Komatsu Hydraulic Excavator PC20R, PC25R, PC27R Repair Service Manual + Operation & Maintenance Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC20R-8, PC25R-8, PC27R-8, PC27R-8 Deluxe, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC20R-8, PC25R-8, PC27R-8, PC27R-8 Deluxe workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 2,419 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

WEBM000200 - Hydraulic Excavator PC20R-8, PC27R-8 Shop Manual.pdf

WEBM000201 - Hydraulic Excavator PC20R-8, PC27R-8 Shop Manual.pdf

WEBM002900 - Hydraulic Excavator PC27R-8 Shop Manual.pdf

WEBM003800 - Hydraulic Excavator PC27R-8 Deluxe Shop Manual.pdf

SEBM010801 - Hydraulic Excavator PC20R-8, PC25R-8, PC27R-8 Shop Manual.pdf

SEAM015203T - Hydraulic Excavator PC20R-8, PC25R-8, PC27R-8 Operation & Maintenance Manual.pdf

WEAM000101 - Hydraulic Excavator PC20R-8, PC27R-8 Operation & Maintenance Manual.pdf

WEAM003100 - Hydraulic Excavator PC27R-8 Operation & Maintenance Manual.pdf

WEAM003102 - Hydraulic Excavator PC27R-8 Deluxe Operation & Maintenance Manual.pdf

MAIN SECTIONS

COVER...1

CONTENTS...2

01 GENERAL...25

GENERAL ASSEMBLY DRAWING...26

SPECIFICATIONS...32

WEIGHT TABLE...38

LIST OF LUBRICANT AND WATER...40

10 STRUCTURE AND FUNCTION...42

POWER TRAIN...43

SWING CIRCLE...45

SWING MACHINERY...47

TRACK FRAME...48

RECOIL SPRING...51

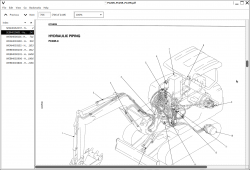

HYDRAULIC PIPING ...52

HYDRAULIC CIRCUIT DIAGRAM...54

HYDRAULIC TANK...57

HYDRAULIC PUMP...59

CONTROL VALVE...82

CLSS...90

CENTER SWIVEL JOINT...113

SWING MOTOR...114

TRAVEL MOTOR...122

VALVE CONTROL...127

PPC VALVE...128

WORK EQUIPMENT...132

ELECTRICAL CIRCUIT DIAGRAM...133

MACHINE MONITOR SYSTEM...134

20 TESTING AND ADJUSTING...139

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS...140

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS...142

STANDARD VALUE TABLE FOR ELECTRICAL PARTS...157

TOOLS FOR TESTING,ADJUSTING,AND TROUBLESHOOTING...159

MEASURING ENGINE SPEED...160

MEASURING EXHAUST COLOR...161

ADJUSTING VALVE CLEARANCE...162

MEASURING COMPRESSION PRESSURE...163

TESTING AND ADJUSTING FUEL INJECTION TIMING...164

MEASURING ENGINE OIL PRESSURE...166

TESTING AND ADJUSTING ALTERNATOR FAN BELT TENSION...167

MEASURING SPROCKET WEAR...168

TESTING AND ADJUSTING TRACK SHOE TENSION...169

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT,SWING,TRAVEL CIRCUIT...170

TESTING AND ADJUSTING LS DIFFERENTIAL PRESSURE...174

ADJUSTING PC VALVE...178

TESTING AND ADJUSTING CONTROL CIRCUIT PRESSURE...179

MEASURING OUTPUT PRESSURE OF PPC LOCK VALVE AND TRAVEL BOOST VALVE...181

TESTING PPC VALVE OUTPUT PRESSURE AND SWING HOLDING BRAKE INLET PORT PRESSURE...182

ADJUSTING WORK EQUIPMENT,SWING PPC VALVE...186

TESTING AND ADJUSTING TRAVEL DEVIATION...187

MEASURING OIL LEAKAGE INSIDE CYLINDER...188

RELEASING REMAINING PRESSURE FROM HYDRAULIC CIRCUIT...189

RELEASING REMAINING PRESSURE FROM HYDRAULIC TANK...189

PRESSURIZING HYDRAULIC TANK...189

BLEEDING AIR...190

TROUBLESHOOTING...192

POINTS TO REMEMBER WHEN TROUBLESHOOTING...193

SEQUENCE OF EVENTS IN TROUBLESHOOTING...194

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE...195

CHECKS BEFORE TROUBLESHOOTING...203

TYPE OF CONNECTOR AND POSITION OF INSTALLATION...204

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...207

METHOD OF USING TROUBLESHOOTING CHARTS...217

TROUBLESHOOTING OF ELECTRICAL SYSTEM(E MODE)...220

E-MODE RELATED ELECTRICAL CIRCUIT DIAGRAM...221

E-1 ENGINE DOES NOT START...222

a) WHEN STARTING MOTOR DOES NOT TURN(STARTING SYSTEM)...222

b) WHEN STARTING MOTOR TURNS(ENGINE STOP SOLENOID SYSTEM)...224

E-2 ENGINE DOES NOT STOP...226

TROUBLESHOOTING OF HYDRAULIC,MECHANICAL SYSTEM(H MODE)...227

TABLE OF FAILURE MODES AND CAUSES...228

H-1 SPEEDS OF ALL WORK EQUIPMENT,SWING,TRAVEL ARE SLOW OR LACK POWER...230

H-2 THERE IS EXCESSIVE DROP IN ENGINE SPEED,OR ENGINE STALLS...231

H-3 NO WORK EQUIPMENT,TRAVEL,SWING MOVE...231

H-4 ABNORMAL NOISE GENERATED(FROM AROUND PUMP)...232

H-5 FINE CONTROL ABILITY IS POOR OR RESPONSE IS POOR...232

H-6 BOOM IS SLOW OR LACKS POWER...233

H-7 ARM IS SLOW OR LACKS POWER...233

H-8 BUCKET IS SLOW OR LACKS POWER...234

H-9 BOOM SWING IS SLOW OR LACKS POWER...234

H-10 BLADE IS SLOW OR LACKS POWER...235

H-11 BOOM,ARM,BUCKET DO NOT MOVE(BOOM SWING,BLADE,TRAVEL AND SWING ARE NORMAL)...235

H-12 EXCESSIVE HYDRAULIC DRIFT(BOOM,ARM,BUCKET,BOOM SWING,BLADE)...236

a) BOOM...236

b) ARM,BUCKET...236

c) BOOM SWING...236

d) BLADE...237

H-13 EXCESSIVE TIME LAG(ENGINE AT LOW IDLING)...237

H-14 IN COMPOUND OPERATIONS,WORK EQUIPMENT WITH LARGER LOAD IS SLOW...237

H-15 TRAVEL DEVIATION...238

a) DEVIATION IN NORMAL TRAVEL...238

b) DEVIATION WHEN STARTING...238

H-16 TRAVEL SPEED IS SLOW OR LACKS POWER...239

H-17 STEERING DOES NOT TURN EASILY...239

H-18 TRAVEL SPEED DOES NOT SWITCH...240

H-19 TRAVEL DOES NOT MOVE(ONE SIDE ONLY)...240

H-20 SWING SPEED IS SLOW OR LACKS POWER...241

a) SPEED IS SLOW OR LACKS POWER IN BOTH DIRECTIONS...241

b) SPEED IS SLOW OR LACKS POWER IN ONE DIRECTION ONLY(LEFT OR RIGHT)...241

H-21 DOES NOT SWING...242

a) DOES NOT SWING IN EITHER DIRECTION...242

b) DOES NOT SWING IN ONE DIRECTION(LEFT OR RIGHT)...242

H-22 SWING ACCELERATION IS POOR...243

a) ACCELERATION IS POOR IN BOTH DIRECTIONS...243

b) ACCELERATION IS POOR IN ONE DIRECTION ONLY(LEFT OR RIGHT)...243

H-23 EXCESSIVE OVERRUN WHEN STOPPING SWING...244

a) OVERRUN WHEN STOPPING IS EXCESSIVE IN BOTH DIRECTIONS...244

b) OVERRUN WHEN STOPPING IS EXCESSIVE IN ONE DIRECTION ONLY(LEFT OR RIGHT)...244

H-24 EXCESSIVE SHOCK WHEN STOPPING SWING(IN ONE DIRECTION ONLY)...245

H-25 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING...245

H-26 EXCESSIVE HYDRAULIC DRIFT OF SWING...245

TROUBLESHOOTING OF MACHINE MONITOR SYSTEM(M MODE)...246

ELECTRICAL CIRCUIT DIAGRAM FOR M MODE RELATED PARTS...247

M-1 WHEN THE STARTING SWITCH IS TURNED ON,NO DISPLAY IS GIVEN...248

M-2 WHEN STARTING SWITCH IS TURNED ON,EVEN WHEN SELF CHECK IS COMPLETED(ALL LAMPS LIGHT UP FOR 3 SECONDS),LAMPS DO NOT GO OUT...248

M-3 WHEN STARTING SWITCH IS TURNED ON,SOME SELF CHECK LAMPS DO NOT LIGHT UP FOR 3 SECONDS...249

a) NO GAUGE LAMPS LIGHT UP(FUEL,COOLANT TEMPERATURE)...249

b) CAUTION LAMPS(ENGINE OIL PRESSURE,BATTERY CHARGE),PILOT LAMP(PREHEATING) DO NOT LIGHT UP...249

M-4 DURING SELF CHECK(ALL LAMPS LIGHT UP FOR 3 SECONDS),EVEN IF STARTING SWITCH IS TURNED TO START,SELF CHECK IS NOT COMPLETED IN 3 SECONDS...249

M-5 WHEN STARTING SWITCH IS ON(ENGINE STOPPED),ENGINE OIL PRESSURE CAUTION LAMP DOES NOT LIGHT UP...250

M-6 WHEN STARTING SWITCH IS ON(ENGINE STOPPED),CHARGE CAUTION LAMP DOES NOT LIGHT UP...251

M-7 WHEN STARTING SWITCH IS TURNED TO HEAT,PREHEATING PILOT LAMP DOES NOT LIGHT UP...252

M-8 WHEN ENGINE IS RUNNING,ENGINE OIL PRESSURE CAUTION LAMP LIGHTS UP...252

M-9 WHEN ENGINE IS RUNNING,CHARGE CAUTION LAMP LIGHTS UP...253

M-10 ABNORMALITY IN COOLANT TEMPERATURE GAUGE...255

a) LEVEL DOES NOT RISE FROM SEGMENT C...255

b) LEVEL DOES NOT GO DOWN FROM SEGMENT H,OR ALL SEGMENTS GO OUT...255

c) COOLANT TEMPERATURE DOES NOT MATCH GAUGE DISPLAY...256

M-11 ABNORMALITY IN FUEL GAUGE...257

a) LEVEL DOES NOT RISE FROM SEGMENT E OR ALL SEGMENTS GO OUT...257

b) LEVEL DOES NOT GO DOWN FROM SEGMENT F...257

c) FUEL LEVEL DOES NOT MATCH GAUGE DISPLAY...258

M-12 DEFECTIVE OPERATION OF ALARM BUZZER...259

a) BUZZER DOES NOT SOUND...259

b) BUZZER CONTINUES TO SOUND AND DOES NOT STOP...259

M-13 WHEN ENGINE IS RUNNING,SERVICE METER DOES NOT ADVANCE...260

a) WHEN CHARGE CAUTION LAMP DOES NOT LIGHT UP...260

b) WHEN CHARGE CAUTION LAMP LIGHTS UP...260

c) PILOT LAMP DOES NOT FLASH(SERVICE METER IS ACTUATED)...260

M-14 NIGHT LIGHTING DOES NOT LIGHT UP...261

a) GAUGE LIGHTING DOES NOT LIGHT UP...261

b) SERVICE METER LIGHTING DOES NOT LIGHT UP...261

30 DISASSEMBLY AND ASSEMBLY...262

METHOD OF USING MANUAL...264

PRECAUTIONS WHEN CARRYING OUT OPERATION...265

SPECIAL TOOL LIST...267

SKETCHES OF SPECIAL TOOLS...271

STARTING MOTOR...276

REMOVAL AND INSTALLATION...276

ALTERNATOR...277

REMOVAL AND INSTALLATION...277

FUEL INJECTION PUMP...278

REMOVAL...278

INSTALLATION...279

NOZZLE HOLDER...280

REMOVAL AND INSTALLATION...280

WATER PUMP...281

REMOVAL...281

INSTALLATION...282

THERMOSTAT...283

REMOVAL AND INSTALLATION...283

ENGINE FRONT SEAL...284

REMOVAL AND INSTALLATION...284

ENGINE REAR SEAL...285

REMOVAL...285

INSTALLATION...286

CYLINDER HEAD...287

REMOVAL...287

INSTALLATION...288

RADIATOR...289

REMOVAL AND INSTALLATION...289

ENGINE,HYDRAULIC PUMP...290

REMOVAL...290

INSTALLATION...293

FUEL TANK...294

REMOVAL AND INSTALLATION...294

DAMPER...295

REMOVAL AND INSTALLATION...295

CENTER SWIVEL JOINT...296

REMOVAL AND INSTALLATION...296

DISASSEMBLY AND ASSEMBLY...297

TRAVEL MOTOR...298

REMOVAL AND INSTALLATION...298

DISASSEMBLY AND ASSEMBLY(PHV-190(FOR PC20R-8))...299

DISASSEMBLY AND ASSEMBLY(PHV-200(FOR PC25R-8),PHV-250(FOR PC27R-8))...310

SPROCKET...325

REMOVAL AND INSTALLATION...325

SWING MOTOR,SWING MACHINERY...326

REMOVAL...326

INSTALLATION...327

DISASSEMBLY...328

ASSEMBLY...331

SWING MOTOR(LMF16AB(FOR PC25R-8 AND PC27R-8)...334

DISASSEMBLY...334

ASSEMBLY...339

REVOLVING FRAME...347

REMOVAL...347

INSTALLATION...348

SWING CIRCLE...349

REMOVAL AND INSTALLATION...349

IDLER...350

REMOVAL AND INSTALLATION...350

DISASSEMBLY...351

ASSEMBLY...352

RECOIL SPRING...354

REMOVAL AND INSTALLATION...354

DISASSEMBLY AND ASSEMBLY...355

TRACK ROLLER...356

REMOVAL AND INSTALLATION...356

DISASSEMBLY...357

ASSEMBLY...358

CARRIER ROLLER...359

REMOVAL AND INSTALLATION...359

DISASSEMBLY AND ASSEMBLY...360

RUBBER SHOE...361

REMOVAL AND INSTALLATION...361

STEEL SHOE...362

REMOVAL AND INSTALLATION...362

HYDRAULIC TANK...363

REMOVAL AND INSTALLATION...363

HYDRAULIC COOLER...364

REMOVAL AND INSTALLATION...364

HYDRAULIC PUMP...365

REMOVAL AND INSTALLATION...365

MAIN PUMP(LPV-30(FOR PC25R-8 AND PC27R-8)...366

DISASSEMBLY...366

ASSEMBLY...374

CONTROL VALVE...385

REMOVAL...385

INSTALLATION...386

DISASSEMBLY...387

ASSEMBLY...392

PPC VALVE...399

REMOVAL AND INSTALLATION...399

DISASSEMBLY...400

ASSEMBLY...401

BOOM CYLINDER...402

REMOVAL...402

INSTALLATION...403

ARM CYLINDER...404

REMOVAL...404

INSTALLATION...405

BUCKET CYLINDER...406

REMOVAL...406

INSTALLATION...407

BOOM SWING CYLINDER...408

REMOVAL...408

INSTALLATION...409

BLADE CYLINDER...410

REMOVAL AND INSTALLATION...410

HYDRAULIC CYLNDER...411

DISASSEMBLY...411

ASSEMBLY...414

WORK EQUIPMENT...417

REMOVAL...417

INSTALLATION...418

BUCKET...419

REMOVAL AND INSTALLATION...419

ARM...420

REMOVAL...420

INSTALLATION...421

BUCKET,ARM...422

REMOVAL...422

INSTALLATION...423

BOOM...424

REMOVAL...424

INSTALLATION...425

BOOM SWING BRACKET...426

REMOVAL...426

INSTALLATION...427

BLADE...428

REMOVAL AND INSTALLATION...428

OPERATOR'S CAB...429

REMOVAL AND INSTALLATION...429

CANOPY...429

REMOVAL AND INSTALLATION...429

FLOOR FRAME...430

REMOVAL...430

INSTALLATION...431

40 MAINTENANCE STANDARD...432

SWING CIRCLE...433

SWING MACHINERY...435

TRACK FRAME,RECOIL SPRING...437

IDLER...438

CARRIER ROLLER...439

TRACK ROLLER...440

TRACK SHOE...441

HYDRAULIC PUMP...443

HYDRAULIC PUMP(LPV30)...444

CONTROL VALVE...445

CENTER SWIVEL JOINT...451

SWING MOTOR...452

TRAVEL MOTOR...454

PPC VALVE...455

HYDRAULIC CYLINDER...456

WORK EQUIPMENT...459

90 OTHERS...465

HYDRAULIC PIPING PC20R-8...466

HYDRAULIC PIPING PC25R,27R-8...467

HYDRAULIC CIRCUIT DIAGRAM PC20R-8...468

HYDRAULIC CIRCUIT DIAGRAM PC25R-8...469

HYDRAULIC CIRCUIT DIAGRAM PC27R-8...470

CLSS 10A. OPERATION OF THE SYSTEM AS A WHOLE PC20R-8...471

CLSS 10B. OPERATION OF THE SYSTEM AS A WHOLE PC25R,PC27R-8...472

ELECTRICAL CIRCUIT DIAGRAM PC20R,25R,27R-8...473

1.1 FOREWORD...3

1.2 INFORMATION ON SAFETY...4

1.3 INTRODUCTION...6

1.3.1 INTENDED USES...6

1.3.2 IMPROPER OR UNAUTHORIZED USES...6

1.3.3 MAIN CHARACTERISTICS...7

1.3.4 RUNNING-IN...7

1.4 PRODUCT IDENTIFICATION...8

1.4.1 MACHINE SERIAL NUMBER...8

1.4.2 MACHINE IDENTIFICATION PLATE...8

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE...9

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER...9

1.4.5 SWING MOTOR SERIAL NUMBER (for PC20R only)...10

1.4.6 SWING REDUCTION GEAR SERIAL NUMBER (for PC27R only)...10

1.4.7 CAB SERIAL NUMBER...10

1.4.8 SERIAL NUMBERS AND DEALER?S ADDRESS...11

TABLE OF CONTENTS...13

1.1 FOREWORD 1...13

1.2 INFORMATION ON SAFETY 2...13

1.3 INTRODUCTION 4...13

1.3.1 INTENDED USES 4...13

1.3.2 IMPROPER OR UNAUTHORIZED USES 4...13

1.3.3 MAIN CHARACTERISTICS 5...13

1.3.4 RUNNING-IN 5...13

1.4 PRODUCT IDENTIFICATION 6...13

1.4.1 MACHINE SERIAL NUMBER 6...13

1.4.2 MACHINE IDENTIFICATION PLATE 6...13

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE 7...13

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER 7...13

1.4.5 SWING MOTOR SERIAL NUMBER (for PC20R only) 8...13

1.4.6 SWING REDUCTION GEAR SERIAL NUMBER (for PC27R only) 8...13

1.4.7 CAB SERIAL NUMBER 8...13

1.4.8 SERIAL NUMBERS AND DEALER?S ADDRESS 9...13

2.1 SAFETY, NOISE AND VIBRATION PLATES 20...13

2.1.1 POSITION OF THE SAFETY PLATES 20...13

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS 22...13

2.1.3 POSITION OF THE NOISE PLATES ON MACHINES WITH CAB 26...13

2.1.4 POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY 27...13

2.1.5 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED 27...13

2.2 GENERAL PRECAUTIONS 28...13

2.2.1 GENERAL SAFETY RULES 28...13

2.2.2 SAFETY DEVICES AND GUARDS 28...13

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS 28...13

2.2.4 UNAUTHORIZED MODIFICATIONS 29...13

2.2.5 LEAVING THE OPERATOR?S SEAT 29...13

2.2.6 GETTING ON AND OFF THE MACHINE 30...13

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL 30...13

2.2.8 PREVENTING BURNS 31...13

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER 31...13

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT 32...13

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT 32...13

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE 32...13

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT 32...13

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE 33...13

2.3.1 SAFETY ON THE WORK SITE 33...13

2.3.2 FIRE PREVENTION 33...13

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB 33...13

2.3.4 ROOM VENTILATION 34...13

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS 34...13

2.3.6 CLEANING THE WINDOWS - CHECKING THE WINDSHIELD WIPER BLADES 34...13

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING 35...14

2.4.1 STARTING THE ENGINE 35...14

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE 35...14

2.4.3 CHECKS FOR TRAVELLING IN REVERSE 35...14

2.4.4 MOVING THE MACHINE 36...14

2.4.5 MOVING ON SLOPES 37...14

2.4.6 WORKING ON SLOPES 38...14

2.4.7 UNAUTHORIZED OPERATIONS 38...14

2.4.8 PREVENTING ELECTROCUTION 39...14

2.4.9 VISIBILITY 40...14

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES 40...14

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT 40...14

2.4.12 WORKING ON LOOSE GROUND 40...14

2.4.13 PARKING THE MACHINE 41...14

2.5 TRANSPORTING THE MACHINE ON MOTOR VEHICLES 42...14

2.5.1 LOADING AND UNLOADING 42...14

2.5.2 TRANSPORT 42...14

2.6 BATTERY 43...14

2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY 43...14

2.6.2 STARTING WITH BOOSTER CABLES 43...14

2.7 PRECAUTIONS FOR THE REMOVAL 44...14

2.8 PRECAUTIONS FOR MAINTENANCE 45...14

2.8.1 WARNING PLATES 45...14

2.8.2 TOOLS 45...14

2.8.3 PERSONNEL 45...14

2.8.4 EQUIPMENT 46...14

2.8.5 WORKING UNDER THE MACHINE 46...14

2.8.6 CLEANING THE MACHINE 46...14

2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS 47...14

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY 47...14

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION 47...14

2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP 48...14

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR 48...14

2.8.12 USING LAMPS 48...14

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR 49...14

2.8.14 PRECAUTIONS CONCERNING THE STARTER 49...14

2.8.15 HANDLING HIGH-PRESSURE PIPES 50...14

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL 50...14

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE 50...14

2.8.18 COOLING FAN AND BELT 51...14

2.8.19 WASTE MATERIALS 51...14

2.8.20 PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES 51...14

3.1 SAFETY LOCKS 54...15

3.1.1 MACHINE LOCKS 54...15

3.2 GENERAL VIEWS 55...15

3.2.1 GENERAL VIEW OF THE MACHINE WITH CAB 55...15

3.2.2 GENERAL VIEW OF THE MACHINE WITH CANOPY 56...15

3.2.3 GENERAL VIEW OF THE DRIVER?S SEAT 57...15

3.3 INSTRUMENTS AND CONTROLS 58...15

3.3.1 INSTRUMENTS 58...15

3.3.2 WARNING LIGHTS 60...15

3.3.3 SWITCHES AND PUSH BUTTONS 62...15

3.3.4 ELECTRICAL ACCESSORIES 65...15

3.3.5 MACHINE CONTROLS 67...15

3.4 FUSES AND RELAYS 75...15

3.4.1 FUSES 75...15

3.4.1.1 EQUIPMENT FUSES 75...15

3.4.1.2 MAIN FUSE 76...15

3.4.2 RELAYS 77...15

3.5 GUARDS AND DRIVER?S SEAT 78...15

3.5.1 ENGINE HOOD 78...15

3.5.2 RIGHT COUNTERWEIGHT 79...15

3.5.3 CANOPY 79...15

3.5.4 CAB 80...15

3.5.5 VENTILATION AND HEATING 83...15

3.5.6 SEAT 84...15

3.5.7 SAFETY BELT 84...15

3.5.8 EMERGENCY EXIT 85...15

3.5.9 TECHNICAL DOCUMENTATION CASE 85...15

3.5.10 FIRE EXTINGUISHER 86...15

3.5.11 FIRST AID KIT 86...15

3.6 USE OF THE MACHINE 87...15

3.6.1 CHECKS BEFORE STARTING THE ENGINE 87...15

3.6.1.1 VISUAL CHECKS 87...15

3.6.1.2 DAILY CHECKS 87...15

3.6.1.3 OPERATIONAL CHECKS 88...15

3.6.2 STARTING THE ENGINE 89...15

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES 89...15

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES 90...15

3.6.3 WARMING THE ENGINE 91...15

3.6.4 HEATING THE HYDRAULIC OIL 91...15

3.6.5 HOW TO MOVE THE MACHINE 91...15

3.6.5.1 STEERING (CHANGING DIRECTION) 93...15

3.6.5.2 MOVING ON SLOPES 94...15

3.6.5.3 MAXIMUM IMMERSION DEPTH 95...15

3.7 PARKING THE MACHINE 96...16

3.7.1 PARKING ON LEVEL GROUND 96...16

3.7.2 PARKING ON SLOPES 97...16

3.8 STOPPING THE ENGINE 98...16

3.9 TRANSPORTING THE MACHINE ON MOTOR VEHICLES 99...16

3.9.1 LOADING AND UNLOADING THE MACHINE 99...16

3.9.2 TRANSPORT 100...16

3.10 LIFTING THE MACHINE 101...16

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON 102...16

3.11.1 FUEL AND LUBRICANTS 102...16

3.11.2 COOLANT 102...16

3.11.3 BATTERY 102...16

3.11.4 OTHER PRECAUTIONS 103...16

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK 103...16

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON 104...16

3.13 USING THE WORK EQUIPMENT 105...16

3.13.1 ORGANIZING THE WORK AREA 105...16

3.13.2 POSITIONING THE MACHINE FOR DIGGING OPERATIONS 106...16

3.13.3 DIGGING METHOD 107...16

3.13.4 CHANGING THE BUCKET 108...16

3.14 LONG PERIODS OF INACTIVITY 109...16

3.14.1 BEFORE THE PERIOD OF INACTIVITY 109...16

3.14.2 DURING THE PERIOD OF INACTIVITY 110...16

3.14.3 AFTER THE PERIOD OF INACTIVITY 110...16

3.15 TROUBLESHOOTING 111...16

3.15.1 OCCURRENCES THAT ARE NOT FAILURES 111...16

3.15.2 HOW TO REMOVE THE MACHINE 111...16

3.15.3 AFTER THE FUEL HAS RUN OUT 112...16

3.15.4 IF THE BATTERY IS DOWN 112...16

3.15.4.1 STARTING WITH BOOSTER CABLES 113...16

3.15.5 OTHER TROUBLES 114...16

3.15.5.1 ELECTRICAL CIRCUIT 114...16

3.15.5.2 HYDRAULIC SYSTEM 114...16

3.15.5.3 ENGINE 115...16

4.1 GUIDE TO MAINTENANCE 118...17

4.2 MAINTENANCE NOTES 120...17

4.2.1 NOTES REGARDING THE ENGINE 120...17

4.2.1.1 ENGINE OIL 120...17

4.2.1.2 COOLANT 120...17

4.2.1.3 FUEL 121...17

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM 121...17

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM 122...17

4.2.4 NOTES REGARDING LUBRICATION 122...17

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING 123...17

4.3 FUEL, COOLANT AND LUBRICANTS 124...17

4.3.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS 126...17

4.4 DRIVING TORQUES FOR SCREWS AND NUTS 127...17

4.4.1 STANDARD DRIVING TORQUES 127...17

4.4.2 SPECIFIC DRIVING TORQUES 127...17

4.5 LUBRICATION 128...17

4.5.1 LUBRICATION DIAGRAM 128...17

4.6 PERIODICAL CHANGE OF THE COMPONENTS THAT ARE CONNECTED WITH SAFETY 129...17

4.6.1 CRITICAL PARTS FOR SAFETY 130...17

4.7 MAINTENANCE PLAN 133...17

4.7.1 WHEN REQUIRED 136...17

4.7.1.a WASHING THE COOLING CIRCUIT 136...17

4.7.1.b DRAINING THE FUEL TANK 137...17

4.7.1.c CHECKING THE ELECTRICAL SYSTEM 138...17

4.7.1.d CHECKING THE STEEL TRACK TENSION 138...17

4.7.1.e CHECKING THE RUBBER TRACKS 140...17

4.7.1.f CHECKING THE RUBBER TRACK TENSION 142...17

4.7.1.g CHANGING THE RUBBER TRACK 144...17

4.7.1.h CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE 146...17

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER) 147...17

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER 147...17

4.7.2.b CHANGING THE HYDRAULIC OIL 147...17

4.7.3 CHECKS BEFORE STARTING 148...17

4.7.3.a VARIOUS CHECKS 148...17

4.7.3.b CHECKING THE COOLANT LEVEL 148...17

4.7.3.c CHECKING THE FUEL LEVEL 149...17

4.7.3.d CHECKING THE ENGINE OIL LEVEL 149...17

4.7.3.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT 150...17

4.7.3.f CHECKING THE AIR CLEANER CLOGGING INDICATOR 151...17

4.7.3.g CHECKING THE FUEL FILTER FOR SEDIMENT AND WATER 151...17

4.7.4 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (Only for machines in which the synthetic...17

4.7.5 MAINTENANCE EVERY 100 HOURS OF OPERATION 153...17

4.7.5.a LUBRICATING THE JOINTS AND THE BALL-BEARING RING 153...17

4.7.6 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION 155...18

4.7.7 MAINTENANCE EVERY 250 HOURS OF OPERATION 155...18

4.7.7.a ADJUSTING THE FAN BELT TENSION 155...18

4.7.7.b CHECKING THE BATTERY ELECTROLYTE LEVEL 156...18

4.7.7.c CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS 156...18

4.7.7.d CHANGING THE HYDRAULIC SYSTEM OIL FILTER 157...18

4.7.7.e CHANGING THE ENGINE OIL 158...18

4.7.8 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines in which the syntheti...18

4.7.9 MAINTENANCE EVERY 500 HOURS OF OPERATION 159...18

4.7.9.a CHANGING THE ENGINE OIL FILTER 159...18

4.7.9.b CHANGING THE FUEL FILTER 160...18

4.7.9.c CHANGING THE FUEL PUMP PRECLEANER 161...18

4.7.9.d CLEANING THE OUTSIDE OF THE RADIATORS 162...18

4.7.9.e DRAINING THE HYDRAULIC OIL TANK (Only for machines in which the synthetic biodegradable o...18

4.7.10 MAINTENANCE EVERY 1000 HOURS OF OPERATION 164...18

4.7.10.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS 164...18

4.7.11 MAINTENANCE EVERY 2000 HOURS OF OPERATION 165...18

4.7.11.a CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER 165...18

4.7.11.b CHANGING THE COOLANT 168...18

4.7.11.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE 169...18

4.7.11.d CHECKING THE ALTERNATOR AND THE STARTER 169...18

5.1 TECHNICAL DATA 172...18

5.1.1 STANDARD OVERALL DIMENSIONS (for model PC20R only) 172...18

5.1.2 TECHNICAL CHARACTERISTICS PC20R 173...18

5.1.3 STANDARD OVERALL DIMENSIONS (for model PC27R only) 174...18

5.1.4 TECHNICAL CHARACTERISTICS PC27R 175...18

5.1.5 LIFTING CAPACITY WITH CAB (for model PC20R only) 176...18

5.1.6 LIFTING CAPACITY WITH CANOPY (for model PC20R only) 177...18

5.1.7 LIFTING CAPACITY WITH CAB (for model PC27R only) 178...18

5.1.8 LIFTING CAPACITY WITH CANOPY (for model PC27R only) 179...18

6.1 AUTHORIZED OPTIONAL EQUIPMENT 182...19

6.1.1 PRECAUTIONS REGARDING SAFETY 182...19

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT 183...19

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT 184...19

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER) 185...19

6.2.1 DESCRIPTION AND CONTROL 185...19

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED 185...19

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER 189...19

6.2.3.1 INSTALLING THE HAMMER 189...19

6.2.3.2 REMOVING THE HAMMER 190...19

6.2.4 MAINTENANCE 190...19

6.3 ARRANGEMENT FOR THE OPERATION OF OPTIONAL EQUIPMENT 191...19

6.3.1 SELECTION VALVE (1) 191...19

6.3.2 CONTROL PEDAL (2) 192...19

6.3.3 ASSEMBLYING AND CONNECTING THE EQUIPMENT 193...19

6.3.4 MAINTENANCE 194...19

2.1 SAFETY, NOISE AND VIBRATION PLATES...22

2.1.1 POSITION OF THE SAFETY PLATES...22

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS...24

2.1.3 POSITION OF THE NOISE PLATES ON MACHINES WITH CAB...28

2.1.4 POSITION OF THE NOISE PLATES ON MACHINES WITH CANOPY...29

2.1.5 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED...29

2.2 GENERAL PRECAUTIONS...30

2.2.1 GENERAL SAFETY RULES...30

2.2.2 SAFETY DEVICES AND GUARDS...30

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS...30

2.2.4 UNAUTHORIZED MODIFICATIONS...31

2.2.5 LEAVING THE OPERATOR?S SEAT...31

2.2.6 GETTING ON AND OFF THE MACHINE...32

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL...32

2.2.8 PREVENTING BURNS...33

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER...33

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT...34

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT...34

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE...34

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT...34

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE...35

2.3.1 SAFETY ON THE WORK SITE...35

2.3.2 FIRE PREVENTION...35

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB...35

2.3.4 ROOM VENTILATION...36

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS...36

2.3.6 CLEANING THE WINDOWS - CHECKING THE WINDSHIELD WIPER BLADES...36

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING...37

2.4.1 STARTING THE ENGINE...37

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE...37

2.4.3 CHECKS FOR TRAVELLING IN REVERSE...37

2.4.4 MOVING THE MACHINE...38

2.4.5 MOVING ON SLOPES...39

2.4.6 WORKING ON SLOPES...40

2.4.7 UNAUTHORIZED OPERATIONS...40

2.4.8 PREVENTING ELECTROCUTION...41

2.4.9 VISIBILITY...42

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES...42

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT...42

2.4.12 WORKING ON LOOSE GROUND...42

2.4.13 PARKING THE MACHINE...43

2.5 TRANSPORTING THE MACHINE ON MOTOR VEHICLES...44

2.5.1 LOADING AND UNLOADING...44

2.5.2 TRANSPORT...44

2.6 BATTERY...45

2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY...45

2.6.2 STARTING WITH BOOSTER CABLES...45

2.7 PRECAUTIONS FOR THE REMOVAL...46

2.8 PRECAUTIONS FOR MAINTENANCE...47

2.8.1 WARNING PLATES...47

2.8.2 TOOLS...47

2.8.3 PERSONNEL...47

2.8.4 EQUIPMENT...48

2.8.5 WORKING UNDER THE MACHINE...48

2.8.6 CLEANING THE MACHINE...48

2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS...49

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY...49

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION...49

2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP...50

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR...50

2.8.12 USING LAMPS...50

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR...51

2.8.14 PRECAUTIONS CONCERNING THE STARTER...51

2.8.15 HANDLING HIGH-PRESSURE PIPES...52

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL...52

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE...52

2.8.18 COOLING FAN AND BELT...53

2.8.19 WASTE MATERIALS...53

2.8.20 PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES...53

3.1 SAFETY LOCKS...56

3.1.1 MACHINE LOCKS...56

3.2 GENERAL VIEWS...57

3.2.1 GENERAL VIEW OF THE MACHINE WITH CAB...57

3.2.2 GENERAL VIEW OF THE MACHINE WITH CANOPY...58

3.2.3 GENERAL VIEW OF THE DRIVER?S SEAT...59

3.3 INSTRUMENTS AND CONTROLS...60

3.3.1 INSTRUMENTS...60

3.3.2 WARNING LIGHTS...62

3.3.3 SWITCHES AND PUSH BUTTONS...64

3.3.4 ELECTRICAL ACCESSORIES...67

3.3.5 MACHINE CONTROLS...69

LEVER 1 (BASIC MANOEUVRES)...70

LEVER 2 (BASIC MANOEUVRES)...70

LEVER 1 (COMBINED MANOEUVRES)...71

LEVER 2 (COMBINED MANOEUVRES)...71

3.4 FUSES AND RELAYS...77

3.4.1 FUSES...77

3.4.1.1 EQUIPMENT FUSES...77

3.4.1.2 MAIN FUSE...78

3.4.2 RELAYS...79

3.5 GUARDS AND DRIVER?S SEAT...80

3.5.1 ENGINE HOOD...80

3.5.2 RIGHT COUNTERWEIGHT...81

3.5.3 CANOPY...81

3.5.4 CAB...82

3.5.5 VENTILATION AND HEATING...85

3.5.6 SEAT...86

3.5.7 SAFETY BELT...86

3.5.8 EMERGENCY EXIT...87

3.5.9 TECHNICAL DOCUMENTATION CASE...87

3.5.10 FIRE EXTINGUISHER...88

3.5.11 FIRST AID KIT...88

3.6 USE OF THE MACHINE...89

3.6.1 CHECKS BEFORE STARTING THE ENGINE...89

3.6.1.1 VISUAL CHECKS...89

3.6.1.2 DAILY CHECKS...89

3.6.1.3 OPERATIONAL CHECKS...90

3.6.2 STARTING THE ENGINE...91

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES...91

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES...92

3.6.3 WARMING THE ENGINE...93

3.6.4 HEATING THE HYDRAULIC OIL...93

3.6.5 HOW TO MOVE THE MACHINE...93

3.6.5.1 STEERING (CHANGING DIRECTION)...95

3.6.5.2 MOVING ON SLOPES...96

3.6.5.3 MAXIMUM IMMERSION DEPTH...97

3.7 PARKING THE MACHINE...98

3.7.1 PARKING ON LEVEL GROUND...98

3.7.2 PARKING ON SLOPES...99

3.8 STOPPING THE ENGINE...100

3.9 TRANSPORTING THE MACHINE ON MOTOR VEHICLES...101

3.9.1 LOADING AND UNLOADING THE MACHINE...101

3.9.2 TRANSPORT...102

3.10 LIFTING THE MACHINE...103

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON...104

3.11.1 FUEL AND LUBRICANTS...104

3.11.2 COOLANT...104

3.11.3 BATTERY...104

3.11.4 OTHER PRECAUTIONS...105

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK...105

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON...106

3.13 USING THE WORK EQUIPMENT...107

3.13.1 ORGANIZING THE WORK AREA...107

3.13.2 POSITIONING THE MACHINE FOR DIGGING OPERATIONS...108

3.13.3 DIGGING METHOD...109

3.13.4 CHANGING THE BUCKET...110

3.14 LONG PERIODS OF INACTIVITY...111

3.14.1 BEFORE THE PERIOD OF INACTIVITY...111

3.14.2 DURING THE PERIOD OF INACTIVITY...112

3.14.3 AFTER THE PERIOD OF INACTIVITY...112

3.15 TROUBLESHOOTING...113

3.15.1 OCCURRENCES THAT ARE NOT FAILURES...113

3.15.2 HOW TO REMOVE THE MACHINE...113

3.15.3 AFTER THE FUEL HAS RUN OUT...114

3.15.4 IF THE BATTERY IS DOWN...114

3.15.4.1 STARTING WITH BOOSTER CABLES...115

3.15.5 OTHER TROUBLES...116

3.15.5.1 ELECTRICAL CIRCUIT...116

3.15.5.2 HYDRAULIC SYSTEM...116

3.15.5.3 ENGINE...117

4.1 GUIDE TO MAINTENANCE...120

4.2 MAINTENANCE NOTES...122

4.2.1 NOTES REGARDING THE ENGINE...122

4.2.1.1 ENGINE OIL...122

4.2.1.2 COOLANT...122

4.2.1.3 FUEL...123

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM...123

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM...124

4.2.4 NOTES REGARDING LUBRICATION...124

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING...125

4.3 FUEL, COOLANT AND LUBRICANTS...126

LUBRICATION WITH GREASE...126

4.3.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS...128

4.4 DRIVING TORQUES FOR SCREWS AND NUTS...129

4.4.1 STANDARD DRIVING TORQUES...129

4.4.2 SPECIFIC DRIVING TORQUES...129

4.5 LUBRICATION...130

4.5.1 LUBRICATION DIAGRAM...130

4.6 PERIODICAL CHANGE OF THE COMPONENTS THAT ARE CONNECTED WITH SAFETY...131

4.6.1 CRITICAL PARTS FOR SAFETY...132

FUEL SUPPLY SYSTEM...132

HYDRAULIC SYSTEM...133

4.7 MAINTENANCE PLAN...135

4.7.1 WHEN REQUIRED...138

4.7.1.a WASHING THE COOLING CIRCUIT...138

4.7.1.b DRAINING THE FUEL TANK...139

4.7.1.c CHECKING THE ELECTRICAL SYSTEM...140

4.7.1.d CHECKING THE STEEL TRACK TENSION...140

4.7.1.e CHECKING THE RUBBER TRACKS...142

4.7.1.f CHECKING THE RUBBER TRACK TENSION...144

4.7.1.g CHANGING THE RUBBER TRACK...146

4.7.1.h CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE...148

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER (BREAKER)...149

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER...149

4.7.2.b CHANGING THE HYDRAULIC OIL...149

4.7.3 CHECKS BEFORE STARTING...150

4.7.3.a VARIOUS CHECKS...150

4.7.3.b CHECKING THE COOLANT LEVEL...150

4.7.3.c CHECKING THE FUEL LEVEL...151

4.7.3.d CHECKING THE ENGINE OIL LEVEL...151

4.7.3.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT...152

4.7.3.f CHECKING THE AIR CLEANER CLOGGING INDICATOR...153

4.7.3.g CHECKING THE FUEL FILTER FOR SEDIMENT AND WATER...153

4.7.4 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (Only for machines in which the synthetic...154

4.7.5 MAINTENANCE EVERY 100 HOURS OF OPERATION...155

4.7.5.a LUBRICATING THE JOINTS AND THE BALL-BEARING RING...155

4.7.6 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION...157

4.7.7 MAINTENANCE EVERY 250 HOURS OF OPERATION...157

4.7.7.a ADJUSTING THE FAN BELT TENSION...157

4.7.7.b CHECKING THE BATTERY ELECTROLYTE LEVEL...158

4.7.7.c CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS...158

4.7.7.d CHANGING THE HYDRAULIC SYSTEM OIL FILTER...159

4.7.7.e CHANGING THE ENGINE OIL...160

4.7.8 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines in which the syntheti...161

4.7.9 MAINTENANCE EVERY 500 HOURS OF OPERATION...161

4.7.9.a CHANGING THE ENGINE OIL FILTER...161

4.7.9.b CHANGING THE FUEL FILTER...162

4.7.9.c CHANGING THE FUEL PUMP PRECLEANER...163

4.7.9.d CLEANING THE OUTSIDE OF THE RADIATORS...164

4.7.9.e DRAINING THE HYDRAULIC OIL TANK (Only for machines in which the synthetic biodegradable o...165

4.7.10 MAINTENANCE EVERY 1000 HOURS OF OPERATION...166

4.7.10.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS...166

4.7.11 MAINTENANCE EVERY 2000 HOURS OF OPERATION...167

4.7.11.a CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER...167

4.7.11.b CHANGING THE COOLANT...170

4.7.11.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE...171

4.7.11.d CHECKING THE ALTERNATOR AND THE STARTER...171

5.1 TECHNICAL DATA...174

5.1.1 STANDARD OVERALL DIMENSIONS (for model PC20R only)...174

MACHINE WITH CAB...174

MACHINE WITH CANOPY...174

5.1.2 TECHNICAL CHARACTERISTICS PC20R...175

5.1.3 STANDARD OVERALL DIMENSIONS (for model PC27R only)...176

MACHINE WITH CAB...176

MACHINE WITH CANOPY...176

5.1.4 TECHNICAL CHARACTERISTICS PC27R...177

5.1.5 LIFTING CAPACITY WITH CAB (for model PC20R only)...178

5.1.6 LIFTING CAPACITY WITH CANOPY (for model PC20R only)...179

5.1.7 LIFTING CAPACITY WITH CAB (for model PC27R only)...180

5.1.8 LIFTING CAPACITY WITH CANOPY (for model PC27R only)...181

6.1 AUTHORIZED OPTIONAL EQUIPMENT...184

6.1.1 PRECAUTIONS REGARDING SAFETY...184

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT...185

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT...186

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER)...187

6.2.1 DESCRIPTION AND CONTROL...187

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED...187

FOR A CORRECT USE, IT IS NECESSARY TO:...187

ALWAYS AVOID THE FOLLOWING INCORRECT USES:...189

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER...191

6.2.3.1 INSTALLING THE HAMMER...191

6.2.3.2 REMOVING THE HAMMER...192

6.2.4 MAINTENANCE...192

6.3 ARRANGEMENT FOR THE OPERATION OF OPTIONAL EQUIPMENT...193

6.3.1 SELECTION VALVE (1)...193

6.3.2 CONTROL PEDAL (2)...194

6.3.3 ASSEMBLYING AND CONNECTING THE EQUIPMENT...195

6.3.4 MAINTENANCE...196