Komatsu Hydraulic Excavator PC20MR Repair Service Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC20MR, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC20MR-2 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 886 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SEBM037001 - Hydraulic Excavator PC20MR-2 Shop Manual.pdf

TEN00101-02 - Hydraulic Excavator GALEO PC20MR-2 Operation & Maintenance Manual.pdf

WEAM007000 - Hydraulic Excavator GALEO PC20MR-2 Operation & Maintenance Manual.pdf

MAIN SECTIONS

MAIN MENU...0

COVER...1

CONTENTS...2

SAFETY...6

SAFETY NOTICE...6

FOREWORD...8

GENERAL...8

HOISTING INSTRUCTIONS...10

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER...11

COATING MATERIALS...13

STANDARD TIGHTENING TORQUE...15

ELECTRIC WIRE CODE...18

CONVERSION TABLE...19

UNITS...25

01 GENERAL...26

SPECIFICATION DIMENSION DRAWING...27

WORKING RANGE DRAWING...28

SPECIFICATIONS...29

WEIGHT TABLE...32

LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS...34

10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD...36

PTO...37

COOLING SYSTEM...39

POWER TRAIN...41

SWING CIRCLE...42

TRACK FRAME...43

IDLER CUSHION...44

IDLER...45

TRACK ROLLER...47

CARRIER ROLLER...48

SPROCKET...49

TRACK SHOE...50

HYDRAULIC COMPONENTS LAYOUT DRAWING...51

HYDRAULIC TANK...52

CENTER SWIVEL JOINT...53

TRAVEL MOTOR...54

HYDRAULIC CYLINDER...63

SOLENOID VALVE...66

MULTI-CONTROL VALVE (IF EQUIPPED)...69

HYDRAULIC PUMP...71

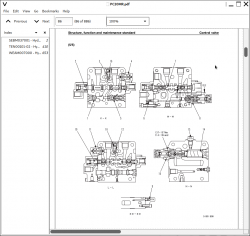

CONTROL VALVE...77

CLSS...90

OPERATION FOR EACH FUNCTION AND VALVE...93

SWING MOTOR...113

PPC VALVE...123

WORK EQUIPMENT...132

DIMENSIONS OF EACH PART OF WORK EQUIPMENT...135

FLOOR...138

ENGINE CONTROL...139

ELECTRIC CONTROL SYSTEM...141

COMPONENT PART OF SYSTEM...146

MONITOR SYSTEM...147

MONITOR PANEL...148

SENSORS...150

20 TESTING AND ADJUSTING...152

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS...153

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS...154

TESTING AND ADJUSTING...164

LIST OF TESTING, ADJUSTING, AND TROUBLESHOOTING TOOLS...165

MEASURING ENGINE SPEED...167

MEASUREMENT OF EXHAUST GAS COLOR...168

ADJUSTING VALVE CLEARANCE...169

MEASURING COMPRESSION PRESSURE...170

MEASURING ENGINE OIL PRESSURE...171

TESTING AND ADJUSTING FUEL INJECTION TIMING...172

BLEEDING AIR FROM FUEL CIRCUIT...174

TESTING AND ADJUSTING FAN BELT TENSION...175

ADJUSTING FUEL CONTROL LEVER LINKAGE...176

MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS...177

TESTING AND ADJUSTING TRACK SHOE TENSION...178

TESTING AND ADJUSTING OIL PRESSURES IN WORK EQUIPMENT, TRAVEL, SWING, AND BLADE CIRCUITS...180

MEASURING CONTROL CIRCUIT BASIC PRESSURE...183

TESTING AND ADJUSTING PUMP LS DIFFERENTIAL PRESSURE...184

MEASURING SOLENOID VALVE OUTPUT PRESSURE...186

MEASURING PPC VALVE OUTPUT PRESSURE...188

ADJUSTING PLAY OF WORK EQUIPMENT AND SWING PPC VALVES...190

MEASURING SWING HOLDING BRAKE RELEASE PRESSURE...190

MEASURING OF OIL LEAKAGE FROM CYLINDER...192

RELEASING RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT...194

BLEEDING AIR FROM CYLINDER...194

PRESSURIZING HYDRAULIC TANK...195

HOW TO OPEN AND CLOSE (TILT) FLOOR...196

INSPECTION PROCEDURES FOR DIODE...198

TROUBLESHOOTING...200

POINTS TO REMEMBER WHEN TROUBLESHOOTING...201

SEQUENCE OF EVENTS IN TROUBLESHOOTING...202

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE...203

CHECKS BEFORE TROUBLESHOOTING...211

CLASSIFICATION AND PROCEDURES OF TROUBLESHOOTING...212

CONNECTORS LIST AND STEREOGRAM...215

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...223

T-ADAPTER-BOXES AND T-ADAPTER TABLE...246

TROUBLESHOOTING OF ELECTRICAL SYSTEM (EXCEPT MONITOR PANEL E-MODE)...250

BEFORE STARTING E-MODE TROUBLESHOOTING...251

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE...253

E-1 ENGINE DOES NOT START...254

E-2 ENGINE DOES NOT STOP...260

E-3 WHEN SAFETY LOCK LEVER IS IN FREE POSITION, WHOLE WORK EQUIPMENT, TRAVEL, SWING, AND BLADE SYSTEMS DO NOT WORK...262

E-4 WHEN SAFETY LOCK LEVER IS IN LOCK POSITION, WHOLE WORK EQUIPMENT, TRAVEL, SWING AND BLADE SYSTEMS WORK...265

E-5 WHEN MACHINE STARTS TRAVELING, TRAVEL ALARM DOES NOT SOUND...267

E-6 WHEN MACHINE STOPS TRAVELING, TRAVEL ALARM DOES NOT STOP SOUNDING...269

E-7 WINDSHIELD WIPER DOES NOT OPERATE [CAB SPECIFICATION]...271

E-8 WINDSHIELD WASHER DOES NOT OPERATE [CAB SPECIFICATION]...273

E-9 HEATER DOES NOT OPERATE...275

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEMS (H MODE)...278

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE...279

H-1 SPEED OR POWER OF WHOLE WORK EQUIPMENT, TRAVEL, SWING, AND BLADE IS LOW...280

H-2 ENGINE SPEED LOWERS EXTREMELY OR ENGINE STALLS...283

H-3 WHOLE WORK EQUIPMENT, TRAVEL SYSTEM, SWING SYSTEM, AND BLADE DO NOT WORK ...284

H-4 ABNORMAL SOUND COMES OUT FROM AROUND HYDRAULIC PUMP...287

H-5 FINE CONTROL PERFORMANCE OR RESPONSE IS LOW...287

H-6 SPEED OR POWER OF BOOM IS LOW...288

H-7 SPEED OR POWER OF ARM IS LOW...289

H-8 SPEED OR POWER OF BUCKET IS LOW...290

H-9 SPEED OR POWER OF BOOM SWING IS LOW...291

H-10 WORK EQUIPMENT DOES NOT MOVE SINGLY...291

H-11 WORK EQUIPMENT HYDRAULIC DRIFT IS LARGE...292

H-12 TIME LAG OF WORK EQUIPMENT IS LARGE...293

H-13 IN COMPOUND OPERATION OF WORK EQUIPMENT, SPEED OF PART LOADED MORE IS LOW...293

H-14 MACHINE DEVIATES DURING TRAVEL...294

H-15 TRAVEL SPEED OR TRAVEL POWER IS LOW...296

H-16 MACHINE IS NOT STEERED WELL OR STEERING POWER IS LOW...296

H-17 TRAVEL SPEED DOES NOT CHANGE...297

H-18 TRAVEL MOTOR DOES NOT WORK (ONE SIDE ONLY)...297

H-19 SPEED OR POWER OF SWING IS LOW...298

H-20 MACHINE DOES NOT SWING...300

H-21 SWING ACCELERATION PERFORMANCE IS LOW...302

H-22 MACHINE OVERRUNS WHEN IT STOPS SWINGING...303

H-23 LARGE SHOCK IS MADE WHEN MACHINE STOPS SWINGING...304

H-24 WHEN UPPER STRUCTURE STOPS SWINGING, IT MAKES LARGE SOUND...304

H-25 HYDRAULIC DRIFT OF SWING IS LARGE...305

H-26 SPEED OR POWER OF BLADE IS LOW...306

H-27 BLADE DOES NOT MOVE...307

H-28 HYDRAULIC DRIFT OF BLADE IS LARGE...307

TROUBLESHOOTING OF MONITOR PANEL SYSTEM (M MODE)...308

BEFORE STARTING M-MODE TROUBLESHOOTING...309

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE...311

M-1 WHEN STARTING SWITCH IS TURNED ON, NO MONITOR/GAUGE OPERATES...313

M-2 WHEN STARTING SWITCH IS TURNED ON, SOME MONITORS/GAUGES DO NO OPERATE...315

M-3 CAUTION BUZZER DOES NOT SOUND OR DOES NOT STOP SOUNDING...317

M-4 WHILE ENGINE IS RUNNING, ENGINE OIL PRESSURE MONITOR FLASHES...319

M-5 WHILE ENGINE IS RUNNING, CHARGE LEVEL MONITOR FLASHES...321

M-6 PREHEATING SYSTEM DOES NOT OPERATE...323

M-7 COOLANT TEMPERATURE GAUGE DOES NOT INDICATE NORMALLY...326

M-8 FUEL LEVEL GAUGE DOES NOT INDICATE NORMALLY...329

M-9 SERVICE METER DOES NOT OPERATE WHILE ENGINE IS RUNNING...331

M-10 TRAVEL SPEED SHIFTING SYSTEM DOES NOT OPERATE NORMALLY...332

M-11 MONITOR PANEL NIGHT LAMP AND WORKING LAMP DO NOT LIGHT UP...335

TROUBLESHOOTING OF ENGINE (S MODE)...340

TROUBLESHOOTING OF ENGINE (S-MODE)...341

30 DISASSEMBLY AND ASSEMBLY...348

HOW TO READ THIS MANUAL...349

PRECAUTIONS WHEN PERFORMING OPERATION...351

SPECIAL TOOL LIST...353

REMOVAL AND INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY...355

REMOVAL AND INSTALLATION OF RADIATOR AND HYDRAULIC OIL COOLER ASSEMBLY...357

REMOVAL AND INSTALLATION OF ENGINE AND HYDRAULIC PUMP ASSEMBLY...362

REMOVAL AND INSTALLATION TRACK SHOE ASSEMBLY...364

DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY...365

DISASSEMBLY AND ASSEMBLYOF RECOIL SPRING ASSEMBLY...367

DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY...370

REMOVAL AND INSTALLATION OF CENTER SWIVEL JOINT ASSEMBLY...371

DISASSEMBLY AND ASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY...373

REMOVAL AND INSTALLATION OF FLOOR FRAME ASSEMBLY...375

REMOVAL AND INSTALLATION OF SWING MOTOR AND SWING MACHINERY ASSEMBLY...380

REMOVAL AND INSTALLATION OF WORK EQUIPMENT ASSEMBLY...381

REMOVAL AND INSTALLATION OF REVOLVING FRAME ASSEMBLY...383

REMOVAL AND INSTALLATION OF SWING CIRCLE ASSEMBLY...385

DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE ASSEMBLY...386

DISASSEMBLY AND ASSEMBLY OF HDYRAULIC CYLINDER ASSEMBLY...390

REMOVAL AND INSTALLATION OF FRONT WINDOW ASSEMBLY...394

REMOVAL AND INSTALLATION OF OPERATOR'S CAB GLASS (STUCK GLASS)...395

90 OTHERS...404

HYDRAULIC CIRCUIT DIAGRAM...406

ELECTRICAL CIRCUIT DIAGRAM (1/2)...407

ELECTRICAL CIRCUIT DIAGRAM (2/2)...408

COVER...1

FOREWORD...2

FOREWORD...3

SAFETY INFORMATION...6

INTRODUCTION...8

DIRECTIONS OF MACHINE...8

PRODUCT INFORMATION...9

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE...9

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION...9

EPA NAMEPLATE...10

SERVICE METER LOCATION...10

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR...11

CONTENTS...12

SAFETY...15

SAFETY INFORMATION...16

SAFETY LABELS...18

LOCATION OF SAFETY LABELS...18

SAFETY LABELS...19

SAFETY INFORMATION...24

SAFETY RULES...24

IF PROBLEMS ARE FOUND...24

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS...24

FIRE EXTINGUISHER AND FIRST AID KIT...24

SAFETY EQUIPMENT...25

KEEP MACHINE CLEAN...25

KEEP OPERATOR'S COMPARTMENT CLEAN...25

LEAVING OPERATOR'S SEAT WITH LOCK...25

HANDRAILS AND STEPS...26

MOUNTING AND DISMOUNTING...26

NO PERSONS ON ATTACHMENTS...26

BURN PREVENTION...27

FIRE PREVENTION AND EXPLOSION PREVENTION...27

ACTION IF FIRE OCCURS...28

WINDSHIELD WASHER FLUID...28

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION...29

CAUTIONS RELATED TO ROPS (ROLLOVER PROTECTION SYSTEM)...29

ATTACHMENT INSTALLATION...30

ATTACHMENT COMBINATIONS...30

CAB WINDOW GLASSES...30

UNAUTHORIZED MODIFICATIONS...30

SAFETY AT JOBSITE...30

WORKING ON LOOSE GROUND...30

DISTANCE TO HIGH VOLTAGE CABLES...31

ENSURE GOOD VISIBILITY...31

VENTILATION FOR ENCLOSED AREA...31

SIGNALMAN'S SIGNAL AND SIGNS...31

EMERGENCY EXIT FROM OPERATOR'S CAB...32

ASBESTOS DUST HAZARD PREVENTION...32

SAFETY MACHINE OPERATION...33

STARTING ENGINE...33

CHECKS BEFORE STARTING ENGINE...33

SAFETY RULES FOR STARTING ENGINE...34

STARTING ENGINE IN COLD WEATHER...34

OPERATION...35

CHECKS BEFORE OPERATION...35

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS...35

SAFETY RULES FOR TRAVELING...36

TRAVELING ON SLOPES...37

OPERATIONS ON SLOPES...38

PROHIBITED OPERATIONS...38

OPERATIONS ON SNOW...40

PARKING MACHINE...40

TRANSPORTATION...41

LOADING AND UNLOADING...41

SHIPPING THE MACHINE...41

BATTERY...42

BATTERY HAZARD PREVENTION...42

STARTING ENGINE WITH BOOSTER CABLES...43

TOWING...44

SAFETY RULES FOR TOWING...44

LIFTING OBJECTS WITH BUCKET...45

SAFETY RULES FOR LIFTING OBJECTS...45

SAFETY MAINTENANCE INFORMATION...46

WARNING TAG...46

KEEP WORK PLACE CLEAN AND TIDY...46

APPOINT LEADER WHEN WORKING WITH OTHERS...46

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE...47

CAUTIONS FOR OPENING (TILTING) FLOOR...48

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING...49

PROPER TOOLS...49

PERSONNEL...49

ATTACHMENTS...50

WORK UNDER THE MACHINE...50

NOISE...50

WHEN USING HAMMER...50

WELDING WORKS...50

REMOVING BATTERY TERMINALS...51

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION...51

DO NOT DISASSEMBLE RECOIL SPRINGS...51

SAFETY RULES FOR HIGH-PRESSURE OIL...51

SAFETY HANDLING HIGH-PRESSURE HOSES...52

WASTE MATERIALS...52

COMPRESSED AIR...52

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS...52

OPERATION...53

MACHINE VIEW ILLUSTRATIONS...54

OVERALL MACHINE VIEW...54

CONTROLS AND GAUGES...55

DETAILED CONTROLS AND GAUGES...56

MONITORING SYSTEM...56

SWITCHES...64

CONTROL LEVERS AND PEDALS...68

WINDSHIELD...74

SLIDING DOOR...78

SLIDING WINDOW...78

EMERGENCY ESCAPE HAMMER...79

CAP WITH LOCK...80

ENGINE REAR COVER...81

COOLING COVER...81

FRONT RIGHT COVER...82

METHOD OF OPENING (TILTING) FLOOR...83

FUSE...88

BLOCK FUSE...89

OPERATION MANUAL STORAGE...89

TOOL BOX...89

GREASE GUN HOLDER...90

ASHTRAY...90

MACHINE OPERATIONS AND CONTROLS...91

BEFORE STARTING ENGINE...91

STARTING ENGINE...106

AFTER STARTING ENGINE...110

STOPPING THE ENGINE...113

MACHINE OPERATION...114

STEERING THE MACHINE...119

SWINGING...121

WORK EQUIPMENT CONTROLS AND OPERATIONS...122

PROHIBITED OPERATIONS...124

GENERAL OPERATION INFORMATION...126

TRAVELING ON SLOPES...128

ESCAPE FROM MUD...130

WORK POSSIBLE USING COMPACT HYDRAULIC EXCAVATOR...131

BUCKET REPLACEMENT...133

PARKING MACHINE...134

MACHINE INSPECTION AFTER DAILY WORK...135

LOCKING...136

RUBBER SHOES (MACHINE WITH RUBBER SHOES ONLY)...137

TRANSPORTATION...142

TRANSPORTATION PROCEDURE...142

LOADING AND UNLOADING WITH TRAILER...143

LIFTING MACHINE...149

COLD WEATHER OPERATION...152

COLD WEATHER OPERATION INFORMATION...152

CAB HEATER IN COLD WEATHER...153

AFTER DAILY WORK COMPLETION...154

AFTER COLD WEATHER SEASON...154

LONG TERM STORAGE...155

BEFORE STORAGE...155

DURING STORAGE...155

AFTER STORAGE...155

TROUBLES AND ACTIONS...156

RUNNING OUT OF FUEL...156

PHENOMENA THAT ARE NOT FAILURES...156

TOWING THE MACHINE...157

SEVERE JOB CONDITION...157

DISCHARGED BATTERY...158

OTHER TROUBLE...162

MAINTENANCE...165

MAINTENANCE INFORMATION...166

OUTLINE OF SERVICE...168

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC...168

ELECTRIC SYSTEM MAINTENANCE...171

HANDLING HYDRAULIC SYSTEM...171

WEAR PARTS...172

WEAR PARTS LIST...172

RECOMMENDED FUEL, COOLANT, AND LUBRICANT...173

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN...175

TIGHTENING TORQUE SPECIFICATIONS...176

TIGHTENING TORQUE LIST...176

SAFETY CRITICAL PARTS...177

SAFETY CRITICAL PARTS LIST...177

MAINTENANCE SCHEDULE...178

MAINTENANCE SCHEDULE CHART...178

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER...179

MAINTENANCE PROCEDURE...180

WHEN REQUIRED...180

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT...180

CLEAN INSIDE OF COOLING SYSTEM...183

CHECK LEVEL OF BATTERY ELECTROLYTE...186

CLEAN FUEL FILTER ELEMENT (WITH WATER SEPARATOR)...188

DRAIN WATER AND SEDIMENT FROM FUEL TANK...188

CHECK AND ADJUST TRACK TENSION (MACHINE EQUIPPED WITH STEEL SHOE)...189

CHECK RUBBER SHOES (MACHINE EQUIPPED WITH RUBBER SHOES)...191

CHECK AND ADJUST RUBBER SHOE TENSION (MACHINE EQUIPPED WITH RUBBER SHOES)...193

REPLACE RUBBER SHOES (MACHINE EQUIPPED WITH RUBBER SHOES)...195

REPLACE BUCKET TEETH...198

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID...201

CHECK, CLEAN AND LUBRICATE CAB SLIDE DOOR RAIL AND ROLLER...202

BLEEDING AIR FROM HYDRAULIC SYSTEM...203

CHECK BEFORE STARTING...204

EVERY 500 HOURS MAINTENANCE...205

LUBRICATING...205

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE...208

REPLACE FUEL FILTER ELEMENT (WITH WATER SEPARATOR)...209

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL...210

REPLACE FUEL FEED PUMP PRE-FILTER...211

CLEAN AND INSPECT RADIATOR FINS AND OIL COOLER FINS...211

CHECK AND ADJUST COOLING FAN BELT TENSION...212

EVERY 1000 HOURS MAINTENANCE...213

CHANGE OIL IN FINAL DRIVE CASE...213

REPLACE HYDRAULIC OIL FILTER ELEMENT...214

CHECK ENGINE VALVE CLEARANCE, ADJUST...215

EVERY 2000 HOURS MAINTENANCE...216

CHANGE OIL IN HYDRAULIC TANK, CLEAN STRAINER...216

CHECK ALTERNATOR, STARTING MOTOR...218

SPECIFICATIONS...219

SPECIFICATIONS...220

ATTACHMENTS, OPTIONS...222

ATTACHMENTS AND OPTIONS - GENERAL INFORMATION...223

SAFETY FIRST...223

ATTACHMENT INSTALLATION...224

BUCKET WITH HOOK...225

PROHIBITED OPERATIONS...225

WINDSHIELD WASHER...226

WINDSHIELD WASHER OPERATION...226

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID...226

MACHINE READY FOR ATTACHMENT...227

LOCATIONS...227

HYDRAULIC CIRCUIT...229

ATTACHMENT OPERATIONS...231

LONG TERM STORAGE...232

SPECIFICATIONS...232

CHANGING MACHINE CONTROL PATTERN (IF PATTERN CHANGE...233

CONTROL PATTERN CHANGE PROCEDURE...233

MACHINE CONTROL PATTERNS...234

ATTACHMENT GUIDE...235

ATTACHMENT COMBINATIONS...235

RECOMMENDED ATTACHMENT OPERATIONS...236

HYDRAULIC BREAKER...236

INDEX...241