Komatsu Hydraulic Excavators PC27MRX, PC30MRX, PC35MRX, PC40MRX, PC45MRX Repair Service Manual + Operation & Maintenance Manual

Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavators PC27MRX-1, PC30MRX-1, PC35MRX-1, PC40MRX-1, PC45MRX-1, with all the technical information to maintain, diagnose, repair, abd rebuild like professional mechanics.

Komatsu Hydraulic Excavators PC27MRX-1, PC30MRX-1, PC35MRX-1, PC40MRX-1, PC45MRX-1 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 2,477 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

SEBM016808 - Hydraulic Excavators PC27MRX-1, PC30MRX-1, PC35MRX-1, PC40MRX-1, PC45MRX-1 Shop Manual.pdf

SEAM035305T - Hydraulic Excavator PC27MR-x1, PC30MR-x1, PC35MR-x1 Operation & Maintenance Manual.pdf

SEAM043000 - Hydraulic Excavator PC40MRx-1, PC45MRx-1 Operation & Maintenance Manual.pdf

SEAM043006T - Hydraulic Excavator PC40MRx-1, PC45MRx-1 Operation & Maintenance Manual.pdf

SEAM055301T - Hydraulic Excavator GALEO PC40MR-2, PC50MR-2 Operation & Maintenance Manual.pdf

TEN00054-03 - Hydraulic Excavator GALEO PC40MR-2, PC50MR-2 Operation & Maintenance Manual.pdf

TEN00193-00 - Hydraulic Excavator GALEO PC40MR-2, PC50MR-2 Operation & Maintenance Manual.pdf

MAIN SECTIONS

COVER...1

CONTENTS...2

01 GENERAL...27

GENERAL ASSEMBLY DRAWING...28

SPECIFICATIONS...38

WEIGHT TABLE...66

LIST OF LUBRICANT AND WATER...76

10 STRUCTURE AND FUNCTION...78

ENGINE CONTROL...79

PTO...81

RADIATOR AND OIL COOLER...83

POWER TRAIN...87

SWING CIRCLE...90

SWING MACHINERY...91

TRACK FRAME...93

IDLER CUSHION...95

HYDRAULIC PIPING...97

VALVE CONTROL...101

HYDRAULIC TANK...107

CLSS...111

HYDRAULIC PUMP(PISTON PUMP)...186

LS/PC VALVE AND SERVO PISTON...201

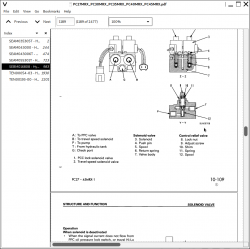

SOLENOID VALVE...206

CONTROL VALVE...209

SWING MOTOR...229

CENTER SWIVEL JOINT...237

TRAVEL MOTOR...240

PPC VALVE...264

SERVICE PPC VALVE...273

WORK EQUIPMENT...277

AIR CONDITIONER...278

ACTUAL ELECTRIC WIRING DIAGRAM...279

MACHINE MONITOR SYSTEM...283

20 TESTING AND ADJUSTING...290

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS...291

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS...296

STANDARD VALUE TABLE FOR ELECTRICAL PARTS...337

TESTING AND ADJUSTING...339

TOOLS FOR TESTING,ADJUSTING,AND TROUBLESHOOTING...340

MEASURING ENGINE SPEED...341

MEASURING EXHAUST COLOR...342

ADJUSTING VALVE CLEARANCE...343

MEASURING COMPRESSION PRESSURE...344

MEASURING ENGINE OIL PRESSURE...346

TESTING AND ADJUSING FUEL INJECTION TIMING...347

TESTING AND ADJUSTING FAN BELT TENSION...348

ADJUSTING FUEL CONTROL LEVER...350

MEASURING SPROCKET WEAR...352

TESTING AND ADJUSTING TRACK SHOE TENSION...353

HYDRAULIC EQUIPMENT ADJUSTING CONTROL LEVERS AND PEDAL...354

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT,SWING,TRAVEL CIRCUIT...357

TESTING AND ADJUSTING LS DIFFERENTIAL PRESSURE...367

ADJUSTING PC VALVE...372

TESTING CONTROL CIRCUIT PRESSURE...373

TESTING AND ADJUSTING CONTROL CIRCUIT PRESSURE...375

MEASURING OUTPUT PRESSURE OF SOLENOID VALVE...377

MEASURING OUTPUT PRESSURE OF PPC VALVE...380

ADJUSTING WORK EQUIPMENT,SWING PPC VALVE...382

TESTING SWING HOLDING BRAKE INLET PORT PRESSURE...383

TESTING AND ADJUSTING TRAVEL DEVIATION...387

MEASURING OIL LEAKAGE INSIDE WORK EQUIPMENT CYLINDER...389

BLEEDING AIR...391

RELEASING REMAINING PRESSURE FROM HYDRAULIC CIRCUIT...393

RELEASING REMAINING PRESSURE FROM HYDRAULIC TANK...393

PRESSURIZING HYDRAULIC TANK...393

TESTING AND ADJUSTING HYDRAULIC BREAKER SERVICE VALVE...394

TESTING AND CHARGING PRESSURE OF HYDRAULIC BREAKER GAS(N2)...395

ELECTRICAL RELATED PARTS PROCEDURE FOR CHECKING DIODE...398

TROUBLESHOOTING...399

POINTS TO REMEMBER WHEN TROUBLESHOOTING...400

SEQUENCE OF EVENTS IN TROUBLESHOOTING...401

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE...402

CHECKS BEFORE TROUBLESHOOTING ...410

CONNECTOR TYPES AND MOUNTING LOCATIONS...411

CONNECTOR PIN ALLOCATION DRAWING...415

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS...421

METHOD OF USING TROUBLESHOOTING CHARTS...435

TROUBLESHOOTING OF ELECTRICAL SYSTEM(E MODE)...437

E-MODE RELATED ELECTRICAL CIRCUIT DIAGRAM...438

E-1 ENGINE DOES NOT START...447

a) WHEN STARTING MOTOR DOES NOT TURN (STARTING SYSTEM)...447

b) WHEN STARTING MOTOR TURNS (ENGINE STOP SOLENOID SYSTEM)...450

E-2 ENGINE DOES NOT STOP...466

E-3 WORK EQUIPMENT DOES NOT MOVE EVEN WHEN WORK EQUIPMENT LOCK LEVER IS CANCELED...470

E-4 WORK EQUIPMENT MOVES EVEN WHEN WORK EQUIPMENT LOCK LEVER IS LOCKED...474

E-5 TRAVEL SPEED DOES NOT INCREASE EVEN WHEN TRAVEL BOOST PEDAL IS DEPRESSED...478

E-6 TRAVEL SPEED DOES NOT DECREASE EVEN WHEN TRAVEL BOOST PEDAL IS RELEASED...481

TROUBLESHOOTING OF HYDRAULIC,MECHANICAL SYSTEM(H MODE)...484

TABLE OF FAILURE MODES AND CAUSES...485

H-1 SPEEDS OF ALL WORK EQUIPMENT,SWING,TRAVEL ARE SLOW OR LACK POWER ...489

H-2 THERE IS EXCESSIVE DROP IN ENGINE SPEED,OR ENGINE STALLS...492

H-3 NO WORK EQUIPMENT,TRAVEL,SWING MOVE...495

H-4 ABNORMAL NOISE GENERATED(FROM AROUND PUMP)...496

H-5 FINE CONTROL ABILITY IS POOR OR RESPONSE IS POOR...497

H-6 BOOM IS SLOW OR LACKS POWER...498

H-7 ARM IS SLOW OR LACKS POWER...500

H-8 BUCKET IS SLOW OR LACKS POWER...502

H-9 BOOM SWING IS SLOW OR LACKS POWER...504

H-10 BLADE IS SLOW OR LACKS POWER...507

H-11 BOOM,ARM,BUCKET DO NOT MOVE(BOOM SWING,BLADE,TRAVEL AND SWING ARE NORMAL)...508

H-12 EXCESSIVE HYDRAULIC DRIFT(BOOM,ARM,BUCKET,BOOM SWING,BLADE)...509

a)BOOM...509

b)ARM,BUCKET,BOOM SWING...509

c)BLADE...509

H-13 EXCESSIVE TIME LAG(ENGINE AT LOW IDLING)...510

H-14 IN COMPOUND OPERATIONS, WORK EQUIPMENT WITH LARGER LOAD IS SLOW...510

H-15 TRAVEL DEVIATION...511

a) WHEN THERE IS DEVIATION DURING NORMAL TRAVEL...511

b) THERE IS DEVIATION WHEN MACHINE MOVES OFF...511

H-16 TRAVEL SPEED IS SLOW OR LACKS POWER...515

H-17 STEERING DOES NOT TURN EASILY...516

H-18 TRAVEL SPEED DOES NOT SWITCH...516

H-19 TRAVEL DOES NOT MOVE(ONE SIDE ONLY)...516

H-20 SWING SPEED IS SLOW OR LACKS POWER...517

a) SPEED IS SLOW OR LACKS POWER IN BOTH DIRECTIONS...517

b) SPEED IS SLOW OR LACKS POWER IN ONE DIRECTION ONLY(LEFT OR RIGHT)...517

H-21 DOES NOT SWING...519

a) DOES NOT SWING IN EITHER DIRECTION...519

b) DOES NOT SWING IN ONE DIRECTION(LEFT OR RIGHT)...519

H-22 SWING ACCELERATION IS POOR...520

a) ACCELERATION IS POOR IN BOTH DIRECTIONS...520

b) ACCELERATION IS POOR IN ONE DIRECTION ONLY(LEFT OR RIGHT)...520

H-23 EXCESSIVE OVERRUN WHEN STOPPING SWING...521

a) OVERRUN WHEN STOPPING IS EXCESSIVE IN BOTH DIRECTIONS(LEFT AND RIGHT)...521

b) OVERRUN WHEN STOPPING IS EXCESSIVE IN ONE DIRECTION ONLY(LEFT OR RIGHT)...521

H-24 EXCESSIVE SHOCK WHEN STOPPING SWING(IN ONE DIRECTION ONLY)...522

H-25 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING...522

H-26 EXCESSIVE HYDRAULIC DRIFT OF SWING...522

TROUBLESHOOTING OF MACHINE MONITOR SYSTEM(M MODE)...523

M-MODE RELATED ELECTRICAL CIRCUIT DIAGRAM...524

M-1 WHEN STARTING SWITCH IS TURNED ON,NO DISPLAY IS GIVEN...528

M-2 WHEN STARTING SWITCH IS TURNED ON,EVEN WHEN SELF CHECK IS COMPLETED(ALL LAMPS LIGHT UP FOR 3 SECONDS),LAMPS DO NOT GO OUT...530

M-3 WHEN STARTING SWITCH IS TURNED ON, SOME SELF CHECK LAMPS DO NOT LIGHT UP FOR 3 SECONDS...531

a) NO GAUGE LAMPS LIGHT UP(FUEL,COOLANT TEMPERATURE)...531

b) CAUTION LAMPS(ENGINE OIL PRESSURE,BATTERY CHARGE),PILOT LAMP(PREHEATING) DO NOT LIGHT UP...531

M-4 DURING SELF CHECK (ALL LAMPS LIGHT UP FOR 3 SECONDS),EVEN IF STARTING SWITCH IS TURNED TO START,SELF CHECK IS NOT COMPLETED FOR 3 SECONDS...531

M-5 WHEN STARTING SWITCH IS ON(ENGINE STOPPED),ENGINE OIL PRESSURE CAUTION LAMP DOES NOT LIGHT UP...532

M-6 WHEN STARTING SWITCH IS ON(ENGINE STOPPED),CHARGE CAUTION LAMP DOES NOT LIGHT UP...533

M-7 WHEN STARTING SWITCH IS TURNED TO HEAT,PREHEATING PILOT LAMP DOES NOT LIGHT UP...534

M-8 WHEN ENGINE IS RUNNING, ENGINE OIL PRESSURE CAUTION LAMP LIGHTS UP...535

M-9 WHEN ENGINE IS RUNNING, CHARGE CAUTION LAMP LIGHTS UP...536

M-10 ABNORMALITY IN COOLANT TEMPERATURE GAUGE...537

a) LEVEL DOES NOT RISE FROM SEGMENT C...537

b) LEVEL DOES NOT GO DOWN FROM SEGMENT H,OR ALL SEGMENTS GO OUT...537

c) COOLANT TEMPERATURE DOES NOT MATCH GAUGE DISPLAY...538

M-11 ABNORMALITY IN FUEL GAUGE...543

a) LEVEL DOES NOT RISE FROM SEGMENT E OR ALL SEGMENTS GO OUT...543

b) LEVEL DOES NOT GO DOWN FROM SEGMENT F...543

c) FUEL LEVEL DOES NOT MATCH GAUGE DISPLAY...544

M-12 DEFECTIVE OPERATION OF ALARM BUZZER...547

a) BUZZER DOES NOT SOUND...547

b) BUZZER CONTINUES TO SOUND AND DOES NOT STOP...547

M-13 WHEN ENGINE IS RUNNING,SERVICE METER DOES NOT ADVANCE...550

a) WHEN CHARGE CAUTION LAMP DOSE NOT LIGHT UP...550

b) WHEN CHARGE CAUTION LAMP LIGHTS UP...550

c) PILOT LAMP DOES NOT FLASH(SERVICE METER IS ACTUATED)...550

M-14 NIGHT LIGHTING DOES NOT LIGHT UP...551

a) GAUGE LIGHTING DOES NOT LIGHT UP...551

b) SERVICE METER LIGHTING DOES NOT LIGHT UP...551

30 DISASSEMBLY AND ASSEMBLY...555

METHOD OF USING MANUAL...557

PRECAUTIONS WHEN CARRYING OUT OPERATION...558

SPECIAL TOOL LIST...560

SKETCHES OF SPECIAL TOOLS...565

STARTING MOTOR...571

REMOVAL AND INSTALLATION...571

ALTERNATOR...573

REMOVAL AND INSTALLATION...573

FUEL INJECTION PUMP...576

REMOVAL...576

INSTALLATION...577

NOZZLE HOLDER...580

REMOVAL AND INSTALLATION ...580

WATER PUMP...582

REMOVAL AND INSTALLATION...582

THERMOSTAT...583

REMOVAL AND INSTALLATION...583

ENGINE FRONT SEAL...584

REMOVAL AND INSTALLATION...584

ENGINE REAR SEAL...585

REMOVING...585

INSTALLATION...586

CYLINDER HEAD ...587

REMOVAL...587

INSTALLATION...589

RADIATOR,HYDRAULIC COOLER...590

REMOVAL...590

INSTALLATION...591

ENGINE,MAIN PUMP...595

REMOVAL...595

INSTALLATION...598

DAMPER...603

REMOVAL AND INSTALLATION...603

CENTER SWIVEL JOINT...604

REMOVAL AND INSTALLATION...604

DISASSEMBLY AND ASSEMBLY...608

TRAVEL MOTOR ...612

REMOVAL AND INSTALLATION...612

TRAVEL MOTOR(PHV-500(FOR PC40MRX-1))...613

DISASSEMBLY AND ASSEMBLY...613

SPROCKET...628

REMOVAL AND INSTALLATION...628

SWING MOTOR,SWING MACHINERY...629

REMOVAL AND INSTALLATION...629

DISASSEMBLY...634

ASSEMBLY...637

SWING MOTOR...640

DISASSEMBLY...640

ASSEMBLY...645

REVOLVING FRAME...653

REMOVAL...653

INSTALLATION...654

SWING CIRCLE...656

REMOVAL AND INSTALLATION...656

IDLER...657

REMOVAL AND INSTALLATION...657

DISASSEMBLY...658

ASSEMBLY...659

RECOIL SPRING...660

REMOVAL AND INSTALLTION...660

DISASSEMBLY...661

ASSEMBLY...663

TRACK ROLLER...665

REMOVAL AND INSTALLATION...665

DISASSEMBLY...666

ASSEMBLY...667

CARRIER ROLLER...668

REMOVAL AND INSTALLATION...668

DISASSEMBLY AND ASSEMBLY...669

RUBBER SHOE...670

REMOVAL AND INSTALLATION...670

HYDRAULIC TANK...671

REMOVAL AND INSTALLATION...671

FUEL TANK ...676

REMOVAL...676

INSTALLATION...677

MAIN PUMP...679

REMOVAL AND INSTALLATION ...679

MAIN PUMP(LPV30 (FOR PC30MRX-1))...680

DISASSEMBLY...680

ASSEMBLY...688

MAIN PUMP(LPD25+25(FOR PC40MRX-1))...699

DISASSEMBLY...699

ASSEMBLY...708

SWING GEAR PUMP...721

REMOVAL AND INSTALLATION...721

PPC PUMP...722

REMOVAL AND INSTALLATION...722

MAIN CONTROL VALVE...724

REMOVAL ...724

INSTALLATION...725

DISASSEMBLY...730

ASSEMBLY...736

WORK EQUIPMENT LEFT PPC VALVE(FOR ARM,SWING CONTROL)...759

REMOVAL AND INSTALLATION...759

WORK EQUIPMENT RIGHT PPC VALVE(FOR BOOM AND BUCKET CONTROL)...761

REMOVAL AND INSTALLATION...761

WORK EQUIPMENT PPC VALVE...763

DISASSEMBLY...763

ASSEMBLY...764

BOOM CYLINDER...765

REMOVAL AND INSTALLATION...765

ARM CYLINDER...768

REMOVAL AND INSTALLATION...768

BUCKET CYLINDER...771

REMOVAL AND INSTALLATION...771

SWING CYLINDER...774

REMOVAL AND INSTALLATION...774

BLADE CYLINDER ...780

REMOVAL AND INSTALLATION...780

HYDRAULIC CYLINDER...783

DISASSEMBLY...783

ASSEMBLY...786

WORK EQUIPMENT...790

REMOVAL AND INSTALLATION...790

BUCKET...793

REMOVAL AND INSTALLATION...793

ARM...795

REMOVAL AND INSTALLATION...795

BUCKET,ARM...798

REMOVAL AND INSTALLATION...798

SWING BRACKET...801

REMOVAL AND INSTALLATION...801

BLADE...804

REMOVAL AND INSTALLATION...804

SEAT BRACKET,R.H. AND L.H. PPC VALVE...807

REMOVAL...807

INSTALLATION...809

SEAT BRACKET...810

REMOVAL AND INSTALLATION...810

SOLENOID VALVE...811

REMOVAL...811

INSTALLATION...812

HEATER...815

REMOVAL AND INSTALLATION...815

FLOOR FRAME...816

REMOVAL ...816

INSTALLATION...819

CANOPY...820

REMOVAL AND INSTALLATION...820

OPERATOR'S CAB...821

REMOVAL ...821

INSTALLATION...822

COUNTERWEIGHT...823

REMOVAL AND INSTALLATION...823

HYDRAULIC BREAKER...824

DISASSEMBLY...824

ASSEMBLY...831

40 MAINTENANCE STANDARD...839

SWING MACHINERY...840

SWING CIRCLE...844

TRACK FRAME...845

IDLER...849

CARRIER ROLLER...852

TRACK ROLLER...854

SPROCKET...856

TRACK SHOE...858

HYDRAULIC PUMP...866

CONTROL VALVE...870

SWING MOTOR...887

TRAVEL MOTOR...889

PPC VALVE...893

SERVICE PPC VALVE...896

CENTER SWIVEL JOINT...898

HYDRAULIC CYLINDER...901

WORK EQUIPMENT...908

DIMENSION OF WORK EQUIPMENT...912

90 OTHERS...928

HYDRAULIC CIRCUIT DIAGRAM...929

PC27MRX-1...929

PC30MRX-1...930

PC35MRX-1...931

PC40MRX-1 (SERIAL NO.:1001-5500)...932

PC40MRX-1 (EU SPEC.)(SERIAL NO.:1001-5500)...934

PC45MRX-1 (SERIAL NO.:1001-3000)...936

ELECTRICAL CIRCUIT DIAGRAM...938

PC27,30MRX-1(CANOPY SPECIFICATION)...938

PC27,30MRX-1(CAB SPECIFICATION)...939

PC35MRX-1(CAB SPECIFICATION)...940

PC40,45MRX-1(CAB SPECIFICATION)...941

PC40MRX-1(CAB SPECIFICATION)(EU SPEC.)...943

PC40,45MRX-1(CAB SPECIFICATION)(USA SPEC.)...945

AIR CONDITIONER ELECTRICAL CIRCUIT DIAGRAM...947

COVER...1

FOREWORD...2

FOREWORD...3

SAFETY INFORMATION...6

INTRODUCTION...8

DIRCTIONS OF MACHINE...8

PRODUCT INFORMATION...9

MACHINE SERIAL NUMBER PLATE AND ITS LOCATION...9

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION...9

EMISSION CONTROL INFORMATION LABEL AND ITS LOCATION...10

SERVICE METER LOCATION...10

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR...11

CONTENTS...12

SAFETY...15

SAFETY INFORMATION...16

SAFETY LABELS...18

LOCATION OF SAFETY LABELS...18

SAFETY LABELS...19

SAFETY INFORMATION...24

SAFTY RULES...24

IF ABNORMALITIES ARE FOUND...24

WORKING WEAR AND PERSONAL PROTECTIVE LTEMS...24

FIRE EXTINGUISHER AND FIRST AID KIT...24

SAFETY EQUIPMENT...25

KEEP MACHINE CLEAN...25

KEEP OPERATOR'S COMPARTMENT CLEAN...25

LEAVING OPERATOR'S SEAT WITH LOCK...25

HANDRAILS AND STEPS...26

MOUNTING AND DISMOUNTING...26

NO PERSONS ON ATTACHMENTS...26

BURN PREVENTION ...27

FIRE PREVENTION AND EXPLOSION PREVENTION...27

ACTION IF FIRE OCCURS...28

WINDSHIELD WASHER FLUID...28

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION...28

ATTACHMENT INSTALLATION...29

ATTACHMENT COMBINATIONS...29

CAB WINDOW GLASSES...29

UNAUTHORIZED MODIFICATIONS...29

SAFETY AT JOBSITE...29

WORKING ON LOOSE GROUND...29

DISTANCE TO HIGH VOLTAGE CABLES...30

ENSURE GOOD VISIBILITY...30

VENTILATION FOR ENCLOSED ARES...31

SIGNALMAN'S SIGNAL AND SIGNS...31

EMERGENCY EXIT FROM OPERATOR'S CAB...31

ASBESTOS DUST HAZARD PREVENTION...31

SAFETY MACHINE OPREATION...32

STARTING ENGINE...32

CHECKS BEFORE STARTING ENGINE...32

SAFETY RULES FOR STARTING ENGINE...32

STARTING ENGINE IN CILD WEATHER...33

OPERATION...34

CHECKS BEFORE OPERATION...34

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS...34

SAFETY RULES FOR TRAVELING...35

TRAVELING ON SLOPES...36

OPERATIONS ON SLOPES...37

PROHIBITED OPERATIONS...37

OPERATIONS ON SNOW...38

PARKING MACHINE...39

TRANSPORTATION...40

LOADING AND UNLOADING...40

SHIPPING THE MACHINE...40

BATTERY...41

BATTERY HAZARD PREVENTION...41

STARTING ENGINE WITH BOOSTER CABLES...42

TOWINE...43

SAFETY RULES FOR TOWING...43

LIFTING OBJECTS WITH BUCKET...44

SAFETY RULES FOR LIFTING OBJECTS...44

SAFETY MACHINE INFORMATION...45

WARNING TAG...45

KEEP WORK PLACE CLEAN AN TIDY...45

APPOINT LEADER WHEN WORKING WITH OTHERS...45

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE...46

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING...47

PROPER TOOLS...47

ACCUMULATOR...48

PERSONNEL...48

ATTACHMENTS...48

WORK UNDER TE MACHINE...48

NOISE...48

WHEN USING HARMMER...49

WELDING WORKS...49

REMOVING BATTERY TERMINALS...49

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION...49

DO NOT DISASSEMBLE RECOIL SPRINGS...49

SAFETY RULES FOR HIGH-PRSSURE OIL...50

SAFETY HANDLING HIGH-PRESSURE HOSES...50

WASTE MATERIALS...50

AIR CONDITIONER MAINTENANCE...51

COMPRESSED AIR...51

PERIODIC REPLACEMENT OF SAFETY CIRTICAL PARTS...51

OPERATION...52

MACHINE VIEW ILLUSTRATIONS...53

OVERALL MACHINE VIEW...53

CONTROLS AND GAUGES...54

DETAILED CONTROLS AND GAUGES...55

MONITORING SYSTEM...55

SWITCHES...61

CONTROL LEVERS AND PEDALS...64

WINSHIELD...69

SLIDING DOOR...73

REAR WINDOW...74

EMERGENCY ESCAPE HAMMER...75

COVER WITH LOCK...76

ENGINE HOOD...77

FUSE...78

BLOCK FUSE...78

OPERATION MANUAL STORAGE ...79

TOOL BOX...79

GRASE GUN HOLDER...79

MACHINE OPERATIONS AND COTROLS...80

BEFORE STARTING ENGINE...80

STARTING ENGINE...92

AFTER STARTING ENGINE...95

STOPPING THE ENGINE...98

CHECK AFTER SHUT OFF ENGINE...98

MACHINE OPERATION...99

STEERING THE MACHINE...103

SWINGING...105

WORK EQUIPMENT CONTROLS AND OPERATIONS...106

PROHIBITED OPERATIONS ...108

GENERAL OPERATION INFORMATION...111

TRAVELING ON SLOPES...112

ESCAPE FROM MUD...114

WORK POSSIBLE USING COMPACT HYDRAULIC EXCAVATOR...115

BUCKET REPLACEMENT...117

PARKING MACHINE...118

MACHINE INSPECTION AFTER DAILY WORK...119

LOCKING...120

RUBBER SHOES AND ROAD LINERS...121

TRANSPORTATION...126

TRANSPOTRATION PROCEDURE...126

LOADING AND UNLOADING WITH TRAILERS...126

LIFTING MACHINE...131

COLD WEATHER OPERATION...133

COLD WEATHER OPERATION INFORMATION...133

CAB HEATER COLD WEATHER...134

AFTER DAILY WORK COMPLETION...135

AFTER COLD WEATHER SEASON...135

LONG TERM STORAGE...136

BEFORE STORAGE...136

DURING STORAGE...137

AFTER STORAGE...137

STARTING MACHINE AFTER LONG-TERM STORAGE...137

TROUBLES AND ACTIONS...138

RUNNING OUT OF FUEL...138

PHENOMENA THAT ARE NOT FAILURES...138

TOWING THE MACHINE...139

SEVERE JOB CONDITION ...139

DISCHARGED BATTERY...140

OTHER TROUBLE...144

MAINTENANCE...148

MAINTENANCE INFORMATION...149

LUBRICANTS, COOLANT AND FILTERS...151

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC...151

ELECTRIC SYSTEM MAINTENANCE...154

WEAR PARTS...155

WEAR PARTS LIST...155

LUBRCANTS, FUEL AND COOLANT SPECIFICATIONS...156

PROPER SELECTION...156

TIGHTENING TORQUE SPECIFICATIONS...160

TIGHTENING TORQUE LIST...160

SAFETY CRITICAL PARTS...161

SAFETY CRITICAL PARTS LIST...161

MAINTENANCE SCHEDULE...162

MAINTENANCE SCHEDULE CHART...162

MAINTENANCE INTERVAL FOR HYDRAURIC BREAKER...163

MAINTENANCE PROCEDURE...164

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS) ...164

REPLACE ENGINE OIL FILTER CARTRIDGE...164

REPLACE FUEL FILTER ELEMENT...164

CHECK ENGINE VALVE CLEARANCE, ADJUST...164

WHEN REQUIPED...165

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT...165

CLEAN INSIDE OF COOLING SYSTEM...168

CHECK BATTERY ELECTROLYTE LEVEL...171

CLEAN FUEL FILTER ELEMENT...174

CHECK AND TIGHTEN TRACK SHOE BOLTS...175

CHECK AND ADJUST TRACK TENSION ...176

CHECK, RUBBER SHOES OR ROAD LINERS...178

CHECK AND ADJUST RUBBER SHOE TENSION ...180

REPLACE RUBBER SHOES...182

REPLACE ROAD LINERS...185

REPLACE BUCKET TEETH...186

CHECK, CLEAN AND LUBRICATE CAB SLIDE DOOR RAIL AND ROLLER...189

DRAIN WATER AND SEDIMENT FROM FUEL TANK...190

BLEEDING AIR...190

CHECK BEFORE STARTING...191

EVERY 100 HOURS MAINTENANCE...192

LUBRICATING...192

EVERY 250 HOURS MANTENANCE...194

REPLACE ENGINE OIL IN ENINE OIL PAN...194

CHECK OIL LEVEL IN FINAL DRIVE CASES, ADD OIL...195

REPLACE HYDRAULIC FILTER ELEMENT...196

CHECK AND ADJUST COOLING FAN BELT TENSION...198

EVERY 500 HOURS MANTENANCE...199

LUBRICATION...199

REPLACE ENGINE OIL FILTER CARTRIDGE...200

REPLACE FUEL FILTER ELEMENT...201

CLEAN AND INSPECT RADIATOR FINS AND OIL COOLER FINS...202

REPLACE FUEL FEED PUMP PRE-FILTER...203

EVERY 1000 HOURS MANTENANCE...204

CHANGE OIL IN FINAL DRIVE CASE...204

EVERY 2000 HOURS MANTENANCE...205

CHANGE OIL IN HYDRAURIC TANK, CLEAN STRAINER...205

CHECK ALTERNATOR, STARTING MOTOR...207

CHECK ENGINE VALVE CLEARANCES,ADJUST...207

SPECIFICATIONS...208

SPECIFICATIONS...209

ATTACHMENTS, OPTIONS...211

ATTACHMENTS AND OPTIONS-GENERAL INFORMATION...212

SAFETY FIRST...212

ATTACHMENT INSTALLATION...213

BUCKET WITH HOOK...214

HOOK CONDITION...214

PROHIBITED OPERATIONS...214

AIR CONDITIONER...215

CONTROL PANEL AND COMPONENTS...215

AIR CONDITIONER CONTROLS...217

AIR CONDITIONER MAINTENANCE...218

RADIO...221

CONTROL PANEL...221

CONTROLS OF RADIO...224

CARE FOR RADIO...225

WINDSHIELD WASHER...226

WINDSHIELD WASHER OPERATION...226

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID...226

MACHINE READY FOR ATTACHMENT...227

LOCATIONS...227

HYDRAULIC CIRCUIT...229

ATTACHMENT OPERATONS...231

LONG TERM STORAGE ...232

SPECIRCATIONS...232

CHANGING MACHINE CONTROL PATTERN (IF PATTERN CHANGE VALVE EQUIPPED)...233

CONTROL PATTREN CHANGE PROCEDURE...233

MACHINE CONTROL PATTERNS...234

ATTACHMENT GUIDE...235

ATTACHMENT COMBINATIONS...236

HYDRAULIC BREAKER...237

INDEX...240

Komatsu Hydraulic Excavators PC27MRX, PC30MRX, PC35MRX, PC40MRX, PC45MRX Repair Service Manual + Operation & Maintenance Manual