Komatsu Hydraulic Excavator PC95R Repair Service Manual

Komatsu Hydraulic Excavator PC95R Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC95R, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC95R workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,465 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

WEBM001700 - Hydraulic Excavator PC95R-2 Shop Manual.pdf

WEBM001701 - Hydraulic Excavator PC95R-2 Shop Manual.pdf

WEBM001702 - Hydraulic Excavator PC95R-2 Shop Manual.pdf

WEAM001504 - Hydraulic Excavator PC95R-2 Operation & Maintenance Manual.pdf

WEAM002900 - Hydraulic Excavator PC95R-2 Operation & Maintenance Manual.pdf

MAIN SECTIONS

COVER...1

CONTENTS...3

REVISED PAGES...5

SAFETY...7

FOREWORD...9

HOW TO READ THE SHOP MANUAL...10

HOISTING INSTRUCTIONS...11

STANDARD TIGHTENING TORQUE...12

COATING MATERIALS...14

ELECTRIC WIRE CODE...15

WEIGHT TABLE...16

TABLE OF OIL AND COOLANT QUANTITIES...17

CONVERSION TABLE...19

10.STRUCTURE AND FUNCTION...27

P.T.O...28

POWER TRAIN...29

TRACK FRAME...31

IDLER AND RECOIL SPRING...32

CARRIER ROLLER - TRACK ROLLER...33

TRACK SHOE...34

SWING CIRCLE...35

SWING MACHINERY...36

FINAL DRIVE...37

HYDRAULIC DIAGRAM STANDARD...39

HYDRAULIC DIAGRAM WITH 2-PIECE BOOM...41

HYDRAULIC PUMP...42

9-SPOOL CONTROL VALVE (STANDARD)...68

10-SPOOL CONTROL VALVE (STANDARD 2-PIECE BOOM)...70

CONTROL VALVE...72

BLADE VALVE...77

L.H. AND R.H. TRAVEL VALVE BOOM VALVE...78

ARM VALVE BUCKET VALVE...79

BOOM SWING VALVE (2-PIECE BOOM VALVE) ATTACHMENT VALVE...80

CONTROL VALVE...81

SWING MOTOR...98

SWIVEL JOINT...104

TRAVEL MOTOR...106

CYLINDERS...108

2-PIECE BOOM...109

SERVOCONTROL FEED UNIT...110

ACCUMULATOR...115

SHUTTLE VALVE...116

PPC VALVE...117

BOOM AND ARM SAFETY VALVE...127

BLADE SAFETY VALVE...128

2-PIECE BOOM SAFETY VALVE...129

OVERLOAD SENSOR SWITCH...130

SOLENOID VALVES...131

AIR-CONDITIONING UNIT...133

ELECTRICAL DIAGRAM (1/5)...135

ELECTRICAL DIAGRAM (2/5)...137

ELECTRICAL DIAGRAM (3/5)...139

ELECTRICAL DIAGRAM (4/5)...141

ELECTRICAL DIAGRAM (5/5)...143

20.TESTING AND ADJUSTMENTS...145

NORMAL OR STANDARD TECHNICAL DATA...146

SPECIAL TOOLS...160

MEASURING THE ENGINE SPEED...161

ADJUSTING VALVE CLEARANCE...162

MEASURING COMPRESSION PRESSURE...163

TESTING AND ADJUSTING FUEL INJECTION TIMING...164

TESTING AND ADJUSTING FAN BELT TENSION...166

CHECKING AND TIGHTENING THE COMPRESSOR FAN-BELT...167

ADJUSTING THE STROKE OF THE ACCELERATOR LEVER...168

ADJUSTING THE SAFETY MICROSWITCH...169

MEASURING THE SWING CIRCLE AXIAL CLEARANCE...170

TESTING AND ADJUSTING TRACK-SHOE TENSION...171

AIR BLEEDING FROM HYDRAULIC CIRCUITS...172

RELEASING RESIDUAL PRESSURE FROM THE CIRCUITS...174

CHECKING AND REGULATING PRESSURE IN THE HYDRAULIC CIRCUITS...175

TESTING AND SETTING OF MAIN VALVES...176

ADJUSTING PC VALVE...178

MEASURING LS DIFFERENTIAL PRESSURE AND ADJUSTING LS VALVE...179

CHECKING AND ADJUSTING PRESSURES IN THE SERVOCONTROL FEED UNIT...181

MEASURING PUMPS DELIVERY AND FLOW CONTROL STARTING POINT PUMP P1...182

MEASURING TRAVEL DEVIATION...183

ADJUSTING THE MAXIMUM SPEED OF THE TRAVEL MOTORS...184

MEASURING INNER OIL LEAKAGE OF TRAVEL MOTOR...185

ADJUSTING BOOM AND ARM SAFETY VALVES...186

ADJUSTING 2nd BOOM SAFETY VALVES...187

MEASURING AND SETTING OF PRESSURE SWITCH SIGNAL OVERLOAD OPERATION...188

MEASUREMENT OF INTERNAL OIL LEAKAGES IN THE SWING MOTOR...189

CHECKING FOR LEAKAGES INSIDE THE SWIVEL JOINT...190

ANALYSIS OF THE CAUSES OF HYDRAULIC DRIFTS...192

TESTING THE AIR-CONDITIONING UNIT...199

EMPTYING THE AIR-CONDITIONING UNIT...201

30.REMOVAL AND INSTALLATION...203

HOW TO READ THE MANUAL...205

PRECAUTIONS TO BE TAKEN WHEN WORKING...206

SPECIAL TOOLS...207

STARTER MOTOR...209

ALTERNATOR...210

AIR-CONDITIONING UNIT COMPRESSOR...211

INJECTION PUMP...213

INJECTION NOZZLE...217

THERMOSTAT...218

MUFFLER...219

CYLINDER HEAD...220

SEAT...224

CABIN...225

ENGINE HOOD...228

CONDENSER UNIT...229

FRONT HOOD...231

HEATING FAN UNIT...232

AIR CONIDTIONING FAN UNIT...234

RADIATOR...237

FUEL TANK...239

HYDRAULIC OIL TANK...241

ENGINE-PUMP GROUP...243

PUMP GROUP...246

ENGINE-PUMP COUPLING JOINT...247

GEAR-PUMP...248

SWIVEL JOINT...249

SWING MOTOR...250

SWING MACHINERY...251

CONTROL VALVE...267

REVOLVING FRAME...268

COUNTERWEIGHT...270

SWING CIRCLE...271

TRACK SHOES...272

SPROCKET ASSEMBLY...273

FINAL DRIVE...274

IDLER AND RECOIL SPRING ASSEMBLY...287

IDLER...288

RECOIL SPRING GROUP AND CYLINDER...289

TRACK ROLLER...290

CARRIER ROLLER...291

R.H. PPC VALVE (BOOM-BUCKET)...292

L.H. PPC VALVE (ARM-SWING)...294

BLADE PPC VALVE...296

TRAVEL PEDAL CONTROL...297

BOOM SWING PEDAL CONTROL...298

1st BOOM PEDAL CONTROL...299

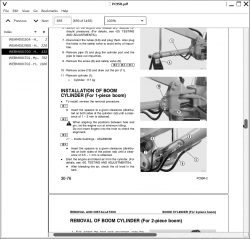

BOOM CYLINDER (For 1-piece boom)...300

BOOM CYLINDER (For 2-piece boom)...301

2nd BOOM CYLINDERS...303

ARM CYLINDER...305

BUCKET CYLINDER...306

BOOM SWING CYLINDER...307

BLADE CYLINDER...308

WORK EQUIPMENT CYLINDERS...309

WORK EQUIPMENT (For 1-piece boom)...314

WORK EQUIPMENT (For 2-piece boom)...315

BUCKET...317

ARM...318

2nd BOOM...321

BOOM (For 1-piece boom)...323

BOOM (For 2-piece boom)...324

SWING SUPPORT...326

BLADE...327

40.STANDARD MAINTENANCE...329

P.T.O...330

SWING CIRCLE...331

TRACK FRAME...332

IDLER...333

CARRIER ROLLER...334

TRACK ROLLER...335

TRACK SHOE...336

SPROCKET...337

SWING MACHINERY...338

FINAL DRIVE...340

HYDRAULIC PUMP...341

CONTROL VALVE...342

SWING MOTOR...351

SWIVEL JOINT...352

TRAVEL MOTOR...353

SERVOCONTROL FEED UNIT...355

PPC VALVES...356

SAFETY VALVE...358

CYLINDERS...360

WORK EQUIPMENT...362

MAIN MENU...0

COVER...1

1.1 FORWORD...4

1.2 INFORMATION ON SAFETY...5

1.3 INTRODUCTION...7

1.3.1 INTENDED USES...7

1.3.2 IMPROPER OR UNAUTHORIZED USE...7

1.3.3 MAIN CHARACTERISTICS...8

1.3.4 RUNNING-IN...8

1.4 PRODUCT IDENTIFICATION...9

1.4.1 MACHINE SERIAL NUMBER...9

1.4.2 MACHINE IDENTIFICATION PLATE...9

1.4.3 ENGINE SERIAL NUMBER AND EMISSION LABEL...10

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER...10

1.4.5 SWING REDUCTION GEAR SERIAL NUMBER...11

1.4.6 CAB SERIAL NUMBER...11

1.4.7 SERIAL NUMBERS AND DEALER'S ADDRESS...12

CONTENTS...13

SAFETY AND ACCIDENT PREVENTION...20

2.1 SAFETY PLATES...21

2.1.1 POSITION OF THE SAFETY PLATES...21

2.1.2 POSITION OF THE PICTOGRAMS...37

2.1.3 PICTOGRAMS AND RELEVANT MEANINGS...38

2.1.4 VIBRATIONS TO WHICH THE OPERTOR IS SUBJECTED...40

2.2 GENERAL PRECAUTIONS...41

2.2.1 GENERAL SAFETY RULES...41

2.2.2 SAFETY DEVICES AND GUARDS...41

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS...41

2.2.4 UNATHORIZED MODIFICATIONS...42

2.2.5 LEAVING THE OPERATOR'S SEAT...42

2.2.6 GETTING ON AND OFF THE MACHINE...43

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL...43

2.2.8 PREVENTING BURNS...44

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER...44

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT...45

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT...45

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE...45

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT...45

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE...46

2.3.1 SAFETY ON THE WORK SITE...46

2.3.2 FIRE PREVENTION...46

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB...46

2.3.4 ROOM VENTILATION...47

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS...47

2.3.6 CLEANING THE WINDOWS AND THE REAR VIEW MIRRORS - CHECKING THE WINDSHIELD WIPER BLADES...47

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING...48

2.4.1 STARTING THE ENGINE...48

2.4.2 CHECK THE DIRECTIONS BEFORE STARTING THE MACHINE...48

2.4.3 CHECKS FOR TRAVELING IN REVERSE...48

2.4.4 MOVING THE MACHINE...49

2.4.5 MOVING ON SLOPES...50

2.4.6 WORKING ON SLOPES...51

2.4.7 UNAUTHORIZED OPERATIONS...51

2.4.8 PREVENTING ELECTROCUTION...52

2.4.9 VISIBILITY...53

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES...53

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT...53

2.4.12 WORKING ON LOOSE GROUND...53

2.4.13 PARKING THE MACHINE...54

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES...55

2.5.1 LOADING AND UNLOADING THE MACHINE...55

2.5.2 SHIPPING...55

2.6 BATTERY...56

2.6.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES...56

2.6.2 STARTING WITH BOOSTER CABLES...56

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY...57

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE...58

2.8.1 WARNING PLATES...58

2.8.2 TOOLS...58

2.8.3 PERSONNEL...59

2.8.4 EQUIPMENT...59

2.8.5 WORKING UNDER THE MACHINE...59

2.8.6 KEEPING THE MACHINE CLEAN...59

2.8.7 USE OF THE ENGINE DURING MAINTENANCE...60

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY...60

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION...60

2.8.10 RULES FOR REFUELLING AND ADDING OIL...61

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR...61

2.8.12 USING LAMPS...61

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR...62

2.8.14 PRECAUTIONS CONCERNING THE STARTER...62

2.8.15 PRECAUTIONS CONCERNING HIGH-PRESSURE HOSES...63

2.8.16 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH-PRESSURE SYSTEMS...63

2.8.17 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES...63

2.8.18 COOLING FAN AND FAN BELT...64

2.8.19 WASTE MATERIALS...64

DESCRIPTION AND USE OF THE MACHINE...66

3.1 SAFETY LOCKS...67

3.1.1 MACHINE LOCKS...67

3.2 GENERAL VIEWS...68

3.2.1 FRONT GENERAL VIEW (MONOBOOM)...68

3.2.2 FRONT GENERAL VIEW (TWO-PIECE BOOM)...69

3.2.3 CAB INSIDE GENERAL VIEW...70

3.3 INSTRUMENTS AND CONTROLS...72

3.3.1 INSTRUMENTS, WARNING LIGHTS AND PUSH BUTTONS...72

3.3.2 MACHINE CONTROLS...81

3.4 FUSES AND RELAYS...92

3.4.1 CENTRAL UNIT FUSES AND RELAYS...92

3.4.1.1 CENTRAL UNIT FUSES...93

3.4.1.2 CENTRAL UNIT RELAYS...94

3.4.2 ENGINE LINE FUSES AND RELAYS...95

3.4.2.1 ENGINE LINE FUSES...95

3.4.2.2 ENGINE LINE RELAYS...96

3.5 GUARDS AND DRIVER'S SEAT...97

3.5.1 ENGINE HOOD...97

3.5.2 SIDE COVER...97

3.5.3 CAB...98

3.5.4 VENTILATION AND HEATING...102

3.5.5 SEAT...103

3.5.6 SAFETY BELT...104

3.5.7 EMERGENCY EXIT...104

3.5.8 TECHNICAL DOCUMENTATION CASE...105

3.5.9 FIRE EXTINGUISHER...105

3.5.10 FIRST AID KIT...105

3.6 USE OF THE MACHINE...106

3.6.1 CHECKS BEFORE STARTING THE ENGINE...106

3.6.1.1 VISUAL CHECKS...106

3.6.1.2 DAILY CHECKS...106

3.6.1.3 OPERATIONAL CHECKS...107

3.6.2 STARTING THE ENGINE...108

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES...108

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES...109

3.6.3 WARMING THE ENGINE...110

3.6.4 HEATING THE HYDRAULIC OIL...110

3.6.5 HOW TO MOVE THE MACHINE...110