Komatsu Hydraulic Excavator PC20, PC25, PC30, PC40, PC45 Repair Service Manual + Operation & Maintenance Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavators PC20-3, PC20-6, PC25-1, PC30-3, PC30-6, PC30-7, PC40-6, PC40-7, PC45-1, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC20-3, PC20-6, PC25-1, PC30-3, PC30-6, PC30-7, PC40-6, PC40-7, PC45-1 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,522 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SEBM020R0604 - Hydraulic Excavator PC20-6, PC30-6, PC40-6 Shop Manual.pdf

SEBM020S0707 - Hydraulic Excavator PC25-1, PC30-7, PC40-7, PC45-1 Shop Manual.pdf

SEBM0225C01 - Hydraulic Excavator PC20-3, PC30-3 Shop Manual.pdf

SEAM020P0700 - Hydraulic Excavator PC20-7 Operation & Maintenance Manual.pdf

SEAM006600 - Hydraulic Excavator PC25-1, PC30-7, PC40-7, PC45-1 Operation & Maintenance Manual.pdf

SEAM009502T - Hydraulic Excavator PC40-7 Operation & Maintenance Manual.pdf

MAIN SECTIONS

MAIN MENU...0

COVER...1

CONTENTS...2

SAFETY...5

SAFETY NOTICE...5

FOREWARD...7

GENERAL...7

HOW TO READ THE SHOP MANUAL...8

HOISTING INSTRUCTIONS...9

COATING MATERIALS...10

STANDARD TIGHTENING TORQUE...11

ELECTRIC WIRE CODE...13

CONVERSION TABLE...14

WEIGHT TABLE...21

WEIGHT TABLE...22

LIST OF LUBRICANT AND WATER...25

10 STRUCTURE AND FUNCTION...28

POWER TRAIN...29

SWING CIRCLE...30

SWING MACHINERY...31

TRACK FRAME AND RECOIL SPRING...33

HYDRAULIC PIPING...36

HYDRAULIC CIRCUIT DIAGRAM...37

HYDRAULIC TANK AND FUEL TANK...41

HYDRAULIC PUMP...42

CONTROL PUMP...50

7 - SPOOL CONTROL VALVE...51

2 - SPOOL CONTROL VALVE...55

SWING MOTOR...59

CENTER SWIVEL JOINT...62

TRAVEL MOTOR...63

HYDRAULIC CYLINDER...68

VALVE CONTROL...72

PPC VALVE...73

SOLENOID VALVE...79

WORK EQUIPMENT...81

HYDRAULIC BREAKER...82

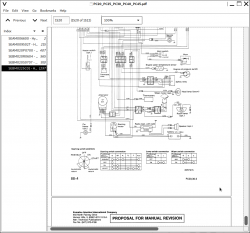

ELECTRICAL CIRCUIT DIAGRAM...85

MONITOR SYSTEM...88

20 TESTING AND ADJUSTING...97

TABLE OF JUDGEMENT STANDARD VALUE...98

STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM...116

TOOL FOR TESTING, ADJUSTING, AND TROUBLESHOOTING...118

ADJUSTING VALVE CLEARANCE...119

MEASURING COMPRESSION PRESSURE...121

ADJUSTING FUEL INJECTION TIMING...122

MEASURING ENGINE OIL PRESSURE...123

ADJUSTING FUEL CONTROL LEVER...125

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT...126

TESTING CONTROL CIRCUIT PRESSURE...129

MEASURING OUTPUT PRESSURE OF PPC VALVE...130

ADJUSTING PPC VALVE...131

ADJUSTING WORK EQUIPMENT, SWING PPC VALVE...132

MEASURING SOLENOID VALVE OUTLET PORT PRESSURE...134

ADJUSTING BLADE CONTROL LEVER...135

TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT...136

BLEEDING AIR FROM HYDRAULIC CIRCUIT...137

RELEASING REMAINING FROM HYDRAULIC CIRCUIT...139

TESTING HYDRAULIC BREAKER GAS PRESSURE...140

TROUBLESHOOTING...142

SEQUENCE OF EVENTS IN TROUBLESHOOTING...143

PRECAUTIONS WHEN CARRYING OUT MAINTENANCE...144

CHECKS BEFORE TROUBLESHOOTING...151

ELECTRICAL CIRCUIT DIAGRAM...152

POSITION OF CONNECTORS FOR TROUBLESHOOTING...155

CONNECTION TABLE FOR CONNECTOR...159

METHOD OF USING TROUBLESHOOTING CHARTS...166

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)...168

E-1 THE ENGINE DOES NOT STOP WHEN THE STARTING SWITCH IS TURNED OFF...169

E-2 WORK EQUIPMENT DOES NOT MOVE EVEN WHEN WORK EQUIPMENT LOCK LEVER IS RELEASED...172

E-3 WORK EQUIPMENT MOVES EVEN WHEN WORK EQUIPMENT LOCK LEVER IS LOCKED...173

E-4 TRAVEL SPEED DOES NOT INCREASE EVEN WHEN TRAVEL SPEED ACCELERATION PEDAL IS DEPRESSED...174

E-5 TRAVEL SPEED INCREASES EVEN WHEN TRAVEL SPEED ACCELERATION PEDAL IS NOT DEPRESSED...175

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)...176

H-1 SPEEDS OF WORK EQUIPMENT, TRAVEL, SWING ARE ALL SLOW...177

H-2 THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS...178

H-3 WORK EQUIPMENT, TRAVEL, SWING DO NOT MOVE, OR SPEED IS EXTREMELY SLOW...179

a) NONE OF WORK EQUIPMENT, TRAVEL, SWING DO NOT MOVE, OR SPEED IS SLOW...179

b) ONLY TRAVEL IS NORMAL, OR DROP IN SPEED IS COMPARATIVELY SMALL...180

H-4 ALL WORK EQUIPMENT, TRAVEL, SWING LACK POWER...180

H-5 ABNORMAL NOISE GENERATED (FROM AROUND PUMP)...180

H-6 WORK EQUIPMENT (BOOM, ARM, BUCKET) SPEED IS SLOW...181

H-7 WORK EQUIPMENT (BOOM, ARM, BUCKET) LACKS POWER...182

H-8 EXCESSIVE HYDRAULIC DRIFT...182

H-9 EXCESSIVE TIME LAG...182

H-10 WHEN MACHINE IS TRAVELING, IT DEVIATES NATURALLY TO ONE SIDE...183

a) DEVIATES IN THE SAME DIRECTION BOTH IN FORWARD AND REVERSE...183

b) DEVIATES IN DIFFERENT DIRECTION IN FORWARD AND REVERSE...187

H-11 EXCESSIVE DEVIATION WHEN STARTING (PC30, 40)...188

H-12 TRAVEL LACKS POWER (OR SPEED IS SLOW)...189

H-13 TRAVEL SPEED DOES NOT SWITCH...190

H-14 MACHINE DOES NOT MOVE (ONE SIDE ONLY)...190

H-15 TRAVEL LEVER IS HEAVY...191

H-16 DOES NOT SWING...191

H-17 SWING SPEED IS SLOW OR ACCELERATION IS POOR...193

H-18 EXCESSIVE OVERRUN WHEN STOPPING SWING...193

H-19 EXCESSIVE SHOCK WHEN STOPPING SWING...194

H-20 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING...194

H-21 EXCESSIVE HYDRAULIC DRIFT OF SWING...195

H-22 EXCESSIVE HYDRAULIC DRIFT OF BOOM SWING...196

TABLE OF FAILURE MODES AND CAUSES...197

TROUBLESHOOTING OF MONITOR SYSTEM (M MODE)...198

M-1 MONITOR PANEL DOES NOT WORK...199

M-2 MONITOR PANEL CAUTION AND GAUGE LAMPS DO NOT LIGHT UP FOR 3 SECONDS AFTER STARTING SWITCH IS TURNED ON, OR ALL LAMPS STAY...200

M-3 (OIL PRESSURE CAUTION LAMP) DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED)...201

M-4 (CHARGE CAUTION LAMP) DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED)...201

M-5 (PREHEATING PILOT LAMP) DOES NOT LIGHT UP WHEN PREHEATING...202

M-6 (ENGINE OIL LEVEL CAUTION LAMP) LIGHTS UP WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED) (ENGINE OIL LEVEL IS NORMAL)...202

M-7 (ENGINE OIL PRESSURE CAUTION LAMP) LIGHTS UP WHEN ENGINE IS RUNNING (ENGINE OIL PRESSURE IS NORMAL)...203

M-8 (CHARGE CAUTION LAMP) LIGHTS UP WHEN ENGINE IS RUNNING...203

M-9 ABNORMALITY IN COOLANT TEMPERATURE GAUGE DISPLAY...204

a) AFTER ENGINE IS STARTED, GAUGE STAYS AT LOWEST LEVEL AND DOES NOT MOVE...204

b) AFTER ENGINE IS STARTED, LEVEL RISES IMMEDIATELY. ENTERS RED RANGE EVEN WHEN ENGINE IS NOT OVERHEATING...204

M-10 ABNORMALITY IN FUEL GAUGE DISPLAY...205

a) ALL SEGMENTS OF FUEL GAUGE GO OUT...205

b) FUEL LEVEL HAS GONE DOWN, BUT FUEL GAUGE STILL GIVES FULL DISPLAY, AND DOES NOT GO DOWN...205

c) FUEL GAUGE DOES NOT GIVE FULL DISPLAY EVEN WHEN FUEL TANK IS FILLED...206

M-11 WHEN STARTING SWITCH IS TURNED ON, BUZZER DOES NOT SOUND FOR 1 SECOND...206

M-12 ABNORMALITY IN SERVICE METER DISPLAY...207

a) SERVICE METER DOES NOT MOVE WHEN ENGINE IS RUNNING...207

b) SERVICE METER PILOT LAMP DOES NOT FLASH...207

M-13 NIGHT LIGHTING DOES NOT LIGHT UP...208

a) WHEN LAMP SWITCH IS AT POSITION 1 OR POSITION 2, INTERNAL LIGHTING OF MONITOR (GAUGE PORTION) DOES NOT LIGHT UP...208

b) WHEN LAMP SWITCH IS AT POSITION 2, WORKING LAMP IS NOT BLOWN BEFORE STARTING TROUBLESHOOTING...208

M-14 HEATER DOES NOT WORK WHEN HEATER SWITCH IS OPERATED (MACHINES WITH CAB SPECIFICATION)...209

TROUBLESHOOTING OF HYDRAULIC BREAKER...210

30 DISASSEMBLY AND ASSEMBLY...213

METHOD OF USING MANUAL...214

PRECAUTIONS WHEN CARRYING OUT OPERATION...215

SPECIAL TOOL LIST...217

WEIGHT TABLE...222

TIGHTENING TORQUES AND STANDARD VALUES TABLE...223

LUBRICANT AND COOLANT TABLE...224

ENGINE, HYDRAULIC PUMP ASSEMBLY...226

REMOVAL...226

INSTALLATION...229

HYDRAULIC PUMP ASSEMBLY...230

HYDRAULIC PUMP ASSEMBLY (PC30-7)...230

DISASSEMBLY...230

ASSEMBLY...232

HYDRAULIC PUMP ASSEMBLY (PC45-1)...238

DISASSEMBLY...238

ASSEMBLY...242

GEAR PUMP ASSEMBLY...249

DISASSEMBLY AND ASSEMBLY...249

CENTER SWIVEL JOINT ASSEMBLY...250

REMOVAL AND INSTALLATION...250

DISASSEMBLY AND ASSEMBLY...251

TRAVEL MOTOR ASSEMBLY ...252

TRAVEL MOTOR ASSEMBLY (PC25-1, PC30-7, PC40-7)...252

DISASSEMBLY...252

ASSEMBLY...258

TRAVEL MOTOR ASSEMBLY (PC45-1)...264

DISASSEMBLY...264

ASSEMBLY...273

SWING MOTOR ASSEMBLY...284

DISASSEMBLY...284

ASSEMBLY...286

SWING MACHINERY ASSEMBLY...290

DISASSEMBLY...290

ASSEMBLY...292

REVOLVING FRAME ASSEMBLY...294

REMOVAL AND INSTALLATION...294

RECOIL SPRING ASSEMBLY...295

DISASSEMBLY...295

ASSEMBLY...297

2 SPOOL CONTROL VALVE ASSEMBLY...300

DISASSEMBLY...300

ASSEMBLY...301

7 SPOOL CONTROL VALVE ASSEMBLY...302

DISASSEMBLY...302

ASSEMBLY...304

PPC VALVE ASSEMBLY...306

DISASSEMBLY...306

ASSEMBLY...307

HYDRAULIC CYLINDER ASSEMBLY...308

DISASSEMBLY...308

ASSEMBLY...310

WORK EQUIPMENT ASSEMBLY...312

REMOVAL AND INSTALLATION...312

BUCKET ASSEMBLY...313

REMOVAL AND INSTALLATION...313

HYDRAULIC BREAKER ASSEMBLY...314

REMOVAL AND INSTALLATION...314

DISASSEMBLY...315

ASSEMBLY...318

HYDRAULIC BREAKER BUSHING...322

REMOVAL...322

CHISEL...323

REMOVAL AND INSTALLATION...323

40 MAINTENANCE STANDARD...326

SWING CIRCLE...327

SWING MACHINERY...328

SPROCKET...330

TRACK FRAME AND RECOIL FRAME...333

IDLER...337

TRACK ROLLER...343

CARRIER ROLLER...349

TRACK SHOE...351

HYDRAULIC PUMP...355

7 SPOOL CONTROL VALVE...357

2 SPOOL CONTROL VALVE...359

SWING MOTOR...360

CENTER SWIVEL JOINT...361

PPC VALVE...362

HYDRAULIC CYLINDER...365

WORK EQUIPMENT...369

HYDRAULIC BREAKER...373

PISTON, CHISEL...375

MAIN MENU...0

COVER...1

1. FOREWORD...2

2. SAFETY INFORMATION...3

3. INTRODUCTION...4

3.1 INTENDED USE...4

3.2 FEATURES...4

3.3 BREAKING IN THE MACHINE...4

4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR...5

4.1 MACHINE SERIAL NO. PLATE POSITION...5

4.2 ENGINE SERIAL NO. PLATE POSITION...5

4.3 TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR...5

CONTENTS...6

SAFETY...10

6. GENERAL PRECAUTIONS...11

7. PRECAUTIONS DURING OPERATION...16

7.1 BEFORE STARTING ENGINE...16

7.2 OPERATING MACHINE...18

7.3 TRANSPORTATION...23

7.4 BATTERY...24

7.5 TOWING...25

7.6 BUCKET WITH HOOK...26

8. PRECAUTIONS FOR MAINTENANCE...29

8.1 BEFORE CARRYING OUT MAINTENANCE...29

8.2 DURING MAINTENANCE...32

9. POSITION FOR ATTACHING SAFETY LABELS...36

OPERATION...40

10. GENERAL VIEW...41

10.1 GENERAL VIEW OF MACHINE...41

10.2 GENERAL VIEW OF CONTROLS AND GAUGES...42

11. EXPLANATION OF COMPONENTS...43

11.1 MACHINE MONITOR...43

11.2 SWITCHES...48

11.3 CONTROL LEVERS AND PEDALS...51

11.4 ENGINE HOOD...55

11.5 FRONT WINDOW (MACHINES EQUIPPED WITH CAB)...56

11.6 DOOR LOCK...58

11.7 FUSE...59

11.8 FUSIBLE LINK...59

11.9 CAP, COVER WITH LOCK...60

11.10 CANOPY (MACHINES EQUIPPED WITH CANOPY)...61

12. OPERATION...62

12.1 CHECK BEFORE STARTING ENGINE...62

12.2 STARTING ENGINE...70

12.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE...72

12.4 MOVING MACHINE OFF...74

12.5 STEERING MACHINE...77

12.6 STOPPING MACHINE...79

12.7 SWINGING...80

12.8 OPERATION OF WORK EQUIPMENT...81