Komatsu Hydraulic Excavator PC15MR Repair Service Manual (SEBM019002) + Operation & Maintenance Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC15MR-1, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC15MR-1 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 613 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SEAM044900T - Hydraulic Excavator PC15MRX-1 Operation & Maintenance Manual.pdf

SEBM019002 - Hydraulic Excavator PC15MR-1 Shop Manual.pdf

MAIN SECTIONS

COVER...1

CONTENTS...2

01 GENERAL...25

GENERAL ASSEMBLY DRAWING...26

SPECIFICATIONS...27

WEIGHT TABLE...30

LIST OF LUBRICANT AND WATER...32

10 STRUCTURE AND FUNCTION...34

SWING CIRCLE...35

TRACK FRAME, RECOIL SPRING...36

HYDRAULIC EQUIPMENT LAYOUT...37

HYDRAULIC TANK...38

HYDRAULIC PUMP...39

CONTROL VALVE...43

CLSS...51

CENTER SWIVEL JOINT...68

SWING MOTOR...70

TRAVEL MOTOR...72

VALVE CONTROL...78

PPC VALVE...79

PPC LOCK SOLENOID VALVE...83

TRAVEL 2-SPEED SELECTER VALVE...85

ELECTRIC WIRING DIAGRAM...86

MONITOR SYSTEM...88

20 TESTING AND ADJUSTING...91

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS...92

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS...93

STANDARD VALUE TABLE FOR ELECTRICAL PARTS...101

TESTING AND ADJUSTING...103

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING...104

MEASURING ENGINE SPEED...105

MEASURING EXHAUST COLOR...106

ADJUSTING VALVE CLEARANCE...107

MEASURING COMPRESSION PRESSURE...108

TESTING AND ADJUSTING FUEL INJECTION TIMING...109

MEASURING ENGINE OIL PRESSURE...110

TESTING AND ADJUSTING FAN BELT TENSION...111

ADJUSTING FUEL CONTROL LEVER...112

MEASURING SPROCKET WEAR...113

TESTING AND ADJUSTING TRACK SHOE TENSION...114

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT...115

TESTING AND ADJUSTING LS DIFFERENTIAL PRESSURE...117

ADJUSTING PC VALVE SPRING...119

TESTING AND ADJUSTING CONTROL CIRCUIT PRESSURE...120

TESTING PPC LOCK VALVE...121

TESTING PPC VALVE OUTPUT PRESSURE AND SWING HOLDING BRAKE INLET PORT PRESSURE...122

ADJUSTING WORK EQUIPMENT, SWING PPC VALVE...124

TESTING AND ADJUSTING TRAVEL DEVIATION...125

MEASURING OIL LEAKAGE INSIDE WORK EQUIPMENT CYLINDER...126

RELEASING REMAINING PRESSURE FROM HYDRAULIC CIRCUIT...127

RELEASING REMAINING PRESSURE FROM HYDRAULIC TANK...128

PRESSURIZING HYDRAULIC TANK...128

BLEEDING AIR...129

TROUBLESHOOTING...131

POINTS TO REMEMBER WHEN TROUBLESHOOTING...132

SEQUENCE OF EVENTS IN TROUBLESHOOTING...133

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE...134

CHECKS BEFORE TROUBLESHOOTING...142

CONNECTOR TYPES AND MOUNTING LOCATIONS...143

CONNECTOR PIN ALLOCATION DRAWING...144

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...146

METHOD OF USING TROUBLESHOOTING CHARTS...156

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)...158

E-MODE RELATED ELECTRICAL CIRCUIT DIAGRAM...159

E-1 ENGINE DOES NOT START...161

a) WHEN STARTING MOTOR DOES NOT TURN (STARTING SYSTEM)...161

b) WHEN STARTING MOTOR TURNS (ENGINE STOP SOLENOID SYSTEM)...163

E-2 ENGINE DOES NOT STOP...165

E-3 WORK EQUIPMENT DOES NOT MOVE EVEN WHEN WORK EQUIPMENT LOCK LEVER IS CANCELED...166

E-4 WORK EQUIPMENT MOVES EVEN WHEN WORK EQUIPMENT LOCK LEVER IS LOCKED...168

E-5 TRAVEL ALARM DOES NOT SOUND...169

TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE)...170

TABLE OF FAILURE MODES AND CAUSES...171

H-1 SPEEDS OF ALL WORK EQUIPMENT, SWING, TRAVEL ARE SLOW OR LACK POWER...173

H-2 THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS...174

H-3 NO WORK EQUIPMENT, TRAVEL, SWING MOVE...174

H-4 ABNORMAL NOISE GENERATED (FROM AROUND PUMP)...175

H-5 FINE CONTROL ABILITY IS POOR OR RESPONSE IS POOR...175

H-6 BOOM IS SLOW OR LACKS POWER...176

H-7 ARM IS SLOW OR LACKS POWER...176

H-8 BUCKET IS SLOW OR LACKS POWER...177

H-9 BOOM SWING IS SLOW OR LACKS POWER...177

H-10 BLADE IS SLOW OR LACKS POWER...178

H-11 BOOM, ARM, BUCKET DO NOT MOVE (BOOM SWING, BLADE, TRAVEL AND SWING ARE NORMAL)...178

H-12 EXCESSIVE HYDRAULIC DRIFT (BOOM, ARM, BUCKET, BOOM SWING, BLADE)...179

a) BOOM, BUCKET, BOOM SWING, BLADE...179

b) ARM...179

H-13 EXCESSIVE TIME LAG (ENGINE AT LOW IDLING)...179

a) BOOM, ARM...179

b) BUCKET...179

H-14 IN COMPOUND OPERATIONS, WORK EQUIPMENT WITH LARGER LOAD IS SLOW...180

H-15 TRAVEL DEVIATION...181

a) DEVIATION IN NORMAL TRAVEL...181

b) DEVIATION WHEN STARTING...181

H-16 TRAVEL SPEED IS SLOW OR LACKS POWER...182

H-17 STEERING DOES NOT TURN EASILY...182

H-18 TRAVEL SPEED DOES NOT SWITCH...182

H-19 TRAVEL DOES NOT MOVE (ONE SIDE ONLY)...183

H-20 SWING SPEED IS SLOW OR LACKS POWER...183

a) SPEED IS SLOW OR LACKS POWER IN BOTH DIRECTIONS...183

b) SPEED IS SLOW OR LACKS POWER IN ONE DIRECTION ONLY...183

H-21 DOES NOT SWING...184

a) DOES NOT SWING IN EITHER DIRECTION...184

b) DOES NOT SWING IN ONE DIRECTION ONLY...184

H-22 SWING ACCELERATION IS POOR...185

a) ACCELERATION IS POOR IN BOTH DIRECTIONS...185

b) ACCELERATION IS POOR IN ONE DIRECTION ONLY...185

H-23 EXCESSIVE OVERRUN WHEN STOPPING SWING...186

a) OVERRUN WHEN STOPPING IS EXCESSIVE IN BOTH DIRECTIONS...186

b) OVERRUN WHEN STOPPING IS EXCESSIVE IN ONE DIRECTION ONLY...186

H-24 EXCESSIVE SHOCK WHEN STOPPING SWING (IN ONE DIRECTION ONLY)...186

H-25 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING...187

H-26 EXCESSIVE HYDRAULIC DRIFT OF SWING...187

TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)...188

ELECTRICAL CIRCUIT DIAGRAM FOR M MODE RELATED PARTS...189

M-1 ABNORMALITY IN ENGINE OIL PRESSURE CAUTION LAMP SYSTEM...190

a) LAMP DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED ON...190

b) LAMP LIGHTS UP WHEN ENGINE IS RUNNING (ENGINE OIL PRESSURE IS NORMAL)...190

M-2 ABNORMALITY IN CHARGE CAUTION LAMP SYSTEM...192

a) LAMP DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED ON...192

b) LAMP LIGHTS UP WHEN ENGINE IS RUNNING (BATTERY CHARGE IS NORMAL)...192

M-3 ABNORMALITY IN ENGINE WATER TEMPERATURE CAUTION LAMP SYSTEM...194

a) LAMP DOES NOT STAY LIGHTED UP FOR 3 SECONDS WHEN STARTING SWITCH IS TURNED ON...194

b) LAMP DOES NOT GO OUT AFTER STARTING SWITCH HAS BEEN AN ON FOR 3 SECONDS...194

c) LAMP LIGHTS UP WHEN ENGINE IS RUNNING (ENGINE WATER TEMPERATURE IS NORMAL)...195

M-4 ABNORMALITY IN PREHEATING PILOT LAMP...196

a) LAMP DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED TO HEAT...196

b) LAMP DOES NOT GO OUT WHEN STARTING SWITCH IS AT HEAT AND PREHEATING TIME (APPROX. 18 SEC.) IS COMPLETED...196

c) LAMP LIGHTS UP WHEN STARTING SWITCH IS AT POSITION OTHER THAN HEAT...197

M-5 ABNORMALITY IN FUEL GAUGE SYSTEM...198

a) GAUGE DOES NOT GO UP FROM E WHEN FUEL IS ADDED TO FUEL TANK...198

b) GAUGE DOES NOT GO DOWN FROM F EVEN WHEN THERE IS NO FUEL IN FUEL TANK...198

c) FUEL LEVEL DOES NOT MATCH GAUGE DISPLAY...199

M-6 ABNORMALITY IN SERVICE METER SYSTEM...200

a) SERVICE METER DOES NOT ADVANCE WHEN STARTING SWITCH IS AT ON...200

b) SERVICE METER ADVANCES WHEN STARTING SWITCH IS AT OFF...200

c) PILOT LAMP DOES NOT FLASH WHEN SERVICE METER IS ADVANCING...200

M-7 ABNORMALITY IN NIGHT LIGHTING SYSTEM...202

a) NIGHT LIGHTING DOES NOT LIGHT UP WHEN LAMP SWITCH IS TURNED ON...202

b) NIGHT LIGHTING LIGHTS UP WHEN LAMP SWITCH IS TURNED OFF...202

30 DISASSEMBLY AND ASSEMBLY...204

METHOD OF USING MANUAL...205

PRECAUTIONS WHEN CARRYING OUT OPERATION...206

SPECIAL TOOL LIST...208

ENGINE AND HYDRAULIC PUMP...209

REMOVAL...209

INSTALLATION...213

CENTER SWIVEL JOINT...214

REMOVAL...214

INSTALLATION...214

DISASSEMBLY...215

ASSEMBLY...215

SWING MOTOR...216

REMOVAL...216

INSTALLATION...216

REVOLVING FRAME...217

REMOVAL...217

INSTALLATION...218

SWING CIRCLE...219

REMOVAL...219

INSTALLATION...219

IDLER...220

ASSEMBLY...220

TRACK ROLLER...221

ASSEMBLY...221

RUBBER SHOE...222

REMOVAL...222

INSTALLATION...222

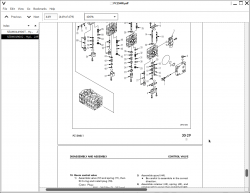

CONTROL VALVE...223

DISASSEMBLY...223

ASSEMBLY...228

HYDRAULIC CYLINDER...235

ASSEMBLY...235

40 MAINTENANCE STANDARD...238

SWING CIRCLE...239

TRACK FRAME, RECOIL SPRING...240

IDLER...241

TRACK ROLLER...242

TRACK SHOE...243

HYDRAULIC PUMP...245

CONTROL VALVE...246

CENTER SWIVEL JOINT...250

SWING MOTOR...251

TRAVEL MOTOR...252

PPC VALVE...253

HYDRAULIC CYLINDER...254

WORK EQUIPMENT...255

90 OTHERS...257

HYDRAULIC CIRCUIT DIAGRAM (VARIABLE GAUGE TYPE)...258

HYDRAULIC CIRCUIT DIAGRAM (FIXED GAUGE TYPE)...259

ELECTRIC CIRCUIT DIAGRAM (SERIAL NO.: 10001-10634)...260

ELECTRIC CIRCUIT DIAGRAM (SERIAL NO.: 10635 AND UP)...261

COVER...1

FOREWORD...2

FOREWORD...3

SAFETY INFORMATION...6

INTRODUCTION...8

DIRECTIONS OF MACHINE...8

PRODUCT INFORMATION...9

MACHINE SERIAL NUMBER PLATE AND ITS LOCATION...9

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION...9

EMISSION CONTROL INFORMATION LABEL...10

SERVICE METER LOCATION...10

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR...10

CONTENTS...11

SAFETY...15

SAFETY INFORMATION...16

POSITION FOR ATTACHING SAFETY LABELS...18

POSITION FOR ATTACHING SAFETY LABELS...19

SAFETY LABELS...20

SAFETY INFORMATION...24

SAFETY RULES...24

IF ABNORMALITIES ARE FOUND...24

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS...24

FIRE EXTINGUISHER AND FIRST AID KIT...24

SAFETY EQUIPMENT...25

KEEP MACHINE CLEAN...25

KEEP OPERATOR'S COMPARTMENT CLEAN...25

LEAVING OPERATOR'S SEAT WITH LOCK...25

HANDRAILS AND STEPS...26

CRUSHING OR CUTTING PREVENTION...26

MOUNTING AND DISMOUNTING...27

NO PERSONS ON ATTACHMENTS...27

BURN PREVENTION...27

FIRE PREVENTION AND EXPLOSION PREVENTION...28

ACTION IF FIRE OCCURS...29

WINDSHIELD WASHER FLUID...29

FALLING OBJECTS,FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION...29

ATTACHMENT INSTALLATION...29

ATTACHMENT COMBINATIONS...30

CAB WIDOW GLASSES...30

UNAUTHORIZED MODIFICATIONS...30

SAFETY AT JOBSITE...30

WORKING ON LOOSE GROUND...30

DISTANCE TO HIGH VOLTAGE CABLES...31

ENSURE GOOD VISIBILITY...31

VENTILATION FOR ENCLOSED AREA...32

SIGNALMAN'S SIGNAL AND SIGNS...32

ASBESTOS DUST HAZARD PREVENTION...32

SAFETY MACHINE OPERATION...33

STARTING ENGINE...33

CHECKS BEFORE STARTING ENGINE...33

SAFETY RULES FOR STARTING ENGINE...34

STARTING ENGINE IN COLD WEATHER...34

OPERATION...35

CHECKS AFTER STARTING ENGINE...35

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS...35

SAFETY RULES FOR TRAVELING...36

TRAVELING ON SLOPES...37

OPERATIONS ON SLOPES...38

PROHIBITED OPERATIONS...38

OPERATIONS ON SNOW...40

PARKING MACHINE...40

TRANSPORTATION...41

LOADING AND UNLOADING...41

SHIPPING THE MACHINE...42

BATTERY...43

BATTERY HAZARD PREVENTION...43

STARTING ENGINE WITH BOOSTER CABLES...44

TOWING...45

SAFETY RULES FOR TOWING...45

LIFTING OBJECTS WITH BUCKET...46