manual.pdf

CEAM021202 - Hydraulic Excavator PC88MR-8 Operation & Maintenance Manual.pdf

MAIN SECTIONS

Cover...1

00 Index and foreword ...3

Index ...4

Foreword, safety and general information ...15

Important safety notice ...15

How to read the shop manual ...22

Explanation of terms for maintenance standard ...24

Handling equipment of fuel system devices ...26

Handling of intake system parts ...27

Handling of hydraulic equipment ...28

Method of disconnecting and connecting of push-pull type coupler ...30

Handling of electrical equipment ...33

How to read electric wire code ...41

Precautions when performing operation ...44

Practical use of KOMTRAX ...49

Standard tightening torque table ...50

List of abbreviation ...56

Conversion table ...61

01 Specification ...67

Table of contents ...68

Specifications ...69

Specification drawing ...69

Working range drawings ...70

Specifications ...71

Weight table ...75

Table of fuel, coolant, and lubricants ...77

10 Structure and function ...79

Table of contents ...80

Engine and cooling system ...81

Engine related parts ...81

PTO ...83

VFT ...84

EGR system piping drawing ...88

EGR system circuit diagram ...90

EGR valve ...91

EGR cooler ...93

KCCV layout drawing ...95

KCCV ventilator ...98

KDOC muffler ...100

Cooling system ...102

Power train ...105

Power train system ...105

Swing circle ...107

Swing machinery ...109

Undercarriage and frame ...111

Track frame ...111

Idler cushion ...113

Hydraulic system ...114

Hydraulic component layout ...114

Valve control ...116

Hydraulic tank ...118

CLSS ...122

Main pump ...126

Control valve ...138

Swing motor ...186

Travel motor ...197

Work equipment and swing PPC valve ...208

Travel PPC valve ...215

Blade PPC valve ...221

Boom swing PPC valve ...223

Solenoid valve ...225

Multi-control valve ...229

Center swivel joint ...230

Accumulator ...231

Work equipment ...233

Work equipment ...233

Work equipment shim ...234

Bucket play adjustment shim ...235

Cab and its attachments ...236

Cab mount and cab tipping stopper ...236

ROPS cab ...238

Electrical system ...240

Electrical control system ...240

Machine monitor system ...285

KOMTRAX system ...307

KOMTRAX terminal ...307

Sensor ...309

20 Standard value tables ...317

Table of contents ...318

Standard service value table ...319

Standard value table for engine ...319

Standard value table for machine ...321

Standard value table for electrical system ...337

30 Testing and adjusting ...343

Table of contents ...344

Related information on testing and adjusting ...345

Tools for testing and adjusting ...345

Sketch of tools for testing and adjusting ...348

Engine and cooling system ...350

Testing engine speed ...350

Testing exhaust gas color ...351

Testing and adjusting valve clearance ...352

Testing compression pressure ...354

Testing blowby pressure ...356

Testing engine oil pressure ...357

Testing fuel pressure ...358

Testing fuel return rate and leakage ...359

Bleeding air from fuel system ...362

Testing fuel circuit for leakage ...364

Handling cylinder cutout mode operation ...365

Handling no-injection cranking operation ...366

Testing and adjusting air conditioner compressor belt tension ...367

Replacing fan belt ...368

Writing compensation values at replacement of injector and engine controller ...370

Power train ...374

Testing swing circle bearing clearance ...374

Undercarriage and frame ...375

Testing and adjusting track tension ...375

Hydraulic system ...376

Releasing remaining pressure from hydraulic circuit ...376

Testing and adjusting oil pressure in work equipment and travel circuits ...378

Testing and adjusting swing and blade circuit oil pressure ...381

Testing oil pressure of control circuit ...384

Testing and adjusting oil pressure in pump PC control circuit ...385

Testing and adjusting oil pressure in pump LS control circuit ...388

Testing outlet pressure of solenoid valve ...391

Testing PPC valve outlet pressure ...392

Adjusting play of work equipment and swing PPC valves ...393

Isolating the parts causing hydraulic drift in work equipment ...394

Testing and adjusting travel deviation ...395

Testing oil leakage ...397

Bleeding air from hydraulic circuit ...401

Cab and its attachments ...404

Testing, cleaning and lubricating slide door rail and roller ...404

Adjusting mirrors ...405

Testing and adjusting hood catcher ...407

Electrical system ...409

Special functions of machine monitor ...409

KOMTRAX terminal start-up procedure ...457

Adjusting rearview camera angle ...461

Handling voltage circuit of engine controller ...463

Handling battery disconnect switch ...464

Testing diodes ...465

Pm clinic ...466

Pm Clinic service ...466

40 Troubleshooting ...475

Table of contents ...476

Related information on troubleshooting ...482

Troubleshooting points ...482

Sequence of events in troubleshooting ...484

Checks before troubleshooting ...486

Inspection procedure before troubleshooting ...488

Preparation for troubleshooting of electrical system ...505

Classification and procedures for troubleshooting ...510

Symptom and troubleshooting numbers ...513

Information in troubleshooting table ...516

Troubleshooting method for open circuit in wiring harness of pressure sensor system ...518

Connector list and layout ...520

Connector contact identification ...529

T-branch box and T-branch adapter table ...567

Fuse location table ...572

Failure codes table ...574

Troubleshooting by failure code (Display of code) ...580

Failure code [879AKA] A/C Recirc Air Temp Sens Open Circuit ...580

Failure code [879AKB] A/C Recirc Air Temp Sens Short ...581

Failure code [879BKA] A/C Fresh Air Temp Sens Open Circuit ...582

Failure code [879BKB] A/C Fresh Air Temp Sens Short Circuit ...583

Failure code [879CKA] Ventilating Sensor Open Circuit ...584

Failure code [879CKB] Ventilating Sensor Short Circuit ...585

Failure code [879DKZ] Sunlight Sensor Open or Short Circuit ...586

Failure code [879EMC] Ventilation Damper Malfunction ...587

Failure code [879FMC] Air Mix Damper Malfunction ...588

Failure code [879GKX] Refrigerant Press Input Sig Out of Range ...589

Failure code [989L00] Engine Controller Lock Caution 1 ...590

Failure code [989M00] Engine Controller Lock Caution 2 ...591

Failure code [989N00] Engine Controller Lock Caution 3 ...592

Failure code [A900FR] Abrupt Engine Stop by Auto Idle Stop 3 ...593

Failure code [A900N6] Abrupt Engine Stop by Auto Idle Stop 1 ...594

Failure code [A900NY] Abrupt Engine Stop by Auto Idle Stop 2 ...595

Failure code [AB00KE] Charge Voltage Low ...596

Failure code [B@BAZG] Eng Oil Press Low ...598

Failure code [B@BCNS] Eng Water Overheat ...599

Failure code [CA115] Eng Ne and Bkup Speed Sens Error ...600

Failure code [CA122] Charge Air Pressure Sensor High Error ...601

Failure code [CA123] Charge Air Pressure Sensor Low Error ...603

Failure code [CA131] Throttle Sensor High Error ...605

Failure code [CA132] Throttle Sensor Low Error ...607

Failure code [CA144] Coolant Temperature Sensor High Error ...609

Failure code [CA145] Coolant Temperature Sensor Low Error ...611

Failure code [CA153] Charge Air Temperature Sensor High Error ...613

Failure code [CA154] Charge Air Temperature Sensor Low Error ...615

Failure code [CA187] Sensor 2 Supply Voltage Low Error ...617

Failure code [CA221] Ambient Pressure Sensor High Error ...619

Failure code [CA222] Ambient Pressure Sensor Low Error ...621

Failure code [CA227] Sensor 2 Supply Voltage High Error ...623

Failure code [CA234] Engine Overspeed ...624

Failure code [CA238] NE Speed Sensor Supply Voltage Error ...625

Failure code [CA239] NE Speed Sensor Supply Voltage High Error ...626

Failure code [CA271] PCV1 Short Circuit Error ...627

Failure code [CA272] PCV1 Open Circuit Error ...628

Failure code [CA322] Injector #1 (L#1) Open or Short Circuit ...629

Failure code [CA324] Injector #3 (L#3) Open or Short Circuit ...631

Failure code [CA331] Injector #2 (L#2) Open or Short Circuit ...633

Failure code [CA332] Injector #4 (L#4) Open or Short Circuit ...635

Failure code [CA343] Engine Controller Internal Failure ...637

Failure code [CA351] Injectors Drive Circuit Error ...638

Failure code [CA352] Sensor1 Supply Voltage Low Error ...639

Failure code [CA356] MAF Sensor High Error ...641

Failure code [CA357] MAF Sensor Low Error ...643

Failure code [CA386] Sensor1 Supply Voltage High Error ...645

Failure code [CA435] Engine Oil Pressure SW Error ...646

CEBM007301 - PC88MR-8 sn A90001-up...0

CONTENTS...2

REVISED PAGES...3

SAFETY...19

Safety Notice...19

Important Safety Notice...19

General Precautions...19

Preparations For Work...19

Precautions During Work...19

GENERAL...22

HOW TO READ THE SHOP MANUAL...23

Volumes...23

Distribution And Updating...23

Filing Method...23

Revised Edition Mark...23

Revisions...23

Symbols...23

HOISTING INSTRUCTIONS...24

Hoisting...24

Wire Ropes...24

PUSH PULL COUPLER...25

Type 1...25

Disconnection...25

Connection...25

Type 2...26

Disconnection...26

Connection...26

Type 3...27

Disconnection...27

Connection...27

EXPLANATION OF MAINTENANCE STANDARD TERMS...28

STANDARD TIGHTENING TORQUE...30

Bolts And Nuts...30

Tightening Torque Of Hose Nuts...31

Tightening Torque Of Split Flange Bolts...31

Tightening Torque For Flared Nuts...31

Tightening Torques For O-ring Boss Piping Joints...32

COVER...1

INTRODUCTION...3

FOREWORD...4

SAFETY INFORMATION...5

Signal Words...5

Other Signal Words...5

Safety Labels...6