Komatsu Hydraulic Excavator PC95 Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC95, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC95 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 810 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

WEBMPC9500 - Hydraulic Excavator PC95-1 Shop Manual.pdf

EEAM004900 - Hydraulic Excavator PC95-1 Operation & Maintenance Manual.pdf

FGAMPC9510 - Hydraulic Excavator PC95-1 Operation & Maintenance Manual.pdf

WEAMPC9501 - Hydraulic Excavator PC95-1 Operation & Maintenance Manual.pdf

MAIN SECTIONS

MAIN MENU...0

COVER PAGE...1

CONTENTS...3

10 STRUCTURE AND FUNCTION...16

P.T.O...17

POWER TRAIN...18

FINAL DRIVE - SPROCKET...19

TRACK FRAME...20

IDLER AND RECOIL SPRING...21

CARRIER ROLLER...22

TRACK ROLLER...22

TRACK SHOE...23

SWING CIRCLE...24

SWING MACHINERY...25

CHECK VALVE AND OIL COOLER SAFETY BY-PASS...26

HYDRAULIC CIRCUIT DIAGRAM...27

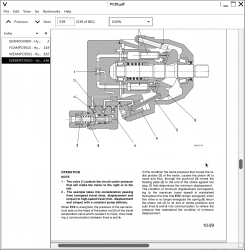

MAIN HYDRAULIC PUMP...28

PUMP DRIVE...29

SUMMATION HORSEPOWER CONTROL...30

3 CIRCUIT CONTROL VALVE...33

MODE-SYSTEM...35

AUXILIARY PUMP...36

CONTROL VALVE (Ports)...37

CONTROL VALVE (Valve)...39

SWING MOTOR...40

SWING MOTOR RELIEF VALVE...41

CENTER SWIVEL JOINT...42

TRAVEL MOTOR...43

TRAVEL ACCELERATION VALVE...44

SERVOCONTROL FEED UNIT...45

SWING MOTOR BRAKING CIRCUIT SELECTOR VALVE...47

ACCUMULATOR...48

R.H. PPC VALVE...49

L.H. PPC VALVE...50

TRAVEL PPC VALVE...51

2nd BOOM PPC VALVE...52

BOOM SWING PPC VALVE...53

BLADE PPC VALVE...54

BLADE SAFETY VALVE...55

SOLENOID VALVES...56

ELECTRICAL CIRCUIT DIAGRAM (Engine Line)...58

ELECTRICAL CIRCUIT DIAGRAM (Solenoid Valve)...60

ELECTRICAL CIRCUIT DIAGRAM (Light Line)...62

20 TESTING AND ADJUSTMENTS...64

NORMAL OR STANDARD TECHNICAL DATA...65

EQUIPMENT FOR TESTING, ADJUSTING, AND IDENTIFYING FAULTS...82

MEASURING THE ENGINE SPEED...84

VALVE CLEARANCE ADJUSTMENT...85

MEASUREMENT OF COMPRESSION PRESSURE...86

CHECKING AND TIGHTENING THE FAN-BELT...87

ADJUSTING THE STROKE OF THE ACCELERATOR LEVER...88

ADJUSTING PPC VALVES CLEARANCE...89

ADJUSTING THE SAFETY MICROSWITCH...91

CENTRING THE STROKE OF THE BLADE CONTROL LEVER...91

MEASURING THE SWING CIRCLE AXIAL CLEARANCE...92

TESTING AND ADJUSTING TRACK-SHOE TENSION...93

BLEEDING AIR - RELEASING RESIDUAL PRESSURE...94

Bleeding air from pumps P1 and P2...94

Bleeding air from the PPC valves circuit...94

Bleeding air from the cylinders...95

Releasing residual pressure from the circuits...95

CHECKING AND REGULATING PRESSURE IN THE HYDRAULIC CIRCUITS...96

CHECKING THE INTERVENTION POINT OF THE SUMMATION HORSEPOWER CONTROL...102

CHECKING THE INITIAL HORSEPOWER CONTROL POINT FOR THE 3-CIRCUIT CONTROL VALVE...103

CHECKING AND ADJUSTING PRESSURES IN THE SERVOCONTROL SUPPLY UNITS...104

ADJUSTING THE MAIN SAFETY VALVE OF PUMP P4...105

MEASURING PUMP DELIVERY...106

MEASURING TRAVEL DEVIATION...107

ADJUSTING THE MAXIMUM SPEED OF THE TRAVEL MOTORS...108

CHECKING THE CORRECT FUNCTIONING OF THE TRAVEL ACCELERATION VALVE...110

TESTING FOR INTERNAL OIL LEAKAGE IN THE TRAVEL MOTORS...111

ADJUSTING BOOM AND ARM SAFETY VALVES...112

ADJUSTING 2nd BOOM SAFETY VALVES...113

MEASURING THE INITIAL INTERVENTION POINT OF THE OVERLOAD SENSOR...114

ADJUSTING THE VALVE THAT CONTROLS THE CLOSING SPEED OF THE 2nd BOOM...115

MEASUREMENT OF INTERNAL OIL LEAKAGES IN THE SWING MOTOR...116

CHECKING FOR LEAKAGES INSIDE THE SWIVEL JOINT...117

ANALYSIS OF THE CAUSES OF HYDRAULIC DRIFTS...119

1. Boom test...119

2. Arm test...119

3. Testing the functionality of the boom and arm safety valve...120

4. 2nd boom test...121

5. Testing the functionality of the 2nd boom safety valves...122

6. Bucket test...122

7. Boom swing test...123

8. Blade test...123

9. Swing motor test...124

10. Testing the travel motors...125

TROUBLESHOOTING...128

PROCEDURES TO FOLLOW WHILE TROUBLESHOOTING...129

RULES TO BE OBSERVED WHEN WORKING ON HYDRAULIC CIRCUITS OR EQUIPMENT...130

TABLE OF FAILURE MODES AND CAUSES TESTS TO BE CARRIED OUT BEFORE TROUBLESHOOTING...132

EXCESSIVE TRAVEL DEVIATION...133

THE MACHINE DEVIATES EXCESSIVELY AT THE COMMENCEMENT OF TRAVEL...137

WORK EQUIPMENT, REVOLVING FRAME SWING AND TRAVEL ARE SLOW OR WITHOUT POWER...138

WORK EQUIPMENT, REVOLVING FRAME SWING AND TRAVEL MECHANISMS FUNCTION INTERMITTENTLY...139

THE REVOLVING FRAME SWING SPEED IS SLOW IN BOTH DIRECTIONS...140

THE REVOLVING FRAME SWING SPEED IS SLOW IN ONE DIRECTION, AND DOES NOT BRAKE PROPERLY ON THAT SIDE...141

DIFFICULTIES WITH RAISING OR LOWERING THE BOOM...142

EXCESSIVE RESPONSE TIME FOR THE BOOM, ARM AND BUCKET...143

BOOM SLOW TO RISE - ARM SLOW TO CLOSE...145

THE SERVOCONTROL SUPPLY GROUP DOES NOT FUNCTION OR THE PRESSURE IS UNSTABLE ...146

THE CONTROL LEVERS MOVE, BUT EQUIPMENT MOVEMENTS ARE INCOMPLETE OR HAVE NO EFFECT...147

SPEEDS DO NOT CHANGE IF THE WORKING MODE SELECTOR IS POSITIONED ON E...149

ABNORMAL NOISES IN THE PUMPS...149

ENGINE LOSES POWER OR STALLS DURING WORK...150

30 DISASSEMBLY AND ASSEMBLY...151

HOW TO READ THE MANUAL...153

PRECAUTIONS TO BE TAKEN WHEN WORKING...154

SPECIAL TOOLS...155

STARTER MOTOR...157

REMOVAL AND INSTALLATION...157

ALTERNATOR...158

REMOVAL AND INSTALLATION...158

NOZZLE HOLDER...159

REMOVAL AND INSTALLATION...159

AIR FILTER GROUP...160

REMOVAL AND INSTALLATION...160

MUFFLER...161

REMOVAL...161

INSTALLATION...162

ENGINE HOOD...163

REMOVAL AND INSTALLATION...163

FIXED HOOD...164

REMOVAL...164

INSTALLATION...165

SEAT...166

REMOVAL AND INSTALLATION...166

CABIN...167

REMOVAL AND INSTALLATION...167

COUNTERWEIGHT...168

REMOVAL AND INSTALLATION...168

RADIATOR...169

REMOVAL AND INSTALLATION...169

HYDRAULIC OIL COOLER...170

REMOVAL AND INSTALLATION...170

HEATING FAN...171

REMOVAL...171

INSTALLATION...172

FUEL TANK...173

REMOVAL AND INSTALLATION...173

HYDRAULIC OIL TANK...174

REMOVAL AND INSTALLATION...174

ENGINE-PUMP GROUP...175

REMOVAL...175

INSTALLATION...177

PUMP GROUP...178

REMOVAL AND INSTALLATION...178

HYDRAULIC PUMP...179

DISASSEMBLY...179

ASSEMBLY...186

GEAR-PUMP...192

REMOVAL AND INSTALLATION...192

DISASSEMBLY...193

ASSEMBLY...196

ENGINE-PUMP COUPLING JOINT...201

REMOVAL AND INSTALLATION...201

SWIVEL JOINT...202

REMOVAL AND INSTALLATION...202

SWING MOTOR...203

REMOVAL AND INSTALLATION...203

SWING MACHINERY...204

REMOVAL AND INSTALLATION...204

DISASSEMBLY...205

ASSEMBLY...213

REVOLVING FRAME...224

REMOVAL...224

INSTALLATION...225

SWING CIRCLE...226

REMOVAL AND INSTALLATION...226

TRAVEL MOTOR...227

REMOVAL AND INSTALLATION...227

TRACK SHOES...228

REMOVAL AND INSTALLATION...228

SPROCKET...229

REMOVAL AND INSTALLATION...229

FINAL DRIVE...230

REMOVAL AND INSTALLATION...230

DISASSEMBLY...231

ASSEMBLY...237

IDLER AND RECOIL SPRING...247

REMOVAL AND INSTALLATION...247

IDLER...248

DISASSEMBLY AND ASSEMBLY...248

RECOIL SPRING AND CYLINDER...249

DISASSEMBLY AND ASSEMBLY...249

TRACK ROLLER...250

REMOVAL AND INSTALLATION...250

CARRIER ROLLER...251

REMOVAL AND INSTALLATION...251

R.H. PPC VALVE (BOOM - BUCKET)...252

REMOVAL AND INSTALLATION...252

L.H. PPC VALVE (ARM-SWING)...253

REMOVAL AND INSTALLATION...253

BLADE PPC VALVE...254

REMOVAL AND INSTALLATION...254

PPC VALVE (For travel, boom swing, 2-piece boom)...255

REMOVAL AND INSTALLATION...255

SERVOCONTROL FEED UNIT...256

REMOVAL AND INSTALLATION...256

CONTROL VALVE...257

REMOVAL AND INSTALLATION...257

BOOM CYLINDER...258

REMOVAL AND INSTALLATION...258

BOOM CYLINDER (For 2-piece boom)...259

REMOVAL...259

INSTALLATION...260

2-PIECE BOOM CYLINDER...261

REMOVAL...261

INSTALLATION...262

ARM CYLINDER...263

REMOVAL AND INSTALLATION...263

BUCKET CYLINDER...264

REMOVAL AND INSTALLATION...264

BOOM SWING CYLINDER...265

REMOVAL AND INSTALLATION...265

BLADE CYLINDER...266

REMOVAL AND INSTALLATION...266

WORK EQUIPMENT CYLINDERS...267

DISASSEMBLY...267

ASSEMBLY...268

OVERLOAD SENSOR...272

REMOVAL AND INSTALLATION...272

WORK EQUIPMENT (For the boom)...273

REMOVAL AND INSTALLATION...273

WORK EQUIPMENT (2-piece boom version)...274

REMOVAL...274

INSTALLATION...275

BUCKET...276

REMOVAL AND INSTALLATION...276

ARM...277

REMOVAL...277

INSTALLATION...279

2-PIECE BOOM...280

REMOVAL...280

INSTALLATION...281

BOOM...282

REMOVAL AND INSTALLATION...282

BOOM (2-piece boom version)...283

REMOVAL...283

INSTALLATION...284

SWING BRACKET...285

REMOVAL AND INSTALLATION...285

BLADE...286

REMOVAL AND INSTALLATION...286

40 MAINTENANCE STANDARD...287

P.T.O...288

TRAVEL MACHINERY...289

SPROCKET...290

TRACK FRAME AND RECOIL SPRING...291

IDLER...292

CARRIER ROLLER...293

TRACK ROLLER...294

TRACK SHOE...295

SWING CIRCLE...296

SWING MACHINERY...297

CHECK VALVE AND OIL COOLER SAFETY BY-PASS...298

PUMP DRIVE...299

SUMMATION HORSEPOWER CONTROL - MODE SYSTEM...300

AUXILIARY PUMP...301

CONTROL VALVE...302

SWING MOTOR RELIEF VALVE...303

TRAVEL MOTOR...304

SERVOCONTROL FEED UNIT...305

L.H. AND R.H. PPC VALVE...306

2nd BOOM, R.H. TRAVEL, L.H. TRAVEL AND BOOM SWING PPC VALVE...307

BLADE PPC VALVE...308

BLADE SAFETY VALVE...309

CYLINDERS...310

WORK EQUIPMENT (1 - piece boom)...312

WORK EQUIPMENT (2 - piece boom)...314

MAIN MENU...0

CONTENTS ...14

FOREWORD...2

SAFETY INFORMATION ...4

INTRODUCTION ...6

PERMITTED USES ...6

MAIN FEATURES ...6

RUNNING IN THE MACHINE ...6

SUMMARY OF PICTOGRAMS ...8

LOCATION OF MACHINE COMPONENT IDENTIFICATION PLATES ...11

SERIAL NUMBERS AND ADDRESS OF DEALER ...12

POSITION AND CONTENTS OF <<CE>> PLATE ...13

SAFETY AND ACCIDENT PREVENTION...21

1. SAFETY MEASURES ...22

1.1 GENERAL PRECAUTIONS ...22

1.2 SAFETY DEVICES ...22

1.3 PERSONAL PROTECTIVE CLOTHING AND EQUIPMENT ...22

1.4 UNAUTHORISED MODIFICATIONS ...23

1.5 LEAVING THE DRIVING SEAT ...23

1.6 ENTERING AND LEAVING THE MACHINE ...24

1.7 PREVENTION OF FUEL AND OIL FIRES ...24

1.8 PREVENTION OF BURNS AND SCALDING ...25

1.9 PREVENTION OF ASBESTOS DUST CONTAMINATION ...26

1.10 PREVENTION OF INJURY BY WORK EQUIPMENT ...26